21

5. Safety precautions

5.1 Basic safety instructions

In addition to the safety precautions listed in the indi-

vidual sections of these operating instructions, the fol-

lowing points must be strictly observed at all times.

5.2 Use as intended

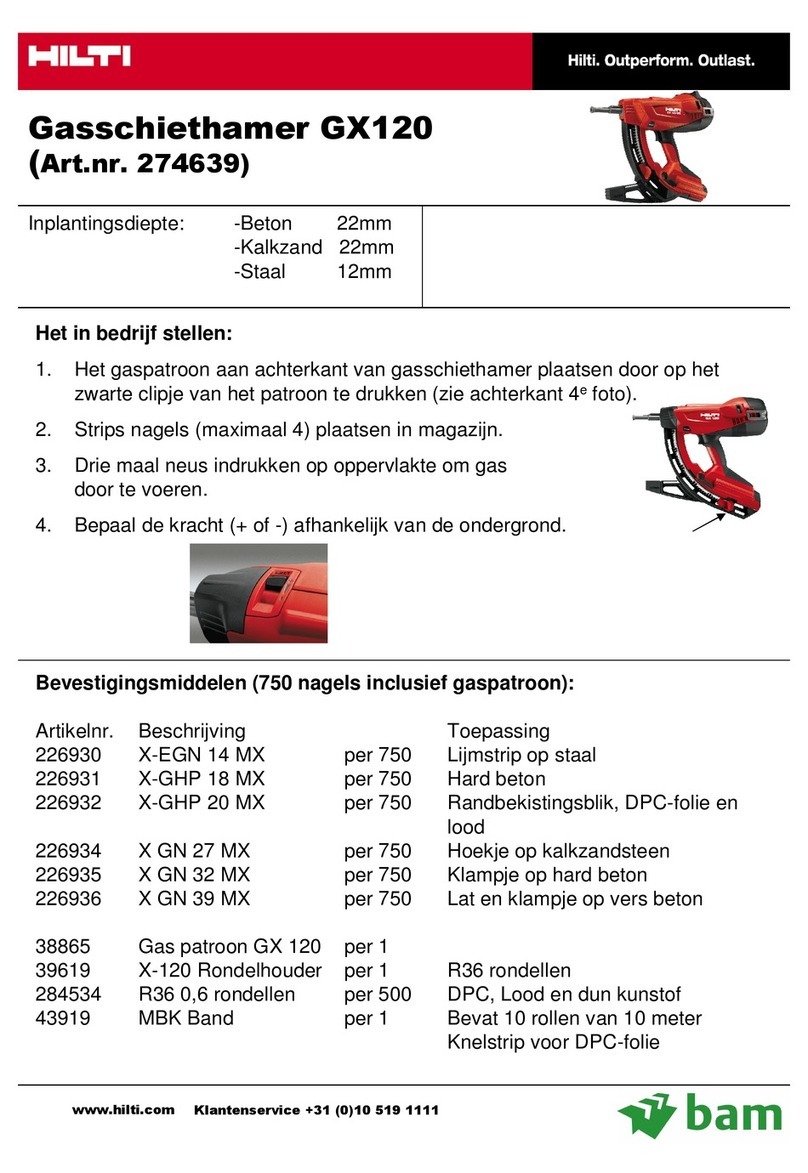

The tool is designed for professional use in fastening

applicationsinconstructionwherenails,threadedstuds

andcomposite fasteners are driven into concrete, steel

and sand-lime block masonry.

5.3 Improper use

●Manipulation or modification of the tool is not per-

missible.

●Donotoperatethetoolinanexplosiveorflammable

atmosphere, unless the tool is approved for such use.

●To avoid the risk of injury, use only original Hilti fas-

teners,cartridges, accessories and spare parts or those

of equivalent quality.

●Observe the information printed in the operating

instructions concerning operation, care and mainte-

nance.

●Never point the tool at yourself or any bystander.

●Neverpressthemuzzleofthetoolagainstyourhand

or other part of your body.

●Do not drive nails into materials like glass, marble,

plastic, bronze, brass, copper, natural rock, insulation

material,hollow brick, glazed tile, thin-gauge sheet metal

(< 4 mm), grey cast iron, spheroidal cast iron and gas

concrete.

5.4 Technology

●This tool is designed with the latest available tech-

nology.

●Thetool and its ancillary equipment may present haz-

ards when used incorrectly by untrained personnel or

not as directed.

5.5 Making the workplace safe

●Avoid unfavourable body positions.

●Objectswhichcouldcauseinjuryshouldberemoved

from the working area.

●The tool is for hand-held use only.

●Keepotherpersons,childreninparticular,outside the

working area.

●Before using the tool, make sure that no one

is standing behind or below the point where fasteners

are to be driven.

●Keepthegripdry,clean and free from oil and grease.

5.6 General safety precautions

●Operate the tool only as directed and only when it is

in faultless condition.

●Usethe stabiliser/splinter guard when the application

permits.

