Henny Penny 301 User manual

Other Henny Penny Fryer manuals

Henny Penny

Henny Penny KVE-071 User manual

Henny Penny

Henny Penny EVOLUTION ELITE EEG-241 User manual

Henny Penny

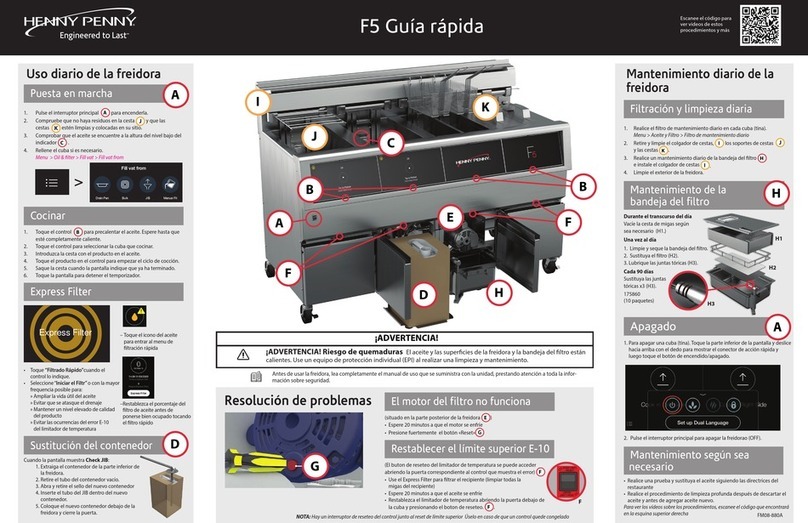

Henny Penny F5 User manual

Henny Penny

Henny Penny 291 Operating instructions

Henny Penny

Henny Penny LOV LVE-100 Series User manual

Henny Penny

Henny Penny MVE-071 User manual

Henny Penny

Henny Penny QSR Solutions FM03-672 User manual

Henny Penny

Henny Penny Pressure Fryer User manual

Henny Penny

Henny Penny LOV LVG-100 Series User manual

Henny Penny

Henny Penny FM03-681 User manual

Henny Penny

Henny Penny GVE-071 User manual

Henny Penny

Henny Penny OFG-390 User manual

Henny Penny

Henny Penny LOV LVE-100 Series User manual

Henny Penny

Henny Penny LOV LVE-100 Series Guide

Henny Penny

Henny Penny OEA-321 User manual

Henny Penny

Henny Penny KFC Velocity Series User manual

Henny Penny

Henny Penny LVE-202 User manual

Henny Penny

Henny Penny Chick-fil-A Controls 500 User manual

Henny Penny

Henny Penny LOV LVE-100 Series User manual

Henny Penny

Henny Penny Evolution Elite EEE-154 User manual