HIMA DIO 24/16 01 User manual

HIMatrix

Safety-Related Controller

DIO 24/16 01 Manual

HIMA Paul Hildebrandt GmbH + Co KG

Industrial Automation

Rev. 1.01 HI 800 205 E

HI 800 205 E Rev. 1.01 (1022)

All HIMA products mentioned in this manual are protected by the HIMA trade-mark. Unless noted

otherwise, this also applies to other manufacturers and their respective products referred to herein.

All of the instructions and technical specifications in this manual have been written with great care and

effective quality assurance measures have been implemented to ensure their validity. For questions,

please contact HIMA directly. HIMA appreciates any suggestion on which information should be

included in the manual.

Equipment subject to change without notice. HIMA also reserves the right to modify the written material

without prior notice.

For further information, refer to the CD-ROM and our website http://www.hima.de and

http://www.hima.com.

© Copyright 2010, HIMA Paul Hildebrandt GmbH + Co KG

All rights reserved

Contact

HIMA Address

HIMA Paul Hildebrandt GmbH + Co KG

P.O. Box 1261

68777 Brühl, Germany

Tel: +49 6202 709-0

Fax: +49 6202 709-107

Type of Change

Revision

index

Revisions

technical editorial

1.00 Added: Configuration with SILworX X X

1.01 Table 11, digital outputs X X

DIO 24/16 01 Table of Contents

HI 800 205 E Rev. 1.01 Page 3 of 40

Table of Contents

1Introduction ............................................................ 5

1.1 Structure and Use of this Manual......................................................................... 5

1.2 Target Audience..................................................................................................... 6

1.3 Formatting Conventions ....................................................................................... 6

1.3.1 Safety Notes ............................................................................................................ 6

1.3.2 Operating Tips ......................................................................................................... 7

2Safety...................................................................... 8

2.1 Intended Use .......................................................................................................... 8

2.1.1 Environmental Requirements................................................................................... 8

2.1.2 ESD Protective Measures........................................................................................ 8

2.2 Residual Risk ......................................................................................................... 9

2.3 Safety Precautions................................................................................................. 9

2.4 Emergency Information......................................................................................... 9

3Product Description .............................................. 10

3.1 Safety Function.................................................................................................... 10

3.1.1 Safety-Related Analog Inputs ................................................................................ 10

3.1.1.1 Reaction in the Event of a Fault............................................................................. 10

3.1.2 Safety-Related Outputs.......................................................................................... 11

3.1.2.1 Reaction in the Event of a Fault............................................................................. 11

3.1.3 Line Control............................................................................................................ 11

3.2 Equipment, Scope of Delivery............................................................................ 11

3.3 Type Label ............................................................................................................ 11

3.4 Assembly.............................................................................................................. 13

3.4.1 Block Diagram........................................................................................................ 13

3.4.2 Front View.............................................................................................................. 14

3.4.3 Module Indicators................................................................................................... 15

3.4.4 I/O LEDs ................................................................................................................ 15

3.5 Product Data......................................................................................................... 15

4Start-Up................................................................. 17

4.1 Installation and Mounting ................................................................................... 17

4.1.1 Mounting and Removing the Modules ................................................................... 17

4.1.2 Connecting the Digital Inputs................................................................................. 18

4.1.2.1 Surges on Digital Inputs......................................................................................... 19

4.1.3 Connecting the Digital Outputs .............................................................................. 19

4.1.4 Mounting the DIO 24/16 01 in Zone 2.................................................................... 20

4.2 Configuration ....................................................................................................... 21

4.2.1 Module Slots .......................................................................................................... 21

4.3 Configuring the Module with SILworX............................................................... 21

4.3.1 Parameters and Error Codes for the Inputs and Outputs ...................................... 22

4.3.2 Digital Inputs and Outputs...................................................................................... 22

4.3.2.1 Module Tab ........................................................................................................... 22

