67

2 VV. Creating innovative solutions for you and your business since 1995.

ver.3 29-04-20

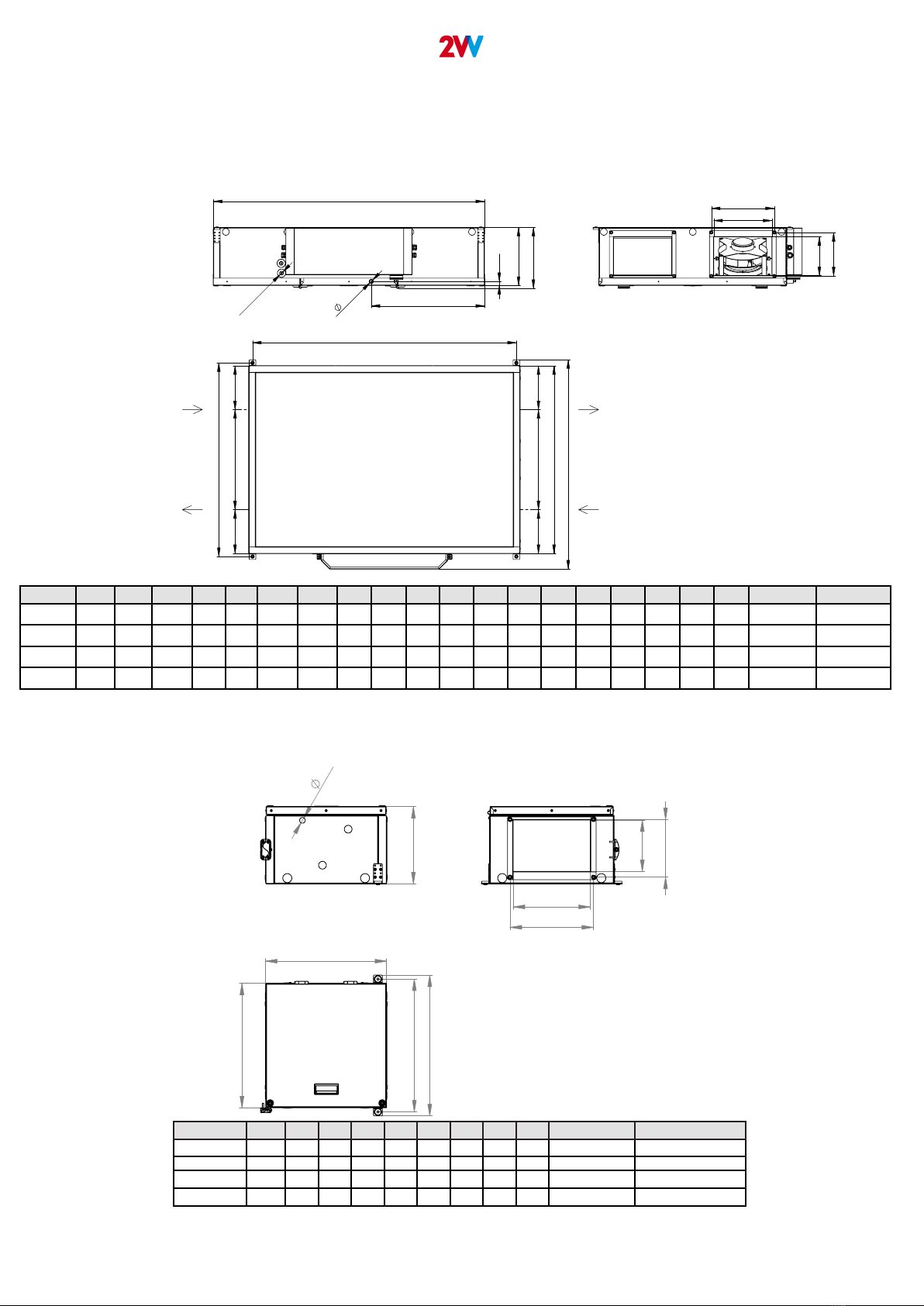

5. TECHNICAL PARAMETERS

Model w/o el. reheating and preheating / with water reheating, C/O, DX

Model with el. preheating

- without reheating, with C/O, DX

- with electric reheating

- with electric reheating

Type Tension Frequency Input power (kW) Current (A)

by phase

HRFL2-040 230 V 50/60 Hz 0.23 2.2

HRFL2-070 230 V 50/60 Hz 0.33 2.5

HRFL2-150 230 V 50/60 Hz 1 5.6

HRFL2-200 230 V 50/60 Hz 1 6.3

Type Tension Frequency Input power (kW) Current (A)

by phase

HRFL2-040 230 V 50/60 Hz 1.7 8.3

HRFL2-070 230 V 50/60 Hz 3.1 14.3

HRFL2-150 400 V 50/60 Hz 6.3 13.3

HRFL2-200 400 V 50/60 Hz 8.3 16.7

Type Tension Frequency Input power (kW) Current (A)

by phase

HRFL2-040 230 V 50/60 Hz 1.1 5.7

HRFL2-070 230 V 50/60 Hz 1.8 8.6

HRFL2-150 230 V 50/60 Hz 3.7 17.4

HRFL2-200 400 V 50/60 Hz 5.9 12

Type Tension Frequency Input power (kW) Current (A)

by phase

HRFL2-040 230 V 50/60 Hz 2.5 11.8

HRFL2-070 400 V 50/60 Hz 4.5 11.7

HRFL2-150 400 V 50/60 Hz 8 17.4

HRFL2-200 400 V 50/60 Hz 13.1 22.5

Characteristic of the motor

Type Phases Tension Frequency Input

power (kW)

Current

(A) Speed (tr/min) IP class

insulation

HRFL2-040 1 230 V 50/60 Hz 169 1.35 4120 54 B

HRFL2-070 1 230 V 50/60 Hz 175 1.3 2800 44 B

HRFL2-150 1 230 V 50/60 Hz 455 3.1 2600 54 B

HRFL2-200 1 230 V 50/60 Hz 500 3.15 1970 54 B

Characteristics of the el. reheating

Type Phases Tension Frequency Input power

(kW)

ΔT

(°C)

HRFL2-040 1 230 V 50/60 Hz 1.1 6.3

HRFL2-070 1 230 V 50/60 Hz 1.6 6.3

HRFL2-150 1 230 V 50/60 Hz 2.7 5.3

HRFL2-200 3 400 V 50/60 Hz 4.8 6.3