Hirose FH63 Series Manual

1

2017.8②

0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

FH63 Series

Fig.3

Robust lock firmly retains FPC/FFC.

GND contact and FFC GND plate

contact at multiple points.

Matedcondition

(correctposition)

Insufficientinsertioncondition

(incorrectposition)

21.94mm

5.15mm

Single action lock (Dimension diagram : 30pos.)

Fig.1

Fig.2

FPC FFC Shield FFC

Shield FFC

GND contact

Two-point contact design for dust prevention

Fig.4Fig.5

Supports FPC/FFC/Shield FFC

High FPC retention force

FPC/FFC can be checked from the top surface after mating.

OK NG

Shielded FFC is acceptable for EMI prevention.

Insert FPC/FFC without opening

the lock lever before insertion!

2.8mm

■Features

1. Automatic single action locking design

· Single action locking by simply inserting FPC after mounting

contributes to enhanced workability. (Fig.1)

(Lock release by operating the lock lever when removing.)

· Operation of the lock lever is not required at the time of

mating FPC. Can be inserted with one hand.

Contributes to reduced assembly time.

The lock lever will not be damaged by operation.

Mating failure is reduced by eliminating the need to operate

a lever while mating.

2.

Two-points of contact prevents contact failure by dust

· High contact reliability by independent spring two-point

contact design, preventing contact failure by dust. (Fig.2)

3. Supports FPC/FFC/Shield FFC

· FH63 allows you to choose from FPC/FFC/Shield FFC.

· Shielded FFC is acceptable for EMI prevention.(Fig.3)

4. High FPC retention force

· The circuit is automatically locked after FPC/FFC is inserted

by a single action. The notches on both sides of FPC are

held by the lock lever, generating a high FPC retention

force in spite of the small contact. (Fig.4)

5.

Visual inspection on the mated status of FPC/FFC is possible.

· As the notches on both sides of FPC can be checked from

the top surface after inserting FPC/FFC, insufficient

insertion during assembly is prevented. (Fig.5)

6. Environmental

· Halogen free

*AS defined by IEC 61249-2-21.

Br : 900ppm max, Cl : 900ppm max, Br+Cl : 1,500ppm

max

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

2

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

Series name : FH

Series No. : 63

No. of contacts : 30

Contact pitch : 0.5mm

Terminal type

SH …SMT horizontal mounting type

Specification

Blank : Standard 3,500pcs/reel

(99) : 500pcs/reel

FH 63 − 30S − 0.5 SH (99)

❹❺ ❻

■Product Specifications

Rating

Rated current 0.5A

Rated voltage 50V AC/DC rms

Operating temperature range : -55ç to +105°C (Note 1)

Operating humidity range : Relative humidity 90% max.

(No condensation)

Storage temperature range : -10ç to +60°C (Note 2)

Storage humidity range : Relative humidity 90% max.

(No condensation)

Adaptive FPC

contact specifications

Thickness : = 0.33 ± 0.03mm Signal layout : Gold plated, GND plate : Tin plated

Item Specification Conditions

1.

Insulation resistance

500Mømin. 100V DC

2.

Withstanding voltage

No flashover or insulation breakdown 150V AC rms / 1 minute

3. Contact

resistance

100mø max.

* Including FPC/FFC conductor resistance 1mA AC

4. Durability

(insertion / withdrawal)

Contact resistance : 100mø max.

No damage, cracks, or parts dislocation 10 cycles

5. Vibration

No electrical discontinuity of 1µs or more

Contact resistance : 100mø max.

No damage, cracks, or parts dislocation

Frequency : 10 to 55Hz, single amplitude of 0.75mm,

10 cycles in each of the 3 directions

6. Shock

No electrical discontinuity of 1µs or more

Contact resistance : 100mø max.

No damage, cracks, or parts dislocation

Acceleration of 981m/s2, duration of 6 ms, sine half-wave

waveform, 3 cycles in each of the 3 axes

7.

Damp heat

(Steady state)

Contact resistance : 100mø max.

Insulation resistance : 50Mø min.

No damage, cracks, or parts dislocation

96 hours at temperature of 60ç and humidity of 90% to

95%

8.

Temperature

cycle

Contact resistance : 100mø max.

Insulation resistance : 50Mø min.

No damage, cracks, or parts dislocation

Temperature: -55°C /+15ç to +35ç /+105ç /+15ç to +35ç

Time : 30 / 2 to 3 / 30 /2 to 3 (Minutes)

5 cycles

9. Resistance to

soldering heat

No deformation of components affecting

performance

Reflow : Recommended Temperature Profile

Manual soldering: 350 ± 10°C for 5 seconds

Note 1 : Includes temperature rise caused by current flow.

Note 2 : The term “storage” refers to products stored for long period of time prior to mounting and use. Operating Temperature Range

and Humidity Range covers non-conducting condition of installed connectors in storage, shipment or during transportation.

■Materials / Finish

Part Materials Finish UL standard

Insulator LCP Grey UL94V-0

LCP Black UL94V-0

Signal contact Copper alloy Nickel barrier gold plated ---------------

Grounding contact Copper alloy Pure tin reflow plated ---------------

Reinforcing metal tabs SUS Pure tin reflow plated ---------------

■Product Number Structure

Refer to the chart below when determining the product specifications from the product number.

Please select from the product numbers listed in this catalog when placing orders.

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

3

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

■Connector Dimensions

Unit : mm

Part No. HRS No. No. of

Contacts ABCDEFG

FH63-10S-0.5SH Under planning (Note 1) 10 12.7 4.5 5.55 4 2 7.15 9.9

FH63-20S-0.5SH Under planning (Note 1) 20 17.7 9.5 6.55 9 1.5 12.15 14.9

FH63-30S-0.5SH 580-4400-0 ** 30 22.7 14.5 5.55 14 2 17.15 19.9

FH63-40S-0.5SH 580-4403-0 ** 40 27.7 19.5 10.55 19 1.5 22.15 24.9

FH63-50S-0.5SH Under planning (Note 1) 50 32.7 24.5 15.55 24 2 27.15 29.9

FH63-60S-0.5SH Under planning (Note 1) 60 37.7 29.5 20.55 29 1.5 32.15 34.9

Note 1 : Contact positions without HRS No. are currently under planning.

Please contact hirose for detailed information about product variation.

HRS mark

G±0.15

(0.65)

(F)

0.5±0.1

(0.25)

2.8±0.2

4.9±0.1

(C)

2±0.1 E±0.1

4.5±0.1

(3.3)

(0.1)

a

(0.1)

3

2

5

4

1

D±0.15

E±0.1

A±0.15

B±0.15

Signal contact No.1

Polarity mark

Grounding contact No.1

Grounding contact No.2

(Pickup area)

Cavity No.

Reinforcing

metal tabs

(Lead of reinforcing metal tabs)

Signal

contact

Grounding

contact

(Signal contact lead)

(Grounding contact lead)

Signal

contactpoint

Ground

contact point

(5.3)

0.55±0.1 4.25±0.2

(0.89)

(5.15)

(0.42)

(0.87)

(2.85)

(2.4)

0.75±0.1

0.35±0.1

3.9±0.2

(4)0.25±0.2

0.25±0.2

(2.2)

(45°)

FPC/FFC/Shield FFC t=0.33

Note

1 : The dimension in parentheses are for reference.

2 : Lead co-planarity including reinforced chucking metals shall be 0.1 max.

3 : To be delivered with tape and reel packages.

See the packaging specifications for details.

4 : Note that preventive hole for sink mark or slit could be added for improvement.

5 : The quality remains good, even with the dark spots, which could occasionally occur on molded plastic.

6 : This product satisfies halogen free requirements defined as 900ppm maximum chlorine,

900ppm maximum bromine, and 1500ppm maximum total of chlorine and bromine.

