Henkel Loctite Shot Miser User manual

EQUIPMENT

EQUIPO

Operation Manual

Manual de Operación

Loctite®Shot Miser™Dispense System

Equipo Dosificador Shot Miser™

Part Number/Numero de Parte 98116

70

100

10

0

bar

psi

30

20

50

40 60

90

80

Shot Miser™

Dispense Valve

Válvula Dosi icadora

# 98085

Henkel Loctite Corp.

Air Cylinder

Cilindro De Aire

# 986131

Vari- Valve / Válvula:

# 97132

Air Cylinder / Cilindro De

Aire:

# 986131

Replacement Parts:

Re acciones:

SUPPLY AIR IN

ENTRADA DE AIRE

SUPPLY AIR IN

ENTRADA DE AIRE

0.2

OMRON H3CR

OUT

POWER

Regulado

0

min

1.2

0.4

0.6

0.8

1.0

MODE

Manual

A

Timed

Shot Miser™

Valve Controller

Controlador De Válvula

# 98079

Dispense Time

Tiempo De Dosi icación

Contents

Page No.

1 Please Observe the Following . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1 Emphasized Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 For Your Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.1 Operating Elements and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

4.1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Connecting the Air line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Product Supply Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 Installing the Anti-Bubbler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Dispense Tip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Priming the Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Adjusting the Amount of Loctite®Product Dispensed. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

6.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.1 Procedure Replacing Vari-Drop™ and Air Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.2 Disassembling the Loctite®Vari-Drop™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.3 Reassembling the Loctite®Vari-Drop™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Spare Parts and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

8.1 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

8.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

1. Please Observe the Following

1

1.1 Emphasized Sections

Warning!

Refers to safety regulations and required safety measures that protect the operator or other

persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not damaged.

Notice:

Gives recommendations for better handling of the unit during operation or adjustment as well as

for service activities.

1.2 For Your Safety

Warning!

•OBSERVE ALL WARNINGS. READ and UNDERSTAND all instructions in the manual before

attempting to install and operate this equipment.

• This equipment has been designed and tested for use with Loctite®products that can be

dispensed using time and pressure. Products can have a viscosity of up to 80,000 centipoise.

•DO NOT USE equipment for other than intended use.

•BE SURE that all adhesives, solvents, or fluids used are chemically compatible with the wetted

parts of the equipment.

•ALWAYS OBTAIN AND READ the Material Safety Data Sheet(s) before using adhesives,

solvents, or any other chemicals in this equipment. COMPLY with ALL WARNINGS and

SAFETY INSTRUCTIONS AS STATED.

•ALWAYS WEAR protective eyewear, gloves, clothing, and respirator as recommended in this

manual or the Material Safety Data Sheet(s).

• Any misuse of the equipment or accessories, such as over pressurizing, modifying parts, using

incompatible chemicals, adhesives, or worn, damaged or not recommended parts, can cause

rupture or breakage and result in fluid injection, splashing in the eyes or on the skin, or other

serious injury or property damage.

•NEVER alter or modify any part of this equipment. Doing so could result in a malfunction.

•CHECK the equipment regularly and repair or replace worn or damaged parts immediately.

•NEVER exceed the recommended working pressure or the maximum air inlet pressure stated

on the equipment or in the manual.

• Properly ground all electrical components as recommended in the manual or technical

data sheet.

• Always KEEP HANDS and FINGERS away from moving parts to reduce the risk of injury.

•ALWAYS RELIEVE any pressure and turn off all power sources when checking or servicing any

part of the equipment to reduce the risk of serious injury.

•RETAIN THIS MANUAL FOR FUTURE REFERENCE.

☞

1. Please Observe the Following (continued)

2

1.3 Unpacking and Inspection

Carefully unpack system components and examine the items contained in the carton. Inspect the

units for any damage that might have occurred in transit. If such damage has occurred, notify the

carrier immediately. Claims for damage must be made by the consignee to the carrier and should

be reported to the manufacturer.

1.4 Items Supplied

Loctite®Shot Miser™ Dispense Valve 98085

Needle Assortment

Product supply tube / 7 feet

Control air line / 6 feet

Operation manual

Vari-Drop™ operation manual

Loctite®Shot Miser™ Valve Controller 98079

Foot Pedal

Foot Pedal Hose / 10 feet

Power Cord

Operations Manual

Loctite®1 Liter Shot Miser™ Reservoir 98090

Anti-Bubbler Adapter

Anti-Bubbler Sleeve

Spring Guard

Product Supply Tube / 6 feet

Operations Manual

1.5 Features

Loctite®Shot Miser™ Dispense Valve 98085

• Disposable fluid path

• Used in semi automatic or fully automatic process applications

• Adaptable to optional reservoirs based on product packages

• Dispenses Loctite®innovative chemistries up to 80,000 centipoise

• Allows repeatable dispensing from light to heavy beads or drops

Loctite®Shot Miser™ Valve Controller 98079

• Easy read analog timer

• Continuous or timed mode from 0.10 seconds to hours

• Pneumatic output for single or double acting dispense valves

• Pneumatic foot switch

Loctite®1 Liter Shot Miser™ Reservoir 98090

• Pressure from 0 to 100 psi

• Reservoir Capacity

• 1 lb. Bottle

• 500 gram Bottle

• 250 ml Bottle

1.6 Usage

The Loctite®Shot Miser™ Dispense System is suitable for semi-automatic or fully automatic

dispensing of all Loctite products that can be dispensed using a pressure/time system. The

Loctite®Shot Miser™ Dispense Valve is capable of dispensing dots, drops or beads of adhesive.

