Henkel OSI Service manual

Technical Bulletin

Henkel TCS Department

26235 First Street

Westlake, OH 44145

1-800-624-7767

Technical Bulletin - OSI Foam Applicator Gun –20171003 Page 1of 3

OSI® Foam Applicator Gun Best Practices

CAUTION: Do not point the applicator gun at people or animals. Always wear eye protection, gloves and protective clothing. Avoid damage to

existing materials in replacement situations. Use a drop cloth to protect work area at all times.

Instructions for Use:

1. Shake can well 15 to 20 times prior to attaching the gun. Align canister and gun. Screw black collar of canister onto the basket adapter of the

gun by hand until snug, being careful not to cross-thread the unit. Do not over tighten. NOTE: It is important to align threads properly to

prevent possible leakage

2. Shake can well before use and during any work interruptions. Note: In colder temperatures we also recommend occasional shaking during

use to ensure consistent flow. Keep product temperature above 45° F for maximum performance and best flow rate.

3. Aim gun into an appropriate receptacle such as a box or bag or on a disposable surface to test flow rate. Pull trigger to start the flow of foam.

4. Adjust the control knob (release valve) on rear of gun to regulate flow. Clockwise decreases flow, counterclockwise increases the flow

5. Do not store gun with empty canister on the gun. When changing canister, replace empty can immediately to avoid hardening or clogging of

foam in the applicator gun.

Maintenance and Cleaning:

1. A partially used can may be left on the applicator gun between jobs when the release valve is fully closed (full clockwise), but no longer than

30 days’ maximum. It is not necessary to clean the applicator gun until the canister is removed. When not in use, ensure that the release

valve is in the closed position (full clockwise) to avoid foam curing up inside the gun. Temporary storage must always have a pressurized foam

can attached to the gun. Never remove a partially used/dispensed can as they are pressurized.

2. Completely emptied cans must be replaced immediately. Clean the applicator gun thoroughly as soon as possible after the canister is

removed if no replacement can be available to avoid the foam hardening inside the applicator gun. Once the foam has cured, cleaners will not

work or dissolve the polyurethane foam.

3. Use OSI® Foam Clean, pressurized cleaning solvent, to clean gun or use OSI® Foam Clean with button actuator on its valve stem for spot

cleaning and the clean up of uncured foam when changing cans. Always CLEAN “basket adapter” completely of any residual foam material

before replacing. Use petroleum jelly lubricant on the basket adapter to prevent over- tightening

4. Screw OSI® Foam Cleaner canister onto the applicator gun. Spray the cleaner onto a disposable surface or into a container for 3-5 seconds.

Open release valve partially (counterclockwise, but do not unscrew the value from the gun). Spray again for 3-5 seconds and repeat as

necessary.

5. For Long term storage: Leave solvent in the applicator gun for 2 minutes. Spray for another 3-5 seconds to remove used solvent from the

applicator gun. Repeat this process until the solvent spray out is completely clean. Remove the OSI® Foam Cleaner canister from gun.

Release pressure by pulling trigger then close regulator valve. Use petroleum jelly on nozzle tip and basket before storing applicator.

6. If necessary, with no can attached, unscrew the regulator knob and remove the needle. Clean the needle with a non-abrasive rag wet with

cleaning solvent.

7. Grease the needle with petroleum jelly lubricant before replacing in the applicator gun. BE CAREFUL not to lose the parts as they cannot be

replaced.

8. Routinely clean the screw-on brass tip to keep it completely free of hardened foam. Spray OSI® Foam Cleaner into the brass tip’s cavity. If

foam has cured inside the brass tip, use a probe to break apart and remove the cured foam to maintain a clear path for the foam to travel.

Warning: Do not completely unscrew release valve from the foam gun while connected to a PU foam or cleaner canister. Back pressure may cause

the valve to fly off from the gun and cause harm.

Helpful Hint: Squeeze trigger when unscrewing an empty can, in order to depressurize dispensing unit (point dispensing unit into appropriate waste

receptacle). This will help to prevent backflow of material from the basket adapter

1. Holding the trigger open during the entire can changing process will help to prevent backflow of material from the basket adapter.

