Henny Penny 500 Operating instructions

Other Henny Penny Fryer manuals

Henny Penny

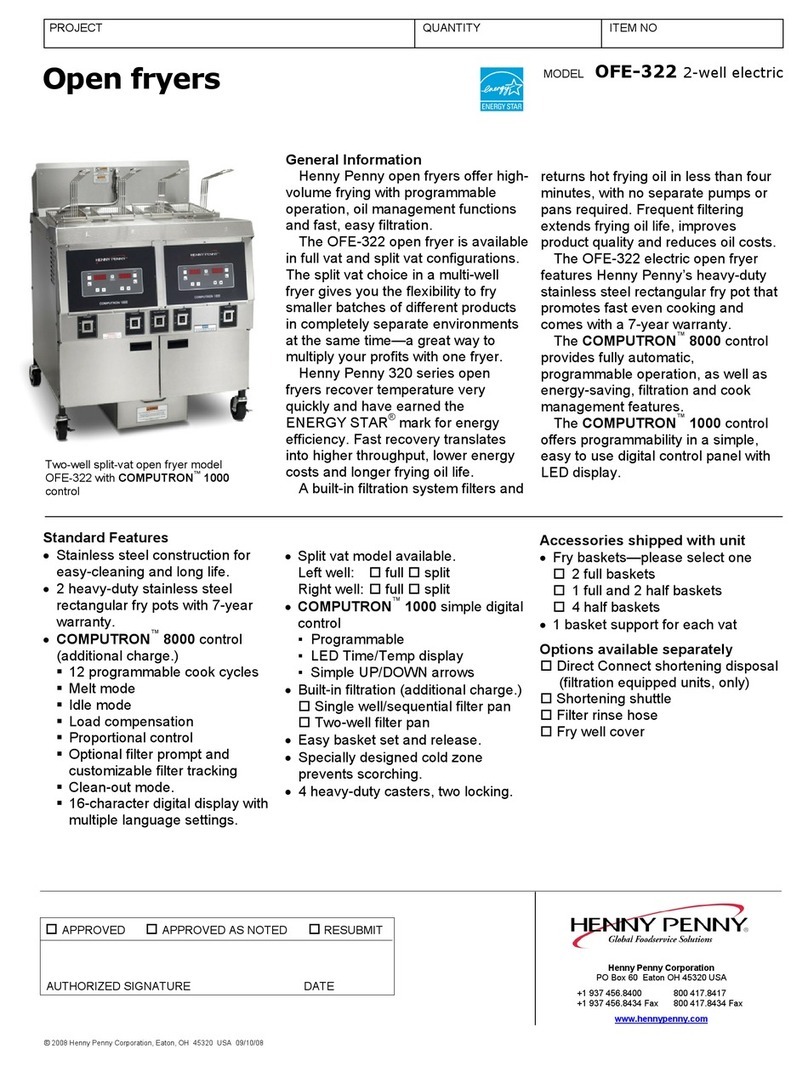

Henny Penny OFE-322 User manual

Henny Penny

Henny Penny FM05-032-G User manual

Henny Penny

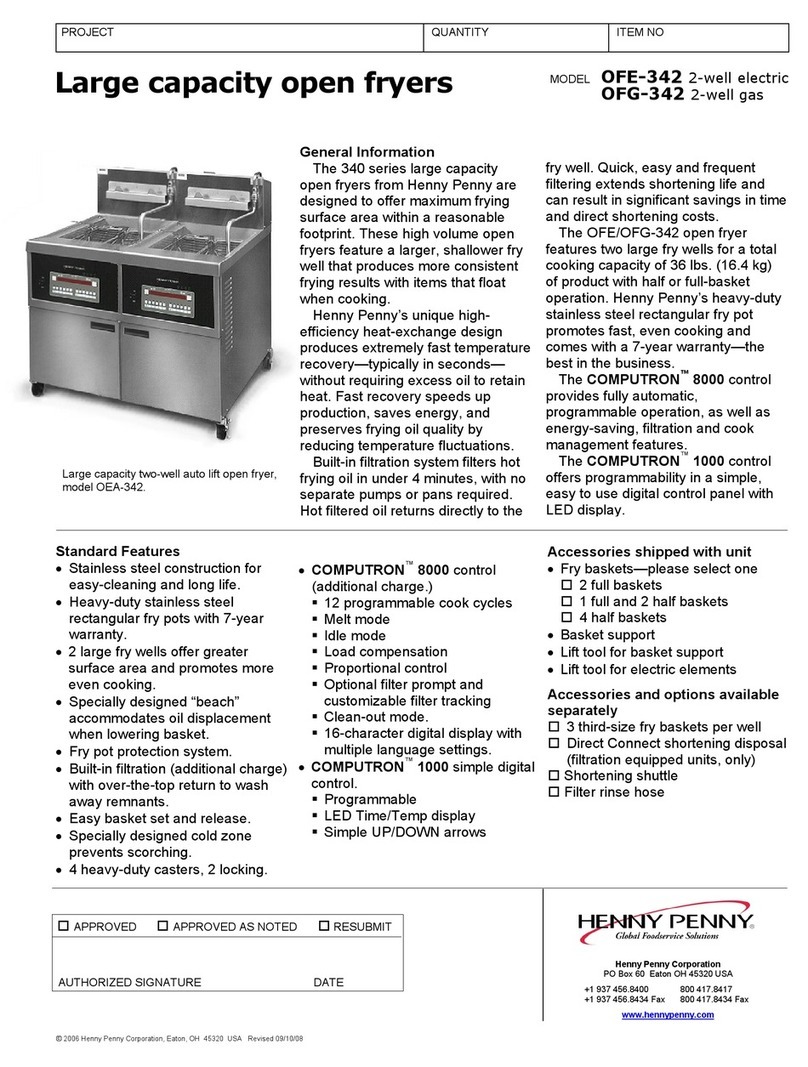

Henny Penny OFE-342 User manual

Henny Penny

Henny Penny LVE-102 User manual

Henny Penny

Henny Penny Pressure Fryer User manual

Henny Penny