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

4

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

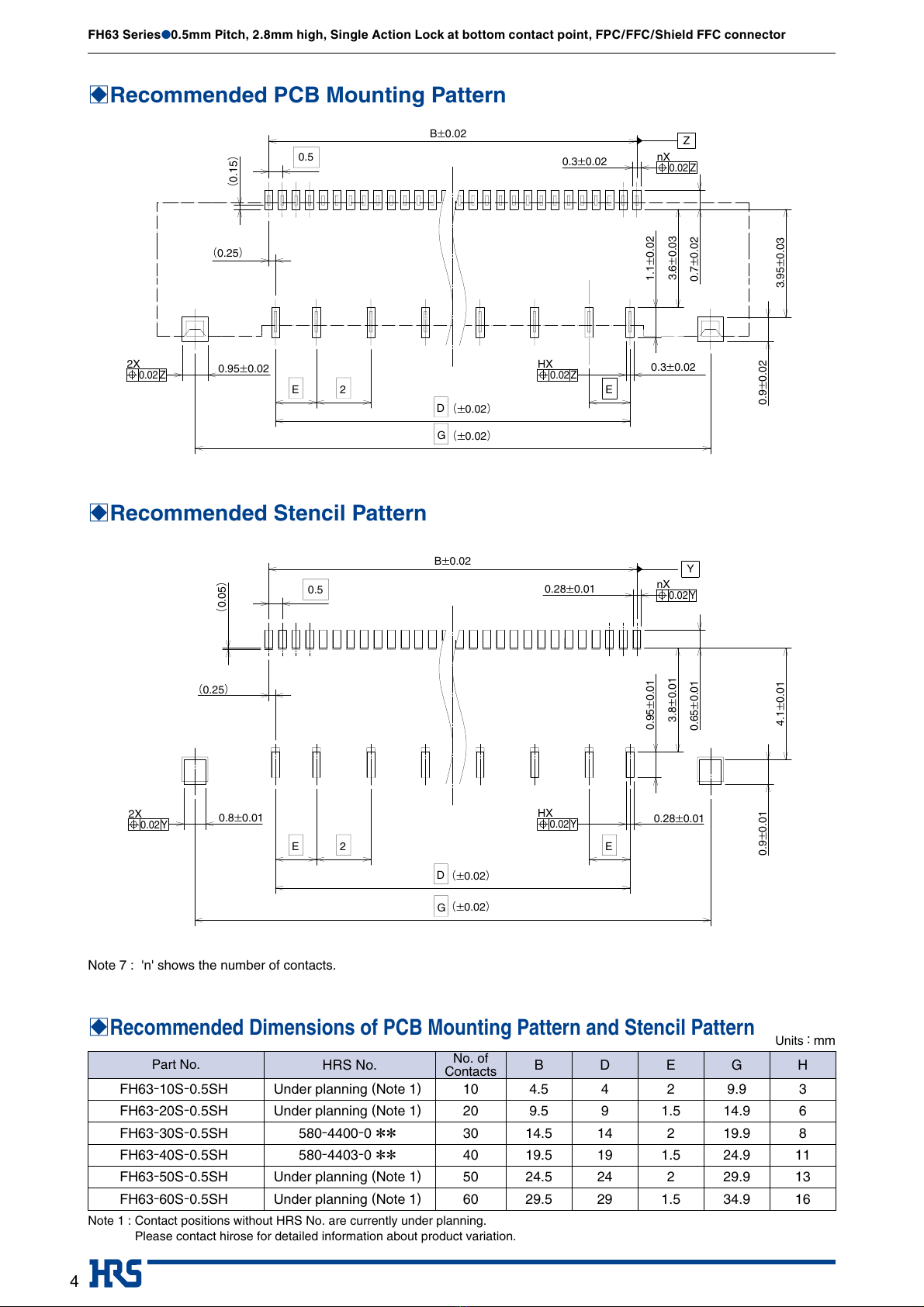

BRecommended PCB Mounting Pattern

B

Recommended Dimensions of PCB Mounting Pattern and Stencil Pattern

BRecommended Stencil Pattern

Units:mm

Part No. HRS No. No. of

Contacts BDEGH

FH63-10S-0.5SH Under planning (Note 1) 10 4.5 4 2 9.9 3

FH63-20S-0.5SH Under planning (Note 1) 20 9.5 9 1.5 14.9 6

FH63-30S-0.5SH 580-4400-0 ** 30 14.5 14 2 19.9 8

FH63-40S-0.5SH 580-4403-0 ** 40 19.5 19 1.5 24.9 11

FH63-50S-0.5SH Under planning (Note 1) 50 24.5 24 2 29.9 13

FH63-60S-0.5SH Under planning (Note 1) 60 29.5 29 1.5 34.9 16

Note 1 : Contact positions without HRS No. are currently under planning.

Please contact hirose for detailed information about product variation.

E

B±0.02

(0.25)

0.3±0.02

HX

0.02Z

0.7±0.02

3.6±0.03

1.1±0.02

0.3±0.02

0.9±0.02

3.95±0.03

G

D

2

0.95±0.02

E

0.5

(0.15)

(±0.02)

(±0.02)

nX

0.02 Z

Z

2X

0.02 Z

(0.05)

E

0.8±0.01

2

D

4.1±0.01

0.9±0.01

0.28±0.01

0.95±0.01

3.8±0.01

0.65±0.01

0.28±0.01

(0.25)

B±0.02

0.5

E

G

(±0.02)

(±0.02)

2X

0.02Y

HX

0.02Y

nX

0.02Y

Y

Note 7 : 'n' shows the number of contacts.

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

5

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BRecommended FPC/FFC Dimensions

BRecommended Shield FFC Dimensions

R0.2

R0.1±0.1

R0.1±0.1

R0.2

R0.2

R0.2

R0.2

B±0.02

(K)

4.75±0.3

4.15±0.1

2.9±0.1

1.25±0.1

L±0.1

J±0.05

1.3±0.07

1.3±0.07

0.8±0.05

0.5 0.4±0.03

1.3±0.07

1.3±0.07

0.8±0.05

J±0.05

1 MIN (overlapping amount)

6 MIN (Reinforcing film)

0.33±0.03

nX

0.02 X

X

R0.2

R0.1±0.1

R0.1±0.1

R0.2

R0.2

R0.2

R0.2

0.8±0.05

0.8±0.05

4.75±0.1

4.15±0.1

2.9±0.1

1.25±0.1

L±0.1

J±0.05

0.32±0.03

1.3±0.08 1.3±0.08

1.3±0.08

1.3±0.08

0.5

B±0.05

(K)

J±0.05

1 MIN (overlapping amount)

6 MIN (Reinforcing film)

0.33±0.03

Grounding plate

Shield

1.1±0.3

(M)

1.1±0.3

0.5±0.3

nX

0.05

W

W

BRecommended Dimensions of FPC/FFC/Shield FFC Units:mm

Part No. HRS No. No. of

Contacts BJKLM

FH63-10S-0.5SH Under planning (Note 1) 10 4.5 7.1 5.5 9.1 4.9

FH63-20S-0.5SH Under planning (Note 1) 20 9.5 12.1 10.5 14.1 9.9

FH63-30S-0.5SH 580-4400-0 ** 30 14.5 17.1 15.5 19.1 14.9

FH63-40S-0.5SH 580-4403-0 ** 40 19.5 22.1 20.5 24.1 19.9

FH63-50S-0.5SH Under planning (Note 1) 50 24.5 27.1 25.5 29.1 24.9

FH63-60S-0.5SH Under planning (Note 1) 60 29.5 32.1 30.5 34.1 29.9

Note 1 : Contact positions without HRS No. are currently under planning.

Please contact hirose for detailed information about product variation.

Note 7 : The value 'n' indicates the number of pos.

Overlap the shield on the grounding plate.