2. Description

3

2.1 Operating Elements and Connections

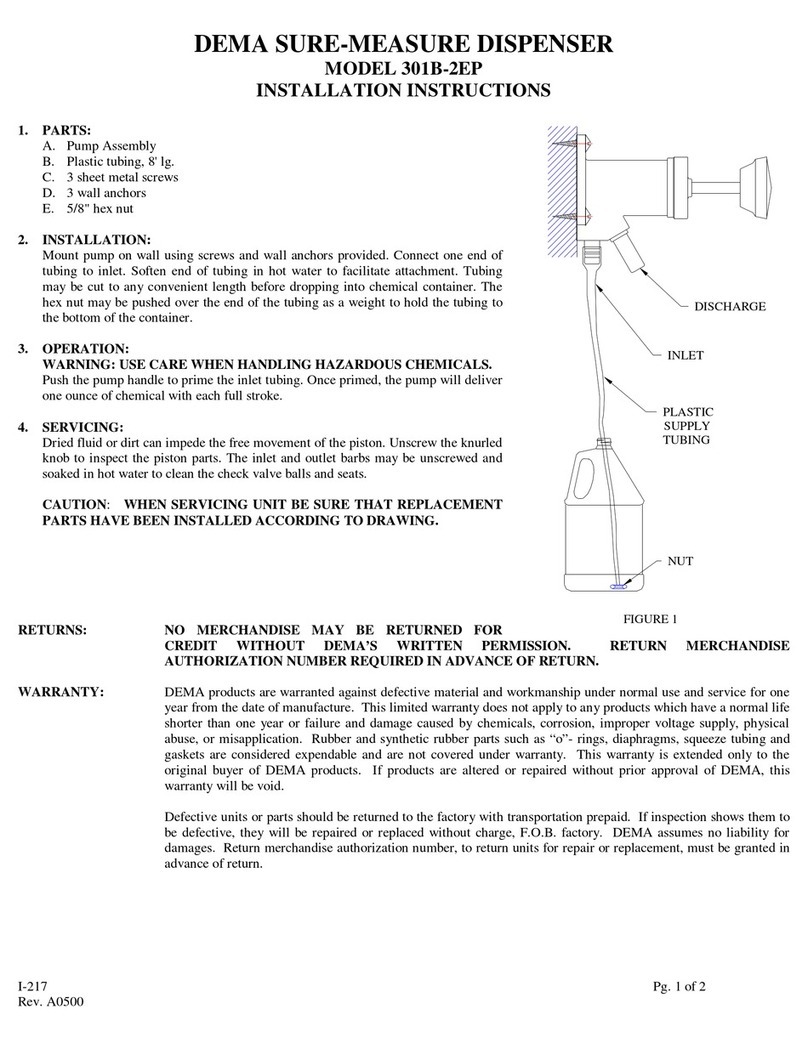

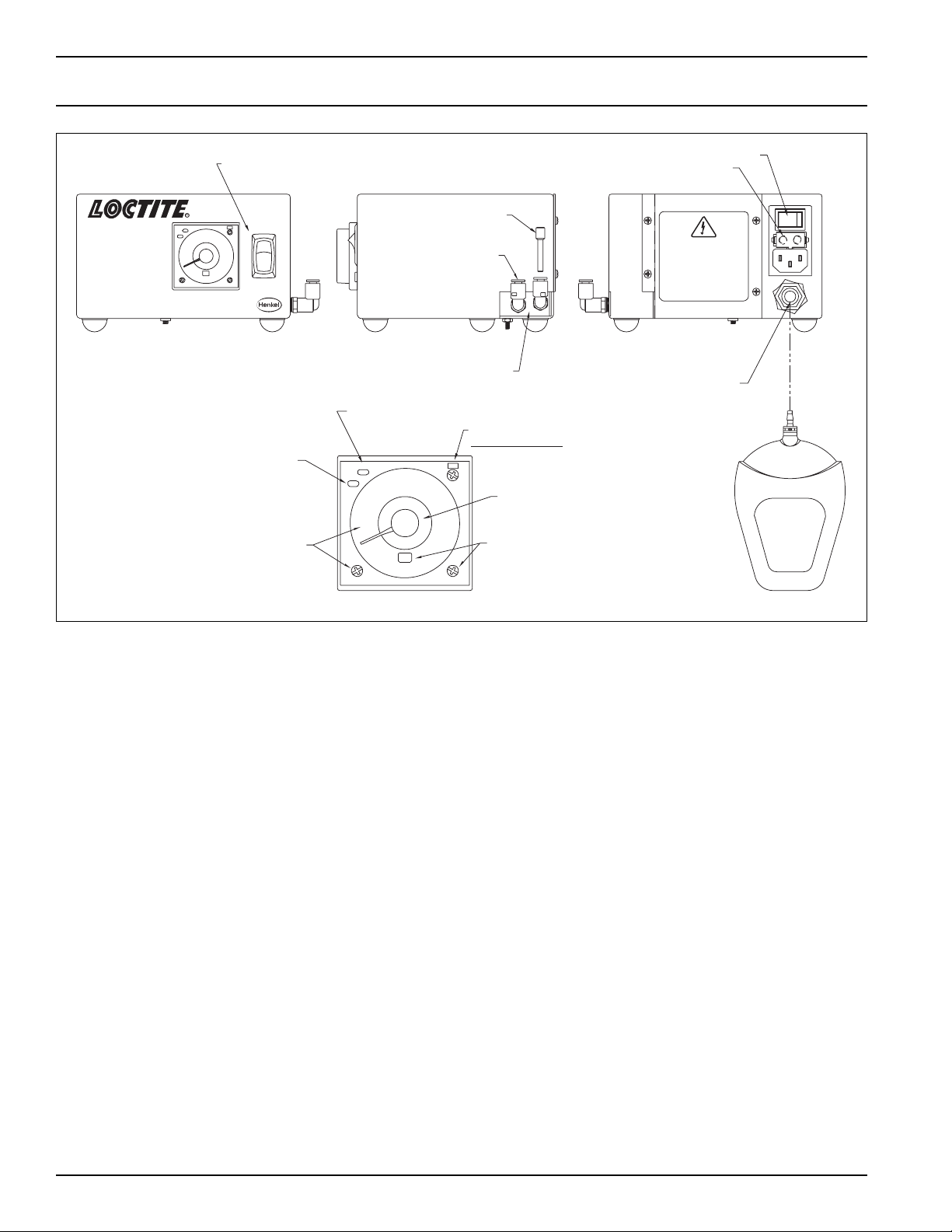

Figure 1. Loctite®Shot Miser™ Dispense System.

VALVE CONTROLLER

DISPENSE

VALVE

1 LITER RESERVOIR

FOOT

PEDAL

PRODUCT FEED LINE

70

100

10

0

bar

psi

30

20

50

40 60

90

80

Shot Miser™

Dispense Valve

Válvula Dosi icadora

# 98085

Henkel Loctite Corp.

Air Cylinder

Cilindro De Aire

# 986131

Vari-Drop™ Valve / Válvula:

# 97132

Air Cylinder / Cilindro De

Aire:

# 986131

Replacement Parts:

Re acciones:

SUPPLY AIR IN

SUPPLY AIR IN

0.2

OMRON H3CR

OUT

POWER

Regulado

0

min

1.2

0.4

0.6

0.8

1.0

MODE

Manual

A

Timed

Shot Miser™

Valve Controller

Controlador De Válvula

# 98079

Dispense Time

Tiempo De Dosi icación

CONTROL AIR LINE

4

2. Description (continued)

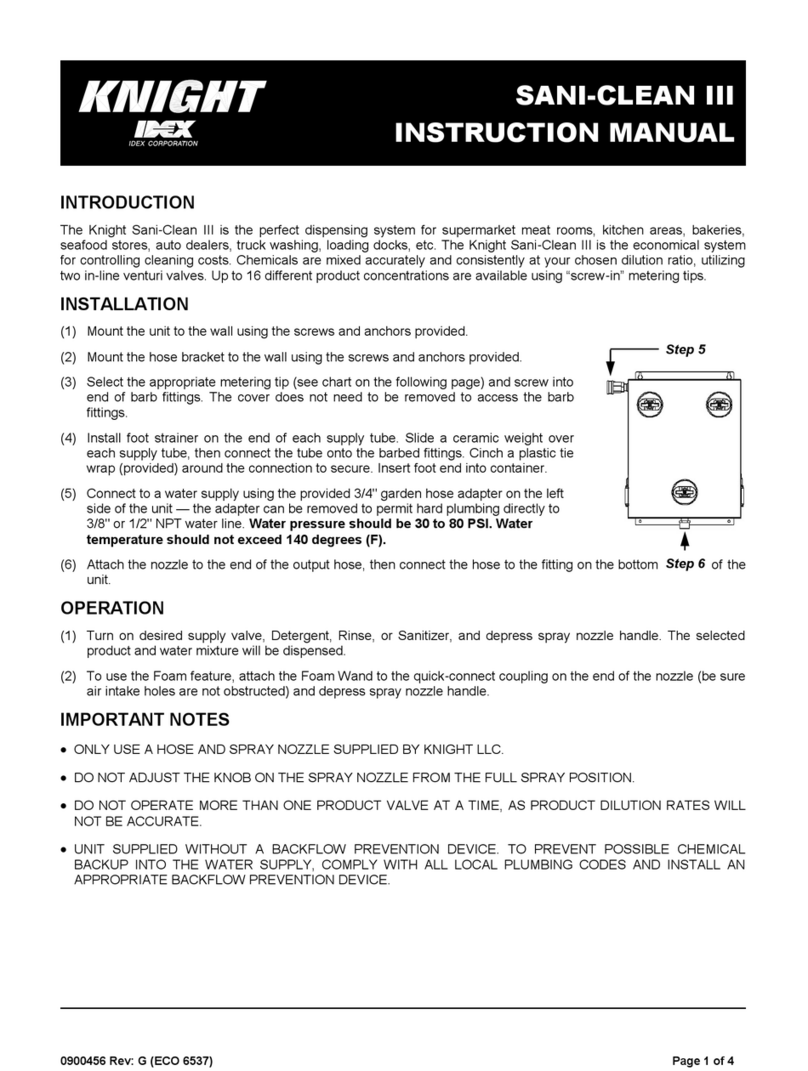

Figure 2. Dispense Valve Assembly (Dimensions In Inches).

