Henkel Loctite RB10 User manual

1

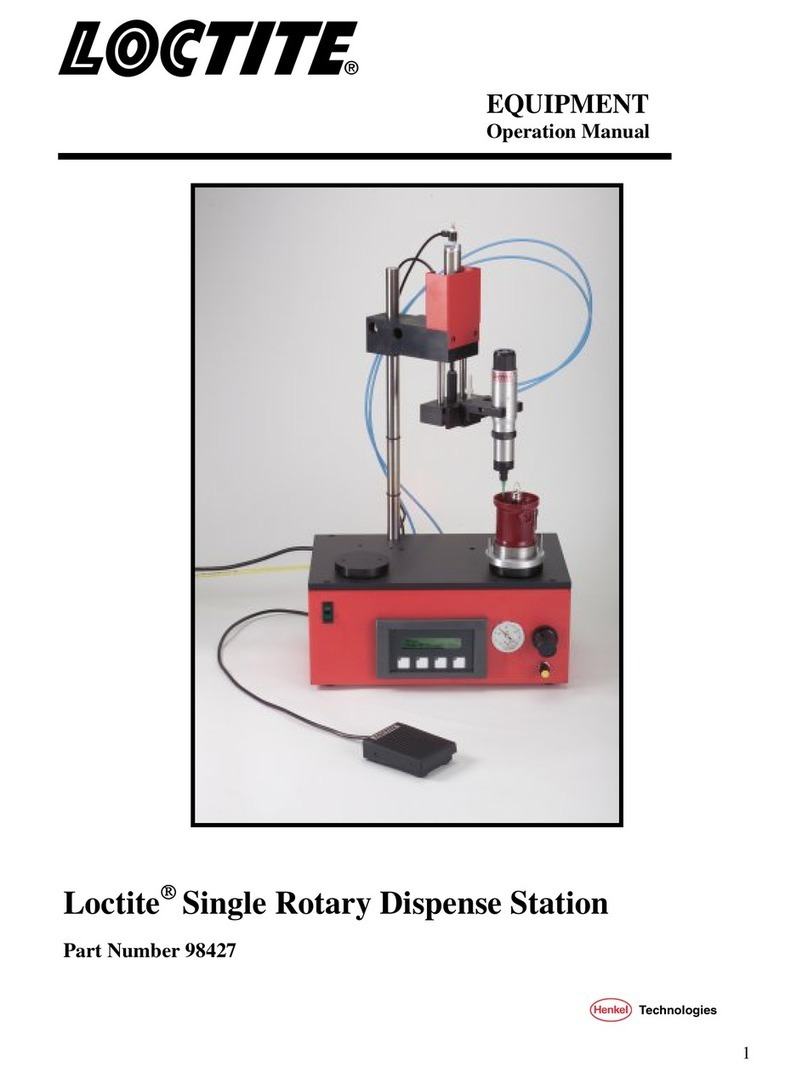

EQUIPMENT

Operation Manual

LoctiteRB10 Rotary Dispense System

Part Number 1635546

2

Table of Contents

1Please Observe The Following 3

1.1 Emphasized Sections 3

1.2 For Your Safety

1.3 Inspection 3

1.4 Items Supplied 4

1.5 Features 4

2 Description 4

2.1 Control Panel 4

2.2 Integration Panel 5

3 Technical Data 5

4 Installation 6

5 Operation 7

5.1 Theory of Operation 7

5.2 Controller Set Up 8

5.3 Mounting Plate 10

5.4 Valve and Syringe Dispenser Integration 11

5.4.1 Light Cure, CA and VA10 Valves 11

5.4.2 Stationary Valves 11

5.4.3 Syringe or Cartridge Dispensing 12

5.5 Slide Adjustment 13

5.6 Reservoir Low Level Control 13

6 Troubleshooting 14

7 Care and Maintenance 14

8 Accessories 15

9 Wiring Schematic 15

10 Warranty 16

3

1 Please Observe The Following

1.1 Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that protect the operator or

other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

Notice:

Gives recommendations for better handling of the unit during operation or

adjustment as well as for service activities.

