Hexagon TP-R-400 User manual

LANGUAGE

DESCRIPTION

PAGE

DE

BETRIEBSANLEITUNG

3

EN

OPERATING INSTRUCTIONS

FR

MANUEL D’INSTRUCTION

IT

ISTRUZIONI OPERATIVE

ES

INSTRUCCIONES DE OPERACIÓN

Manual Version V01.00-REV01.00

Release Date 2021-09-29

TP-R-400 Table of Contents

3

Table of Contents

1Description.......................................................................................................................................................... 5

1.1 General....................................................................................................................................................... 5

1.1.1 Preface .......................................................................................................................................... 5

1.1.2 Safety Instructions ......................................................................................................................... 5

1.1.3 Validity........................................................................................................................................... 5

1.2 Purpose...................................................................................................................................................... 6

1.3 Declarations and Approvals........................................................................................................................ 7

1.3.1 Europe and UK (EU and UKCA Declaration of Conformity) ........................................................... 7

1.3.2 USA (FCC Declaration) ................................................................................................................. 7

1.3.3 Canada (IC /RSS Declaration)....................................................................................................... 7

1.3.4 China ............................................................................................................................................. 7

1.3.5 Japan............................................................................................................................................. 7

1.4 System Components .................................................................................................................................. 8

1.5 Variant Overview ........................................................................................................................................ 9

1.6 Technical Data.......................................................................................................................................... 10

1.6.1 Technical Data, General (all Measuring Units)............................................................................. 10

1.6.2 Technical Data with Measuring Unit MY21.00 ............................................................................. 10

1.6.3 Technical Data with Measuring Unit PP41.00 .............................................................................. 10

1.6.4 Technical Data with Measuring Unit HPP41.10............................................................................ 10

1.7 Dimensions............................................................................................................................................... 11

1.7.1 Dimensions with Measuring Unit MY21.00................................................................................... 11

1.7.2 Dimensions with Measuring Unit PP41.00 ................................................................................... 12

1.7.3 Dimensions with Precision Measuring Unit HPP41.10 ................................................................. 13

1.8 Transmission and Reception Area............................................................................................................ 14

1.9 Delivery Contents, Accessories and Spares ............................................................................................. 15

1.9.1 Delivery Contents ........................................................................................................................ 15

1.9.2 Styli.............................................................................................................................................. 15

1.9.3 Tool holders................................................................................................................................. 15

1.9.4 Accessories, General................................................................................................................... 16

1.9.5 Spares ......................................................................................................................................... 17

2Operation .......................................................................................................................................................... 18

2.1 Tools, Measurement and Test Equipment ................................................................................................ 18

2.2 Commissioning and Setup of the Touch Probe......................................................................................... 19

2.2.1 Installing/Changing the Stylus...................................................................................................... 19

2.2.1.1 Installing/Changing the Stylus (Measuring Unit MY21.00) ............................................. 19

2.2.1.2 Installing/Changing the Stylus (Measuring Unit PP41.00/HPP41.10)............................. 20

2.2.2 Mounting/dismounting the tool holder .......................................................................................... 21

2.2.2.1 Mounting tool holders Ø20 ............................................................................................ 21

2.2.2.2 Mounting tool holders Ø28 ............................................................................................ 22

2.2.3 Inserting/Changing the Battery .................................................................................................... 23

2.2.4 Setting the Touch Probe and pairing with a Receiver................................................................... 24

2.2.4.1 Menu Structure.............................................................................................................. 24

2.2.4.2 Operating the menu....................................................................................................... 25

2.2.4.3 Possible settings in the "Setup” menu ........................................................................... 26

2.2.4.4 Setting Procedure.......................................................................................................... 26

Table of Contents TP-R-400

4

2.2.5 Aligning Stylus to Spindle Centre................................................................................................. 28

2.2.6 Adjusting the touch probe in the tool holder with a 90° adapter.................................................... 29

2.3 Optical Status Display............................................................................................................................... 30

2.4 Replacing Measuring Unit......................................................................................................................... 31

2.5 Force setting (Measuring Unit PP41.00 only)............................................................................................ 32

2.6 Maintenance and Cleaning (Measuring Unit PP41.00 only)...................................................................... 33

2.7 Modular System (for Measuring Units PP41.00 and MY21.00 only).......................................................... 34

TP-R-400 Description

5

1 Description

1.1 General

1.1.1 Preface

The safety instructions in this manual have to be strictly observed to guarantee a safe and reliable function of the

touch probe and to avoid personal and material damage. The meaning of the symbols related to the safety

instructions is described in the table below:

NOTICE NOTICE indicates important information that, if not observed, could lead to

property damage/malfunctions.