Valve / Válvula:

# 986131

Aire:

Air Cylinder / Cilindro De

# 97132

Vari-Drop™

# 986131

Cilindro De Aire

Air Cylinder

Henkel Loctite Corp.

Válvula Dosi icadora

Re acciones:

Replacement Parts:

# 98085

Dispense Valve

Shot Miser™

Luer-Lok Needle

Connection

Access To Stroke

Adjuster Screw

Air Cylinder

Housing

Control Air Line

Vari-Drop™

Product Supply Tubing

.63

5.17

.66

2.28

.88

1.75

.42

1.03

6.19

Mounting Holes

0.22 Diameter

1.00 3.06

5

2. Description (continued)

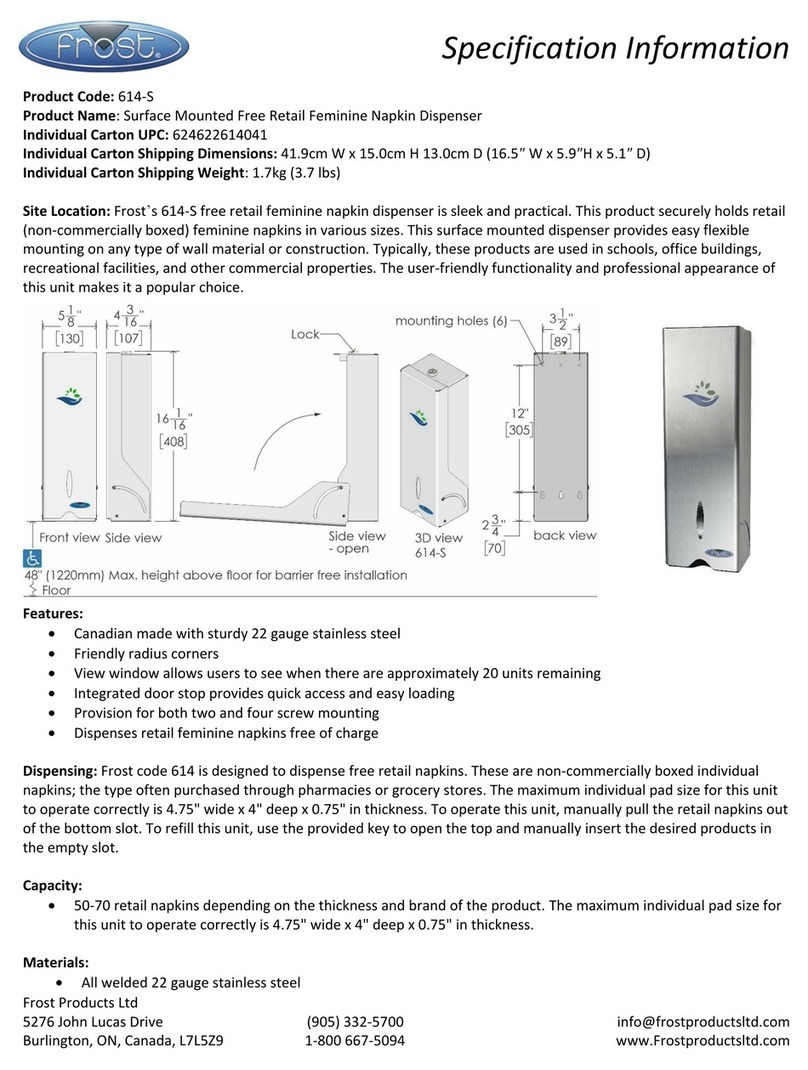

Figure 3. Reservoir Assembly.

Strain Relie Spring

Thermocouple Fitting

Wire Stand

Cover Clamp

Pressure Relie Valve

Lid O-Ring

When Dispensing Acetone Based

Primers Use O-Ring # 983055

1 Pound CA Bottle Shown

Te lon

®

Lined Feed Tube

Anti-Bubble Adapter Sleeve

Anti-Bubble Adapter

Do Not Pour Product Into Reservoir.

Place Product Bottle Into Reservoir.

Pressure Regulator Control

Air In

Pressure Gauge

Pressure

Vent

70

100

10

0

bar

psi

30

20

50

40 60

90

80

1/2

0-100 PSI / 0-6.9 BAR

# 98090

1L Reservoir / Recipiente

WARNING

CAUTION

PRECAUCIONES

ADVERTENCIA

Hand Tighten Only, Do Not Exceed 50 In. Lbs.

Apriete A Mano Solamente, No Exceda 50 Pulg. Lb.

Do Not Pour Liquid Into Reservoir, Insert Container With Liquid

Shot Miser™

No Vierta Líquido En El Depósito

Inserte Le Envase Con El Líquido

6

2. Description (continued)

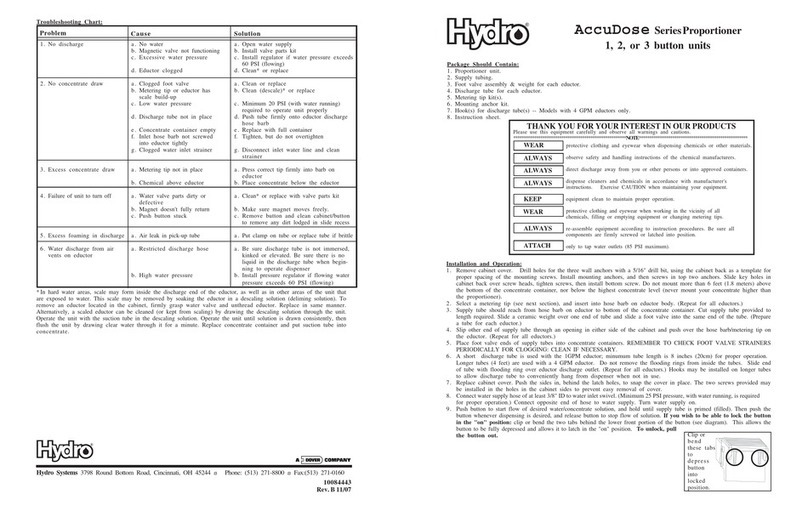

Figure 4. Valve Controller Assembly.

FRONT ELEVATION BACK ELEVATIONRIGHT SIDE ELEVATION

Pneumatic

Foot Switch

Rotation Changes Time Units

Choices: (sec) (min) (hrs) (10hrs)

Time Adjustment Control

Factory Set At “E”

Must Be Set To “E”

Rotation Changes

Scale Numbers

Choices: (0-1.2)

(0-3)

(0-12)

(0-30)

Output Indicator

On During Dispense

Power Indicator

On When Power

Is Applied

Dual Action Valve Output

Timed / Manual

Switch

Foot Switch Connection

On / O Switch

Fuses

OMRON H3CR

0

sec

1.2

POWER

0.4

0.2

OUT

E

1.0

0.8

0.6

MODE

AB

oI

Manual

Regulado

Timed

OMRON H3CR

0.6

sec

0.4

0

0.2

OUT

POWER

0.8

1.2

1.0

MODE

E

Shot Miser™

Valve Controller

Controlador De Válvula

# 98079

Dispense Time

Tiempo De Dosi icación

Plug Port

(For Single Acting Valves)

Pressure Out

(During Dispense)

Warning: Electrical Hazard Disconnect

Power Cord Be ore Removing Cover.