Henny Penny LOV LVE-100 Series User manual

Henny Penny

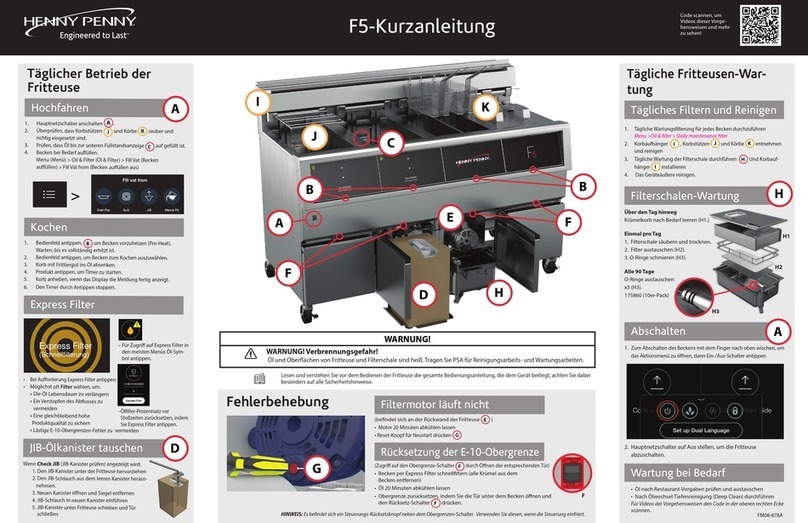

Henny Penny F5 User manual

Henny Penny

Henny Penny LVG-202 User manual

Henny Penny

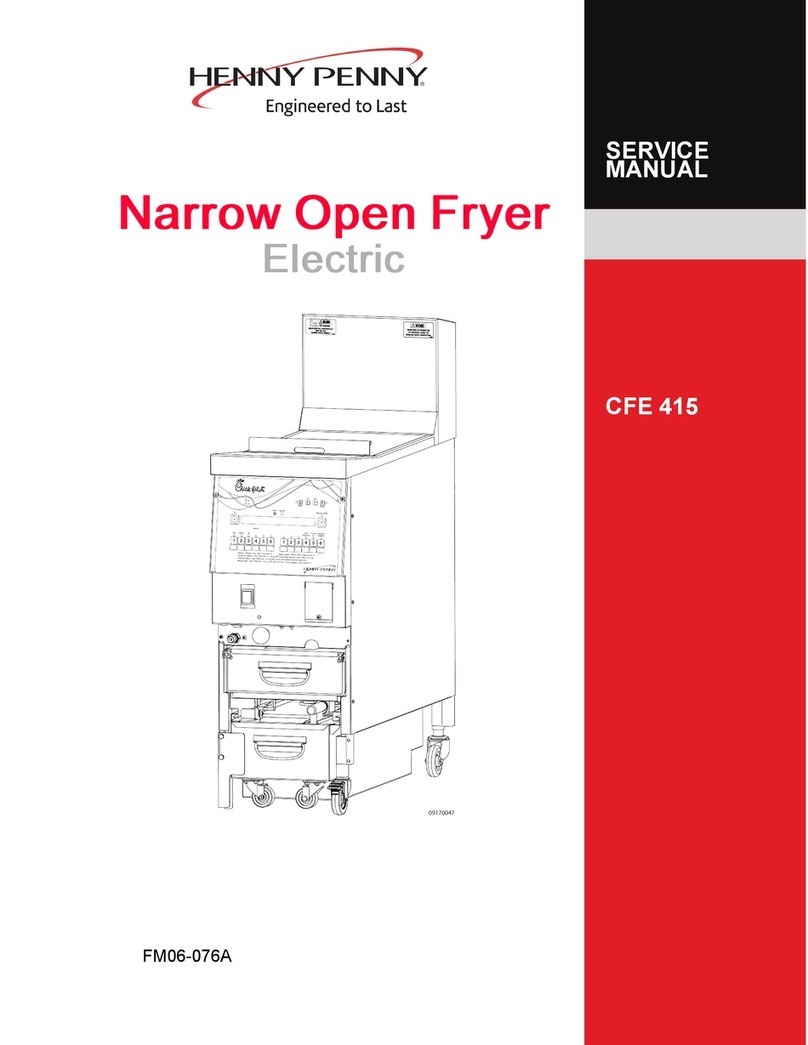

Henny Penny CFE-415 User manual

Henny Penny

Henny Penny OFE-391 User manual

Henny Penny

Henny Penny LOV LVG-100 Series User manual

Henny Penny

Henny Penny PFE-590 User manual

Henny Penny