Table of Contents DIO 24/16 01

Page 4 of 40 HI 800 205 E Rev. 1.01

4.3.2.2 DIO 24/16 01_1: DO Channels Tab ...................................................................... 24

4.3.2.3 DIO 24/16 01_1: DI Channels Tab........................................................................ 24

4.4 Configuring a Module Using ELOP II Factory....................................................25

4.4.1 Configuring the Inputs and Outputs........................................................................25

4.4.2 Signals and Error Codes for the Inputs and Outputs.............................................. 25

4.4.3 Digital Inputs...........................................................................................................25

4.4.4 Digital outputs.........................................................................................................27

5Operation .............................................................. 28

5.1 Handling................................................................................................................28

5.2 Diagnosis ..............................................................................................................28

6Maintenance.......................................................... 29

6.1 Faults.....................................................................................................................29

6.2 Maintenance Measures........................................................................................30

6.2.1 Loading the Operating System...............................................................................30

6.2.2 Proof Test...............................................................................................................30

7Decommissioning.................................................. 31

8Transport .............................................................. 32

9Disposal................................................................ 33

Appendix............................................................... 35

Glossary................................................................................................................35

Index of Figures....................................................................................................36

Index of Tables .....................................................................................................37

Index......................................................................................................................38

DIO 24/16 01 1 Introduction

HI 800 205 E Rev. 1.01 Page 5 of 40

1 Introduction

This manual describes the technical characteristics of the module and its use. It also

includes instructions on how to install, start up and replace it.

1.1 Structure and Use of this Manual

The content of this manual is part of the hardware description of the HIMatrix

programmable electronic system.

This manual is organized in the following main chapters:

Introduction

Safety

Product Description

Start-Up

Operation

Maintenance

Decommissioning

Transport

Disposal

This manual distinguishes between the following variants of the HIMatrix system:

Programming tool Processor operating system Communication operating

system

SILworX Versions beyond 7 Version 12 and beyond

ELOP II Factory Versions prior to 7 Versions prior to 12

Table 1: HIMatrix System Variants

The manual distinguishes among the different variants using:

Separated chapters,

Tables differentiating among the versions, e.g., versions beyond 7, or prior to 7.

iProjects created with ELOP II Factory cannot be edited with SILworX, and vice versa!

iThis manual usually refers to compact controllers and remote I/Os as devices, and to the

plug-in cards of a modular controller as modules.

1 Introduction DIO 24/16 01

Page 6 of 40 HI 800 205 E Rev. 1.01

Additionally, the following documents must be taken into account:

Name Content Document number

HIMatrix System Manual

Compact Systems

Hardware description of the HIMatrix

compact systems

HI 800 141 E

HIMatrix System Manual

Modular System F60

Hardware description of the HIMatrix

modular system

HI 800 191 E

Himatrix Safety Manual Safety functions of the HIMatrix

system

HI 800 023 E

HIMatrix Engineering

Manual

Project planning description for

HIMatrix systems

HI 800 101 E

SILworX Online Help Instructions on how to use SILworX -

ELOP II Factory Online

Help

Instructions on how to use ELOP II

Factory, Ethernet IP protocol,

INTERBUS protocol

-

First Steps

SILworX

Introduction to SILworX using the

HIMax system as an example

HI 801 103 E

First Steps

ELOP II Factory

Introduction to ELOP II Factory HI 800 006 E

Table 2: Additional Relevant Documents

The latest manuals can be downloaded from the HIMA website www.hima.com. The

revision index on the footer can be used to compare the current version of existing manuals

with the Internet edition.

1.2 Target Audience

This document addresses system planners, configuration engineers, programmers of

automation devices and personnel authorized to implement, operate and maintain the

modules and systems. Specialized knowledge of safety-related automation systems is

required.

1.3 Formatting Conventions

To ensure improved readability and comprehensibility, the following fonts are used in this

document:

Bold: To highlight important parts

Names of buttons, menu functions and tabs that can be clicked and

used in the programming tool.

Italics: For parameters and system variables

Courier Literal user inputs

RUN Operating state are designated by capitals

Chapter 1.2.3 Cross references are hyperlinks even though they are not

particularly marked. When the cursor hovers over a hyperlink, it

changes its shape. Click the hyperlink to jump to the corresponding

position.

