Troubleshooting

Troubleshooting

End-Point

»

If the end-point modes are disabled in the

software, ensure that an end-point rack has

been connected to the system's AUX port.

»

If the software reports a calibration error, there might

be air bubbles around the sensor optics. Dislodge the

air bubbles by moving the tube up and down a couple

of times. If this does not solve the problem, replace

the end-point sensor as described on page 14.

Evaporation

»

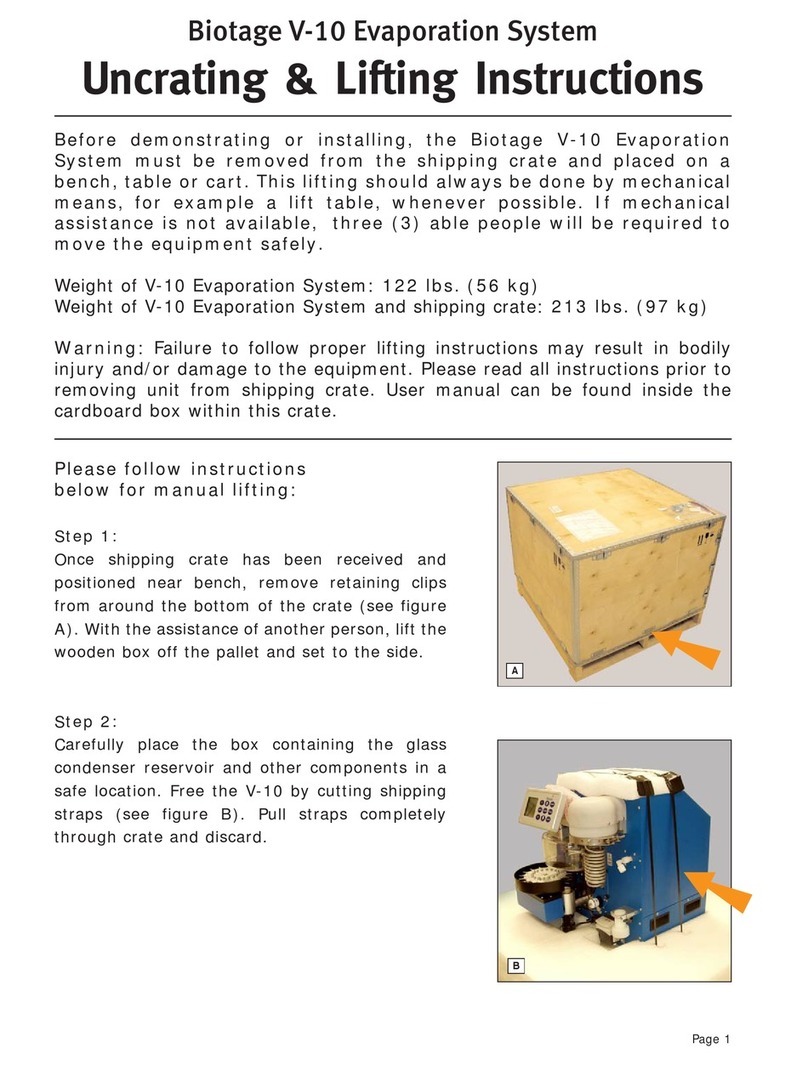

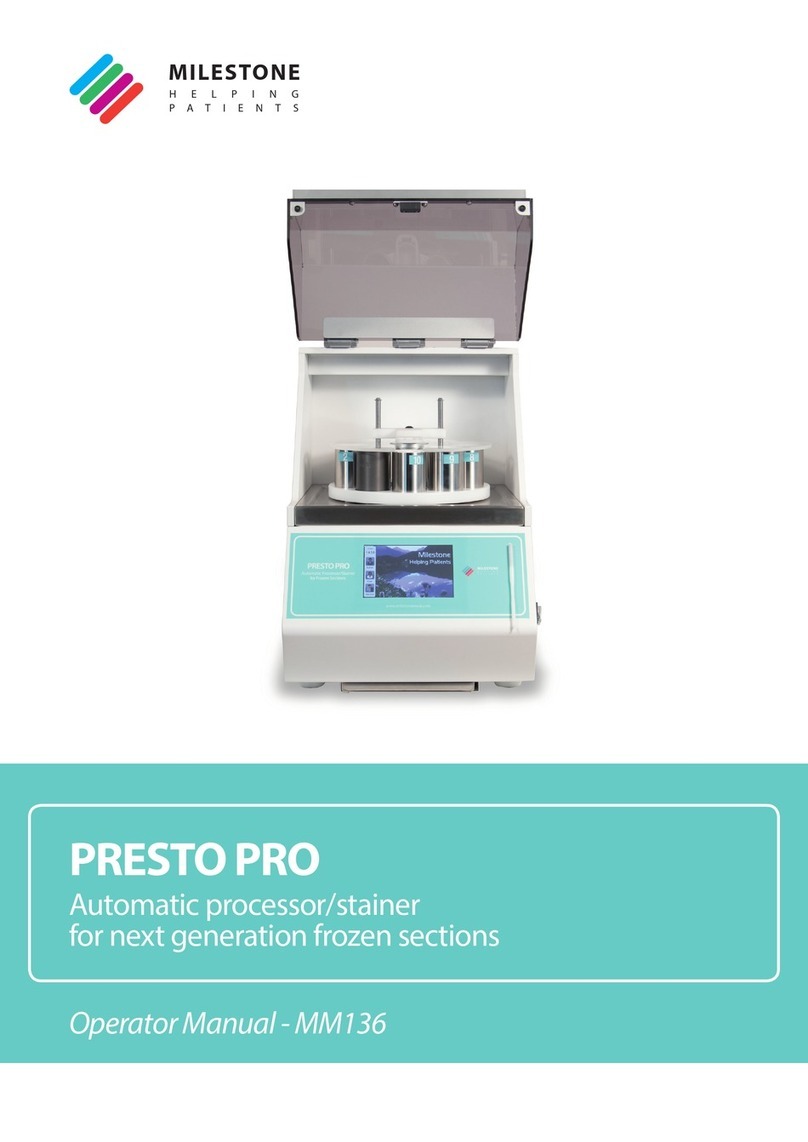

If the evaporation is uneven between tubes, one or more

nozzles may be leaking and need to be tightened or

replaced. A nozzle should be finger tightened and then

tightened 1/6 turn using a 5 mm hexagon socket wrench.

Check for leakage by applying water around the suspected

area (see image below) and starting a run with the lid

open (press Override in the open lid warning dialog).

»

If the evaporation rate is too slow:

»

Ensure that the nozzles are adjusted properly;

see "Adjust the Nozzles" on page 9.

»

Ensure that the water level is not too low; see

"Adjust the Water Level" on page 8.

»

Ensure that the water bath temperature is

not too low; see "Determine the Appropriate

Water Bath Temperature" on page 4.

»

Ensure that the gas flow is not too low; see "Determine

the Appropriate Gas Flow" on page 4.

»

If the evaporation rate is too fast or splashing occurs:

»

Ensure that the water bath temperature is not too high

and causing the solvent to boil; see "Determine the

Appropriate Water Bath Temperature" on page 4.

»

Ensure that the gas flow is not too high; see "Determine

the Appropriate Gas Flow" on page 4.

»

If there is no gas flow:

»

Ensure that the gas supply is turned on and that

there is enough gas available for the run.

»

Ensure that the gas inlet tube is not obstructed.

»

If there is no evaporation in a row of tubes, ensure

that the nozzles for all rack positions that contain

sample tubes are enabled in the software.