Henny Penny 500 User manual

Henny Penny

Henny Penny LOV LVG-100 Series Guide

Henny Penny

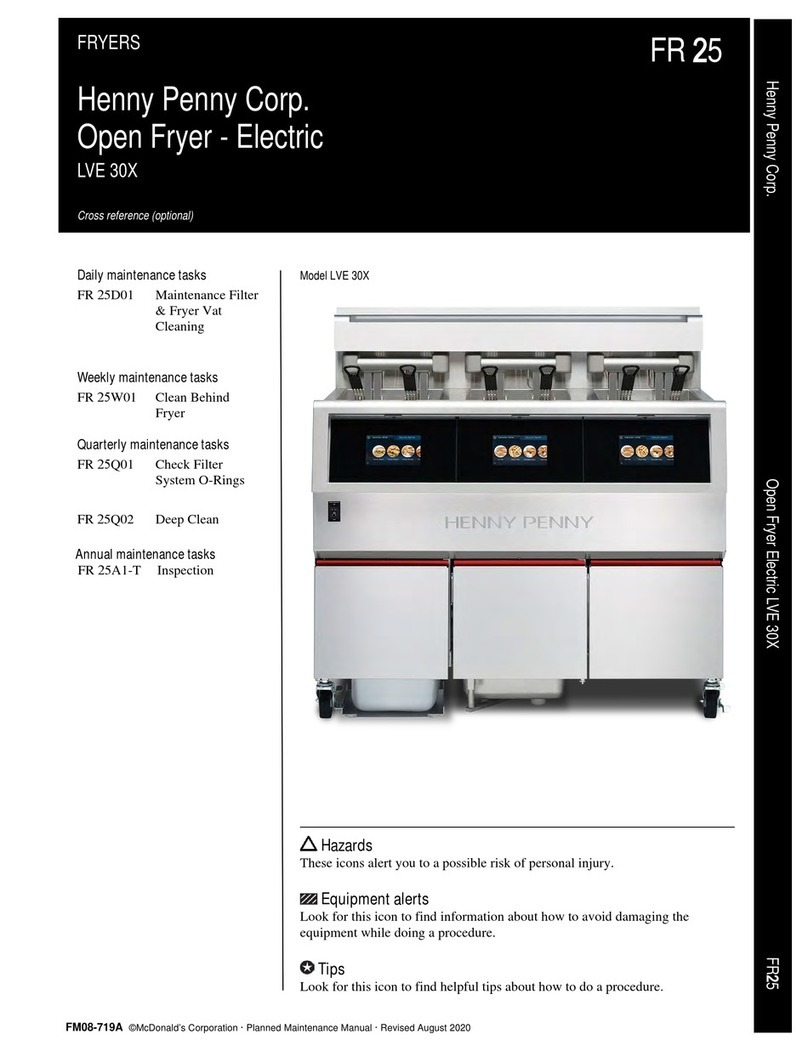

Henny Penny LVE 30 Series User manual

Henny Penny

Henny Penny Evolution Elite EEE-153 User manual

Henny Penny

Henny Penny OFE-341 User manual

Henny Penny

Henny Penny 581 Programming manual

Henny Penny

Henny Penny CFE-415 User manual

Henny Penny

Henny Penny OFE- 290 Instruction Manual