Hirose GT43 User manual

ETAD-P0398 First edition

GT43 Harness

Shielding Plate Assembly

Process

Instruction Manual

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

CAUTION

In order to use the product safely, be sure to read this instruction manual before using

the product. Furthermore, keep this instruction manual in a place where it can be

accessed quickly when needed.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

FORWARD

Thank you very much for purchasing our GT43 harness equipment.

This tool is a jig to assemble shielding plate to the external cylinder terminal of the harness product.

Be sure to read this instruction manual carefully and fully understand itscontents before using the product.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

i

FOR SAFE OPERATION

Because of the machine's design, there is always a possibility of contact with moving parts.The operators

of the machine and the maintenance personnel who are in charge of maintenance and repair work are

required to read the following SAFETY INSTRUCTIONS so as to avoid injury.

To fully understand the descriptions given in this Instruction Manual and the warning labels attached on

the machine, the warning messages are used in accordance with the below-stated classification. Please

be sure to thoroughly understand the messages and follow the instructions.

( I ) Description of warning messages

DANGER :

Used in the case where it is assumed that misuse of the machine will expose the operator

to immediate danger of major injury or death.

WARNING :

Used in the case where it is assumed that misuse of the machine can expose the operator

to danger of major injury or death.

CAUTION :

Used in the case where it is assumed that misuse of the machine can expose the operator

to danger of injury and can cause damage to property.

* Determine the degree of impairment referring to the below-stated classification.

Major injury

:

Indicates the loss of eyesight, wounds, burns (hyperthermal and hypothermal

burns), electric shocks, fracture of a bone, poisoning, etc. requiring emergency

of extended medical care.

Minor injury

:

Indicates wounds, burns, electric shocks, etc. requiring medical treatment.

Property damage

:

Indicates damage to the machinery and or the surrounding area.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

ii

PRECAUTIONS FOR SAFETY

CAUTION

Basic safety instructions

1. Be sure to read this Instruction Manual and any other instructions or materials supplied with

the unit as accessories. Keep this Instruction Manual and make it available for reference.

Safety device and warning labels

1. To avoid possible accidents due to lack of the safety device, be sure to operate the machine

after ascertaining that the safety device is properly installed at the predetermined position.

Refer to page viii for detailed description of the safety device.

2. If the safety device is detached from the machine for any reason, replace it to its original

position and check to be sure that it normally functions.

Application

1. This machine shall only be used as specified in this Instruction Manual.

2. Modifications to this machine is prohibited. We assume no responsibility for accidents

resulting from modifications.

Operating environment

1. To avoid accidents caused by malfunction, the machine shall be operated under an

environment that is not affected by high noise sources (electromagnetic waves) such as high-

frequency welders.

2. To avoid accidents caused by malfunction, the machine shall not be used in such an

environment that would subject it to any voltage rating outside of "rated voltage ±10%".

3. The machine shall be used under the following environment for safety.

Atmospheric temperature under operating conditions : 5°C to 35°C

Relative humidity under operating conditions : 35% to 85 %

4. Condensation can be observed when the environment of the machine is changed abruptly

from cold to warm. To avoid accidents or damage, do not operate this machine in condition

where the humidity is greater than the upper limit of the relative humidity specified above.

5. To avoid accidents caused by a damaged electrical part function, in the event of thunder and

lightning, stop your work and pull out the power plug.

Training

1. To prevent possible accidents caused by unfamiliarity with the operation of the machine, the

machine should only be operated by fully trained personnel. Itis recommended that a training

procedure be established by the employer and that the operator be provided with this

Instruction Manual for reference.

Working wear

1. To protect against possible accidents resulting in personal injury or damage to personal

property (i.e., clothing), be sure wear a work uniform or fit clothing with sleeve cuffs fastened.

2. The operator should secure their hair with a hat or ponytail to protect his/her hair from being

caught in the machine.

3. The operator should wear safe, rubber bottom, close toe shoes or work boots.

Event that requires turn-off of the power.

1. In the eventof abnormalconditions, machine failure or power failure, the powershould be turned

off immediately.