Advertencia: Peligro eléctrico

Desconecte el cable eléctrico antes de

quitar la cubierta.

115 VAC, 50/60 Hz.

Fuses/Fusibles: 1A, 5mm x 20mm

2.2 Theory of Operation

The Loctite®Shot Miser™ Dispense System operates as follows:

• Product under pressure is supplied from a reservoir to the fluid inlet of the dispense valve.

• An air signal is supplied from valve controller to the air cylinder of the dispense valve.

• The air cylinder operates the Vari-Drop™ lever, opening the pinch tube.

• Product flows out of the dispense needle.

• The control timer times out.

• The air cylinder rod retracts.

• The pinch tube closes and the product flow stops.

The amount of product dispensed is controlled by:

• The reservoir pressure.

• The time the pinch valve is open.

• The dispense tip I.D.

• Th amount that the pinch valve opens.

7

3. Technical Data

Loctite®Shot Miser™ Dispense Valve 98085

Pneumatic Supply min. 30 psig, max. 70 psig

Quality filtered to 10 µm, oil free, non-condensing

Control Air Connection 4 mm (.157")

Compressed Air Usage less than 1 scfm per stroke.

Product Pressure 0 psig to 80 psig

Product feed line 6.3 mm (.250")

Weight (less tubing & dispense needle) 228 grams (0.5 lbs.)

Loctite®Shot Miser™ Valve Controller 98079

Input Voltage / Cycles 115 VAC, 50/60 Hz

Fuse 1 Amp, 250V, 5 mm X 20 mm, Fast Acting

Size (width x depth x height) 6.1 inches X 6.9 inches X 3.9 inches

Weight 3.5 pounds

Loctite®1 Liter Shot Miser™ Reservoir 98090

Pneumatic Supply 100 PSI maximum

Size (width x depth x height) 8.5 inches X 8.5 inches X 13.25 inches

Weight 8.5 pounds

4. Installation

Caution!

DO NOT REMOVE ANY ITEMS THAT ARE SEALED IN PLASTIC BAGS UNTIL THEY ARE TO

BE USED AS THEY MAY BECOME CONTAMINATED, RESULTING IN PERFORMANCE

PROBLEMS.

4.1 Mounting

Secure Loctite®Shot Miser™ Dispense Valve (Part no. 98085) to a mounting surface with #10

dia. or 5 mm dia. screws. The hole pattern is given in Figure 2. Tighten the mounting screws to

approximately 10-inch pound torque.

Loctite®1 Liter Shot Miser™ Reservoir 98090

Notice:

• Always use wire stand to support the reservoir.

• Never pour product directly into the reservoir

☞

Adapter

Feedline to Valve

Connection

Sleeve Adapter

Feedline to Valve

8

4. Installation (continued)

B. Anti-bubbler Installation - 3⁄8" Feedtube

Install the spring guard, the fitting nut, and the ferrule onto the feedline. Insert the feedline into the

fitting located in the reservoir lid. Insert the anti-bubbler into the 3⁄8" feedline. Position the feedline

so that the anti-bubbler is close to the bottom of the adhesive bottle.

4.5 Dispense Tip

•Position a suitable dispense needle in the Luer-Lok adapter and tighten securely.

4.2 Connecting the Air Line / Reference – Figure 1

Loctite®Shot Miser™ Dispense System

•Connect the foot pedal, as shown in Figure 1, to the valve controller.

•Connect 4 mm air line from the normally not passing port, first the air line connection from front

of controller, then to the air cylinder on the dispense valve.

•Insure that normally passing port has port plug installed (second air line connection from front

of controller).

•Connect the supply air to “Air In Port”on valve controller.

•Connect the supply air to “Air In Port”on reservoir.

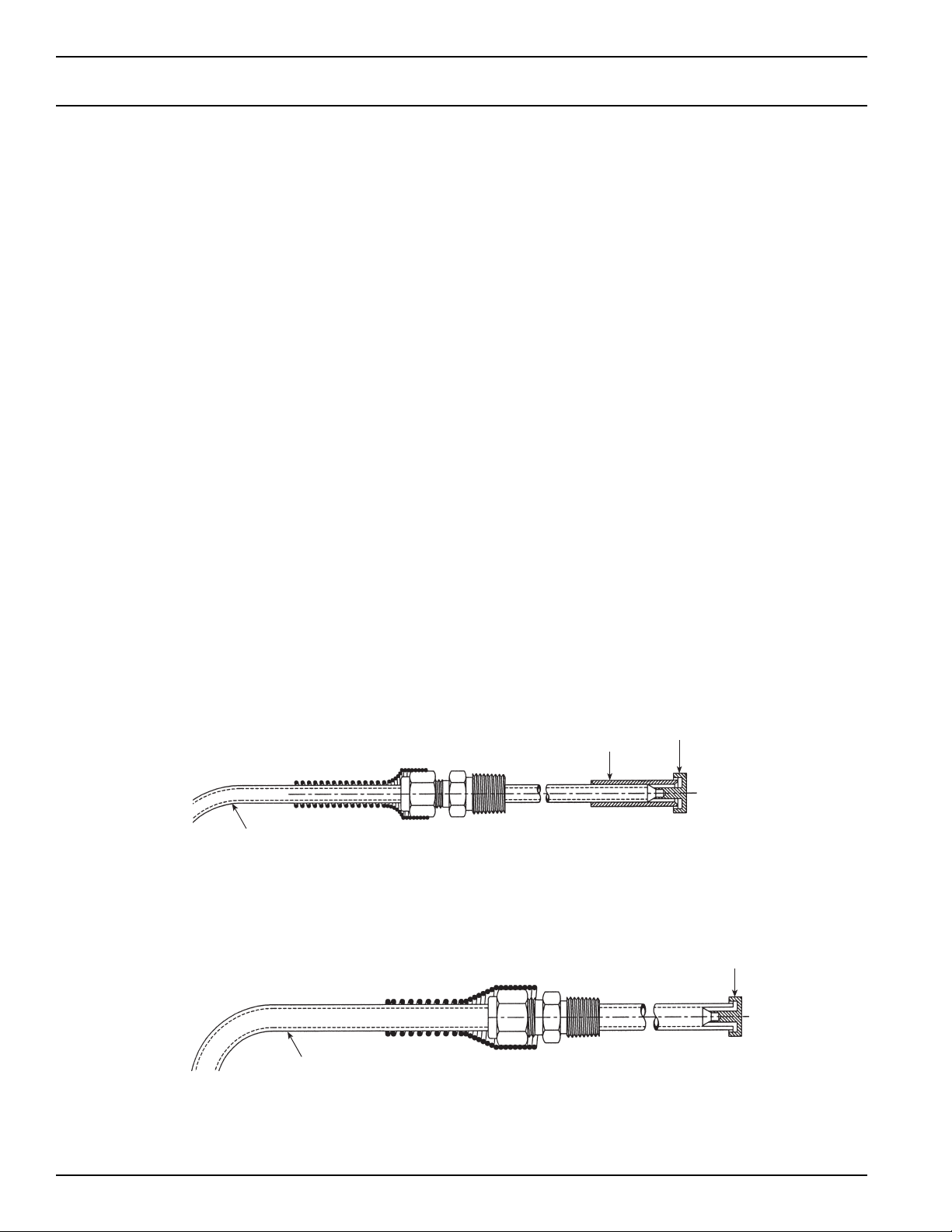

4.3 Product Supply Tube

•Note that this is a Teflon®lined tube.