INFORMATION INFORMATION indicates important information or helpful advices for the work with

the described device.

1.1.2 Safety Instructions

NOTICE

Risk of material damage!

•Manual or automatic positioning of the touch probe must be protected, in a way that the machine axis stops

feeding if the probe is triggered outside the measuring process!

NOTICE

Risk of material damage!

•Feedhold or spindle-stop resulting from a trigger or ready signal from a touch probe should only happen if the

probe is actually in the spindle. This safety logic prevents the spindle or feed being stopped during normal

milling operations if a signal from a measuring probe is triggered for one of the following reasons:

•Battery replacement and subsequent functional check of the touch probe by manually switching it on.

•Another machine with a radio-wave touch probe installed is started up and this touch probe transmits on

the same channel as a touch probe previously installed.

NOTICE

Risk of material damage caused by third-party parts!

•Only use the original spare parts listed in these operating instructions to perform maintenance and repairs.

INFORMATION

The information given in this manual can be changed by the manufacturer at any time. Thus the user is

responsible to regularly inquire about updated information.

1.1.3 Validity

These operating instructions are valid for the hardware available at the date of creation of these operating

instructions. The manufacturer reserves the right to make technical modifications.

Description TP-R-400

6

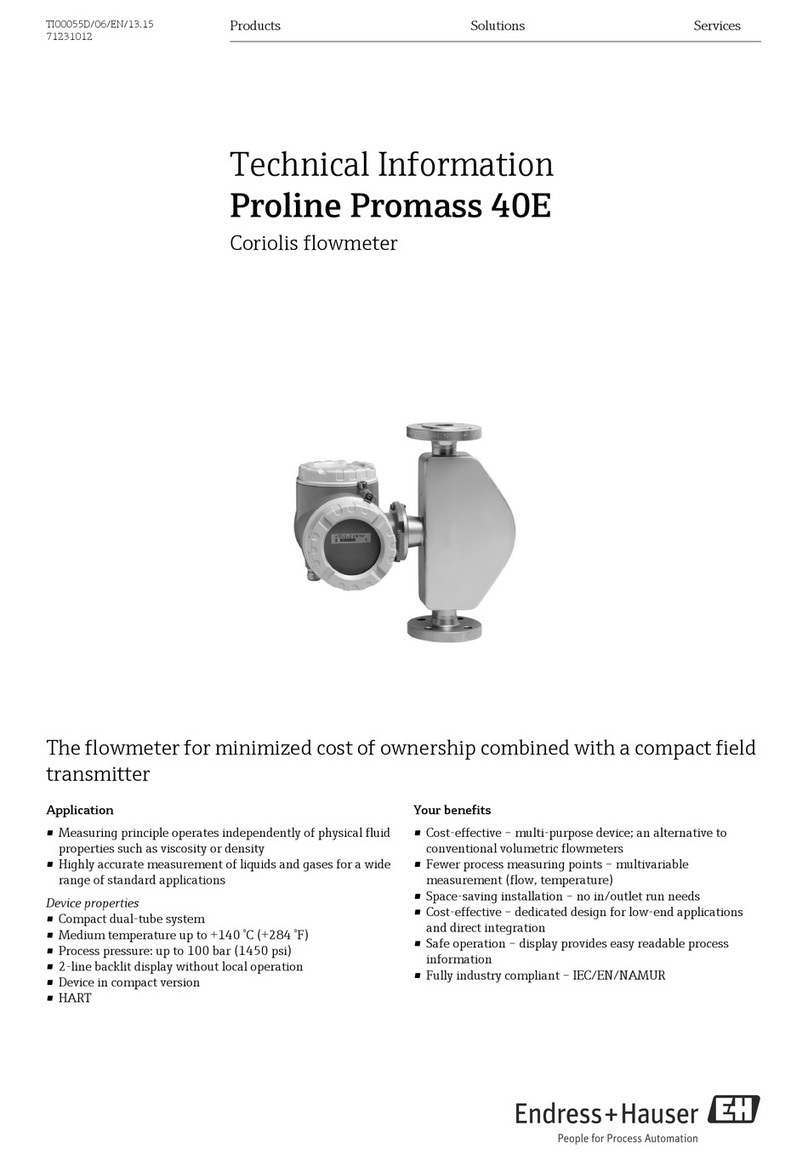

1.2 Purpose

The radio-wave touch probe TP-R-400 is used for workpiece measurement, and automatic determination and

compensation of deviating angular positions of workpieces. Moreover, it is used for setting zero points inside the

machine tool.