1.2 For Your Safety

For safe and successful operation of the unit, read these instructions

completely. If the instructions are not observed, the manufacturer can assume no

responsibility.

Do not expose the connecting cable to heat, oil, or sharp edges.

Make sure the Unit stands stable and secure.

Use only original equipment replacement parts.

Always disconnect the power supply before servicing the unit.

Observe general safety regulations for the handling of chemicals such as

Loctite®adhesives and sealants. Observe the manufacturer’s instructions as stated

in the Material Safety Data Sheet (MSDS).

While under warranty, the unit may be repaired only by an authorized Loctite service

representative.

1.3 Unpacking and Inspection

Carefully unpack the Loctite®RB10 Rotary Dispense System and examine the

items contained in the carton. Inspect the unit for any damage that might have

occurred in transit. If such damage has occurred, notify the carrier immediately.

Claims for damage must be made by the consignee to the carrier and should be

reported to the manufacturer.

4

1.4 Items supplied

(1) Rotary Dispense System

(1) Foot Switch

(1) Power Supply with Cord

(1) Instruction Manual

1.5 Features

Integrated Solution –plug and play with Loctite valves, reservoirs, and

Syringe Systems

Digital Control of rotation, dispense start, dispense stop and delays

Adjustable height, position, angle of dispense, and advance slide speed

Reservoir low-level interface with cycle interruption and display message

Part position sensing allows orientation of adhesive bead start and end

Threaded and non threaded mounting holes for fixtures

Operator lockout for supervisory control of settings

Dispense valve and syringe mounting hardware available

2 Description

The Loctite®RB10 Rotary Dispense System is a fully integrated system used for

dispensing adhesives onto parts in a circular or arc pattern. It will control a syringe system,

cartridge, or dispense valve without requiring a separate valve controller. Internally

synchronized operation of an advancing slide, turntable, and dispense timer makes for easy

and repetitive placement of the adhesive. The set-up is simple, using only preset distance

and rotation speed adjustment. No complex programming required!

2.1 Control Panel (Front of Controller)

5

2.2 Integration Panel (Back of Controller)

3 Technical Data

Attribute Value

Dispense Pattern Circles or Arcs in a Circular Pattern

Slide Stroke 0 –2”(0 –50 mm)

Rotation Range 0 –999 Degrees

Rotation Speed 5 to 55 RPM

Maximum Part Height 12”(305 mm)

Maximum Part Diameter 18”(475 mm)

Maximum Part Weight 6 lbs (2.7 kg)

Width 12”(305 mm)

Depth 8¾”(222 mm)

Dimensions

Height 22”(559 mm) Minimum

25”(635 mm) Maximum

Weight 18.5 lb (8.4 kg)

Air Input*Clean, dry air not to exceed 125 psig (8.5 bar),

and filtered with a maximum of 50 micron

Power Supply: 110 –230 V / 50 –60 Hz

Internal: 24 VDC

* If the required air quality is not available, install a Loctite®filter regulator. In the US order a

5m filter using part number 985397. In Europe or Asia, order a 10 m filter using part

number 97120.

6

4 Installation

Before using the tool for the first time check it carefully for signs of external

damage. If any shipping damage is found DO NOT USE THE TOOL - return it to

your supplier immediately.

1. Assemblethe standtothemaincontrolunit byattaching theverticalmountingpole(the

longerbarsupplied)intotheverticalsupport bracketonthecontroloftheunit. Tighten

theM4 fromthesideofthesupport brackettosecure theverticalmountingpole.

2. Assemblethe slide assemblytothestand.

3. SecuretheslideassemblybytighteningtheM6 screwontheslide assemblybracket.

4. Connect the Cylinder Extend and Cylinder Retract Air hoses to the Cyl Extend

and Cyl Retract ports on the back of the unit.

5. Connect the Advance Slide Cable to the Advance Slice Limit Switch connector

of the back of the unit.

6. Plugthepower adapterwithcordintothe“24VDC”inputonthebackofthecontrollerand

intothewallsocket.

Notice: The power adapter has auto ranging power function that can be used

with either 110 or 220V and 50 or 60 Hz.