Safety notes and operating tips are particularly marked.

1.3.1 Safety Notes

The safety notes are represented as described below.

These notes must absolutely be observed to reduce the risk to a minimum. The content is

structured as follows:

Signal word: danger, warning, caution, notice

Type and source of danger

DIO 24/16 01 1 Introduction

HI 800 205 E Rev. 1.01 Page 7 of 40

Consequences arising from the danger

Danger prevention

The signal words have the following meanings:

Danger indicates hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates hazardous situation which, if not avoided, could result in death or

serious injury.

Warning indicates hazardous situation which, if not avoided, could result in minor or

modest injury.

Notice indicates a hazardous situation which, if not avoided, could result in property

damage.

NOTE

Type and source of damage!

Damage prevention

1.3.2 Operating Tips

Additional information is structured as presented in the following example:

iThe text corresponding to the additional information is located here.

Useful tips and tricks appear as follows:

TIP The tip text is located here.

SIGNAL WORD

Type and source of danger!

Consequences arising from the danger

Danger prevention

2 Safety DIO 24/16 01

Page 8 of 40 HI 800 205 E Rev. 1.01

2 Safety

The following safety information, notes and instructions must be strictly observed. The

product may only be used if all guidelines and safety instructions are adhered to.

This product is operated with SELV or PELV. No imminent danger results from the product

itself. The use in Ex-Zone is permitted if additional measures are taken.

2.1 Intended Use

HIMatrix components are designed for assembling safety-related controller systems.

When using the components in the HIMatrix system, comply with the following general

requirements

2.1.1 Environmental Requirements

Requirement type Range of values

Protection class Protection class III in accordance with IEC/EN 61131-2

Ambient temperature 0...+60 °C

Storage temperature -40...+85 °C

Pollution Pollution degree II in accordance with IEC/EN 61131-2

Altitude < 2000 m

Housing Standard: IP20

Supply voltage 24 VDC

Table 3: Environmental Requirements

Exposing the HIMax system to environmental conditions other than those specified in this

manual can cause the HIMatrix system to malfunction.

2.1.2 ESD Protective Measures

Only personnel with knowledge of ESD protective measures may modify or extend the

system or replace devices.

NOTE

Device damage due to electrostatic discharge!

When performing the work, make sure that the workspace is free of static and

wear an ESD wrist strap.

If not used, ensure that the device is protected from electrostatic discharge, e.g.,

by storing it in its packaging.

DIO 24/16 01 2 Safety

HI 800 205 E Rev. 1.01 Page 9 of 40

2.2 Residual Risk

No imminent danger results from a HIMatrix system itself.

Residual risk may result from:

Faults in the engineering

Faults in the user program

Faults in the wiring

2.3 Safety Precautions

Observe all local safety requirements and use the protective equipment required on site.

2.4 Emergency Information

A HIMatrix system is a part of the safety equipment of a site.If a device or a module fails,

the site adopts the safe state.

In case of emergency, no action that may prevent the HIMatrix systems from operating

safely is permitted.

3 Product Description DIO 24/16 01

Page 10 of 40 HI 800 205 E Rev. 1.01

3 Product Description

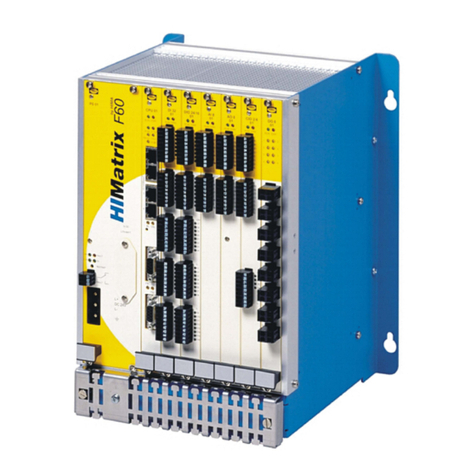

DIO 24/16 01 is a plug-in module for the modular F60 HIMatrix system.