•Slide the nut and ferrule onto the product supply tube.

•Push the end of the product supply tube into the Vari-Drop™. Make sure that the end of the

product supply tube bottoms out in the Vari-Drop™.

•Position the nut and ferrule and tighten the fitting nut 1 to 11⁄2turns past finger tight.

•Connect the other end of the product supply tube to the product pressure reservoir as stated in

“Install Anti-Bubbler”.

4.4 Installing the Anti-Bubbler to .5 liter and 2 liter Reservoirs

Anti-Bubbler

The anti-bubbler is inserted at the end of the feedtube which resides in the product reservoir. The

purpose of the anti-bubbler is to minimize the amount of adhesive which will run out of the

feedtube when the reservoir lid is removed to re-fill the product reservoir.

A. Anti-bubbler Installation - 1⁄4" Feedtube

Install the spring guard, the fitting nut, and the ferrule onto the feedline. Insert the feedline into the

fitting located in the reservoir lid. Insert the anti-bubbler into the anti-bubbler connection sleeve.

Push the anti-bubbler connection sleeve onto the 1⁄4" feedline. Position the feedline so that the

anti-bubbler is close to the bottom of the adhesive bottle.

9

5. Operations

5.1 Priming the Valve

•Connect the utilities.

•Place a full product bottle in the reservoir.

•Set the reservoir pressure to a value suitable to the product viscosity (low pressure for low

viscosity product, higher pressure for high viscosity product).

•Position a container under the dispense nozzle. If it is not possible to position the container

under the dispense nozzle, use the silicone tube to route the outlet point to a container in a

remote location.

•Set the valve controller on “Manual”control to open the valve.

•On the reservoir set pressure/vent control (toggle switch) to pressure positon.

•Open the valve until air free product flows at the dispense point.

•Remove the container or tube. The valve is ready to dispense.

•Once the valve has been primed, set the valve controller to “Timed Mode”.

5.2 Adjusting the Amount of Loctite®Product Dispensed

The Loctite®Shot Miser Valve™is part of a pressure-time dispense system. Here are the

variables that control the amount of product dispensed:

•Product pressure

Higher pressure = more product flow

Lower pressure = less product flow

•Time the valve is open

Longer time = more product flow

Shorter time = less product flow

•Needle size

Larger needle inside diameter = more product flow

Smaller needle inside diameter = less product flow

•Stroke adjuster setting.

More valve opening = more product flow

Less valve opening = less product flow

Generally speaking the stroke adjuster setting is the least useful of the above (4) variables. This is

because it has no numerical set point. Pressure, time, and needle size all have numerical values

that can be recorded and repeated.

Because of the large number of products, only general guidelines will be given for dispensing.

Higher viscosity products will require higher pressures, longer times, and larger needle I.D. The

reverse is true for lower viscosity products.

10

6. Maintenance and Cleaning

6.1 Cleaning

The product dispensing section of the Loctite®Vari-Drop™can be flushed with Loctite®Equipment

Flushing Solvent supplied from a suitable reservoir. Adjust the reservoir pressure to a low value to

reduce the flow rate.

6.2 Maintenance

There are two main components, the air cylinder and the Vari-Drop™applicator that can be

replaced.

6.2.1 Procedure for Replacing Vari-Drop™ and Air Cylinder

Caution!

•Before starting the replacement procedure make sure that the product reservoir pressure is

(0) psig.

•Detach the Loctite®Vari-Drop™from any mounting bracket.

•Drain any product from the Loctite®Vari-Drop™by elevating it and the product supply tube to

a level higher than the product reservoir. Actuate the Loctite®Vari-Drop™and let gravity move

the product down into the product reservoir.

•Shut off the control air pressure to the Loctite®Vari-Drop™.

•Disconnect the control air line from the fitting on the air cylinder.

•Disconnect the product supply tube from the Loctite®Vari-Drop™.

•Secure the tubes in a safe manner so there is no siphoning from the product supply tube and

no whipping from the control air tube if the air is accidentally turned on.

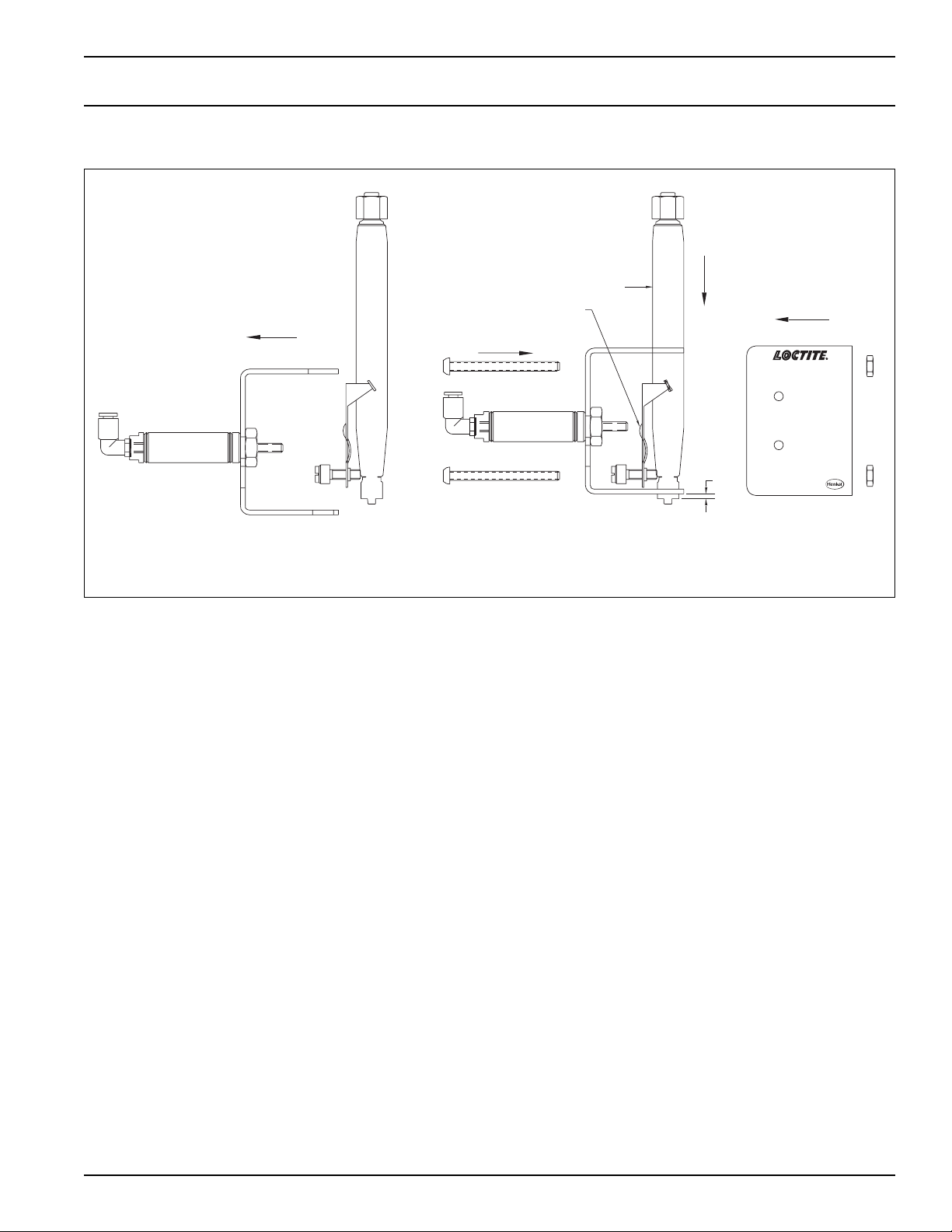

6.2.2 Disassembling the Loctite®Vari-Drop™

Figure 5.