7. Connectthefootswitch,orPLCstartsignalcable,tothe“StartSwitchXS1”connectoron

thebackofthecontroller.

8. Connecttheairinputlineto theAirInputfittingusing6mmO.D.pneumatictubing(not

supplied).

9. Turn on the local airsupply. This must be a minimum of 80 psi anda maximum of 125

psi.

Warning! When the air is connected, the slide may retract. Be sure to keep

your hands and other objects clear of the slide before connecting the air.

Caution! Clean, dry, filtered air must be used. If it is not, the solenoids in the

controller will be fouled over time. If the required air quality is not achieved,

install a Loctite®filter regulator. In the US order a 5 m filter using Part Number

985397. In Europe or Asia, order a 10 m filter using Part Number 97120.

7

5 Operation

5.1 Theory of Operation

1. After turning on the unit, press the footswitch or ENTER button to activate the

system.

2. The advancing slide will start to extend and the rotary disc will start to rotate with

the preset speed.

3. The advancing slide will activate the proximity sensor when it reaches the preset

position.

4. The start of disc rotation, or the locator pin reaching the proximity sensor (in

homing mode), will trigger the rotation distance counter and the unit will start to

dispense for preset dispensing time. Use of the homing mode ensures that each

dispense start will be at the same point.

5. After the dispensing timer has reached the preset dispense time, the advancing slide

will retract and the rotary disc will be stopped.

6. The dispense start position “DS Position”determines how far the disc will rotate

before starting to dispense. This ensures the rotation has reached a constant speed

when dispense begins.

7. The “Off Delay”feature determines how long the disc will continue to rotate after

the dispense has stopped. This allows product remaining on the tip of the dispenser

to be transferred to the part after the dispense stops, prior to retracting.

8. The reservoir low level sensor setting disables the start signal and displays “Alarm:

RESERVOIR LOW LEVER.”The Low Level state can be manually overridden

allowing the system to cycle by pressing the ENTER button, however the alarm will

continue to be displayed and the system will not cycle using a footswitch or PLC.

8

5.2 Controller Set Up

Display

Step

Enter

To Unlock Press 1 & 3

Together For Three Seconds Toggle

Notice: Upon start-up, the system will be in operator lockout mode.

To unlock the controller, press 1 & 3 simultaneously for three seconds. To return to

operator lockout mode simply turn system off; all settings will be stored. The system will

always start in operator lockout mode.

The Display at Power ON will be:

READY

press START

Unlock the controller by pressing 1 & 3 simultaneously for three seconds.

The Display will still be:

READY

press START

Press Step and the Display will change to

LOW LEVEL SENSOR

enabled

To disable the low level sensor, press the Toggle Arrow then press ENTER

Press Step and the Display will change to

HOMING

OFF

To enable homing, press the Toggle Arrow then press ENTER

9

Press Step and the Display will change to

Speed: 10 RPM

Dist: 90 deg

To change the speed (revolutions per minute), type the desired speed with key pad,

then press ENTER

To change the distance (in degrees) that product will dispense, type the desired

distance using the key pad, then press ENTER

Notice: The distance setting determines how far the rotation motor receives power

and is intended to be an aid in initial set up not as an absolute setting of rotation. Higher

speed setting and heavier part weights create momentum that will cause mounting plate to

carry beyond the preset degrees in a repeatable fashion.

Press Step and the Display will change to

DS Position: 0

OFF Delays: 0.0

To set the Dispense Start position (how far the disc will rotate before dispense

starts) type the desired distance, in degrees, then press ENTER

To set the desire off delay (how long in seconds the disc will rotate after dispense

stops, type the desired time then press ENTER

Press Step and the Display will change to

READY

press START

You have completed Controller Set Up. The Controller will remain unlocked until power

is turned off.

Notice: The settings can be tested without exiting mode by pressing 1 & ENTER.

This will start a cycle.

Changes can be made by pressing STEP key until you get to the desired parameter.

To save the changes and exit Program Mode, simply turn the power off.

10

5.3 Mounting Plate

The drawing below shows the RB10 Rotary Dispense System mounting plate. This

through holes on the mounting plate can be used for fixture alignment and the threaded ¼-

20 holes can be used to secure the fixture.

