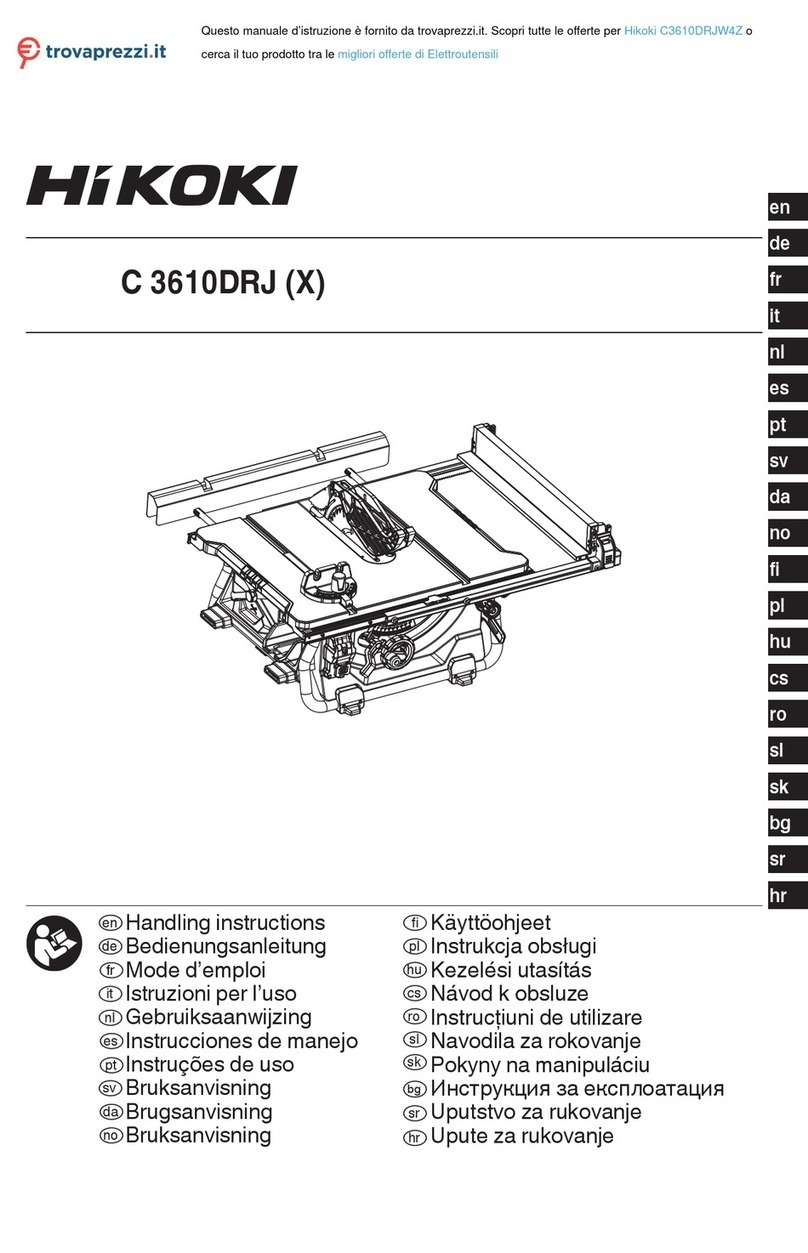

HIKOKI C 3610DRA User manual

Other HIKOKI Saw manuals

HIKOKI

HIKOKI CR 13VEY User manual

HIKOKI

HIKOKI C8FSHE User manual

HIKOKI

HIKOKI C 12RSH2 User manual

HIKOKI

HIKOKI CR 13V2WSZ User manual

HIKOKI

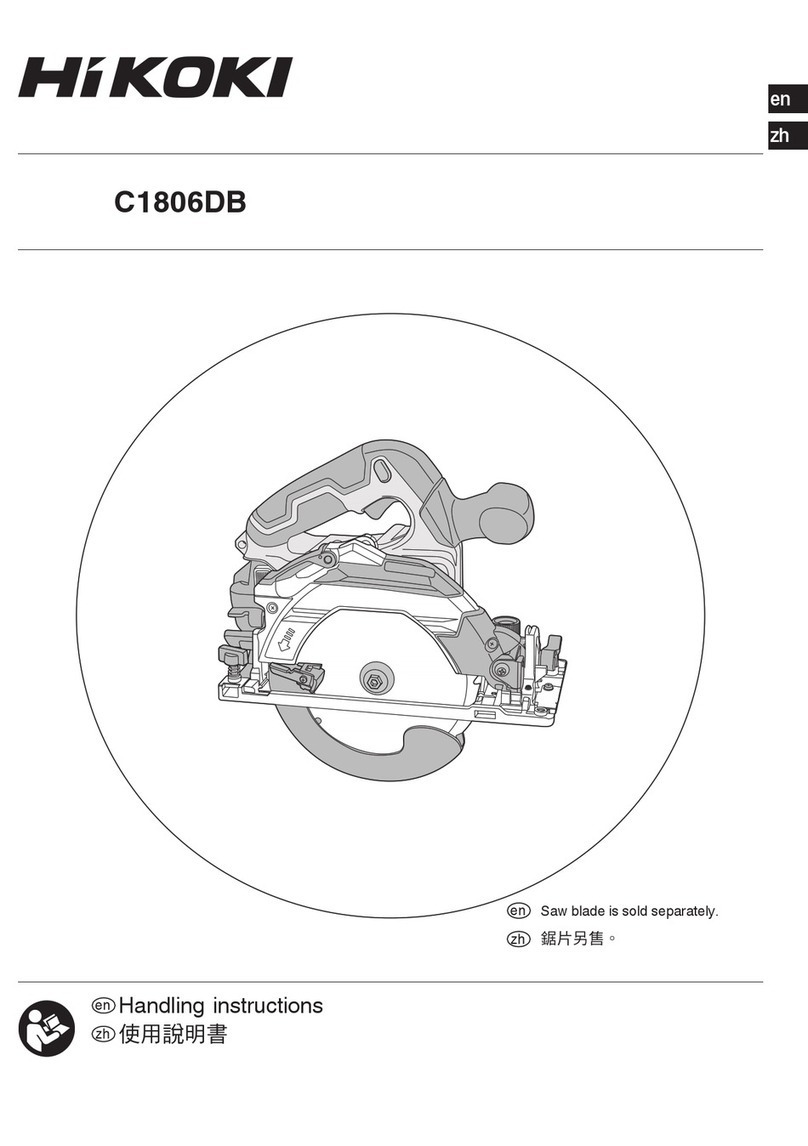

HIKOKI C1806DB User manual

HIKOKI

HIKOKI C 9U3 User manual

HIKOKI

HIKOKI C 6BUY User manual

HIKOKI

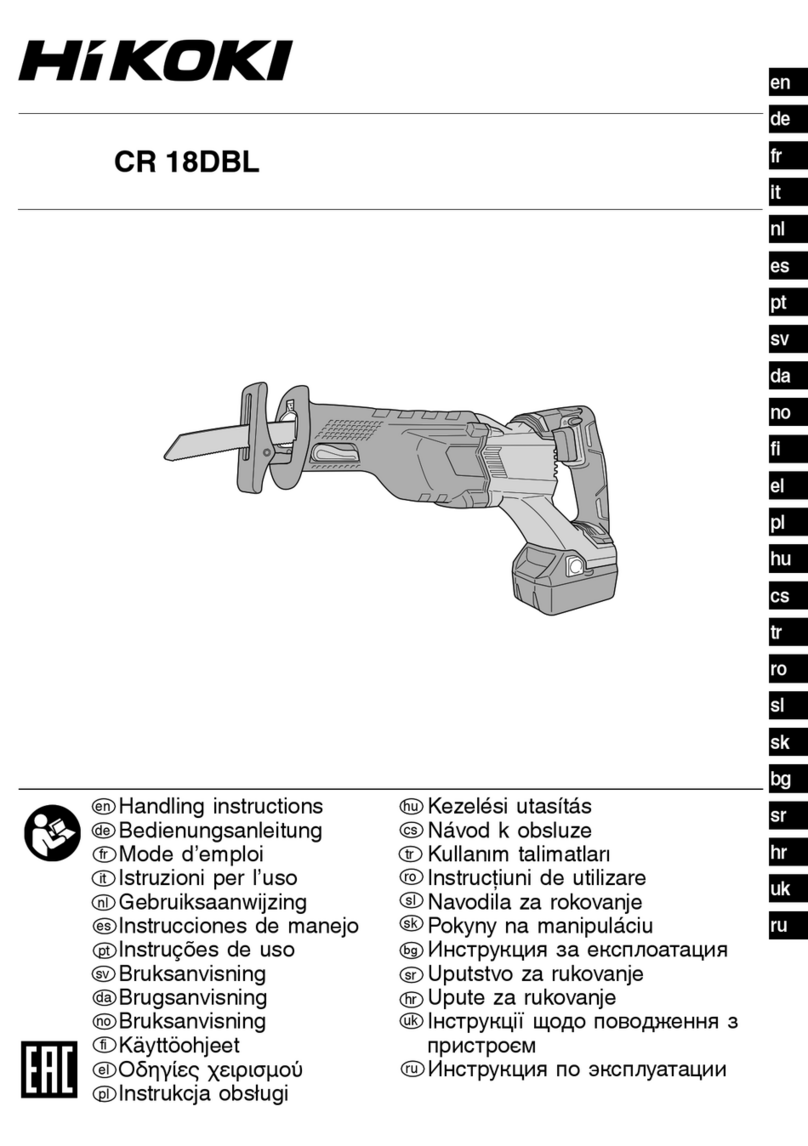

HIKOKI CR18DBL User manual

HIKOKI

HIKOKI CR 13VC User manual

HIKOKI

HIKOKI C 1806DA User manual

HIKOKI

HIKOKI C8FSHE User manual

HIKOKI

HIKOKI C3607DRA User manual

HIKOKI

HIKOKI C 10FCH2 User manual

HIKOKI

HIKOKI CD 3605DB User manual

HIKOKI

HIKOKI C18DSL User manual

HIKOKI

HIKOKI CR 13VEY User manual

HIKOKI

HIKOKI C 3612DRA User manual

HIKOKI

HIKOKI CR 13V2 User manual

HIKOKI

HIKOKI CD 3605DA User manual

HIKOKI

HIKOKI C 6SS User manual