The DIO 24/16 01 module has 24 digital input channels and 16 digital output channels that

are galvanically isolated from the I/O bus. The status of the input and output signals is

displayed by LEDs located on the front plate next to the terminal plugs.

The module can be inserted in the F60 subrack's slot 3...8 as many times as required. Slots

1 and 2 are reserved for the power supply module and CPU module, respectively.

However, the load on the outputs must not exceed the total current input of the power

supply module.

The module has been certified by the TÜV for safety-related applications up to SIL 3 (IEC

61508, IEC 61511 and IEC 62061), Cat. 4 (EN 954-1) and PL e (EN ISO 13849-1). Further

safety standards, application standards and test standards are specified in the certificate

available on the HIMA website.

3.1 Safety Function

The module is equipped with safety-related inputs and outputs.

3.1.1 Safety-Related Analog Inputs

Each group of 8 inputs is provided with a common, short-circuit-proof supply LS+ on the

clamps.

The safety-related application (SIL 3 in accordance with IEC 61508) of the inputs and the

sensors connected must comply with the safety requirements. For more information, refer

to the HIMatrix Safety Manual.

3.1.1.1 Reaction in the Event of a Fault

If the module detects a fault on a digital input, the user program processes a low level in

accordance with the de-energized to trip principle.

The module activates the FAULT LED.

In addition to the channel signal value, the user program must also consider the

corresponding error code.

The error code allows the user to configure additional fault reactions in the user program.

DIO 24/16 01 3 Product Description

HI 800 205 E Rev. 1.01 Page 11 of 40

3.1.2 Safety-Related Outputs

Each group of 8 outputs is provided with a connector on the clamps for the common

ground.

If an output channel is overloaded, it is switched off for ten seconds until the overload is no

longer present. If the module output range has a total load of more than 8 A, the outputs

are all switched off for 10 seconds and a new test is performed.

3.1.2.1 Reaction in the Event of a Fault

If the module detects a faulty signal on a digital output, the affected module output is set to

the safe (de-energized) state using the safety switches.

If a fault in the module occurs, all digital outputs are switched off.

In both cases, the module activates the FAULT LED.

The error code allows the user to configure additional fault reactions in the user program.

3.1.3 Line Control

The digital outputs DO 1 through DO 8 of the DIO 24/16 01 module can be used to monitor

the own digital inputs or the digital inputs of other modules (e.g., DI 32 01) for short-circuits

and open-circuits, e.g., for an EMERGENCY STOP button complying with Cat. 4 in

accordance with EN 954-1. To this end, the outputs are pulsed and connected to the

safety-related digital inputs. In this case, the outputs assume the function of pulsed outputs.

The parameters for the line control are set via system parameters; refer to the HIMatrix

Engineering Manual for more details.

iPulsed outputs must not be used as safety-related outputs!

3.2 Equipment, Scope of Delivery

The following list specifies the available components and the corresponding part numbers:

Designation Description Part no.

DIO 24/16 01 Plug-in module with 24 digital inputs and 16 digital

outputs.

98 2200100

Table 4: Part Numbers

3.3 Type Label

The type plate contains the following details:

Product name

Bar code (1D or 2D code)

Part no.

Production year

Hardware revision index (HW Rev.)

Firmware revision index (FW Rev.)

Operating voltage

Mark of conformity

3 Product Description DIO 24/16 01

Page 12 of 40 HI 800 205 E Rev. 1.01

Figure 1: Sample Type Label

DIO 24/16 01 3 Product Description

HI 800 205 E Rev. 1.01 Page 13 of 40

3.4 Assembly

This chapter describes the layout and function of the plug-in module.