8

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

6

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

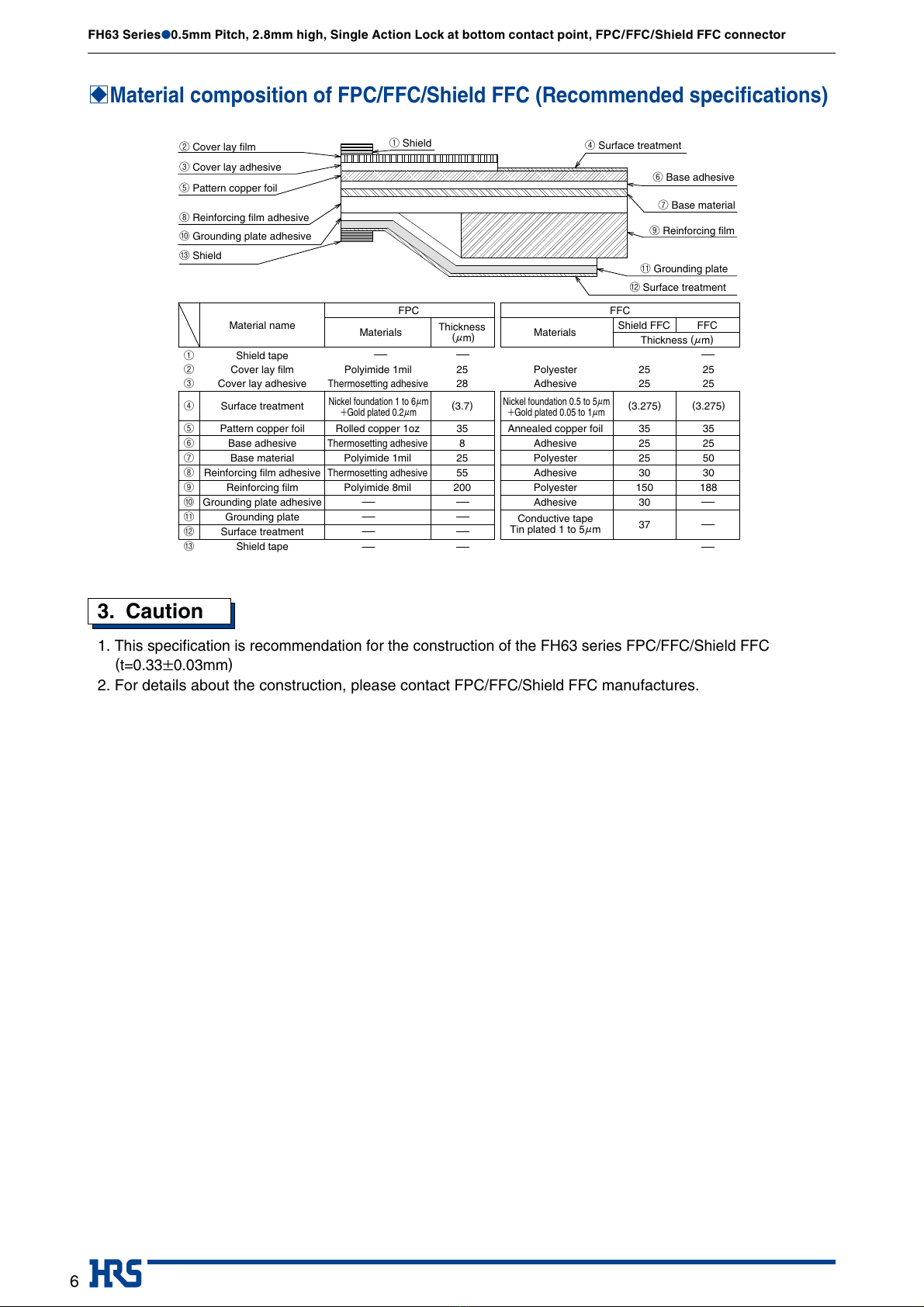

B

Material composition of FPC/FFC/Shield FFC (Recommended specifications)

FPC FFC

②Cover lay film ①Shield

③Cover lay adhesive

⑤Pattern copper foil

⑧Reinforcing film adhesive

⑩Grounding plate adhesive

⑬Shield

Nickel foundation 1 to 6μm

+Gold plated 0.2μm

Nickel foundation 0.5 to 5μm

+Gold plated 0.05 to 1μm

Materials Shield FFC FFC

Materials

Thickness

(μm) Thickness (μm)

Material name

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

Shield tape

Cover lay film

Cover lay adhesive

Surface treatment (3.7)

Pattern copper foil

Base adhesive

Base material

Reinforcing film adhesive

Reinforcing film

Grounding plate adhesive

Grounding plate

Surface treatment

Shield tape

Polyester

Adhesive

Annealed copper foil

Adhesive

Polyester

Adhesive

Polyester

Adhesive

Conductive tape

Tin plated 1 to 5μm

Polyimide 1mil

Thermosetting adhesive

Rolled copper 1oz

Thermosetting adhesive

Polyimide 1mil

Thermosetting adhesive

Polyimide 8mil

25

28

35

8

25

55

200

(3.275)

25

25

35

25

25

30

150

30

37

(3.275)

25

25

35

25

50

30

188

⑪Grounding plate

⑫Surface treatment

⑨Reinforcing film

⑦Base material

⑥Base adhesive

④Surface treatment

3. Caution

1.

This specification is recommendation for the construction of the FH63 series FPC/FFC/Shield FFC

(t=0.33±0.03mm)

2. For details about the construction, please contact

FPC/FFC/Shield FFC

manufactures.

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

7

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

P±0.3

R±0.1

(2)

4±0.1

8±0.1

1.75±0.1

(3)

6

7

9

(0.3)

Ø1.5

+0.1

0

Unreeling

direction

(0.3)

(3)

1.75±0.1

8±0.1

4±0.1

(2)

R±0.1

Q±0.1

P±0.3

6

7

9

Ø1.5

+0.1

0

Unreeling

direction

●Embossed Carrier Tape Dimensions

●Reel Dimensions

tape width 24mm or less tape width 32mm or less

●Leader, Trailer Dimensions

BPackaging Specifications

Unit : mm

Part No. HRS No. No. of

Contacts PQRSU

FH63-10S-0.5SH Under planning (Note 1) 10 24 ---- 11.5 29.4 25.4

FH63-20S-0.5SH Under planning (Note 1) 20 32 28.4 14.2 37.4 33.4

FH63-30S-0.5SH 580-4400-0 ** 30 44 40.4 20.2 49.4 45.4

FH63-40S-0.5SH 580-4403-0 ** 40 44 40.4 20.2 49.4 45.4

FH63-50S-0.5SH Under planning (Note 1) 50 56 52.4 26.2 61.4 57.4

FH63-60S-0.5SH Under planning (Note 1) 60 56 52.4 26.2 61.4 57.4

Note 1 : Contact positions without HRS No. are currently under planning.

Please contact hirose for detailed information about product variation.

U±1 (Reel inner width)

Unreeling

direction

S±1 (Reel outer width)

8

Ø380±2

Ø80±1

(Ø13)

160mmMIN

Embossedcarriertape

(Trailer,emptycomponents)

Topcovertape

400mmMIN(Leader)

Unreeling direction

100mmMIN

(emptycomponents)

Note 9 : 3500 pieces shall be packaged in one reel. (For standard products)

Note 10 : The package complies with JIS C 0806 and IEC 60286-3 (Packaging of automotive mounting parts).

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

8

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BTemperature Profile

MAX 250℃

start

25℃60 to 90 sec.

20 to 40 sec.

120±5 sec.

Preheating time Soldering time

Peak temperature

0

50

100

150 150℃

180℃

220℃

200

245

Temperature(℃)

Time(sec.)

Applicable Conditions

Reflow method : IR/Hot air

Reflow environment : Room air

Solder : Paste type Sn/3.0Ag/0.5Cu

(M705-GRN360-K2-V made by Senju

Metal Industry Co.)

Test PCB : PCB material and size

Glass epoxy 45×25×1mm

Land size, per recommended on page 4.

Metal mask : Thickness and opening size

Per recommended on page 4.

This temperature profile is based on the above conditions.

It may vastly depending on solder paste type, manufacturer,

PCB size and mounting materials. Please use only after

checking the mounting conditions.