Shot Miser™

Válvula Dosi icadora

# 98085

Dispense Valve

Re acciones:

Replacement Parts:

Valve / Válvula:

Air Cylinder / Cilindro De

Vari-Drop™

# 97132

Aire:

# 986131

Henkel Loctite Corp.

# 986131

Cilindro De Aire

Air Cylinder

Remove the Cover

Remove the #10-32

Nuts and Screws

Vari-Drop™ Remove the Valve

Luer-Lok Adapter

11

6.2.3 Reassembling the Loctite®Vari-Drop™

•Connect the product supply tube to the Loctite®Vari-Drop™.

•Connect the control air line to the fitting on the air cylinder.

•Attach the Loctite®Vari-Drop™to the mounting bracket.

•Prime the Loctite®Vari-Drop™per the instructions on page 8 of this manual.

•The Loctite®Vari-Drop™is now ready for operation.

6. Maintenance and Cleaning

Figure 6.

Henkel Loctite Corp.

Air Cylinder

Cilindro De Aire

# 986131

Henkel Loctite Corp.

Air Cylinder

Cilindro De Aire

# 986131

Depress The Vari-Drop™ Lever To

Horizontal Then Slide The Vari-Drop™

Down Into The Clamp.

Then Slide The Vari-Drop™ Forward Into The

Clamp So That The Luer-Lok Adapter Is At

The Speci ied Dimension Beyond The Clamp.

In Clamp & Cover

Position #10-32 Screws

Vari-Drop™ Position Cover Over The

Vari-Drop™ & Clamp

.100

Apply Lithum Grease To

Vari-Drop™ Lever

Shot Miser™

Válvula Dosi icadora

# 98085

Dispense Valve

Re acciones:

Replacement Parts:

Valve / Válvula:

Air Cylinder / Cilindro De

Vari-Drop™

# 97132

Aire:

# 986131

12

Type of Malfunction Possible Cause Correction

Loctite®Vari-Drop™does –No pressure in product reservoir. •Switch pressure/vent control to

not dispense product and pressure position.

the Stroke Adjuster does –Valve controller is not functioning. •Check that is plugged in to

not move when the unit 120 volt receptacle.

is cycled. –Mode setting on timer is incorrect. •Set timer mode, located on front face

of timer, to “E”mode.

–No air supply. •Turn on air supply.

–Low air pressure. •Adjust air pressure to at least 60 psig.

–Stroke Adjuster is set to zero stroke. •Reset Stroke Adjuster.

–Air cylinder is defective. •Replace air cylinder.

–Control valve is faulty. •Replace control valve.

Unit does not dispense –Control logic problem. •Check program and components.

product but the Stroke –No or low reservoir pressure. •Increase reservoir pressure.

Adjuster moves normally –Product reservoir is empty. •Refill reservoir.

when the unit is cycled. –Unit is not primed. •Re-prime the unit and check product

tubing and product tube fittings

for leaks.

–Cured product in product tubing •Replace tubing or fittings.

or fittings.

–Cured product in dispense needle. •Replace needle.

–Vari-Drop™lever failure. •Replace Vari-Drop™.

Product leaks from –Vari-Drop™pinch tube failure. •Replace or repair Vari-Drop™.

dispenser. –Reservoir pressure to high. •Reduce reservoir pressure.

7. Troubleshooting

Description Loctite Part No.

Air Cylinder 986131

Loctite®Vari-Drop™97312

Loctite®Vari-Drop™Repair Kit 97249

Nut and Sleeve for Product Tubing 993247

Grease, silicone, 6 gr. tube 997569

8. Spare Parts and Accessories

The following is a list of recommended parts or assemblies that may be required to repair the

Loctite®Shot Miser™Dispense System.

8.1 Spare Parts

Loctite®Shot Miser™ Dispense Valve 98085

13

Description Loctite Part No.

Foot Pedal with fitting and Tubing 98126

Air Actuated Remote Electrical Switch 986262

Solenoid Valve, 4 Way 986264

8. Spare Parts and Accessories (continued)

Loctite®Shot Miser™ Valve Controller 98079

Description Loctite Part No.

Pressure Relief Valve 992641

3 Way Toggle Valve 98094

Pressure Regulator 98129

Anti-Bubbler Kit 2 adapters & 2 sleeves 984687

O-Ring , standard for lid 997312

O-Ring for use with acetone based primers 983055

Pressure Gauge 98130

Loctite®Shot Miser™ Reservoir 98090

Description Loctite Part No. Qty.

Needle Kit 97262 1

Dispense Tips, Stainless Steel - Striaght

Dispense Tip, Luer-Lok, 15 gauge 97225 Box of 50

Dispense Tip, Luer-Lok, 18 gauge 97226 Box of 50

Dispense Tip, Luer-Lok, 20 gauge 97227 Box of 50

Dispense Tip, Luer-Lok, 25 gauge 97228 Box of 50

Dispense Tips, Flexible

Dispense Tip, Luer-Lok, 15 gauge 97229 Box of 50

Dispense Tip, Luer-Lok, 18 gauge 97230 Box of 50

Dispense Tip, Luer-Lok, 20 gauge 97231 Box of 50

Dispense Tip, Luer-Lok, 25 gauge 97232 Box of 50

Dispense Tips, Taper Tip

Dispense Tip, Luer-Lok, 16 gauge 97221 Box of 50

Dispense Tip, Luer-Lok, 18 gauge 97222 Box of 50

Dispense Tip, Luer-Lok, 20 gauge 97223 Box of 50

Dispense Tip, Luer-Lok, 22 gauge 97224 Box of 50

Dispense Tip, Luer-Lok, 25 gauge PTFE 97238 Box of 50

lined Stainless Steel Tip

Dispense Tip, Luer-Lok, Plastic, 15 gauge 97261 Box of 50

8.2 Accessories

9. Warranty

Henkel Loctite expressly warrants that all products referred to in this Instruction Manual under

Loctite®Shot Miser™Dispense System 98116 (hereafter called “Products”) shall be free from

defects in materials and workmanship. Liability for Henkel Loctite shall be limited, at its option, to

replacing those Products which are shown to be defective either in materials or workmanship or to

credit to the purchaser the amount of the purchase price thereof (plus freight and insurance

charges paid therefore by the user). The purchaser’s sole and exclusive remedy for breach of

warranty shall be such replacement or credit.

A claim of defect in materials or workmanship in any Products shall be allowed only when it is

submitted to Henkel Loctite in writing within one month after discovery of the defect or after the

time the defect should reasonably have been discovered and in any event, within twelve months

after the delivery of the Products to the purchaser. No such claim shall be allowed in respect of

Products which have been neglected or improperly stored, transported, handled, installed,

connected, operated, used or maintained or in the event of unauthorized modification of the

Products including, where products, parts or attachments for use in connection with the Products

are available from Henkel Loctite, the use of products, parts or attachments which are not

manufactured by Henkel Loctite.

No Products shall be returned to Henkel Loctite for any reason without prior written approval from

Henkel Loctite. Products shall be returned freight prepaid, in accordance with instructions from

Henkel Loctite.