11

5.4 Valve and Syringe Dispenser Integration

The Loctite®RB10 Rotary Dispense System is designed to be used with syringes, cartridges,

single acting product valves and double acting product valves. To integrate these dispense

systems please use the following instructions:

5.4.1 98009 Light Cure, 98013 Cyanoacrylate and VA10 Micro Dispense Valves

Must be purchased separately:

Mounting Rail –P/N98328

Mounting Bracket –P/N98326

Mounting Bracket –P/N1638885

PressureReservoir

- P/N 982726,Bond-A-Matic reservoir,0-15psi for use withadhesives with <3,000cPs viscosity.

- P/N 982727,Bond-A-Matic reservoir,0-100 psi for use with adhesives with >3,000 cPs viscosity.

1. Insertthe4mm tubeplugin the upper“DispenseOut”(normallyclosed) connection.

2. Addthedispensetip onto thevalve.

3. Secure themounting rail to the advance slideusingthe M4 screws provided.

4. Slidethemounting bracketoverthemountingrail ontheslideassemblyandsecureit in

position withthewhite nylonthumbscrew.

5. Manuallypullthe slide downto thefullyextendedposition.

6. Slidethevalveintothemountingbracketandsecure it usingtheblack thumbscrews.

7. Adjust the height andpositionofthemounting brackettothe approximate positiondesired.

Toadjusttheposition, loosenthescrews on theclamp blockscounter clockwise,setthe

position andthensecurebyturningthescrewsclockwise.

Caution! It is important to ensure that the dispense tip will not crash with the

mounting plate, fixture or part. Please ensure that the height is set to avoid crashes.

8. Connecttheairinletonthevalvetotheupper“DispenseOut”on the back ofthecontroller

usingthe4mmairlinetubingsupplied withthevalve.

5.4.2 97113 and 97114 Stationary Valves

Must be purchased separately:

Mounting Rail –P/N98328

Mounting bracket–P/N98327

PressureReservoir

- P/N 982726,Bond-A-Matic reservoir,0-15psi for use withadhesives with <3,000cPs viscosity.

- P/N 982727,Bond-A-Matic reservoir,0-100 psi for use with adhesives with >3,000 cPs viscosity.

- P/N982720, Bond-A-Maticreservoir,0-15psi, withlowlevelsensor.

- P/N982723, Bond-A-Maticreservoir,0-100psi,withlowlevel sensor.

1. Using 4mmtubingsuppliedwiththevalve, connect boththe upper“DispenseOut”

(normallyclosed)andlower“DispenseOut”(normallyopen)connectionsfrom the valve

to theback ofthecontroller.

2. Addthedispensetip tothe valve.

3. Secure themounting rail to the advance slideusingthe screws provided with the bracket.

4. Slidethemounting bracketoverthemountingrail ontheslideassemblyandsecureit in

position withthewhite nylonthumbscrew.

5. Manuallypullthe slide downto thefullyextendedposition.

6. Slidethevalveintothemountingbracketandsecure it usingtheblack thumbscrews.

12

7. Adjust the height andpositionofthemounting brackettothe approximate position

desired. Toadjusttheposition,loosenthescrews ontheclampblockscounterclockwise,

setthe positionandthensecure byturningthescrews clockwise.

Caution! It is important to ensure that the dispense tip will not crash with the

mounting plate, fixture or part. Please ensure that the height is set to avoid

crashes.

5.4.3 Syringe or Cartridge Dispensing

Must be purchased separately:

Loctite Part Number

Syringe CartridgeAccessory 10 ml 30 ml 55 ml 300 ml

Syringe Dispenser (Required) 883976 883976 883976 883976

3 ¾”Mounting Rail (required) 98328 98328 98328 98328

Mounting Bracket (required) 98316 98316 98316 98318

Syringe Adapter (required) 98320 N/A N/A N/A

Dispense Tip Connectors (required) N/A N/A N/A 982644

97233

Clear Syringe Barrel Kit (optional) 97207 97244 98314 N/A

Black Syringe Barrel Kit (optional) 97263 97264 98315 N/A

1. Refer to the operation manualofthesyringedispenserforsetupinstructions.

2. Connectthesyringedispenser tothesystemwithXS2cable partnumber 989432(need

to purchaseseparately).