»

If there is no or slow evaporation in a single tube:

»

When using a system with TurboVap II configuration,

ensure that the nozzles for all rack positions that

contain sample tubes are enabled in the software.

»

The nozzle may be blocked. Replace it; see page 14.

»

If the water bath temperature and gas flow settings

are disabled in the Evaporate view, the evaporation

mode is set to Method. To change the temperature

and/or gas flow settings for a method, see "Define

Methods" on page 12. Note that it is not possible

to change these settings when running a method.

»

If the recovery of sample is low:

»

Ensure that the water bath temperature is not too high

and causing the solvent to boil; see "Determine the

Appropriate Water Bath Temperature" on page 4.

»

Ensure that the sample is not left too long in the

water bath after the evaporation is completed.

»

Ensure that the gas flow is not too high

and causing splashing; see "Determine the

Appropriate Gas Flow" on page 4.

»

When using a system with TurboVap II configuration,

check if there is sample residues on the tube wall.

Reconstitute to the desired volume, 0.5 or 1.0 mL,

and use this volume to rinse the angled part of

the tube and end-point stem several times.

Gas Supply

»

If there is a leakage at the gas inlet (the N2port):

»

Ensure that the gas inlet tube is securely attached.

»

Ensure that a gas inlet tube with the correct

outer diameter is used, i.e. 6 mm. Always use

tubing and adapters supplied by Biotage.

Sleep Mode and Automatic Wake-Up

»

If the system turns on or off by itself, the sleep

mode feature is activated. To disable or change

the sleep mode settings, see page 6.

Water Bath

»

If the water is turbid, clean the water bath and add water

treatment according to the supplier's recommendations.

See "Clean the Water Bath" on page 13.

»

If the heating of the water bath is too slow, ensure

that the voltage selector switch (located on the right

side of the system) is in the correct position.