NO WARRANTY IS EXTENDED TO ANY EQUIPMENT WHICH HAS BEEN ALTERED,

MISUSED, NEGLECTED, OR DAMAGED BY ACCIDENT, OR IF THE SYSTEM USED TO

DISPENSE ANY LIQUID MATERIAL OTHER THAN LOCTITE®PRODUCTS.

EXCEPT FOR THE EXPRESS WARRANTY CONTAINED IN THIS SECTION, HENKEL LOCTITE

MAKES NO WARRANTY OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, WITH

RESPECT TO THE PRODUCTS.

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND

OTHER WARRANTIES OF WHATEVER KIND (INCLUDING AGAINST PATENT OR

TRADEMARK INFRINGEMENT) ARE HEREBY DISCLAIMED BY HENKEL LOCTITE AND

WAIVED BY THE PURCHASER.

THIS SECTION SETS FORTH EXCLUSIVELY ALL OF LIABILITY FOR HENKEL LOCTITE TO

THE PURCHASER IN CONTRACT, IN TORT OR OTHERWISE IN THE EVENT OF

DEFECTIVE PRODUCTS.

WITHOUT LIMITATION OF THE FOREGOING, TO THE FULLEST EXTENT POSSIBLE UNDER

APPLICABLE LAWS, HENKEL LOCTITE EXPRESSLY DISCLAIMS ANY LIABILITY

WHATSOEVER FOR ANY DAMAGES INCURRED DIRECTLY OR INDIRECTLY IN

CONNECTION WITH THE SALE OR USE OF, OR OTHERWISE IN CONNECTION WITH, THE

PRODUCTS, INCLUDING, WITHOUT LIMITATION, LOSS OF PROFITS AND SPECIAL,

INDIRECT OR CONSEQUENTIAL DAMAGES, WHETHER CAUSED BY NEGLIGENCE FROM

HENKEL LOCTITE OR OTHERWISE.

EQUIPMENT

EQUIPO

Operation Manual

Manual de Operación

Loctite®Shot Miser™Dispense System

Equipo Dosificador Shot Miser™

Part Number/Numero de Parte 98116

70

100

10

0

bar

psi

30

20

50

40 60

90

80

Shot Miser™

Dispense Valve

Válvula Dosi icadora

# 98085

Henkel Loctite Corp.

Air Cylinder

Cilindro De Aire

# 986131

Vari- Valve / Válvula:

# 97132

Air Cylinder / Cilindro De

Aire:

# 986131

Replacement Parts:

Re acciones:

SUPPLY AIR IN

ENTRADA DE AIRE

SUPPLY AIR IN

ENTRADA DE AIRE

0.2

OMRON H3CR

OUT

POWER

Regulado

0

min

1.2

0.4

0.6

0.8

1.0

MODE

Manual

A

Timed

Shot Miser™

Valve Controller

Controlador De Válvula

# 98079

Dispense Time

Tiempo De Dosi icación

Contents

No. Página

1 Por Favor Observe lo Siguiente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1 Secciones Importantes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Para su Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Desempaque e Inspección. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Partes Suministradas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Características . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Uso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Descripción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2.1 Elementos de Operación y Controles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

2.2 Teoría de Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Datos Técnicos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

4.1 Montaje. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Conectando la Alimentación de Aire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Tubo de Suministro de Producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 Instalación del Anti-Burbujas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Punta de Dosificación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Operaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Purga de la Válvula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Ajustando la Cantidad a Dosificar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Limpieza y mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

6.1 Limpieza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.1 Procedimiento de Reemplazo de Loctite®Vari-Drop™y Cilindro de Aire . . . . . . . . . . 10

6.2.2 Desensamblando el Loctite®Vari-Drop™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.3 Ensamblando el Loctite®Vari-Drop™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Solución de Fallas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Refacciones y Accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

8.1 Refacciones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

8.2 Accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Portada Posterior

1. Por Favor Observe lo Siguiente

1

1.1 Secciones Importantes

Advertencia!

Se refiere a medidas y regulaciones de seguridad que protegen al operador o a otras personas.

Precaución!

Enfatiza sobre lo que debe ser hecho o evitar para que la unidad o el propietario no sufran daño.

Nota:

Da recomendaciones para el mejor manejo de la unidad durante la operación o actividades

de servicio.

1.2 Para su Seguridad

Advertencia!

•Observe todas las advertencias. Lea y entienda todas las instrucciones en el manual antes

de instalar u operar el equipo.

•Este equipo ha sido diseñado y probado para ser usado con productos Loctite®tanto para

tiempo y presión. Los productos pueden tener una viscosidad de hasta 80,000 centiopoise.

•No use el equipo para otro fin mas que para el señalado

•Asegúrese que los adhesivos, solventes o fluidos usados son compatibles químicamente con

las partes húmedas.

•Siempre verifique y lea las hojas de datos de seguridad de los materiales antes de usar

cualquier adhesivo, solvente u otro químico en este equipo. Cumpla con todas las

advertencias e instrucciones de seguridad.

•Siempre use protección de ojos, guantes, ropa y respirador tal como se recomienda en este

manual o en la hoja de seguridad del material.

•Cualquier uso inadecuado de este equipo o accesorios como una sobre presión, partes

modificadas, uso de químicos incompatibles, adhesivos o solventes, partes dañadas o no

recomendadas, pueden causar ruptura y fugas, salpicaduras en los ojos o piel o cualquier otro

daño personal.

•Nunca altere o modifique las partes del equipo. Hacerlo puede ocasionar mala funcionalidad.

•Verifique el equipo regularmente y repare o reemplace las partes dañadas de inmediato.

•Nunca exceda la presión de trabajo recomendada o la presión máxima de entrada estipulada

en el equipo o en el manual.

•Aterrice apropiadamente las conexiones eléctricas como lo recomienda este manual o la hoja

de datos de seguridad.

•Siempre mantenga las manos y dedos lejos de las partes móviles para evitar riesgo de daño.

•Siempre libere la presión y apague el equipo cuando haga revisiones de servicio.

•Mantenga este manual para futuras referencias.

☞

1. Por Favor Observe lo Siguiente (continua)

2

1.3 Desempaque e Inspección

Desempaque cuidadosamente los componentes del sistema y examine los artículos suministrados

en la caja. Verifique las partes de cualquier daño que pudo haber sufrido durante el transporte. Si

existe daño notifique al transportista inmediatamente. Las reclamaciones deben ser a través del

transportista y deben ser notificadas al proveedor.

1.4 Artículos Suministrados

Válvula Dosificadora Loctite®Shot Miser™ 98085

Selector de agujas

Tubo de producto / 7 pies

Línea de control de aire / 6 pies

Manual de operación

Manual de operación del Varidrop

Controlador de Válvula Loctite®Shot Miser™ 98079

Pedal

Manguera de pedal / 10 pies

Cable de energía

Manual de operación

Tanque de 1 litro Loctite®Shot Miser™ 98090

Adaptador anti burbujas

Conector anti-burbujas

Resorte de protección

Tubo de suministro de producto / 6 pies

Manual de operación

1.5 Características

Válvula Dosificadora Loctite®Shot Miser™ 98085

•Usado en aplicaciones semi automáticas o procesos completamente automatizados

•Tanques adaptables al tamaño de la presentación del producto

•Dosifica productos Loctite de hasta 80,000 cP

•Permite repitibilidad en la dosificación desde gotas hasta cordones.

Controlador de Válvula Loctite®Shot Miser™ 98097

•Cronometro análogo de fácil lectura

•Modo continuo o cronometrado de 0.10 segundos a horas

•Salida neumática para válvulas de una o doble acción

•Pedal neumático

Tanque de 1 litro Loctite®Shot Miser™ 98090

•Presión de 0 a 100 psi

•Capacidad del recipiente: botella 1 lb, 500 gr, 250 ml.

