PN/CAN Gateway, PROFINET/CANopen Slave | Version 2 | 1/26/2021 3

Contents

1General............................................................................................................. 5

1.1 Target audience for this manual............................................................................................... 5

1.2 Safety instructions ................................................................................................................... 5

1.3 Note symbols and signal words ............................................................................................... 6

1.4 Intended use ........................................................................................................................... 7

1.5 Improper use........................................................................................................................... 7

1.6 Liability.................................................................................................................................... 8

1.6.1 Disclaimer of liability............................................................................................................ 8

1.6.2 Warranty.............................................................................................................................. 8

1.7 Recycling / WEEE ..................................................................................................................... 9

2System overview.............................................................................................10

2.1 General/area of application ................................................................................................... 10

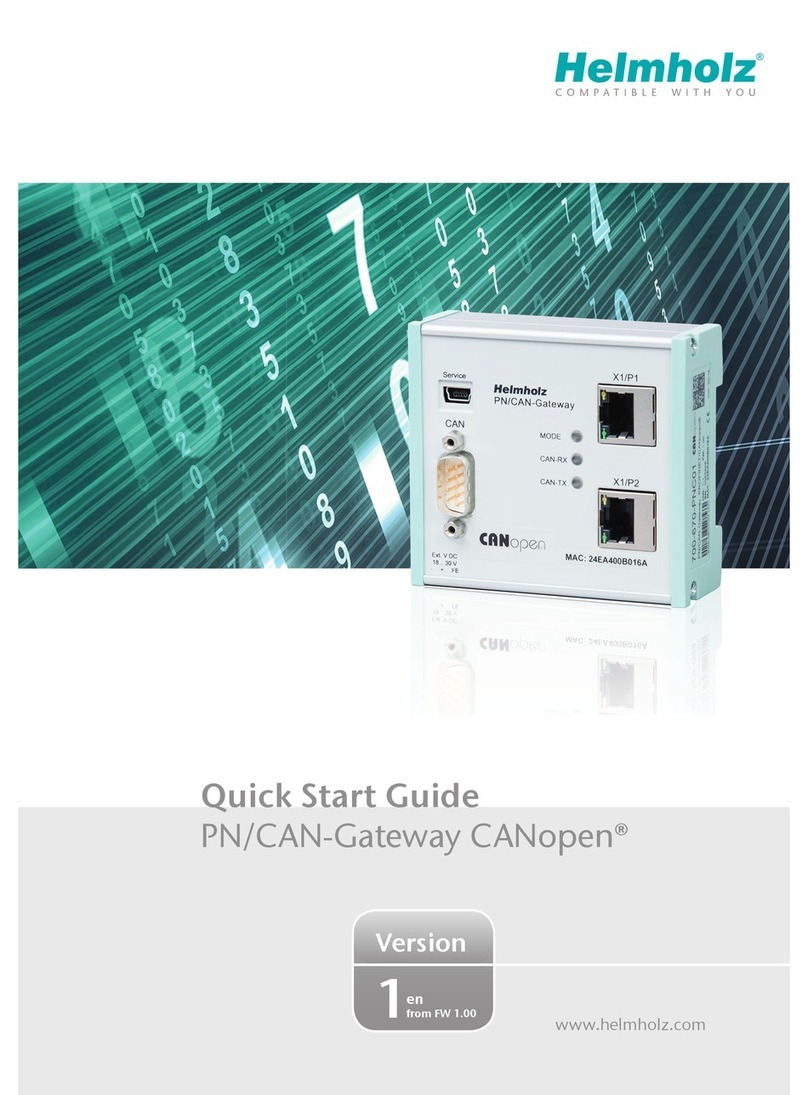

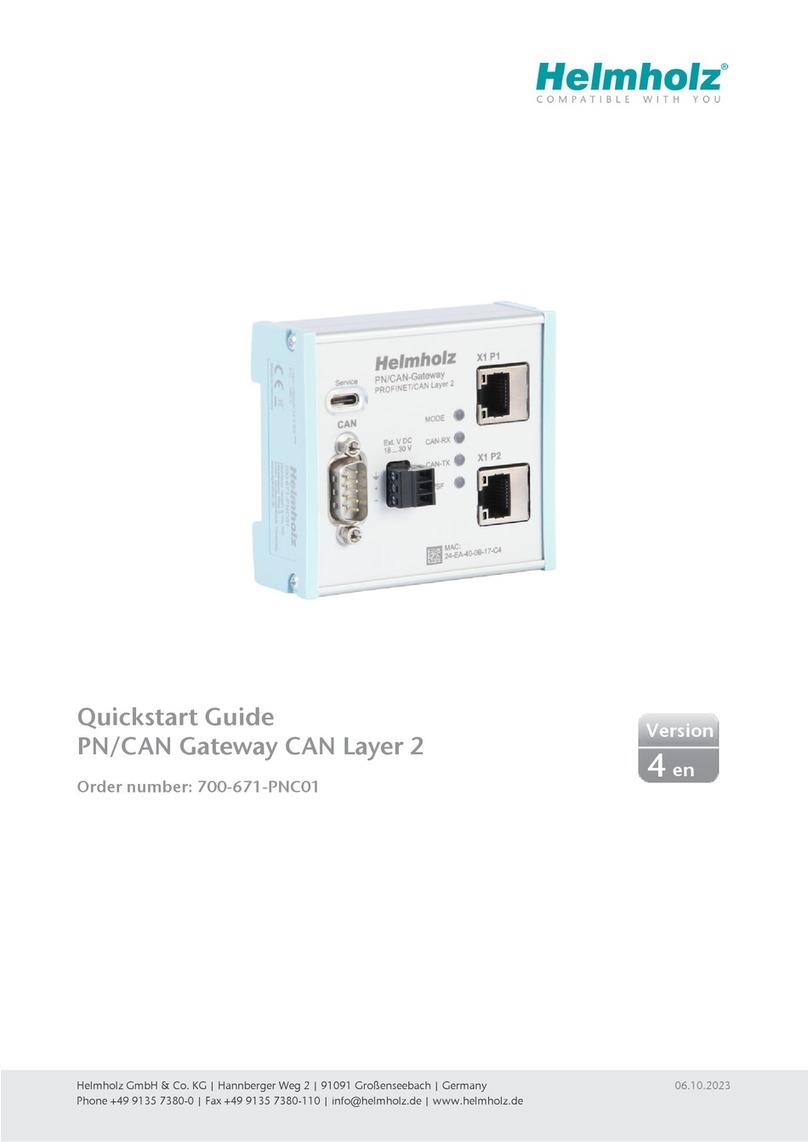

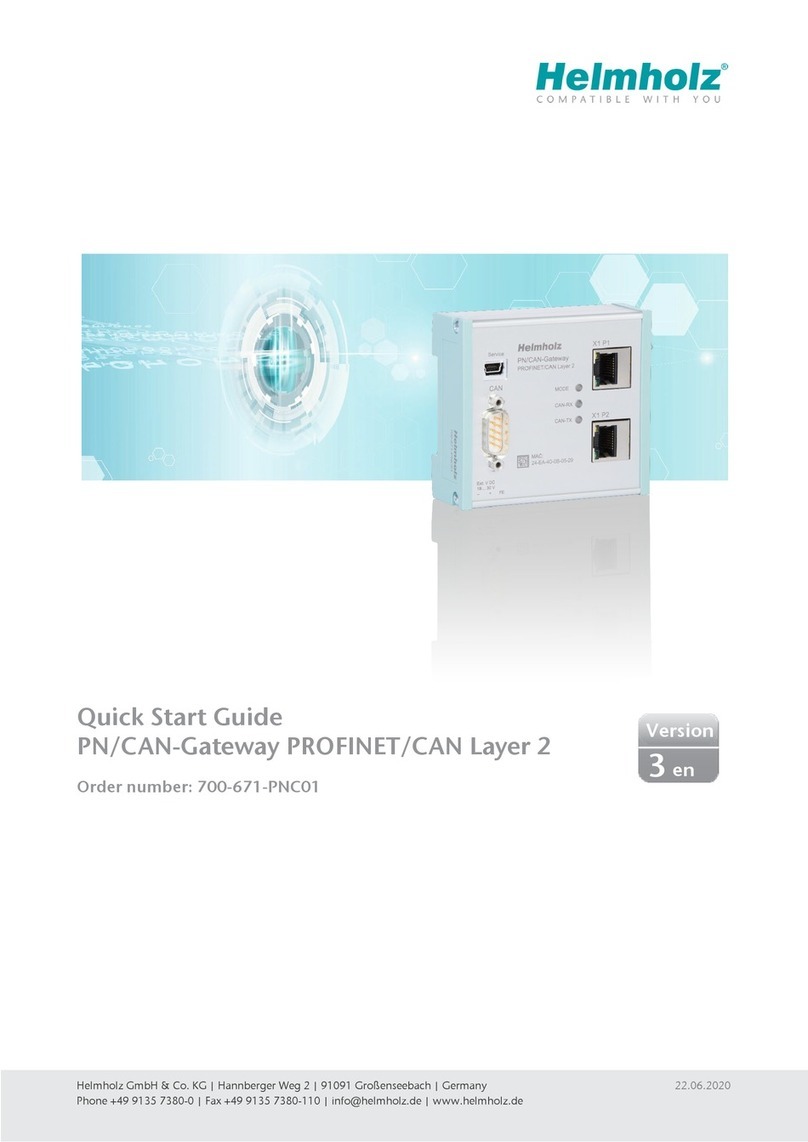

2.2 Properties of PN/CAN-Gateways CANopen ............................................................................ 10

3Installation .....................................................................................................11

3.1 Access restriction ................................................................................................................... 11

3.2 Electrical installation .............................................................................................................. 11

3.3 Protection against electrostatic discharges ............................................................................. 11

3.4 Overcurrent protection.......................................................................................................... 11

3.4.1 Operation .......................................................................................................................... 11

3.5 Installation position ............................................................................................................... 12

3.6 Minimum clearance............................................................................................................... 12

4Setup and wiring ............................................................................................13

4.1 EMC/safety/shielding............................................................................................................. 13

4.2 Wiring of the PN/CAN Gateway ............................................................................................. 14

4.2.1 Voltage supply................................................................................................................... 14

4.2.2 CAN bus connection .......................................................................................................... 14

4.2.3 PROFINET connection ........................................................................................................ 14

4.2.4 USB interface ..................................................................................................................... 14

5CAN bus.......................................................................................................... 15

5.1 Wiring a CAN Bus .................................................................................................................. 15

5.2 CAN bus plug........................................................................................................................ 15

5.3 The CANopen protocol.......................................................................................................... 16

5.3.1 CANopen objects............................................................................................................... 16