3. Insertthe4mm tubeplugin the both theupper “DispenseOut”(normallyclosed) and lower

“DispenseOut”(normallyopen) connections.

4. Addthe dispensetip ontothesyringeor cartridge. Forsome cartridges, itwill be

necessarytoinstall thecartridge adapterPartNo. 982644and luerlock adapterPartNo.

97233beforeconnectingthe dispensetip.

5. Secure themounting rail to the advance slideusingthe M4 screws provided.

6. Slidethemounting bracketoverthemountingrail ontheslideassemblyandsecureit in

position withthewhite nylonthumbscrew.

7. Manuallypullthe slide downto thefullyextendedposition.

8. Adjust the height andpositionofthemounting brackettothe approximate position

desired. Toadjusttheposition,loosenthescrews ontheclampblockscounterclockwise,

setthe positionandthensecure byturningthescrews clockwise.

9. Slidethesyringe or cartridgeinto the mountingbracket andsecure itusingtheblack

thumbscrews.

Caution! It is important to ensure that the dispense tip will not crash with the

mounting plate, fixture or part. Please ensure that the height is set to avoid

crashes.

13

5.5 Slide Adjustments

The speed controls on the slide can be adjusted to increase or decrease the speed that the

slide advances or retracts. The speed should be set so that the slide moves at a controlled

rate. This may need to be adjusted to account for more weight on the slide or to change the

slide advance / retract time.

5.6 Reservoir Low Level Control

5.6.1 Disabling the Low Level Function

1. In Set Up mode (see section 5.2) set Low Level Sensor to “Disabled.”

5.6.2 Enabling the Low Level Function

1. Connect the 9 pins D-sub female (XS2 Low Lev) cable the to the Low Level Sensor

(XS2) Connector.

2. In Set Up mode (see section 5.2) set Low Level Sensor to “Enabled.”

Notice: When a Reservoir Low Level state occurs during a cycle, the cycle will

complete and the display will read “Alarm: RESERVOIR LOW LEVER.”The Low

Level setting disables the start signal.

Notice: In run mode, the Low Level state can be manually overridden allowing the

system to cycles by pressing the ENTER button. Pressing the ENTER button will cycle the

unit, however the alarm will continue to be displayed and the system will not cycle using a

footswitch or PLC.

Notice: In Set Up mode, pressing the ENTER button will clear the Low Level state

for one cycle fully disabling the alarm and allowing use of the foot switch or PLC.

3. After eliminate the Low Level state, pressing ENTER will run another cycle and

reset the Low Level alarm. The Low Level alarm can also be re-set by turning the

system off after eliminating the Low Level state.

Adjust Slide Advance

Rate Here

Adjust Slide Retract

Rate Here

14

6 Troubleshooting

Before proceeding with any repair or maintenance operation disconnect the

tool from the main electricity supply.

Symptom Possible Corrective Action(s)

Plug the unit inThe “POWER”does not turn

“ON” Set the “POWER”button “ON”position

1. Confirm that the “Air Input”is connected

2. Confirm that the air supply is 80-125 psi.

The system will not pressurize.

3. Confirm that the “Dispense Out”fittings are properly connected or

plugged.

Mounting plate rotates further

than distance setting. Higher speeds and part weights will cause the mounting plate to carry

beyond the distance setting. The distance setting is intended for reference

purposes only as an aid to initial set up.

The slide is advancing or

retracting too fast or slow. The slide advance and retract rate should be set so that the slide moves at a

controlled rate. The factory default is for the full slide stroke to take

approximately 0.5 seconds. If this needed to be adjusted, see Section 5.5

for instructions.

1. Confirm that the air supply is pressurized and at 80-125 psi.The disc will not stop rotating

and the display reads

“Homing… ”OR

Display read "Dispenser in wait"

2. Confirm that the advancing slide moves down when the cycle starts.

1. Check that XS2 cable between the reservoir and the RB10 is connected.The “Reservoir Low Level

Alarm Light”(1) does not work 2. Check that Low Level Sensor Switch setting is in the “enabled”state.