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

9

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

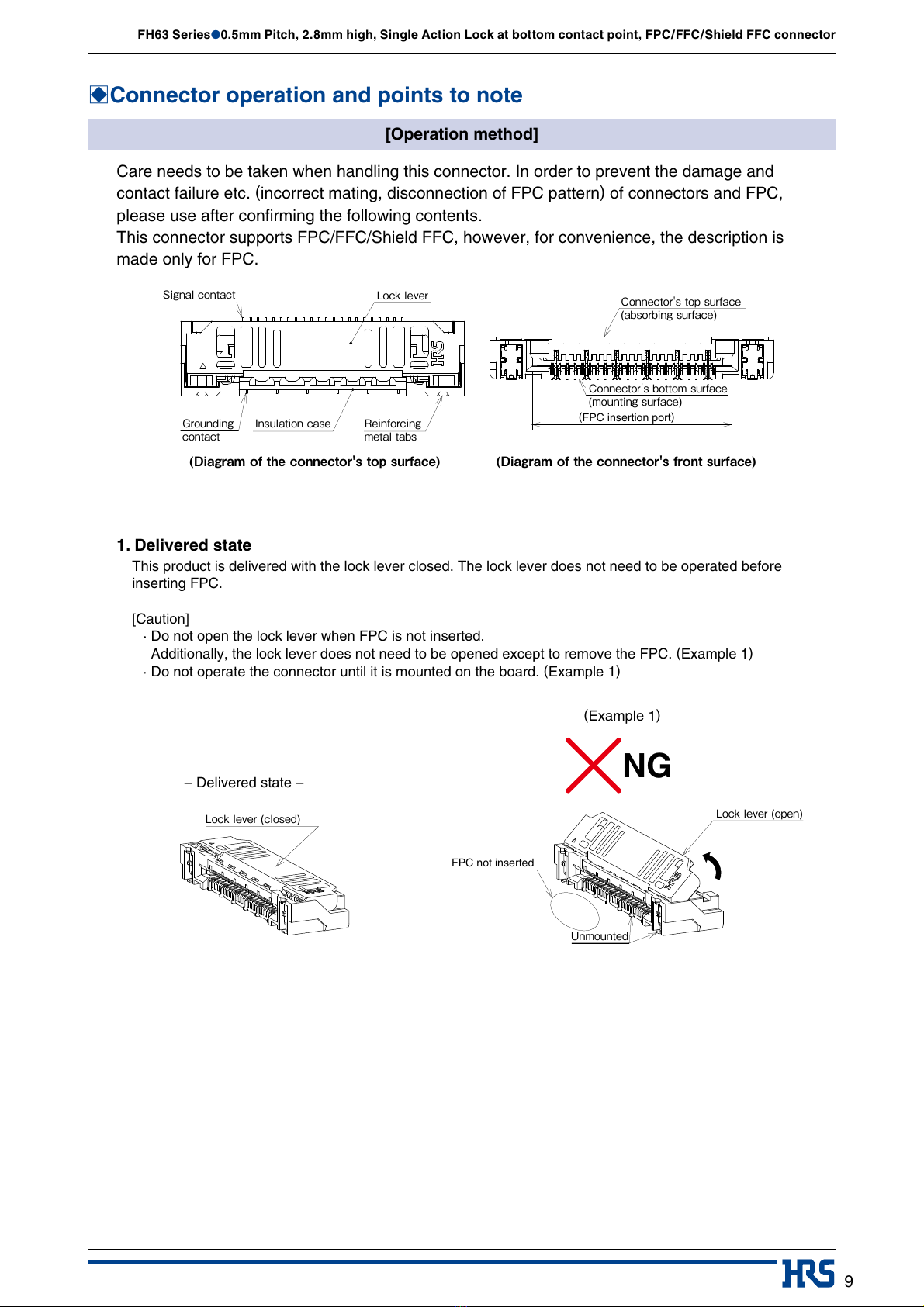

BConnector operation and points to note

[Operation method]

Care needs to be taken when handling this connector. In order to prevent the damage and

contact failure etc. (incorrect mating, disconnection of FPC pattern) of connectors and FPC,

please use after confirming the following contents.

This connector supports FPC/FFC/Shield FFC, however, for convenience, the description is

made only for FPC.

1. Delivered state

This product is delivered with the lock lever closed. The lock lever does not need to be operated before

inserting FPC.

[Caution]

· Do not open the lock lever when FPC is not inserted.

Additionally, the lock lever does not need to be opened except to remove the FPC. (Example 1)

· Do not operate the connector until it is mounted on the board. (Example 1)

(FPC insertion port)

Signalcontact

Grounding

contact

Insulationcase Reinforcing

metaltabs

Locklever Connector'stopsurface

(absorbingsurface)

Connector'sbottomsurface

(mountingsurface)

FPC not inserted

Locklever(closed) Locklever(open)

Unmounted

NG

(Diagramoftheconnector'stopsurface) (Diagramoftheconnector'sfrontsurface)

(Example 1)

– Delivered state –

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

10

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BConnector operation and points to note

[Operation method]

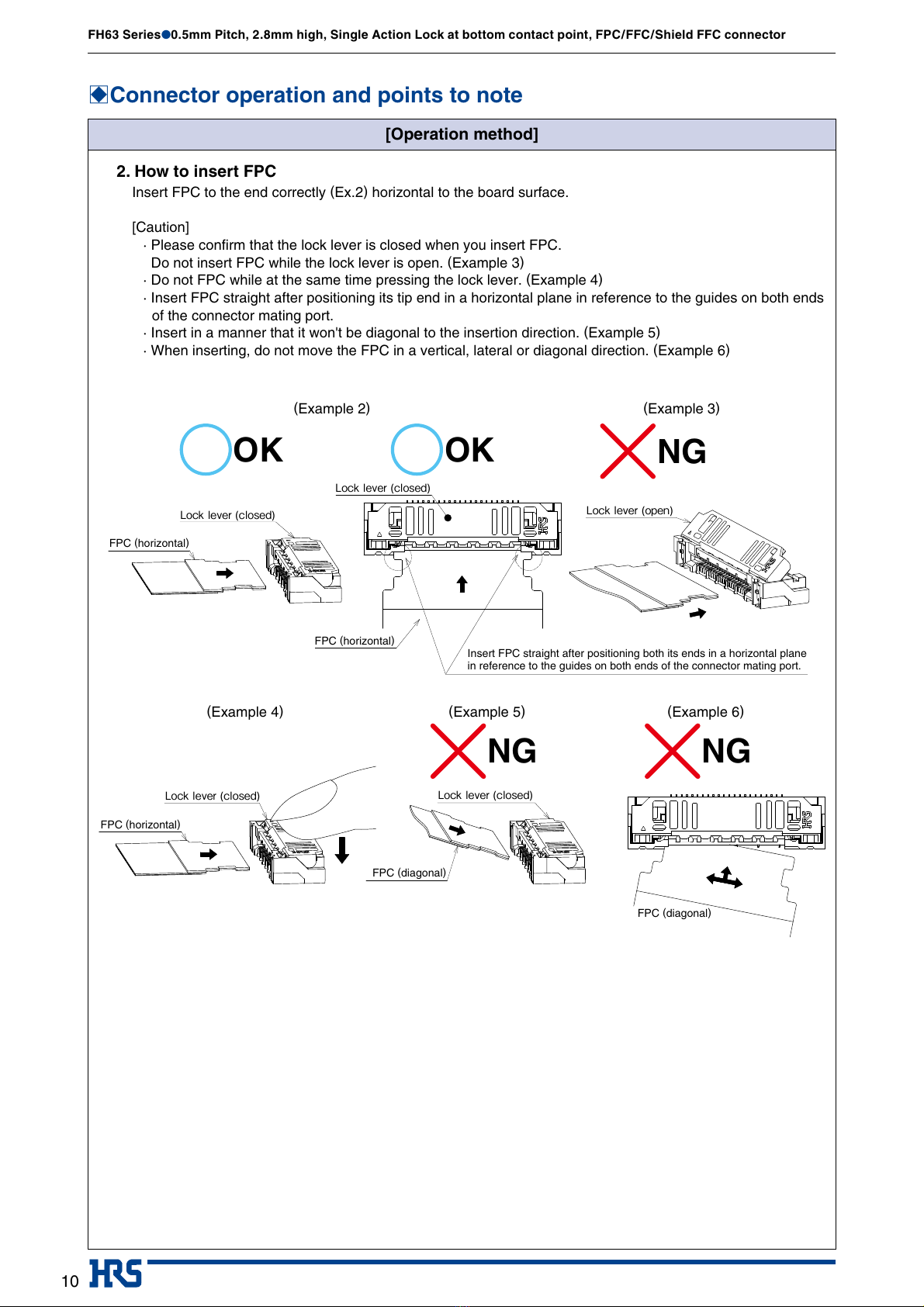

2. How to insert FPC

Insert FPC to the end correctly (Ex.2) horizontal to the board surface.

[Caution]

· Please confirm that the lock lever is closed when you insert FPC.

Do not insert FPC while the lock lever is open. (Example 3)

· Do not FPC while at the same time pressing the lock lever. (Example 4)

· Insert FPC straight after positioning its tip end in a horizontal plane in reference to the guides on both ends

of the connector mating port.