The radio-wave touch probe TP-R-400 is capable of measuring workpiece geometries, like edges, bores, pins, slots,

webs, angles, corners and circular arches. It is also suitable for measuring complex geometries, like three-

dimensional surfaces and for measurements involving picot axes.

Radio-wave transmission ensures that the measuring signals from the touch probe can be transmitted to the receiver

over large distances.

TP-R-400 Description

7

1.3 Declarations and Approvals

1.3.1 Europe and UK (EU and UKCA Declaration of Conformity)

The EU and UKCA Declarations of Conformity can be found at the end of these operating instructions.

If required, a copy of the signed original declarations of conformity may be requested from the address given on the

back cover.

1.3.2 USA (FCC Declaration)

This device complies with Part 15 of the FCC. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired operation.

This device has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

device is operated in a commercial environment. This device generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this device in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

The radiated output power of the device is far below the FCC radio frequency exposure limits. Nevertheless, the

device shall be used in such a manner that the potential for human contact during normal operation is minimized.

Changes or modifications not expressly approved by m&h Inprocess Messtechnik GmbH may void the FCC/RSS

authorization to operate this equipment.

FCC ID: MFFR400

1.3.3 Canada (IC /RSS Declaration)

English:

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired operation.

IC: 5782A-R400

Français:

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

IC: 5782A-R400

1.3.4 China

This device has an RTA certificate (Radio Transmission Equipment Type Approval Certificate) issued by the SRRC

(State Radio Regulatory Committee) for use in China.

CMIIT ID: XXXXXXXXXX

1.3.5 Japan

This device has a certificate issued by the Japanese MIC (Ministry of Internal Affairs and Communications) for use in

Japan. This certification complies with the Japanese Radio Law:

202-DGJ094

R

Description TP-R-400

8

1.4 System Components

System Components

m&h Radio-wave Touch Probe

TP-R-400

m&h Radio-wave Receiver

RWR95.51

Measuring unit

MY21.00

Precision

measuring unit

HPP44.10

Measuring unit

PP41.00

m&h Radio-wave Receiver

RC-R-100

TP-R-400 Description

9

1.5 Variant Overview

TP-R-400-MY# TP-R-400-PP# TP-R-400-HPP#

Measuring unit

MY21.00

Measuring unit

PP41.00

Precision measuring unit

HPP44.10

Description TP-R-400

10

1.6 Technical Data

1.6.1 Technical Data, General (all Measuring Units)

Transmission frequency

2400-2483.5 MHz (2.4 GHz)

Transmission/reception range

Up to 18 m

Power supply

2x battery (3.6 V / ½ AA)

Material

Stainless steel, POM

Temperature range

Operation: 10°C - 50°C, Storage: -20°C - 70°C

Sealing

IP68: EN60529

1.6.2 Technical Data with Measuring Unit MY21.00

Sensing Directions

±X; ±Y; -Z

Maximum Stylus Overtravel

XY = ±14°; Z = -4.5 mm

Trigger Force with 50 mm Stylus

XY = 1 N

Z = 6 N

Recommended Probing Feedrate

max. 2000 mm/min

Unidirectional Repeatability

(deflection from one direction)

max. 1 µm (2 Sigma) with 50 mm stylus

and 254 mm/min probing feedrate

Weight TP-R-400-MY without tool holder

approx. 365 g

Maximum Battery Life with Lithium Battery Operation: 300 h

Standby: 12 months

1.6.3 Technical Data with Measuring Unit PP41.00

Sensing Directions

±X; ±Y; -Z

Maximum Stylus Overtravel

XY = ±12.5°; Z = -6 mm

Trigger Force with 50 mm Stylus

XY = 0.3 - 1.4 N (factory setting = 1 N)

Z = 2.5 - 12.5 N (factory setting = 8.5 N)

Recommended Probing Feedrate

max. 2000 mm/min

Unidirectional Repeatability

(deflection from one direction)

max. 1 µm (2 Sigma) with 50 mm stylus

and 254 mm/min probing feedrate

Weight TP-R-400-PP without tool holder

approx. 320 g

Maximum Battery Life with Lithium Battery Operation: 300 h

Standby: 12 months

1.6.4 Technical Data with Measuring Unit HPP41.10

Sensing Directions

±X; ±Y; -Z

Maximum Stylus Overtravel

XY = ±12.5°; Z = -5 mm

Tripping force* with 50 mm stylus

XY = 0.1 N (typical value)