2. To protect against possible accidents caused by abrupt start of the machine, the power must be

turned off before conducting inspection, repair, or cleaning. Be sure to turn the power off when

the operator leaves the machine.

3. To pull out the power plug, hold the plug rather than the cord..

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

iii

Safety instructions in each category of work following

the delivery of the machine

Transportation

1. In order to avoid damage accident, this machine must be held by two or more people. Use a

wheeled platform when moving the machine.

2. The machine shall be lifted or moved in such a way that secures safety to avoid falling and

dropping.

3. To protect against accidents or damage to the machine re-package, if necessary, to achieve

the originally-delivered state. Prior to re-packaging, wipe off an oil gathered on the machine.

Unpacking

1. The product is packaged in a cardboard box. When unpacking, be careful not to drop the

machine, and take the machine out of the box carefully.

Installation

(1)Workbench

1. Use a table or a work bench that will sufficiently withstand the machine weight and the

reaction force developed while the machine is in operation.

2. If casters are to be mounted on the main unit of the work bench, use durable casters

provided with a locking mechanism.

(2)Cable and wiring

1. To prevent electric shocks, electrical leak or fire, be careful not to strain the cables at any

time.

2. To protect against hazards from electric shocks, electrical leak and fire, multiple

connection must be avoided. Plug the machine direct into a socket.

3. In order to avoid electric shock, electric leakage or fire, make sure that connectors are

firmly connected. Furthermore, when unplugging the connector, be sure to hold and pull

the connector.

(3)Grounding

1. In order to avoid electric leakage and accident due to dielectric strength voltage, have a

person with professional knowledge in electric install an appropriate power plug.

Before operation

1. To protect against possible accidents resulting in injury or death, check to be sure that

connectors and cables are in good condition and fastened securely.

2. To protect against possible accidents resulting in injury or death, never place hands in or

near moving parts of the machine.

Maintenance

1. To prevent possible accidents, repair and adjustment of the machine shall be conducted only

by maintenance personnel who have been trained on the machine. Any repair and

adjustment not specified in this Instruction Manual are prohibited. We assume no

responsibilityfor accidents caused by improper repair or adjustment including the use of non-

genuine part(s).

2. In order to avoid accidents due to unfamiliarity with the machine or accident due to electric

shock, repair or maintenance (including wiring) related to electric parts shall be undertaken

by a person who has professional knowledge in electric. Or, send a request for

repair/maintenance to us or to the dealer near you.

3. To protect against personal injury, check to be sure that screws and nuts are tightened after

the completion of repair/adjusting and/or replacement of parts.

4. Periodically clean the machine as long as it is commissioned. To prevent possible accidents

caused by an abrupt start of the machine during cleaning, be sure to turn the power off

including unplugging it, before beginning cleaning.

5. In the event that your machine fails to perform normally after repair/adjusting works,

immediately stop operation. Contact Hirose for service to protect against personal injury.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

iv

SAFETY INSTRUCTIONS TO BE FOLLOWED WHEN USING THE

TOOLS FOR GT43 SHIELDING PLATE ASSEMBLY

DANGER

1. To protect against shock hazards, open the cover, if necessary, after turning

the power off and waiting for a minimum of five minutes.

CAUTION

1. To avoid possible accidents resulting in personal injury caused by being

caught in the moving parts of the machine, extreme caution has to be taken to

keep your hands, fingers, clothing, head or hair away from the moving parts

and surrounding area. Also, do not place any matter that is not necessary in

the use of the machine near any of the moving parts.

2. To protect against possible personal injury, when turning the power on, take

care to keep your hands, fingers, clothing, head or hair away from the moving

parts and the surrounding area. Also, do not place any matter that is not

necessary in the use of the machine near any of the moving parts.

3. To protect against electric shock and accidents caused by any damaged

electrical component, be sure to turn off the power switch before connecting

or detaching the power plug.

4. To protect against possible accidents caused by any damaged electrical

component,be sureto stop yourwork and disconnectthe powerplug for safety

purposes in the case of thunder and lightning.