· Insert in a manner that it won't be diagonal to the insertion direction. (Example 5)

· When inserting, do not move the FPC in a vertical, lateral or diagonal direction. (Example 6)

FPC (horizontal)

FPC (horizontal)

Insert FPC straight after positioning both its ends in a horizontal plane

in reference to the guides on both ends of the connector mating port.

Locklever(open)

Locklever(closed)

Locklever(closed)

FPC (horizontal)

FPC (diagonal)

FPC (diagonal)

Locklever(closed) Locklever(closed)

OK OK

NGNG

NG

(Example 2)

(Example 4) (Example 5) (Example 6)

(Example 3)

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

11

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BConnector operation and points to note

[Operation method]

3. Confirming the mated state of FPC

When FPC is completely inserted, visually inspect the inserted status of FPC. (Example 7)

(This connector uses the lock protrusion of the lock lever for positioning FPC.)

[Caution]

· FPC is not inserted deep enough or in a diagonal direction. (Example 8)(Example 9)

· Because of the single action lock, The lever does not need to be operated after inserting FPC.

FPC (shallow) FPC (diagonal)

FPC

FPC is inserted diagonally, and

leaves a large gap between FPC

and the housing.

FPC is not inserted deep enough,

leaving a large gap between FPC

and the housing.

The protrusion of the lock lever

runs over the FPC tab.

The protrusion of the lock lever

runs over the FPC tab.

Outer shape of FPC is

parallel to the outer

shape of the housing.

FPC is inserted diagonally,

and is not inserted to the

back of the mating port.

FPC is not inserted deep

enough down to the back

of the mating port.

The FPC tab inserted to

the back of the mating port

can be visually confirmed.

Case butting position Case butting position Case butting position

NGNG

OK

(Example 7) (Example 8) (Example 9)

– Cross section of the lock section – – Cross section of the lock section – – Cross section of the lock section –

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

12

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BConnector operation and points to note

[Operation method]

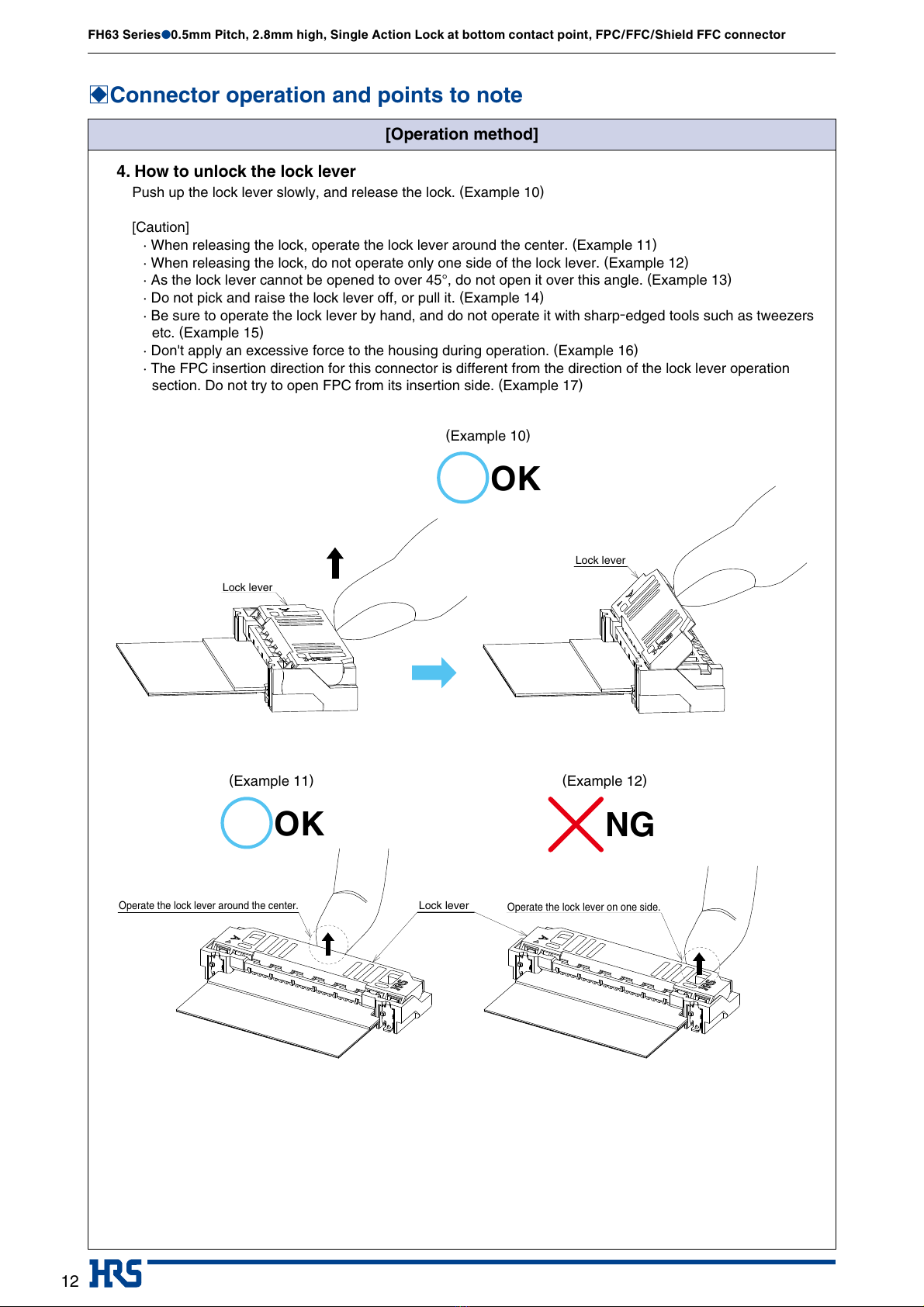

4. How to unlock the lock lever

Push up the lock lever slowly, and release the lock. (Example 10)

[Caution]

· When releasing the lock, operate the lock lever around the center. (Example 11)

· When releasing the lock, do not operate only one side of the lock lever. (Example 12)

· As the lock lever cannot be opened to over 45°, do not open it over this angle. (Example 13)

·Do not pick and raise the lock lever off, or pull it. (Example 14)

· Be sure to operate the lock lever by hand, and do not operate it with sharp-edged tools such as tweezers

etc. (Example 15)

· Don't apply an excessive force to the housing during operation. (Example 16)

· The FPC insertion direction for this connector is different from the direction of the lock lever operation

section. Do not try to open FPC from its insertion side. (Example 17)

Lock lever

Lock lever

Lock lever

Operate the lock lever around the center. Operate the lock lever on one side.

OK

OK

NG

(Example 10)

(Example 11) (Example 12)