1. Check the pneumatic connection.The dispense valve does not

dispense 2. Check the pneumatic supply.

7 Care and Maintenance

7.1 Care

This unit should be stored in a level, dry location at ambient condition out of direct

sunlight.

7.2 Maintenance

To minimize wear of the slide assembly, periodically apply several drops of light machine

oil to the slide rods, manually advance and retract the slide several times then remove the

excess lubricant using a rag.

Warning! Be sure to release the pressure and shut of the pressure supply before

lubricating the slide rods.

Notice: Clean, dry, filtered air must be used. If it is not, the solenoids on the

controller will be fouled over time.

Notice: If the required air quality is not achieved, install a Loctite®filter regulator.

In the US order a 5 m filter using Part Number 985397. In Europe or Asia, order a 10 m

filter using Part Number 97120.

15

8 Accessories

Syringe Dispenser Accessories:

Loctite Part Number

Syringe CartridgeAccessory 10 ml 30 ml 55 ml 300 ml

Syringe Dispenser (Required) 883976 883976 883976 883976

3 ¾”Mounting Rail (required) 98328 98328 98328 98328

Mounting Bracket (required) 98316 98316 98316 98318

Syringe Adapter (required) 98320 N/A N/A N/A

Dispense Tip Connectors (required) N/A N/A N/A 982644

97233

Clear Syringe Barrel Kit (optional) 97207 97244 98314 N/A

Black Syringe Barrel Kit (optional) 97263 97264 98315 N/A

Additional Mounting Hardware:

Description Item Number

98009 and 98013 Valve Mounting Bracket 98326

97113 and 97114 Valve Mounting Bracket 98327

VA10 Valve Mounting Bracket 1638885

3 3/4 inch mounting rail with two cap screws 98328

8 3/4 inch mounting rail with two cap screws 98329

C Rail Kit for Mounting Brackets 98331

986300 Poppet Valve Mounting Bracket Kit 98406

98084 or 98520 Valve Mounting Bracket Kit 98441

9 Wiring Schematic

16

10 Warranty

Henkel expressly warrants that all products referred to in this Instruction Manual for 1635546 LoctiteRB10

Rotary Dispense System (hereafter called “Products”) shall be free from defects in materials and

workmanship. Liability for Henkel shall be limited, as its option, to replacing those Products which are shown

to be defective in either materials or workmanship or to credit the purchaser the amount of the purchase price

thereof (plus freight and insurance charges paid therefor by the user). The purchaser’s sole and exclusive

remedy for breach of warranty shall be such replacement or credit.

A claim of defect in materials or workmanship in any Products shall be allowed only when it is submitted in

writing within one month after discovery of the defect or after the time the defect should reasonably have

been discovered and in any event, within (12) months after the delivery of the Products to the purchaser. This

warranty does not apply to perishable items, such as fuses. No such claim shall be allowed in respect of

products which have been neglected or improperly stored, transported, handled, installed, connected,

operated, used or maintained. In the event of unauthorized modification of the Products including, where

products, parts or attachments for use in connection with the Products are available from Henkel, the use of

products, parts or attachments which are not manufactured by Henkel, no claim shall be allowed.

No Products shall be returned to Henkel for any reason without prior written approval from Henkel. Products

shall be returned freight prepaid, in accordance with instructions from Henkel.

NO WARRANTY IS EXTENDED TO ANY EQUIPMENT WHICH HAS BEEN ALTERED, MISUSED,

NEGLECTED, OR DAMAGED BY ACCIDENT.

EXCEPT FOR THE EXPRESS WARRANTY CONTAINED IN THIS SECTION, HENKEL MAKES NO

WARRANTY OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, WITH RESPECT TO THE

PRODUCTS.

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND

OTHER WARRANTIES OF WHATEVER KIND (INCLUDING AGAINST PATENT OR TRADEMARK

INFRINGEMENT) ARE HEREBY DISCLAIMED BY HENKEL AND WAIVED BY THE PURCHASER.