3.4.1 Block Diagram

24 Digital Inputs

Module Indicators

16 Digital Outputs

I/O Bus

Figure 2: Block Diagram

3 Product Description DIO 24/16 01

Page 14 of 40 HI 800 205 E Rev. 1.01

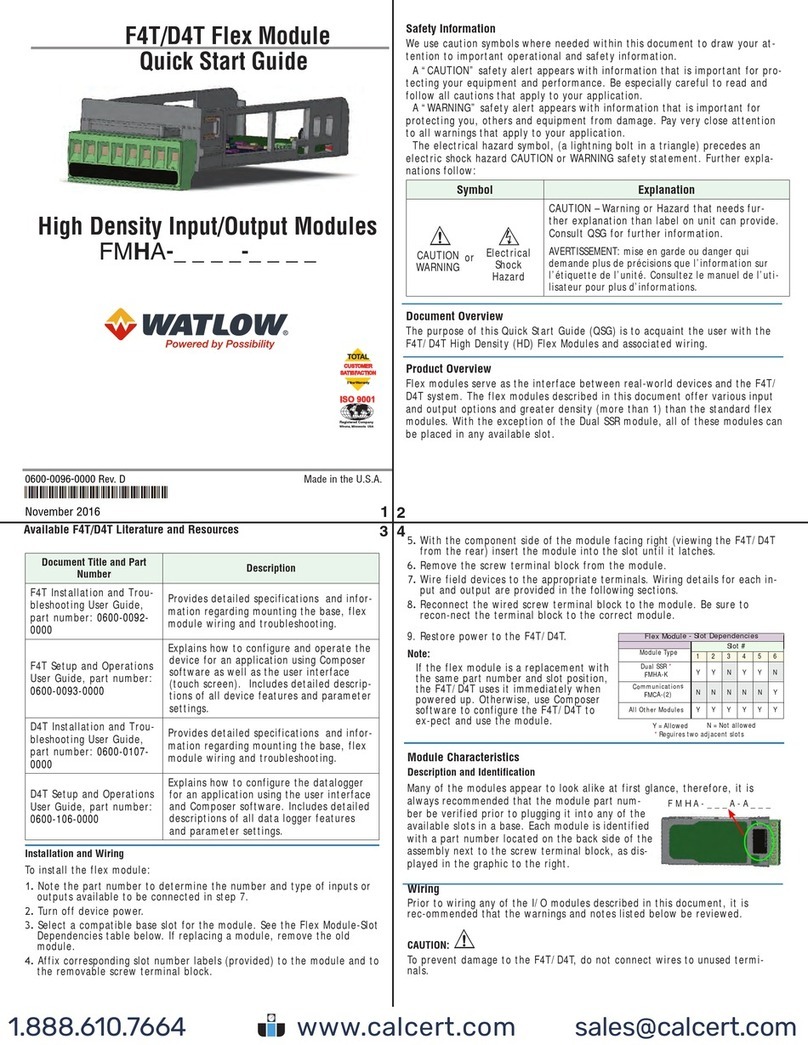

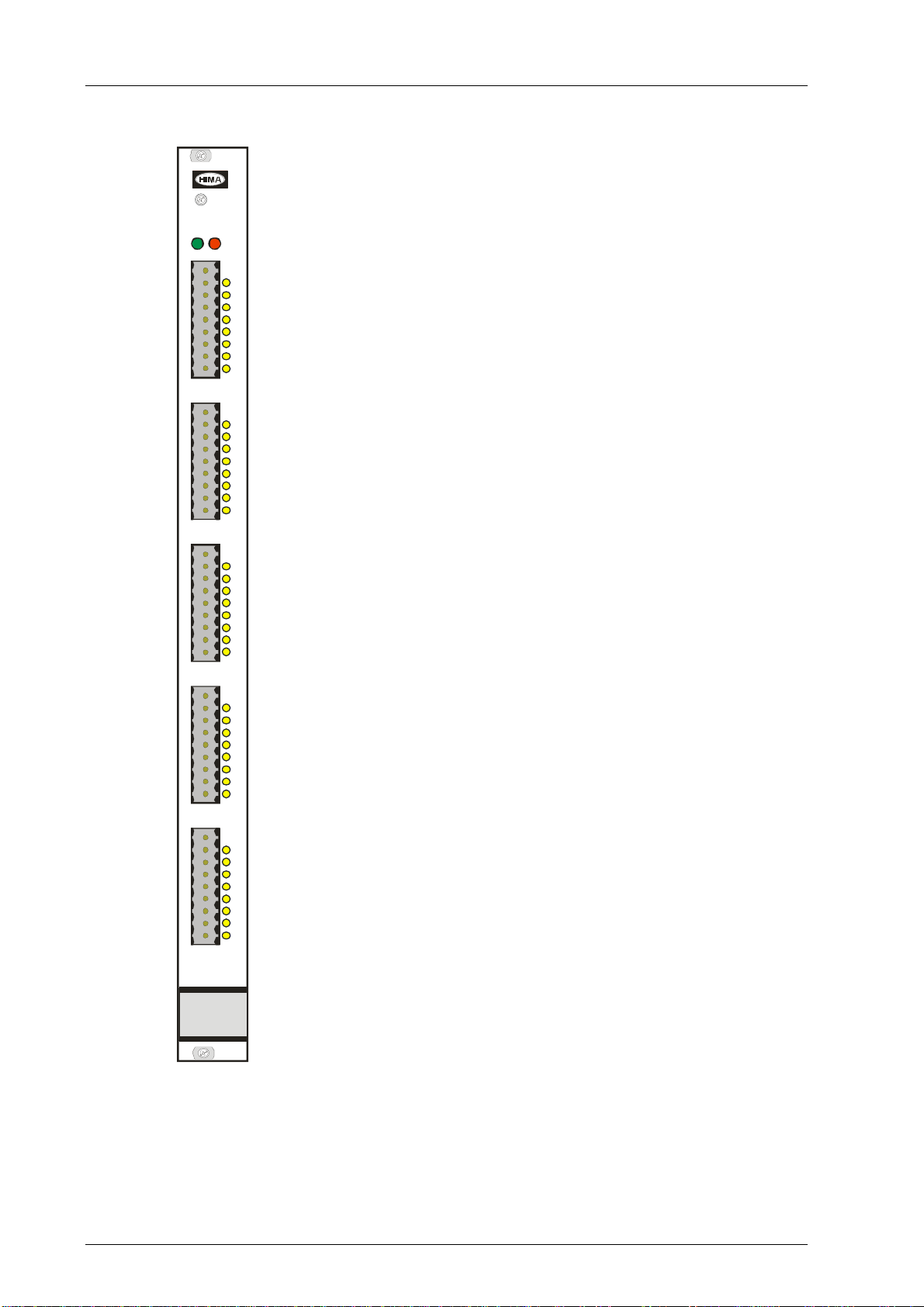

3.4.2 Front View

DIO 24/16

01

LS+

I1

I2

I3

I4

I5

I6

I7

I8

LS+

I9

I10

I11

I12

I13

I14

I15

I16

LS+

I17

I18

I19

I20

I21

I22

I23

I24

L-

O1

O2

O3

O4

O5

O6

O7

O8

L-

O9

O10

O11

O12

O13

O14

O15

O16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

RUN ERR

Figure 3: Front View

DIO 24/16 01 3 Product Description

HI 800 205 E Rev. 1.01 Page 15 of 40

3.4.3 Module Indicators

LED Color Status Description

On Operating voltage presentRUN Green

Off No operating voltage

On Module faulty or external faults

Reaction as dictated by the diagnosis

ERR Red

Off No module faults and / or no channel faults

Table 5: Module Indicators

3.4.4 I/O LEDs

LED Color Status Description

On The related input is active (energized).I 1...24 Yellow

Off The related input is inactive (de-energized).

On The related output is active (energized).O 1...16 Yellow

Off The related output is inactive (de-energized).

Table 6: I/O LEDs

3.5 Product Data

General

Operating voltage 24 VDC, -15 %...+20 %, wss ≤15 %,

provided by a power supply unit with safe isolation

in accordance with IEC 61131-2 requirements.