1.6 Uso

El equipo dosificador Loctite®Shot Miser™es apropiado para una dosificación semi o

completamente automatizada de todos los productos Loctite®que pueden ser controlados con

presión y tiempo. Este puede dosificar puntos, gotas o cordones de adhesivo.

Table of contents

Languages:

Other Henkel Dispenser manuals

Henkel

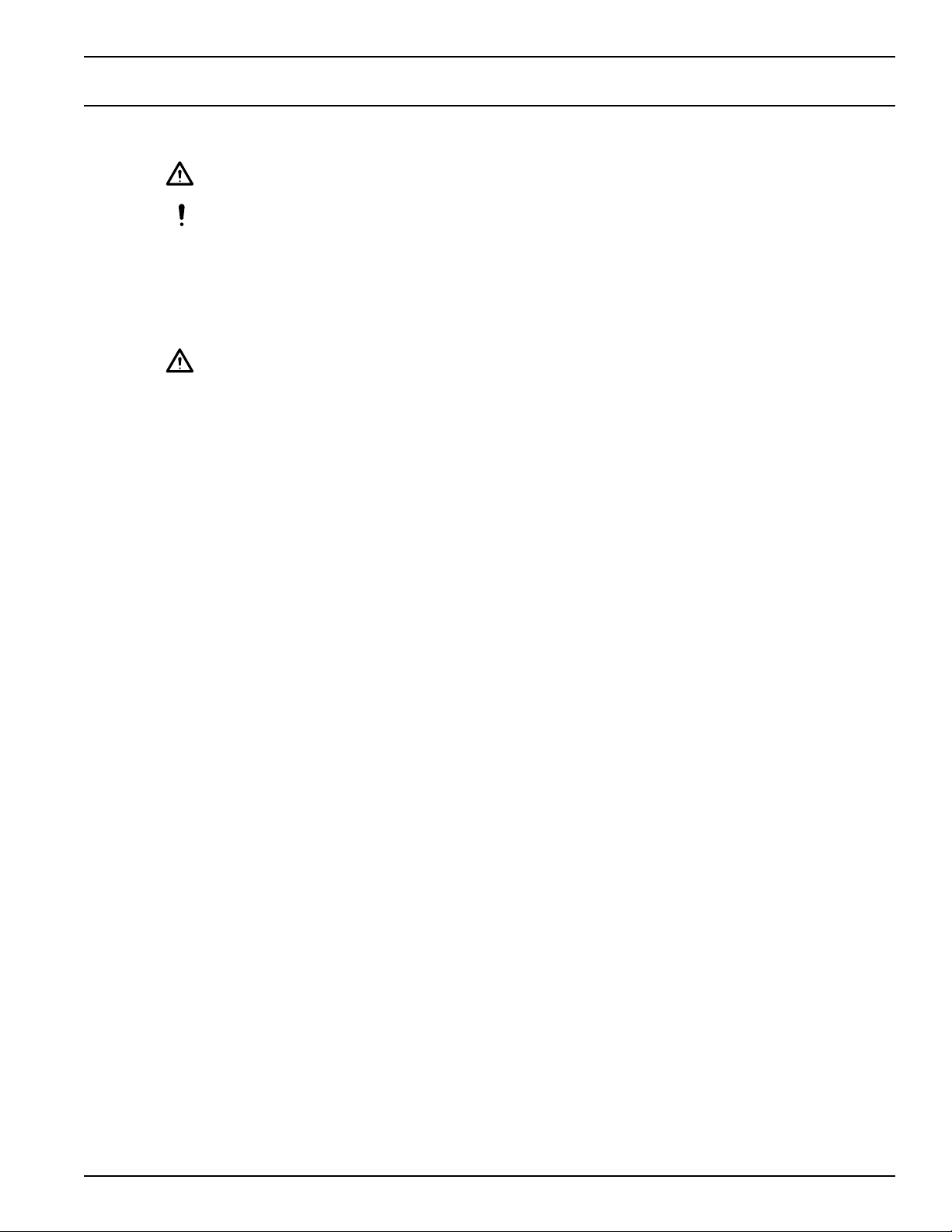

Henkel Loctite 98427 User manual

Henkel

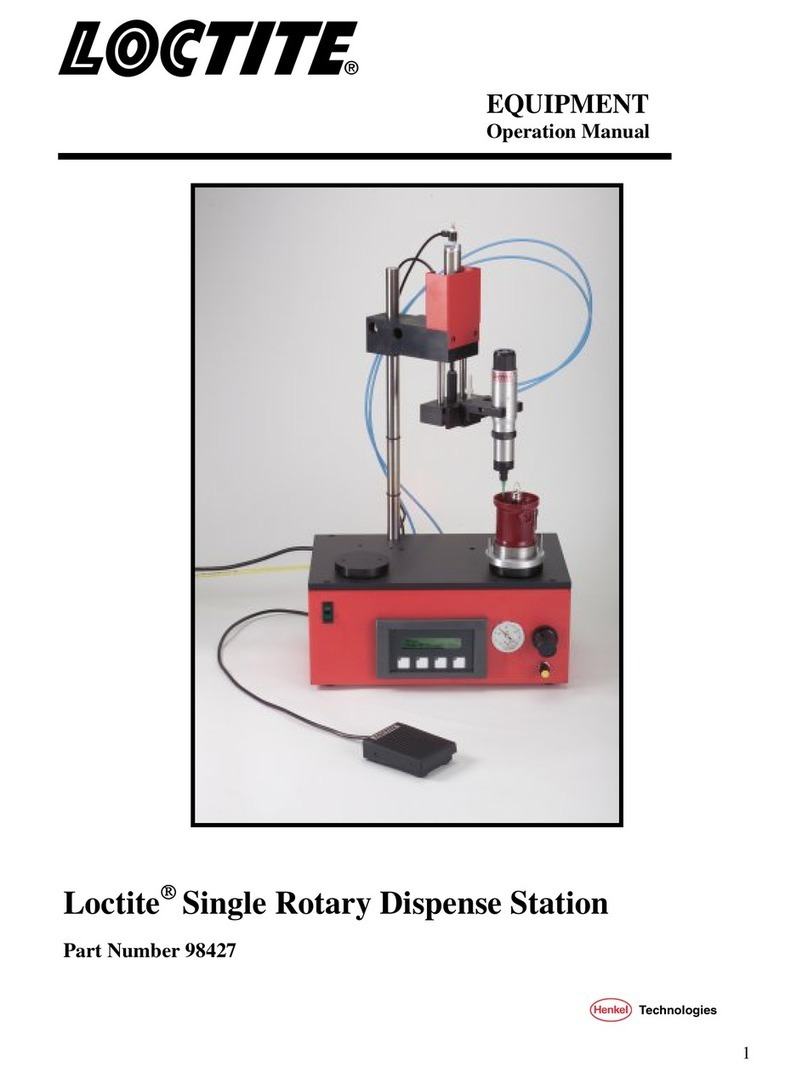

Henkel Loctite RB10 User manual

Henkel

Henkel Loctite 98548 User manual

Henkel

Henkel Loctite 97631 User manual

Henkel

Henkel LOCTITE 97130 User manual

Henkel

Henkel Loctite EQ RC40 User manual

Henkel

Henkel Loctite User manual

Henkel

Henkel Loctite 97008 User manual

Henkel

Henkel OSI Service manual

Henkel

Henkel Loctite EQ HD12 manual