Technical Bulletin

Henkel TCS Department

26235 First Street

Westlake, OH 44145

1-800-624-7767

Technical Bulletin - OSI Foam Applicator Gun –20171003 Page 2of 3

TROUBLESHOOTING

PROBLEM: No product extrudes from the gun applicator when trigger is pulled, or product extrudes too slowly.

POSSIBLE CAUSE

SOLUTION

➢Cured product at the tip of the gun can partially or completely block the

flow of the product

➢Rub the gun tip on a piece of soft lumber, or use a knife, wire brush,

etc. to remove cured residue.

➢Product is too cold. This will thicken the liquid in the can and reduce

the propellant pressure, resulting in a slower flow rate

➢It is recommended to store the cans between 65-75°F (18-24°C) prior

to use. Maintain chemical temperature above 40°F (5°C) for best flow

rate. DO NOT heat cans with local heat sources (stove, radiators, hot

plates, etc.)

➢Basket adapter may become clogged with cured foam product if gun is

stored without can attached, or if it not cleaned thoroughly when

changing cans.

➢Foam gun may no longer be useable and needs to be replaced.

➢Slow flow towards end of can may indicate a loss of propellant

pressure due to either cold temperatures or from dispensing foam

horizontally.

➢Keep can vertical as possible during dispensing, with valve down. If

“spitting” or gas lose is excessive, shake can periodically as the can

empties.

➢Regulating screw on back of gun is in closed position.

➢Open regulating screw on back of gun by turning counterclockwise

➢Product is past its shelf Life

➢Shake can. If no liquid movement is felt (or product is very thick) then

it may be past its shelf life and needs to be replaced

➢Product does not dispense after storage.

➢Product was stored beyond 30 days after original opening, or product

has expired shelf life.

➢PU foam leaks out of gun when it is off:

➢Remove the canister, release the pressure and empty the foam

remaining in the applicator. Clean gun then remove and clean the

needle with OSI® Foam Cleaner (see above steps 5 and 6). If the gun

continues to leak the parts may be worn and the gun needs to be

replaced.

PROBLEM: trigger will not depress

POSSIBLE CAUSE

SOLUTION

➢Regulating screw on back of gun is in closed position.

➢Open regulating screw on back of gun by turning counter-clockwise

➢Cured product on needle valve may cause the trigger to stick.

Excessive force should not be used if trigger will not open readily, as

this may cause damage to parts

➢If the needle valve cannot be dislodged using the trigger, it may be

able to be “broken free” by turning or carefully removing the regulator

screw being careful not to lose the spring and ball. Turn the needle

valve using a set of pliers. If this does not free the valve, then the

internal parts are clogged with cured foam and the gun needs to be

replaced.

PROBLEM: Properties of dispensed product not acceptable or behaving unusually

POSSIBLE CAUSE

SOLUTION

➢“Spitting” during dispensing or propellant bursts can be caused by not

keeping can vertical with valve down.

➢Slight spitting can be expected. Excessive spitting is not normal. Keep

can vertical with valve down. Intermittent shaking of can is required to

keep the contents mixed properly. Aerosol cans must be shaken

during and in between work interruptions.

➢Cured product on needle valve may cause the trigger to stick.

Excessive force should not be used if trigger will not open readily, as

this may cause damage to parts

➢If the needle valve cannot be dislodged using the trigger, it may be

able to be “broken free” by turning or carefully removing the regulator

screw being careful not to lose the spring and ball. Turn the needle

valve using a set of pliers. If this does not free the valve, then the

internal parts are clogged with cured foam and the gun needs to be

replaced.

➢The appearance of the dispensed bead of foam can be greatly

affected by the condition of the dispensing gun. Larger open celled

appearance may result if gun is not properly maintained. Also, product

that is left in the barrel of the gun, or allowed to get too cold may also

affect appearance.

➢The initial burst of material from the barrel may be more open celled

than normal. If unacceptable appearance continues, then the basket

adapter may need a thorough cleaning. Test with a fresh can or

product that is at the proper dispensing temperature for dispensing.