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

13

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

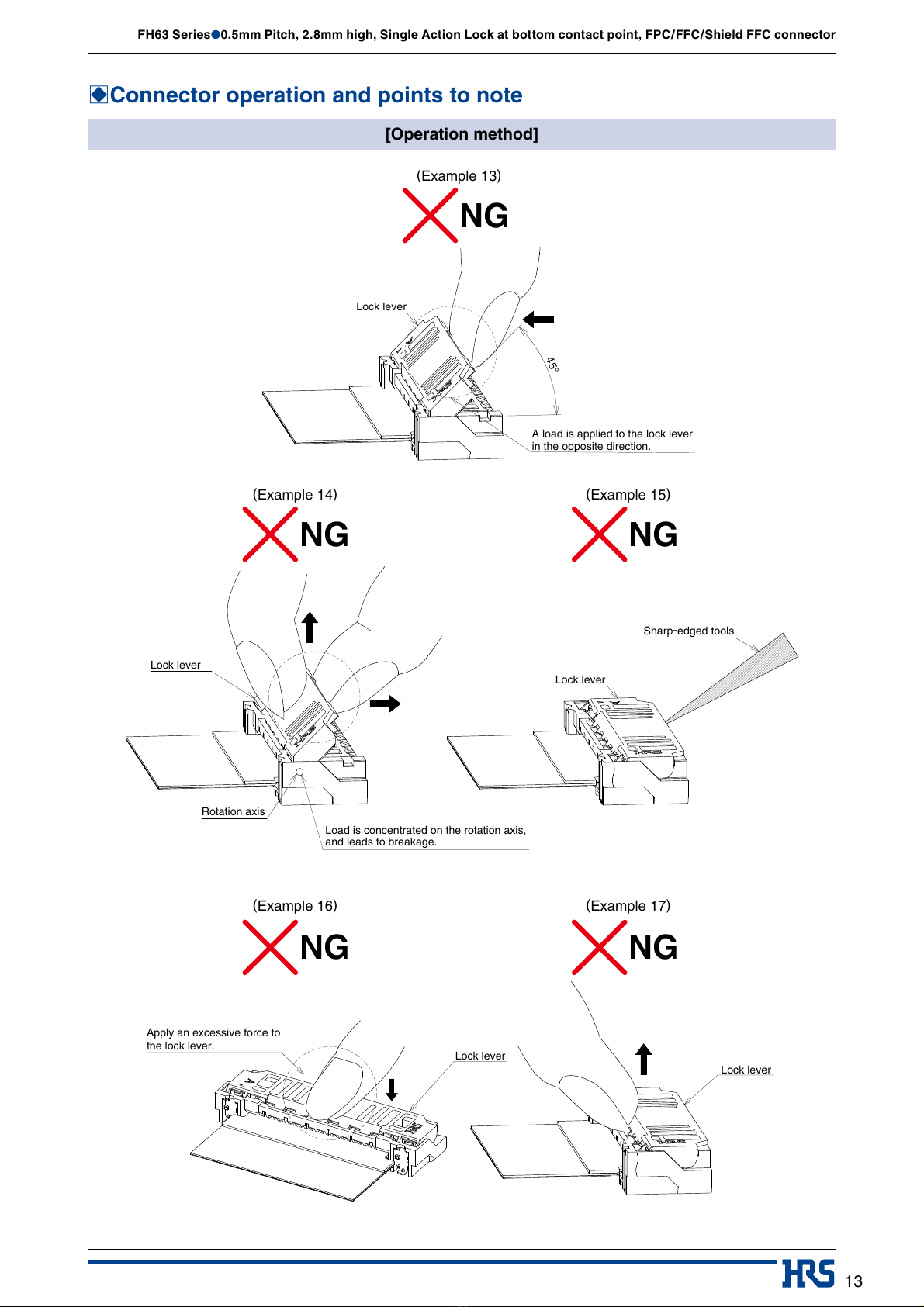

BConnector operation and points to note

[Operation method]

45°

A load is applied to the lock lever

in the opposite direction.

Lock lever

Lock lever

Lock lever

Load is concentrated on the rotation axis,

and leads to breakage.

Rotation axis

Sharp-edged tools

Lock lever

Lock lever

Apply an excessive force to

the lock lever.

NG

NG

NG

NG

NG

(Example 14)

(Example 16)

(Example 15)

(Example 17)

(Example 13)

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

14

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BConnector operation and points to note

[Operation method]

5. How to remove FPC

After releasing the lock lever, remove the FPC in the horizontal direction. (Example 18)

When removing the FPC, do not press the lock lever. (Example 19)

As the released lock lever automatically closes when removing the FPC, the lever does not need to be

operated after removal. (Example 20)

[Caution]

· Do not pull out FPC while the lever is locked. (Example 21)

· This connector is equipped with the FPC retention mechanism by means of the lock lever. When pulling

out FPC, do not apply load in the upward or lateral direction. (Example 22)

Locklever(open)

Locklever(open)

Locklever(closed) Locklever(closed)

Locklever(closed)

FPC (diagonal)

FPC (diagonal)

OK OK NG

NG

NG

NG

(Example 18) (Example 19)

(Example 20)

(Example 22)

(Example 21)

(Example 23)

– Condition after FPC is pulled out –

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

15

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

BConnector operation and points to note

[Operation method]

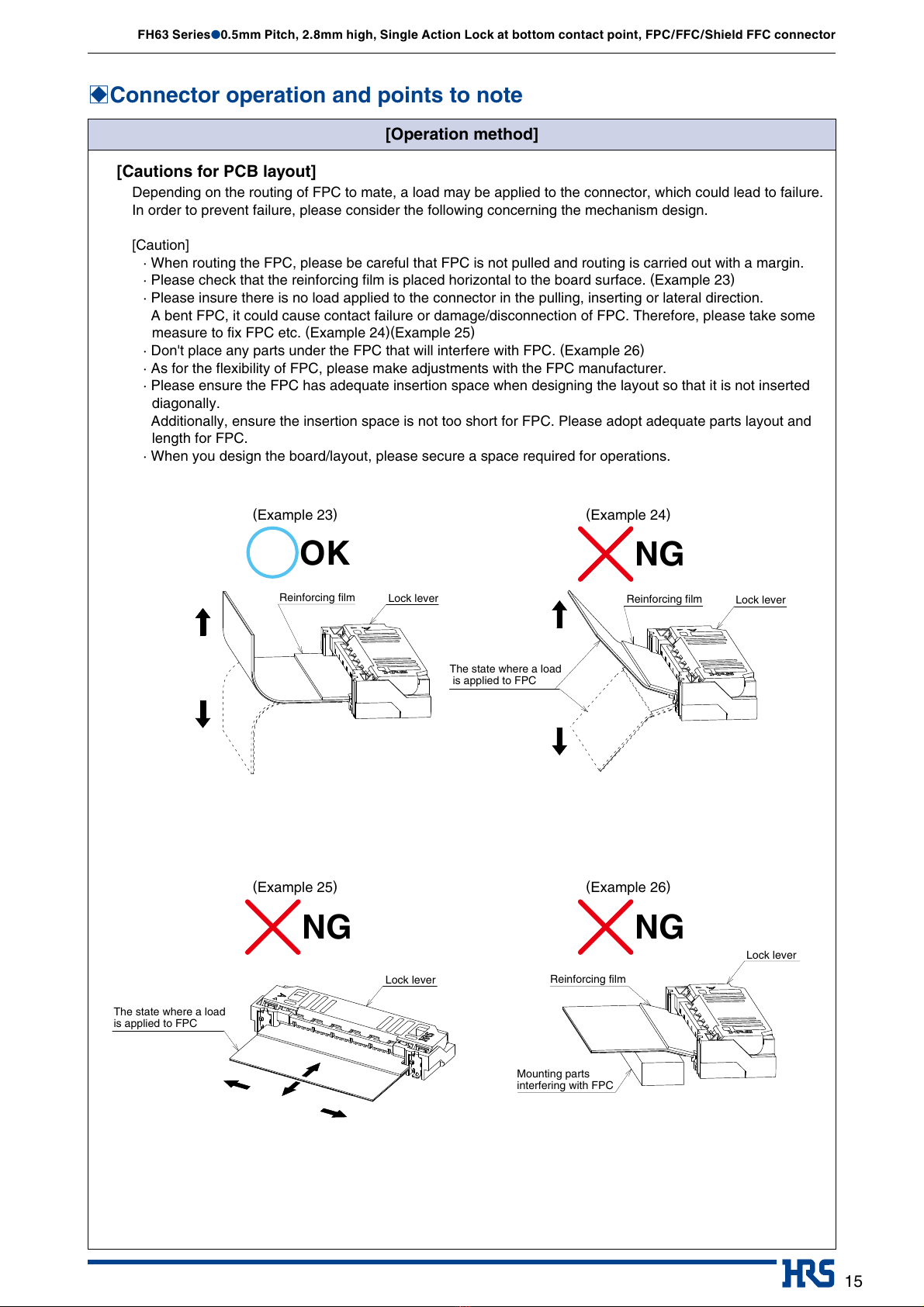

[Cautions for PCB layout]

Depending on the routing of FPC to mate, a load may be applied to the connector, which could lead to failure.

In order to prevent failure, please consider the following concerning the mechanism design.

[Caution]

· When routing the FPC, please be careful that FPC is not pulled and routing is carried out with a margin.

· Please check that the reinforcing film is placed horizontal to the board surface. (Example 23)

· Please insure there is no load applied to the connector in the pulling, inserting or lateral direction.

A bent FPC, it could cause contact failure or damage/disconnection of FPC. Therefore, please take some

measure to fix FPC etc. (Example 24)(Example 25)

· Don't place any parts under the FPC that will interfere with FPC. (Example 26)

· As for the flexibility of FPC, please make adjustments with the FPC manufacturer.

