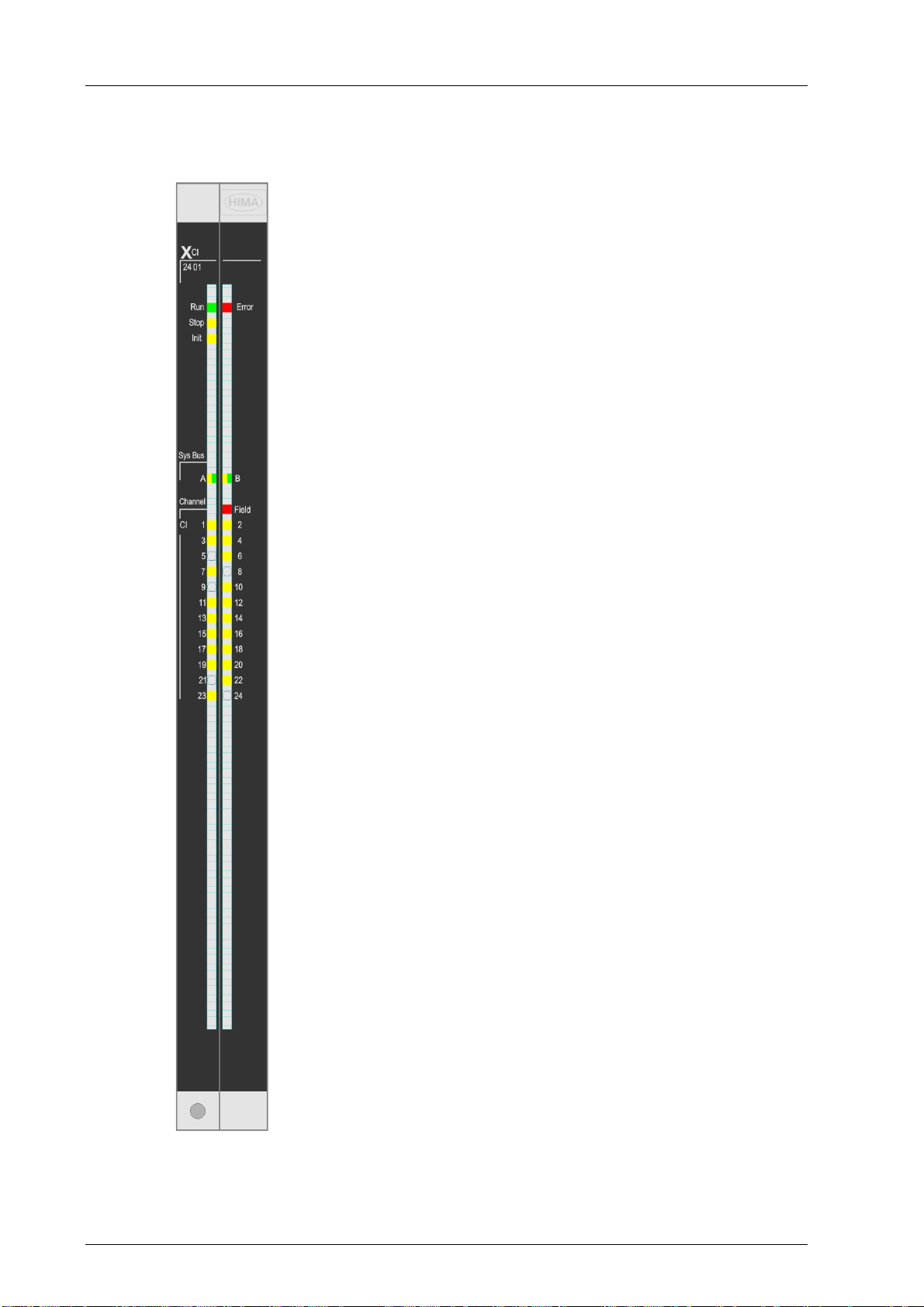

Table of Contents X-CI 24 01

HI 801 113 E Rev. 4.00 Page 4 of 68

4Start-up................................................................. 29

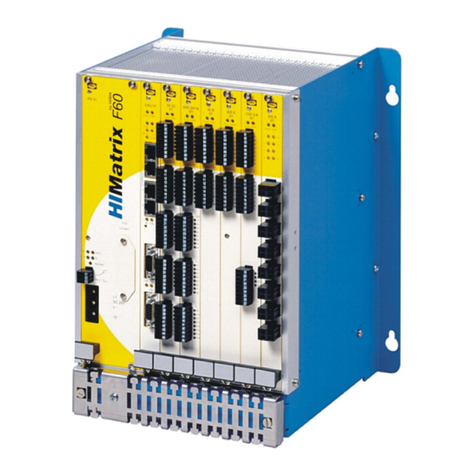

4.1 Mounting ...............................................................................................................29

4.1.1 Wiring Inputs Not in Use.........................................................................................29

4.2 Mounting and Removing the Module..................................................................30

4.2.1 Mounting a Connector Board .................................................................................30

4.2.2 Using the Sensor Selection Plug to Define the Sensors ........................................32

4.2.3 Mounting and Removing the Module......................................................................33

4.3 Counter Module Sampling...................................................................................35

4.3.1 Type of Evaluation Count Pulses ...........................................................................36

4.4 Deviation Tab........................................................................................................38

4.5 Configuring the Counter Module in SILworX.....................................................39

4.5.1 Tab: Module ...........................................................................................................40

4.5.2 Tab: I/O Submodule CI24_01................................................................................. 41

4.5.3 Tab: I/O Submodule CI24_01: Channels................................................................42

4.5.4 Submodule Status [DWORD] ................................................................................. 46

4.5.5 Diagnostic Status [DWORD]...................................................................................47

4.6 Connection Variants.............................................................................................48

4.6.1 Single-Channel Input Wiring................................................................................... 48

4.6.2 Single-Channel Input Connection via X-FTA 002................................................... 50

4.6.3 Redundant Input Wiring..........................................................................................52

4.6.4 Measuring the Rotational Speed with Recognition of Rotation Direction ............... 56

5Operation .............................................................. 58

5.1 Handling................................................................................................................58

5.2 Diagnosis ..............................................................................................................58

6Maintenance.......................................................... 59

6.1 Maintenance Measures........................................................................................59

6.1.1 Loading the Operating System...............................................................................59

6.1.2 Proof Test...............................................................................................................59

7Decommissioning.................................................. 60

8Transport .............................................................. 61

9Disposal................................................................ 62

Appendix............................................................... 64

Glossary................................................................................................................64

Index of Figures....................................................................................................65

Index of Tables .....................................................................................................66

Index......................................................................................................................67