Technical Bulletin

Henkel TCS Department

26235 First Street

Westlake, OH 44145

1-800-624-7767

Technical Bulletin - OSI Foam Applicator Gun –20171003 Page 3of 3

Table of contents

Other Henkel Dispenser manuals

Henkel

Henkel Loctite EQ HD12 manual

Henkel

Henkel Loctite 98548 User manual

Henkel

Henkel Loctite EQ RC40 User manual

Henkel

Henkel Loctite 97008 User manual

Henkel

Henkel LOCTITE 97130 User manual

Henkel

Henkel Loctite 98427 User manual

Henkel

Henkel Loctite User manual

Henkel

Henkel Loctite 97631 User manual

Henkel

Henkel Loctite Shot Miser User manual

Henkel

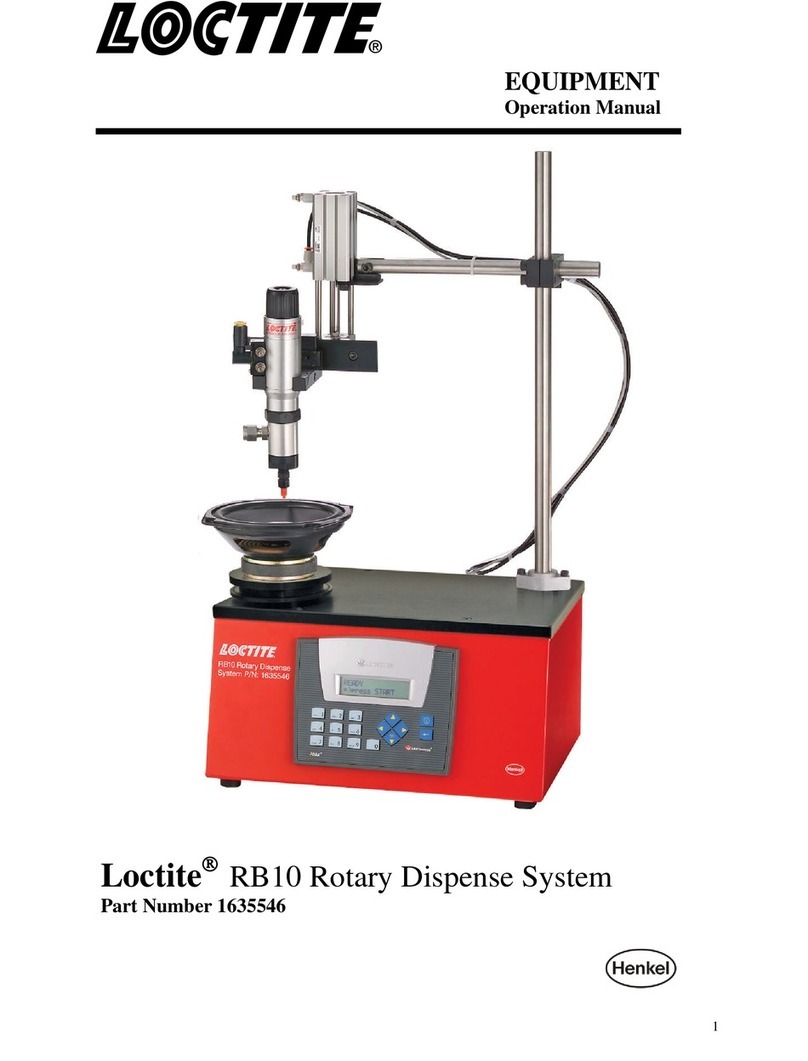

Henkel Loctite RB10 User manual

Popular Dispenser manuals by other brands

BOWMAN

BOWMAN CL003-0111 manual

SIKA

SIKA Power Cure operating instructions

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

Franke

Franke F3Dn Twin Service manual

HURAKAN

HURAKAN HKN-MT1 manual

STIEBEL ELTRON

STIEBEL ELTRON UltraHot Plus Operation and installation instructions