· Please ensure the FPC has adequate insertion space when designing the layout so that it is not inserted

diagonally.

Additionally, ensure the insertion space is not too short for FPC. Please adopt adequate parts layout and

length for FPC.

· When you design the board/layout, please secure a space required for operations.

Lock lever Lock lever

Reinforcing film

Reinforcing film

Reinforcing film

Lock lever

Lock lever

The state where a load

is applied to FPC

The state where a load

is applied to FPC

Mounting parts

interfering with FPC

NGNG

OK NG

(Example 25) (Example 26)

(Example 23) (Example 24)

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

16

FH63 Series●0.5mm Pitch, 2.8mm high, Single Action Lock at bottom contact point, FPC/FFC/Shield FFC connector

The characteristics and the specifications contained herein are for reference purpose. Please refer to the latest customer drawings prior to use.

The contents of this catalog are current as of date of 08/2017. Contents are subject to change without notice for the purpose of improvements.

2-6-3,Nakagawa Chuoh,Tsuzuki-Ku,Yokohama-Shi 224-8540,JAPAN

TEL: +81-45-620-3526 Fax: +81-45-591-3726

http://www.hirose.com

http://www.hirose-connectors.com

®

BConnector operation and points to note

[Notes for mounting on the board/after mounting on the board]

[Notes for mounting on the board]

Please be careful of the following at the time of board mounting.

[Caution]

· Please confirm recommendations for mount board land shape, metal mask opening shape, and FPC

shape.

· If the land is narrower than recommend, or if the metal mask opening is wider than recommend, solder

(flux) wicking is more likely to occur.

If there is difference from the recommendation, please use check the mounted state.

· The level difference between the bottom surfaces of contact lead and the mold is designed to be small.

When there is silk print etc. on the bottom surface of the connector, it could push up the connector bottom

surface, and cause non-sticking solder or defective fillet formation.

When there is silk print etc. on the bottom surface of the connector, please use it after checking the

mounted state.

· Use the reflow conditions within the specifications of our company.

The mounted status may vary due to external conditions such as the type of cream solder, manufacturer,

and board size. Please use it after checking the mounted state.

· Please control the board warpage as much as possible. While the coplanarity of this connector is 0.1mm or

less, defective soldering could occur if the board warpage is considerable.

· When mounted on FPC, be sure to provide a reinforcing plate to ease handling. We recommend a

reinforcing plate of 0.3mm or thicker made of glass epoxy material.

· When pulling out the emboss from the reel, or when the connector is absorbed from the emboss and so on,

do not apply any excessive external force (of 1N or more) to the connector before mounting.

[Cautions when handling the board after mounting]

Please be careful of the following when handling the board after mounting operation.

[Caution]

· Do not apply any load to the board in the assembly process, such as "dividing a multi-piece board" or

"securing the board to the frame".

Such action could apply a load to the connector and damage it.

· Use the board with the deflection being 1mm or less when the board width is 100mm. (Example 27)

If the board has some deflection, it could apply a load to the connector and damage it.

[Cautions for hand-soldering]

Please be careful of the following when hand-soldering for repair work etc.

[Caution]

· Do not hand-solder while FPC is inserted.

· Please be careful not to apply excessive heat, or allow the solder iron to touch any place other than the

connector contact lead.

Such action could cause the connector to be deformed or melted.

· Do not supply an excessive amount of solder (flux).

If too much solder (flux) is supplied to the contact, the solder or flux could adhere on the contact point and

cause contact failure.

Additionally, if you supply too much solder to the reinforcing metal tabs the rotational action of the lock

lever could be defective and the connector could be damaged.

Connector

PCB

Connector

100

100

1 MAX1 MAX

(Example 27)

Mar.1.2018 Copyright 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Powered by TCPDF (www.tcpdf.org)

