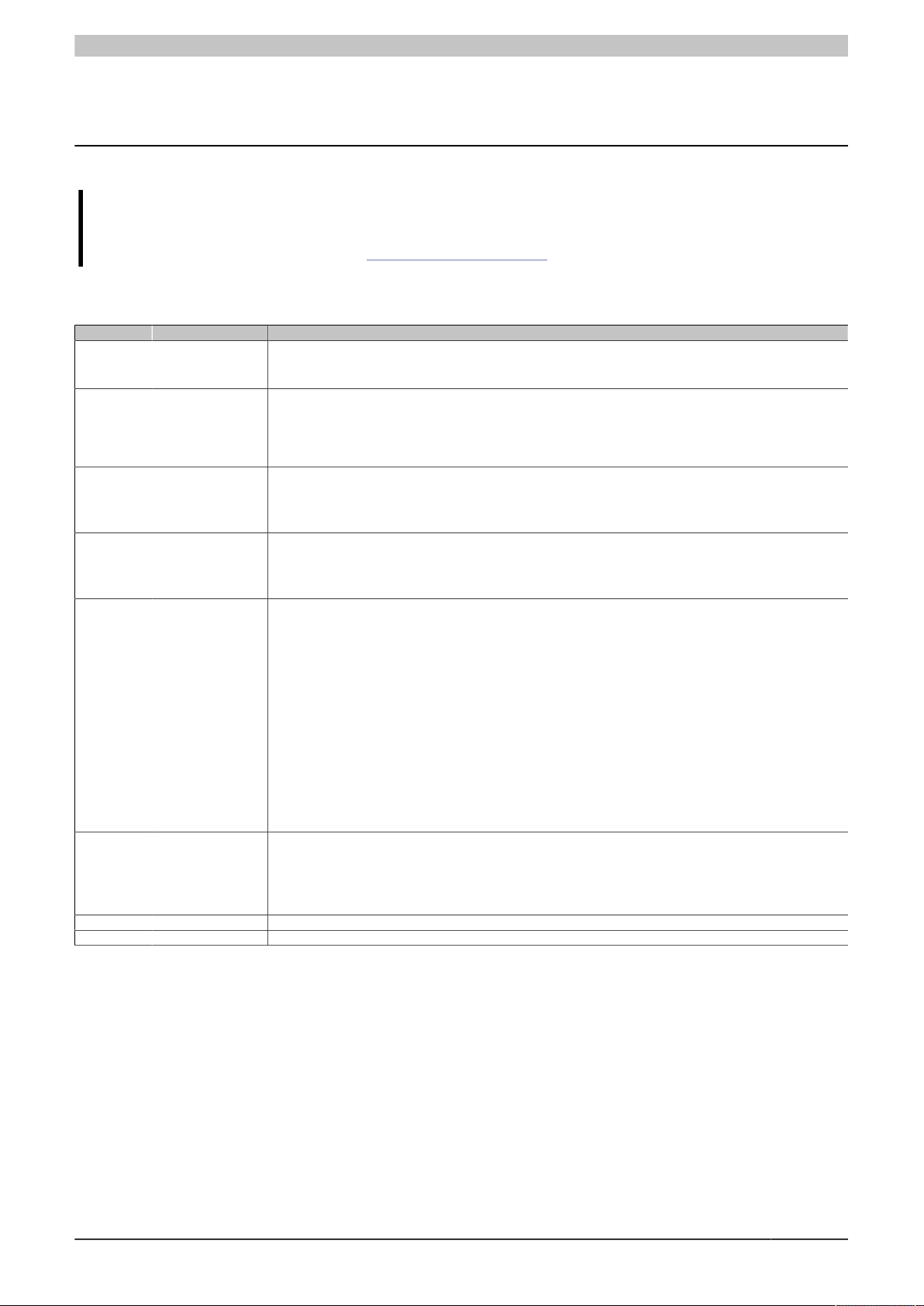

Table of contents

2 Power Panel FT50 User's manual V1.19

1 Introduction................................................................................................................5

1.1 Manual history.................................................................................................................................................5

1.2 Information about this document.................................................................................................................... 6

1.2.1 Organization of notices..............................................................................................................................6

1.2.2 Guidelines.................................................................................................................................................. 6

2 General safety guidelines........................................................................................ 7

2.1 Introduction......................................................................................................................................................7

2.2 Intended use................................................................................................................................................... 7

2.3 Protection against electrostatic discharge...................................................................................................... 7

2.3.1 Packaging.................................................................................................................................................. 7

2.3.2 Regulations for proper ESD handling....................................................................................................... 8

2.4 Transport and storage.................................................................................................................................... 8

2.5 Installation....................................................................................................................................................... 8

2.6 Operation.........................................................................................................................................................8

2.6.1 Protection against contact with electrical parts.........................................................................................8

2.6.2 Ambient conditions - Dust, moisture, aggressive gases........................................................................... 9

2.7 Cybersecurity disclaimer for products...........................................................................................................10

3 System overview..................................................................................................... 11

3.1 System overview........................................................................................................................................... 11

3.1.1 Compact solution.....................................................................................................................................11

3.1.2 Flexibility.................................................................................................................................................. 11

3.1.3 Simple HMI.............................................................................................................................................. 11

3.2 Model number key........................................................................................................................................ 12

3.3 System characteristics.................................................................................................................................. 13

3.3.1 Type overview..........................................................................................................................................13

3.3.2 System requirements...............................................................................................................................13

3.3.3 Projected capacitive touch (PCT)............................................................................................................13

3.3.4 Viewing angles........................................................................................................................................ 14

3.3.5 Surface resistance...................................................................................................................................14

4 Technical data......................................................................................................... 15

4.1 Power Panel FT50 5.0"................................................................................................................................ 15

4.1.1 Order data............................................................................................................................................... 15

4.1.2 Technical data......................................................................................................................................... 16

4.1.3 Dimensions.............................................................................................................................................. 17

4.2 Power Panel FT50 7.0"................................................................................................................................ 18

4.2.1 Order data............................................................................................................................................... 18

4.2.2 Technical data......................................................................................................................................... 18

4.2.3 Dimensions.............................................................................................................................................. 20

4.3 Power Panel FT50 10.1".............................................................................................................................. 21

4.3.1 Order data............................................................................................................................................... 21

4.3.2 Technical data......................................................................................................................................... 21

4.3.3 Dimensions.............................................................................................................................................. 23

4.4 Power Panel FT50 15.6".............................................................................................................................. 24

4.4.1 Order data............................................................................................................................................... 24

4.4.2 Technical data......................................................................................................................................... 24

4.4.3 Dimensions.............................................................................................................................................. 26

4.5 Power Panel FT50 21.5".............................................................................................................................. 27

4.5.1 Order data............................................................................................................................................... 27

4.5.2 Technical data......................................................................................................................................... 27

4.5.3 Dimensions.............................................................................................................................................. 29

5 Installation................................................................................................................30

5.1 General information.......................................................................................................................................30

5.1.1 General conditions...................................................................................................................................30