Z = 2.5 N (typical value)

Trigger force* with 50 mm stylus

(probing feedrate 254 mm/min)

XY = 0.75 ±0.25 N

Z = 7 N ±10%

Recommended Probing Feedrate

100 - 500 mm/min

Maximum Probing Feedrate

1000 mm/min

Unidirectional Repeatability

(deflection from one direction)

max. 0.25 µm (2 Sigma) with 50 mm stylus

and 254 mm/min probing feedrate

Weight TP-R-400-HPP without tool holder

approx. 325 g

Maximum Battery Life with Lithium Battery

Operation: 110 h

Standby: 12 months

*

Tripping force

= Force when the probing signal is tripped at the touch point not influenced by the machine

dynamics (stops without delay when the touch point is reached)

Trigger force

= Force after passing the touch point influenced by the machine dynamics (positioning speed,

delay)

TP-R-400 Description

11

1.7 Dimensions

1.7.1 Dimensions with Measuring Unit MY21.00

Dimensions with Measuring Unit MY21.00

INFORMATION

The dimension X for the length of the tool holder, required to calculate the total length L of the probe system, can

be found in the accessories catalogue.

The total length L is the sum of the probe length and the dimension X.

Battery compartment,

Display,

Setting button

Aligning stylus

to spindle centre

Stylus

Customer specified

tool holder

Measuring unit MY21.00

Description TP-R-400

12

1.7.2 Dimensions with Measuring Unit PP41.00

Dimensions with Measuring Unit PP41.00

INFORMATION

The dimension X for the length of the tool holder, required to calculate the total length L of the probe system, can

be found in the accessories catalogue.

The total length L is the sum of the probe length and the dimension X.

Battery compartment,

Display,

Setting button

Aligning stylus

to spindle

centre

Stylus

Customer specified

tool holder

Measuring unit PP41.00

TP-R-400 Description

13

1.7.3 Dimensions with Precision Measuring Unit HPP41.10

Dimensions with Measuring Unit HPP41.10

INFORMATION

The dimension X for the length of the tool holder, required to calculate the total length L of the probe system, can

be found in the accessories catalogue.

The total length L is the sum of the probe length and the dimension X.

Battery compartment,

Display,

Setting button

Aligning stylus

to spindle centre

Stylus

Customer specified

tool holder

Measuring unit PP41.00

Description TP-R-400

14

1.8 Transmission and Reception Area

INFORMATION

The transmission/reception ranges shown below only apply under optimum operating conditions. For a secure

signal transmission probe and receiver must be located in the transmission area of the other device. The range

for a secure signal transmission is up to 18 m.

Transmission and reception area (emission/reception behaviour of antenna)

0…1 ≙0%...100%

of the maximum possible

transmission/reception area

under the given conditions of use

Example:

If the receiver is mounted at an angle of

60° above the touch probe, then:

S = 0.9 * Smax

S = Transmission/reception range

Smax = Max. transmission/reception range

TP-R-400 Description

15

1.9 Delivery Contents, Accessories and Spares

1.9.1 Delivery Contents

INFORMATION

A complete order number must contain at least the number of the touch probe and the description of the

measuring unit (refer to chapter 1.5) (e.g. TP-R-400-PP).

Order Number

Description

TP-R-400-MM#

MM = Measuring unit

Radio-wave Touch Probe TP-R-400

1.9.2 Styli

A variety of different styli, extensions and stylus adapters are available for m&h touch probes. It is possible to adapt

the touch probe system to a wide range of use cases. A comprehensive overview of the possible stylus options can

be found in the accessories catalogue.

1.9.3 Tool holders

A variety of different tool holders is available for m&h touch probes. It is possible to adapt the touch probe system to

a wide range of use cases. An comprehensive overview of possible tool holders can be found in the accessories

catalogue.