Operating data 24 VDC / 380 mA

3.3 VDC / 150 mA

Ambient temperature 0 °C...+60 °C

Storage temperature -40 °C...+85 °C

Space requirement 6 RU, 4 HP

Weight 260 g

Table 7: Product Data

Digital Inputs

Number of inputs 24 (galvanically isolated)

Input voltage

High level

Low level

nom. 24 VDC

10 V...30 V

max. 5 V

Input current

High level

Low level

2 mA at 10 V, 5 mA at 24 V

1 mA at 5 V

Switching point typ. 7.5 V

Supply 3 x 20 V / 100 mA (at 24 V), short-circuit-proof

Table 8: Specifications for Digital Inputs

3 Product Description DIO 24/16 01

Page 16 of 40 HI 800 205 E Rev. 1.01

Digital outputs

Number of outputs 16 (galvanically isolated)

Output voltage 18.4...26.8 VDC

Internal voltage drop max. 2 W at 2 A

Output current

(at 30 °C)

2 A each channel, max. 8 A each module,

permanently short-circuit-proof

Minimum load 2 mA for each channel

Leakage current (low level) max. 1 mA at 2 V

Table 9: Specifications for the Digital Outputs

DIO 24/16 01 4 Start-Up

HI 800 205 E Rev. 1.01 Page 17 of 40

4 Start-Up

To start up the controller, it must be mounted, connected and configured in the

programming tool.

4.1 Installation and Mounting

The module is mounted in the subrack of the modular HIMatrix F60 system.

4.1.1 Mounting and Removing the Modules

To mount and remove the modules, the connection cable clamp terminals must be

unplugged.

Additionally, personnel must be protected from electrostatic discharge. For details, refer to

Chapter 2.1.2.

Mounting the Modules

To mount a module into the rack

1. Insert the module as far as it can go – without jamming it – into the two guiding rails

which are located on the on the housing's upper and lower part.

2. Apply pressure to the upper and lower extremity of the front plate until the module plugs

snap into the backplane socket.

3. Secure the module with the screws located on upper and lower extremity of the front

plate.

The module is mounted.

Removing the Modules

To remove a module from the rack

1. Remove the plugs from the module front plate.

2. Release the locking screws located on the upper and lower extremity of the front plate.

3 Loosen the module using the handle located on the lower part of the front plate and

remove it from the guiding rails.

The module is removed.

The use of shielded cables is not required, but improves the EMC conditions significantly.

To allow the connection of the clamps to the earth grid of the F60, the diameter of the cable

shielding should not exceed 12 mm.

The inputs and outputs are connected using 9-pole connectors with numbered terminals.

The terminal pins on the front plate of the module have the same numbered sequence to

avoid improper connections.

4 Start-Up DIO 24/16 01

Page 18 of 40 HI 800 205 E Rev. 1.01

4.1.2 Connecting the Digital Inputs

Use the following terminals to connect the digital inputs:

Terminal Designation Function

01 LS+ Supply of inputs 1...8

02 I1 Digital input 1

03 I2 Digital input 2

04 I3 Digital input 3

05 I4 Digital input 4

06 I5 Digital input 5

07 I6 Digital input 6

08 I7 Digital input 7

09 I8 Digital input 8

Terminal Designation Function

10 LS+ Supply of inputs 9...16

11 I9 Digital input 9

12 I10 Digital input 10

13 I11 Digital input 11

14 I12 Digital input 12

15 I13 Digital input 13

16 I14 Digital input 14

17 I15 Digital input 15

18 I16 Digital input 16

Terminal Designation Function

19 LS+ Supply of inputs 17...24

20 I17 Digital input 17

21 I18 Digital input 18

22 I19 Digital input 19

23 I20 Digital input 20

24 I21 Digital input 21

25 I22 Digital input 22

26 I23 Digital input 23

27 I24 Digital input 24

Table 10: Terminal Assignment for the Digital Inputs

DIO 24/16 01 4 Start-Up

HI 800 205 E Rev. 1.01 Page 19 of 40

4.1.2.1 Surges on Digital Inputs

Due to the short cycle time of the HIMatrix systems, a surge pulse as described in

EN 61000-4-5 can be read in to the digital inputs as a short-term high level.