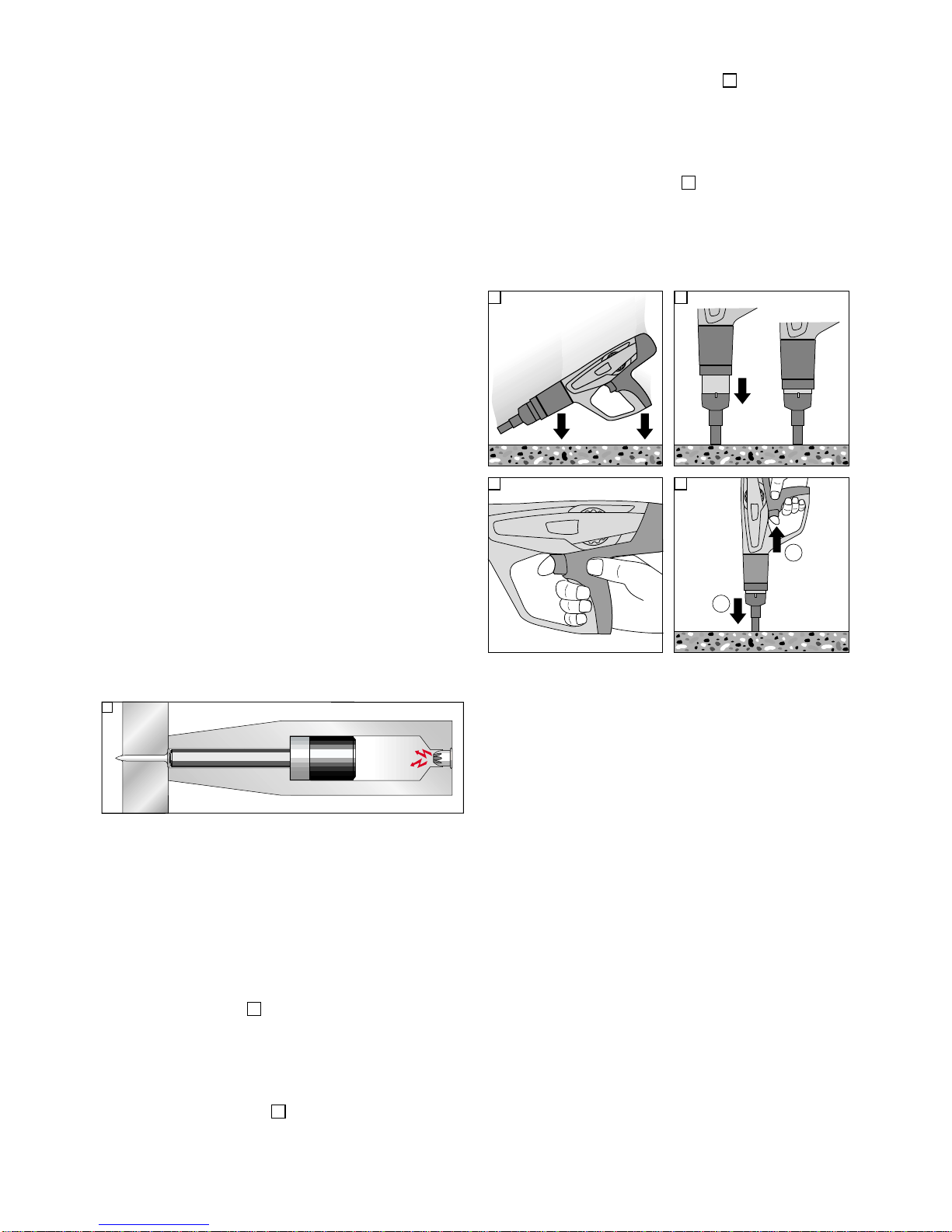

●Ifacartridgemisfiresor fails to ignite, proceed as fol-

lows:

1. Keep the tool pressed against the working surface

for 30 seconds.

2. If the cartridge still fails to fire, withdraw the tool

from the working surface, taking care that it is not

pointed towards your body or bystanders.

3. Manually advance the cartridge strip one cartridge.

Use up the remaining cartridges on the strip.

Remove the used cartridge strip and dispose of it in

such a way that it can be neither reused nor mis-

used.

●Never attempt to pry a cartridge from the magazine

strip or the tool.

●Keep the arms flexed when the tool is fired (do not

straighten the arms).

●Never leave the loaded tool unattended.

●Always unload the tool before beginning cleaning,

servicing or changing parts and before storage.

●Storecartridgesandunusedtoolsunloaded,inadry,

high or locked place out of the reach of children.

5.7 Temperature

●Do not disassemble the tool while it is hot.

●Never exceed the recommended maximum fastener

driving rate (number of fastenings per hour). The tool

may otherwise overheat.

●Shouldthe plastic cartridgestrip begin tomelt, stop

using the tool immediately and allow it to cool down.

5.8 Requirements to be met by users

●The tool is intended for professional use.

●Thetoolmaybeoperated,serviced and repaired only

by authorised, trained personnel. This personnel must

beinformed of any special hazards that may be encoun-

tered.

●Proceed carefully and do not use the tool if your full

attention is not on the job.

●Stop working with the tool if you feel unwell.

5.9 Personal protective equipment

●Theoperatorandotherpersonsintheimmediatevicin-

itymustalwaysweareyeprotection,ahardhatandear

protection.