Description TP-R-400

16

1.9.4 Accessories, General

Order Number

Description

Illustration

91.00-SWV-XX

(on request) Air jet with swivel screw fitting

D20-VDI-90 Angle adapter for tool holder VDI

D20-MO-B Modular adapter D20/D28 (Ø20/Ø28)

41.00-PP# Measuring unit PP41.00

41.10-HPP# Precision measuring unit HPP41.10

21.00-MY# Measuring unit MY21.00

41.00-KA Cross adapter

41.00-KA-V Screw plug for cross adapter

21.00-VE30 Extension (L=30 mm/1.18")

21.00-VE50 Extension (L=50 mm/1.97")

41.00-VE100 Extension (L=100 mm/3.94")

41.00-VE200 Extension (L=200 mm/7.87")

TP-R-400 Description

17

1.9.5 Spares

Order Number Description Illustration

4316 Battery (3.6 V, ½ AA)

40.02-

BATTERIE-

DECKEL

Battery cover

5764 Battery cover lock

5186 20x1 Viton O-ring for battery cover

1351 Clamping screw M5x0.5x7 (AF2.5 mm)

1352 Adjustment screw M4x8 (AF2 mm)

3240 Service cover

3455 O-ring 16x1 for service cover

2906 Metal eyelid

2931 Conical spring

5642 O-ring 25x2 for measuring unit holder

Operation TP-R-400

18

2 Operation

2.1 Tools, Measurement and Test Equipment

Order Number Description Illustration

0227 Hexagon key AF1.3 mm

1097 Hexagon key AF2 mm

1346 Hexagon key AF2.5 mm

1780 Hexagon key AF3 mm

3489 Hexagon key AF4 mm

5840 Assembly key for battery cover

1665 Spanner AF4 mm

0885 Mounting pin

2951 C-spanner

3079 Dial gauge

TP-R-400-TB

Tool box, consisting of:

2x Battery (3.6 V / ½ AA) (4316)

1x Mounting pin (0885)

1x Spanner AF4 mm (1665)

2x C-Spanner (2951)

2x Hexagon key AF2 mm (1097)

2x Hexagon key AF2.5 mm (1346)

1x Hexagon key AF3 mm (1780)

2x Hexagon key AF4 mm (3489)

1x Hexagon key AF1.3 mm (0227)

1x Assembly key for battery cover (5840)

Not illustrated

TP-R-400 Operation

19

2.2 Commissioning and Setup of the Touch Probe

2.2.1 Installing/Changing the Stylus

2.2.1.1 Installing/Changing the Stylus (Measuring Unit MY21.00)

NOTICE

Risk of damage to the equipment!

•Do not apply any turning force to the measuring unit!

•During replacement, always hold the stylus connection with the spanner AF4 mm!

1. Unscrew the stylus from the touch probe using the mounting pin.

1. Carefully screw the new stylus with mounting pin into the touch probe (Fig. 6).

2. Align the stylus to spindle center (refer to chapter 2.2.5).

3. Calibrate the touch probe.

Stylus change with measuring unit MY21.00

Mounting pin

(0885)

Stylus

M=0.6 Nm (0.44 lbf.ft)

Spanner

AF4

mm

(1665)

Operation TP-R-400

20

2.2.1.2 Installing/Changing the Stylus (Measuring Unit PP41.00/HPP41.10)

NOTICE

Risk of damage to the equipment!

The probe mechanic is sensitive, therefore never use excessive force when screwing in the stylus!

•The screwing torque is M=2 Nm!

•When using a break shaft adapter (91.00-S-M4/M4), only screw in the stylus with a maximal torque of 1 Nm

(0.74 lbf.ft)!

•The use of a break shaft adapter (91.00-S-M4/M4) is not permitted in conjunction with precision measuring

unit HPP41.10!

1. Unscrew the stylus from the touch probe using the mounting pin.

2. Carefully screw the new stylus with mounting pin into the touch probe (Fig. 7).

3. Align the stylus to spindle center (refer to chapter 2.2.5).

4. Calibrate the probe.

Stylus change with measuring unit PP41.00/HPP41.10 (using PP41.00 as an example)

Mounting pin

(0885)

Stylus

M=2 Nm (1.47 lbf.ft)

Table of contents

Other Hexagon Measuring Instrument manuals

Hexagon

Hexagon TT80 User manual

Hexagon

Hexagon GeoMax ZEL400HV User manual

Hexagon

Hexagon TESA RUGOSURF 10G User manual

Hexagon

Hexagon TESA FMS Series User manual

Hexagon

Hexagon TESA ALESOMETRE User manual

Hexagon

Hexagon Aptiv ESR 2.5 User manual

Hexagon

Hexagon DIGICO 200 User manual

Hexagon

Hexagon TESA INOTEST User manual

Hexagon

Hexagon TESA IMICRO User manual

Hexagon

Hexagon TESA Compact Series User manual