The following measures ensure proper operation in environments where surges may occur:

1. Install shielded input wires

2. Activate noise blanking: a signal must be present for at least two cycles before it is

evaluated.

iActivating noise blanking increases the response time of the HIMatrix system!

iThe measures specified above are not necessary if the plant design precludes surges from

occurring within the system.

In particular, the design must include protective measures with respect to overvoltage,

lightning, earth grounding and plant wiring in accordance with the relevant standards and

the instructions specified in the System Manual (HI 800 141 or HI 800 191).

4.1.3 Connecting the Digital Outputs

Use the following terminals to connect the digital outputs:

Terminal Designation Function

28 L- Supply of outputs 1...8

29 O1 Digital output 1

30 O2 Digital output 2

31 O3 Digital output 3

32 O4 Digital output 4

33 O5 Digital output 5

34 O6 Digital output 6

35 O7 Digital output 7

36 O8 Digital output 8

Terminal Designation Function

37 L- Supply of outputs 9...16

38 O9 Digital output 9

39 O10 Digital output 10

40 O11 Digital output 11

41 O12 Digital output 12

42 O13 Digital output 13

43 O14 Digital output 14

44 O15 Digital output 15

45 O16 Digital output 16

Table 11: Terminal Assignment for the Digital Outputs

4 Start-Up DIO 24/16 01

Page 20 of 40 HI 800 205 E Rev. 1.01

4.1.4 Mounting the DIO 24/16 01 in Zone 2

(EC Directive 94/9/EC, ATEX)

The device is suitable for mounting in zone 2. Refer to the corresponding declaration of

conformity available on the HIMA website.

When mounting the device, observe the special conditions specified in the following

section.

Special Conditions X

1. The HIMatrix F60 DIO 24/16 01 must be mounted in an enclosure, which fulfills the

requirements of the EN 60079-15 with the type of protection at least IP 54, according to

EN 60529. Provide the enclosure with the following label:

Work is only permitted in the de-energized state

Exception:

If a potentially explosive atmosphere has been precluded, work can also performed

when the controller is under voltage.

2. The enclosure in use must be able to safely dissipate the generated heat. The power

dissipation (PV) of each HIMatrix F60 DIO 24/16 01 module is 25 W at maximum output

load.

3. The HIMatrix F60 DIO 24/16 01 module must be supplied with 24 VDC from a power

supply unit with safe isolation. Only power supply units of type PELV or SELV may be

used.

4. Applicable standards:

VDE 0170/0171 Part 16, DIN EN 60079-15: 2004-5

VDE 0165 Part 1, DIN EN 60079-14: 1998-08

Pay particular attention to the following sections:

DIN EN 60079-15:

Chapter 5 Design

Chapter 6 Terminals and cabling

Chapter 7 Air and creeping distances

Chapter 14 Connectors

DIN EN 60079-14:

Chapter 5.2.3 Equipment for use in zone 2

Chapter 9.3 Cabling for zones 1 and 2

Chapter 12.2 Equipment for zones 1 and 2

The controller is additionally equipped with the label represented below:

Figure 4: Label for Ex Conditions

Table of contents

Other HIMA Control Unit manuals

HIMA

HIMA HIMatrix F60 Installation and operation manual

HIMA

HIMA HIMax X-CI 24 51 User manual

HIMA

HIMA HIMax X-DI 32 51 User manual

HIMA

HIMA HIMax X-DI 32 05 User manual

HIMA

HIMA HIMax X-DI 64 01 User manual

HIMA

HIMA HIMax X-DI 32 52 User manual

HIMA

HIMA HIMax X-DI 32 02 User manual

HIMA

HIMA HIMax X-DI 64 51 User manual

HIMA

HIMA HIMax X-HART 32 01 User manual

HIMA

HIMA HIMax X-DO 32 51 User manual