THIS SECTION SETS FORTH EXCLUSIVELY ALL OF LIABILITY FOR HENKEL TO THE

PURCHASER IN CONTRACT, IN TORT OR OTHERWISE IN THE EVENT OF DEFECTIVE

PRODUCTS.

WITHOUT LIMITATION OF THE FOREGOING, TO THE FULLEST EXTENT POSSIBLE UNDER

APPLICABLE LAWS, HENKEL EXPRESSLY DISCLAIMS ANY LIABILITY WHATSOEVER FOR

ANY DAMAGES INCURRED DIRECTLY OR INDIRECTLY IN CONNECTION WITH THE SALE OR

USE OF, OR OTHERWISE IN CONNECTION WITH, THE PRODUCTS, INCLUDING, WITHOUT

LIMITATION, LOSS OF PROFITS AND SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES,

WHETHER CAUSED BY NEGLIGENCE FROM HENKEL OR OTHERWISE.

Henkel Corporation

One Henkel Way

Rocky Hill, CT 06067-3910

Henkel Canada Corporation

2225 Meadowpine Boulevard

Mississauga, Ontario L5N 7P2

Henkel Capital, S.A. de C.V.

Calzada de la Viga s/n Fracc. Los Laureles

Loc. Tulpetlac, C.P. 55090

Ecatepac de Morelos, Edo. de México

Henkel Corporation

Automotive / Metals HQ

32100 Stephenson Hwy.

Madison Heights, MI 48071

Henkel Ltda.

Rua Karl Huller, 136 –Jd.

Canhema 09941-410

Diadema/SP, Brazil www.loctite.com

® and ™designate trademarks of Henkel Corporation or its affiliates. ® = registered in the U.S. and elsewhere. © Henkel Corporation,

