USER MANUAL | NOVA TRANSMITTERS

2

User Manual

Table of Contents

1. Safety....................................................................................................................................................................................................... 4

1.1 Intended Use...................................................................................................................................................................................... 4

1.2 Symbol Notation................................................................................................................................................................................. 4

1.3 Practices and Laws............................................................................................................................................................................ 4

1.4 Required Operator Training............................................................................................................................................................... 4

1.5 Possible Sources of Danger.............................................................................................................................................................. 4

1.6 Protective Features............................................................................................................................................................................ 5

1.7 STOP in case of EMERGENCY........................................................................................................................................................ 5

1.8 Caring for your NOVA Transmitter.................................................................................................................................................... 5

2. Introduction and Functional Description................................................................................................................................................. 6

2.1 Production and System Numbers ..................................................................................................................................................... 6

2.2 Before Operating Your Wireless Control Unit................................................................................................................................... 6

2.3 Unit Labels ......................................................................................................................................................................................... 6

3. Your NOVA Transmitter.......................................................................................................................................................................... 7

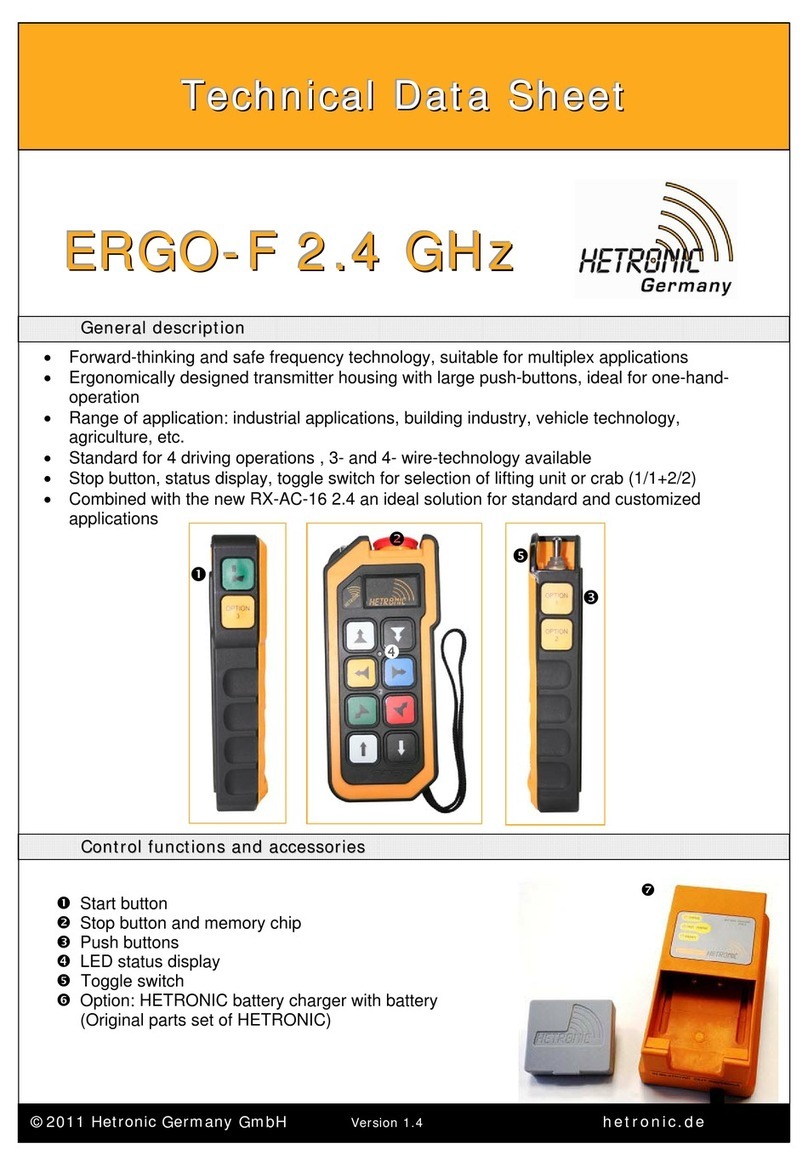

3.1 General Description........................................................................................................................................................................... 7

3.2 NOVA Basic Features ....................................................................................................................................................................... 7

3.3 Standard NOVA Configurations ........................................................................................................................................................ 7

4. Product Description............................................................................................................................................................................... 11

5. Operating Your Transmitter .................................................................................................................................................................. 12

5.1 Holding Your Transmitter................................................................................................................................................................. 12

5.2 Visually Checking Your Transmitter................................................................................................................................................ 12

5.3 Powering ON and Starting Your Transmitter.................................................................................................................................. 12

5.4 Transmitter Initialization with Standard Status LED Indicator........................................................................................................ 12

5.5 Transmitter Initialization with Graphic User Interface (TFT) and Standard Status LED Indicator ................................................ 12

5.6 Stopping the Radio Remote Control ............................................................................................................................................... 13

5.7 Battery ‘State of Charge’ Indication ................................................................................................................................................ 13

5.8 LED Behaviour and Meanings......................................................................................................................................................... 13

5.9 Powering OFF the Transmitter........................................................................................................................................................ 14

5.10 Belts ............................................................................................................................................................................................... 14

6. Generic Radio Remote System functionalities..................................................................................................................................... 15

6.1 “Start” Function ................................................................................................................................................................................ 15

6.2 Stop Switch...................................................................................................................................................................................... 15

6.3 Digital and Proportional Functions .................................................................................................................................................. 15

6.4 Quickset/Programming mode.......................................................................................................................................................... 16

7. Setting up your Nova Transmitter for Operation .................................................................................................................................. 17

7.1 Coder................................................................................................................................................................................................ 17

7.2 Communication................................................................................................................................................................................ 17

7.3 DK Configuration.............................................................................................................................................................................. 17

7.4 AK Configuration.............................................................................................................................................................................. 17

7.5 Digital Outputs ................................................................................................................................................................................. 17

7.6 Inactivity Warning ............................................................................................................................................................................ 18

7.7 Multi-Address Mode......................................................................................................................................................................... 18

7.8 Optional Add-Ons ............................................................................................................................................................................ 18

7.9 Cable Control (optional)................................................................................................................................................................... 18

8. Theory of Operation .............................................................................................................................................................................. 21

9. Installing the Radio Remote Control..................................................................................................................................................... 22

10. Troubleshooting .................................................................................................................................................................................. 23

11. Warranty, Service, Repairs and Maintenance ................................................................................................................................... 24

12. Regulatory Information........................................................................................................................................................................ 25

12.1 Europe............................................................................................................................................................................................ 25

12.2 North America................................................................................................................................................................................ 25

12.3 Industry Canada (IC/ISED) Statement.......................................................................................................................................... 26

Appendix A ................................................................................................................................................................................................ 28

Definition of terms.................................................................................................................................................................................. 28

Appendix B ................................................................................................................................................................................................ 29

B.1 Operator Safety Basics ................................................................................................................................................................... 29

B.2 Safety Checklist............................................................................................................................................................................... 29

B.3 Nova Variants and Current Rating.................................................................................................................................................. 30

Appendix C ................................................................................................................................................................................................ 32

C.1 TFT Protection Film Replacement.................................................................................................................................................. 32