This manual suits for next models

6

Table of contents

Other Hirose Cables And Connectors manuals

Hirose

Hirose GT16GM Series User manual

Hirose

Hirose BM10 Series User manual

Hirose

Hirose GT43 User manual

Hirose

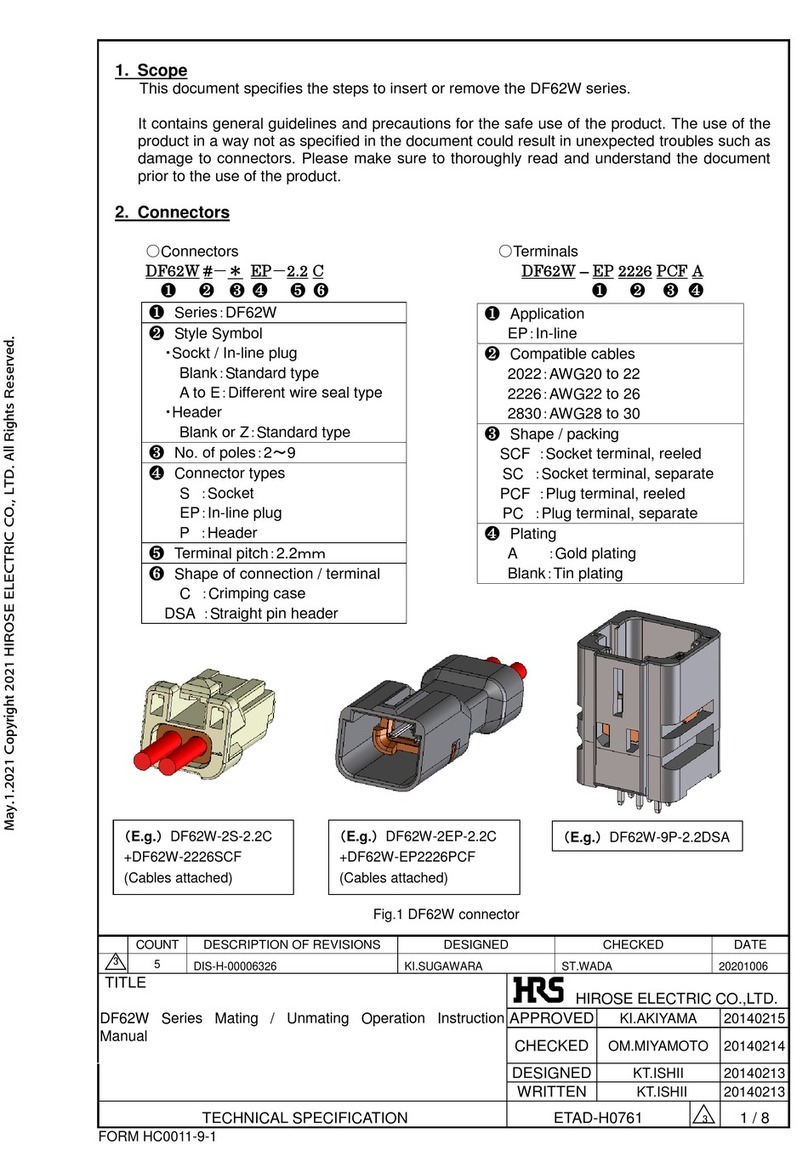

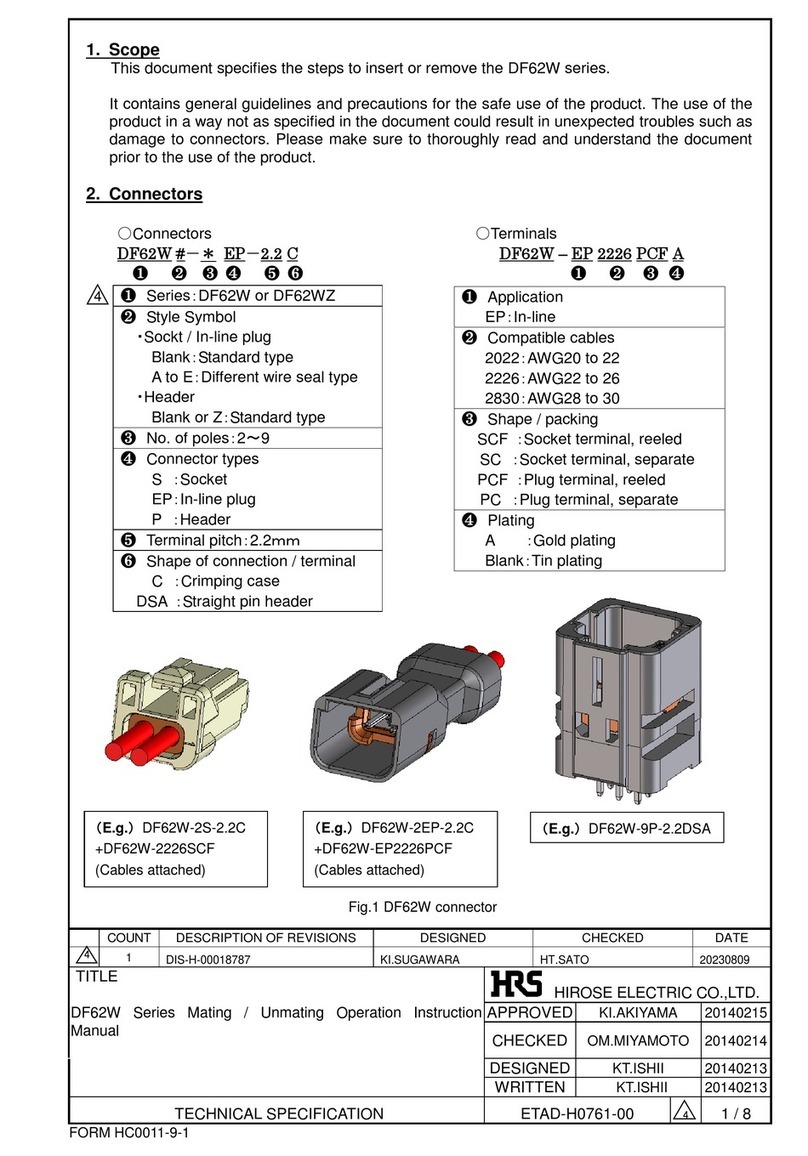

Hirose DF62W Series Manual

Hirose

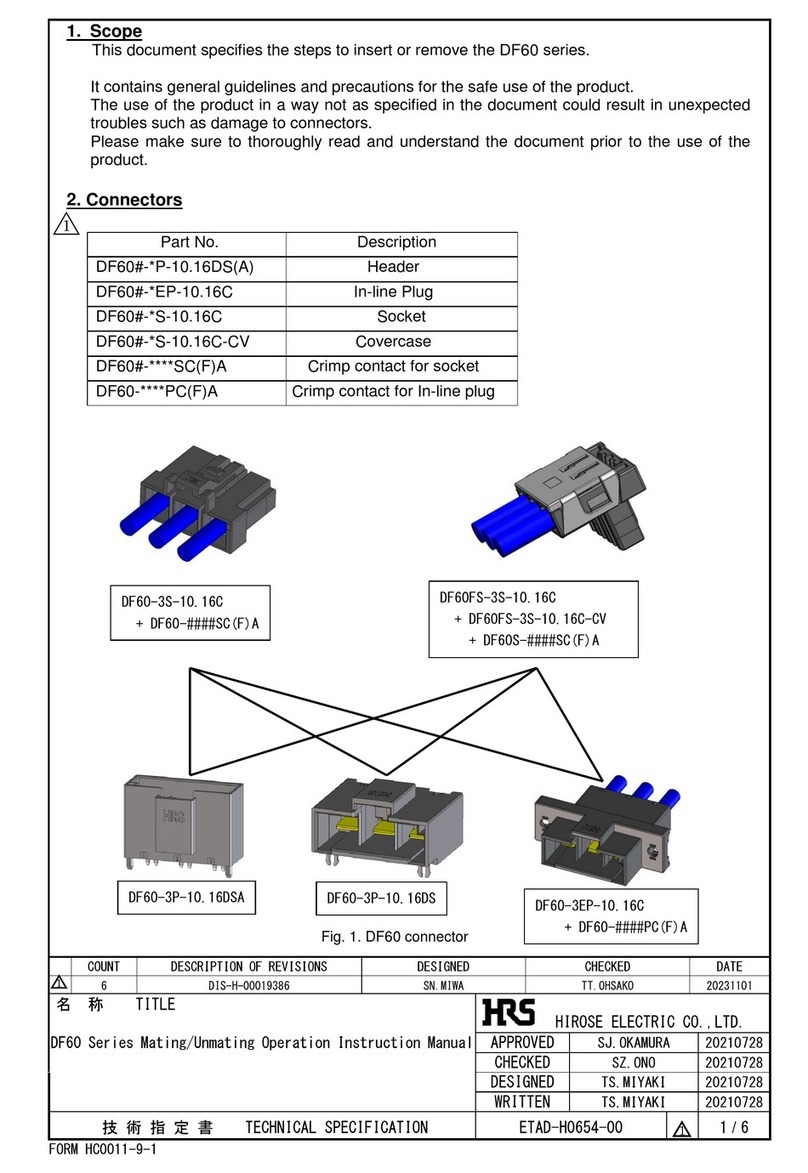

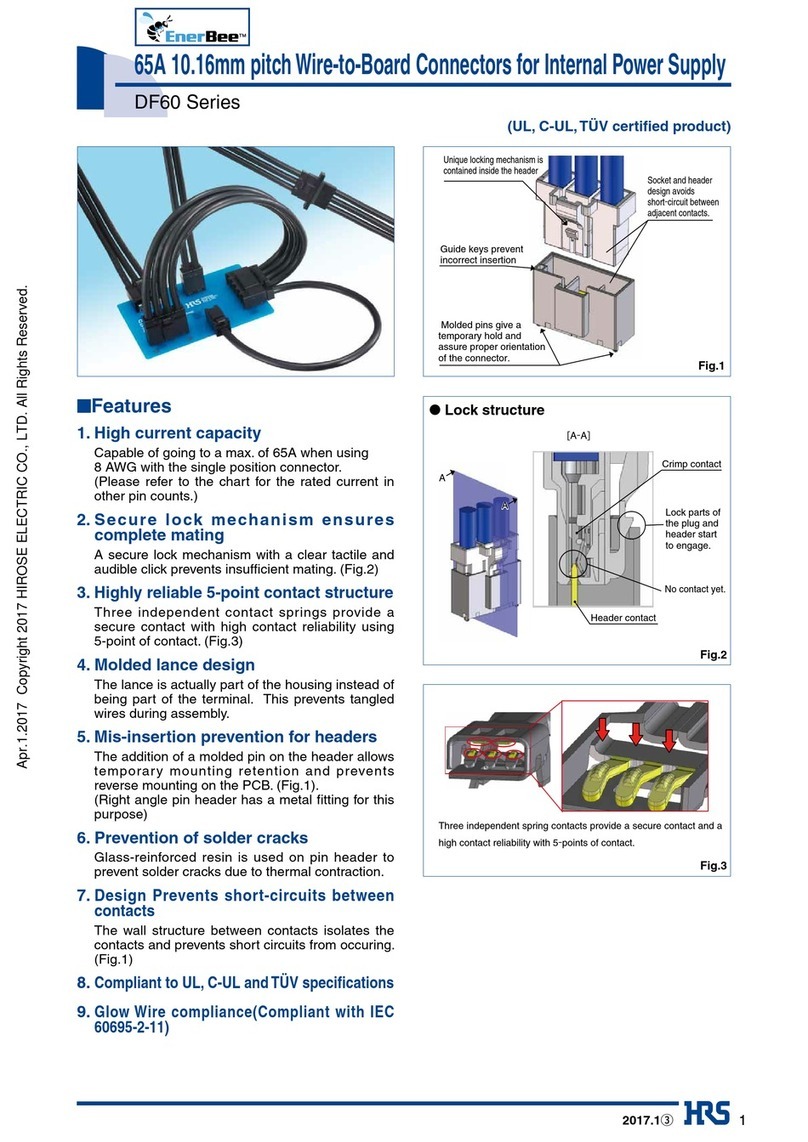

Hirose EnerBee DF60 Series User manual

Hirose

Hirose HIF Series User manual

Hirose

Hirose EnerBee DF60 Series User manual

Hirose

Hirose DF62WZ-6P-2.2DSA(20) User manual

Hirose

Hirose BM56G Series Instruction Manual

Hirose

Hirose GT50 Series User manual