2009. All rights reserved. Data in this operation manual is subject to change without notice.

Manual P/N: 8903134, Rev A, Date: 08/13/2012

This manual suits for next models

1

Table of contents

Other Henkel Dispenser manuals

Henkel

Henkel Loctite 98427 User manual

Henkel

Henkel Loctite 98548 User manual

Henkel

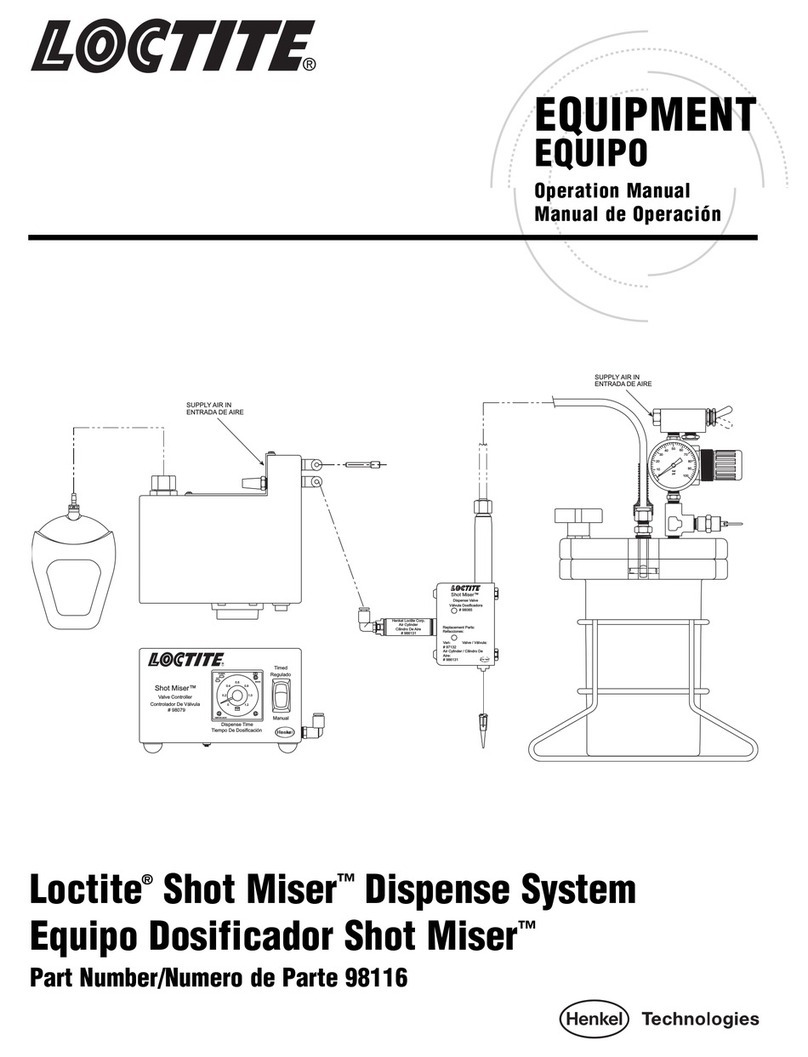

Henkel Loctite Shot Miser User manual

Henkel

Henkel Loctite 97631 User manual

Henkel

Henkel Loctite EQ HD12 manual

Henkel

Henkel Loctite User manual

Henkel

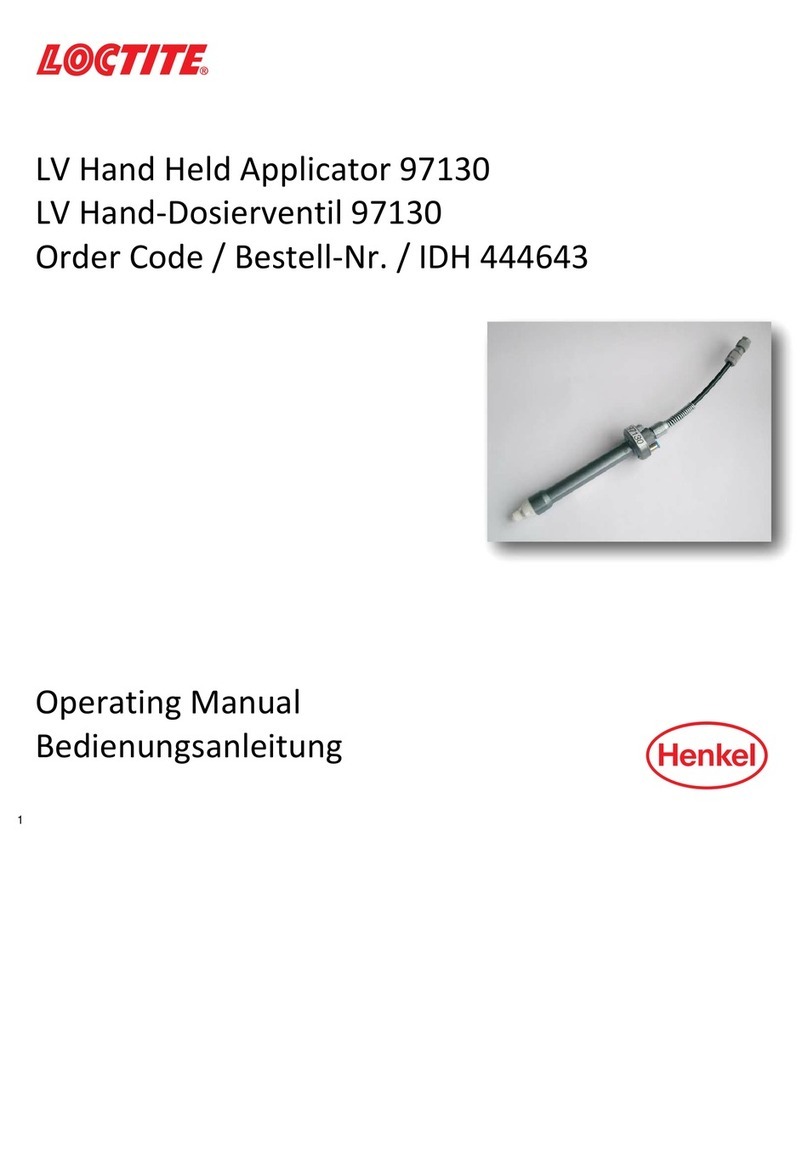

Henkel LOCTITE 97130 User manual

Henkel

Henkel Loctite 97008 User manual

Henkel

Henkel OSI Service manual

Henkel

Henkel Loctite EQ RC40 User manual