5. In the case where the machine is suddenly moved from a cold to warm

weather conditions condensation can result. To protect against possible

accidents due to any damaged electrical component, turn the power on only

after making sure that no condensation is present.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

v

CONTENTS

1. MODELAND SPECIFICATIONS ........................................................................................................... 1

1-1. Model........................................................................................................................................... 1

1-2. Specifications............................................................................................................................... 1

2. NAME OF EACH PART.......................................................................................................................... 2

3. INSTALLATION ...................................................................................................................................... 3

3-1. Cable connection, air tube connection, power connection.......................................................... 3

4. OPERATING PROCEDURE.................................................................................................................. 5

4-1. Pre-working preparation.............................................................................................................. 5

4-2. Working method........................................................................................................................... 6

4-3. Ending work................................................................................................................................. 7

5. CONFIRMATION OF THE QUALITY..................................................................................................... 7

5-1 Checking the shielding plate assembly dimensions..................................................................... 7

5-2. Checking the dimension of the shielding plate assembly position.............................................. 7

5-3. Checking the shielding plate cut off tab dimension..................................................................... 8

5-4. Appearance Inspection................................................................................................................ 8

6. SETTING METHOD AND OPERATIONAL FLOW................................................................................. 8

7. ADJUSTMENT AND SUPPLEMENTAL SPECIFICATIONS................................................................ 10

7-1. Adjustment of various speed controllers.................................................................................... 10

7-2.Adjustment of cable clamp transfer amount...............................................................................11

7-3. Control box default state............................................................................................................ 12

7-4. Control box IN-OUT table.......................................................................................................... 14

7-5. How to adjust air pressure sensor............................................................................................. 16

7-6.Adjusting the shielding plate assembly height........................................................................... 17

8. MAINTENANCE................................................................................................................................... 18

8-1. Daily maintenance..................................................................................................................... 18

8-2. Replacement of expendable parts............................................................................................. 18

8-3. List of expendable parts ............................................................................................................ 22

8-4. List of maintenance parts .......................................................................................................... 22

9. TROUBLESHOOTING......................................................................................................................... 23

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

1

1. MODEL AND SPECIFICATIONS

1-1. Model

Product serial number

HRS No.

1

GT43-1PS-CSB/CRAD (shielding plate assembly jig)

CL 902-5156-0

2

WGT43-SHIELD/CRAD (shielding plate cable transfer 1

set)

CL 902-5157-0

* Dedicated reel stand is not provided with this equipment.

In case a reel stand is required, the user is expected to provide one.

1-2. Specifications

Item

Specifications

Compatible connector

GT43-1P/S-CSB/753-1005-0-00

Compatible cable

Cable external diameter: φ3.0

Fabricated minimum cable length

MIN 400 mm

①GT43-1PS-CSB/CRAD

(Shielding plate assembly jig)

It is an air driven assembly jig. When the start SW is turned ON,

1 cycle operation is performed.

Equipment capacity

Assemble shielding plate to the external cylinder terminal.

Production capacity: 12 sec/piece (including assembly

fabrication time)

* It may vary depending on the skill level.

External dimension/weight (main body)

350 (W) x 300 (D) x 350 (H) mm/approximately 25 kg

External dimensions/weight

(control box)

160 (W) x 250 (D) x 70 (H) mm/approximately 1.5 kg

Power supply

AC100V (50/60 Hz)

Consumed power

Approximately 30 W

Air pressure setting range

0.5 - 0.6 MPa

②WGT43-SHIELD/CRAD

(Shielding plate cable transfer 1 set)

Transfer cable to shielding plate assembly position.

Equipment capacity

Move the cable clamp to its home position.

Production capacity: 12 sec/piece (including assembly

fabrication time)

* It may vary depending on the skill level.

External dimension/weight (main body)

300 (W) x 300 (D) x 300 (H) mm/approximately 23 kg

External dimensions/weight

(control box)

160 (W) x 250 (D) x 70 (H) mm/approximately 1.5 kg

External dimensions/weight (electric

wiring section)

100 (W) x 1150 (D) x 300 (H) mm/approximately 1.5 kg

Power supply

AC 100 V (50/60 Hz)

Consumed power

Approximately 30 W

Air pressure setting range

0.5 - 0.6 MPa

Presence/absence of environmental

load substance

Absence

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

2

2. NAME OF EACH PART

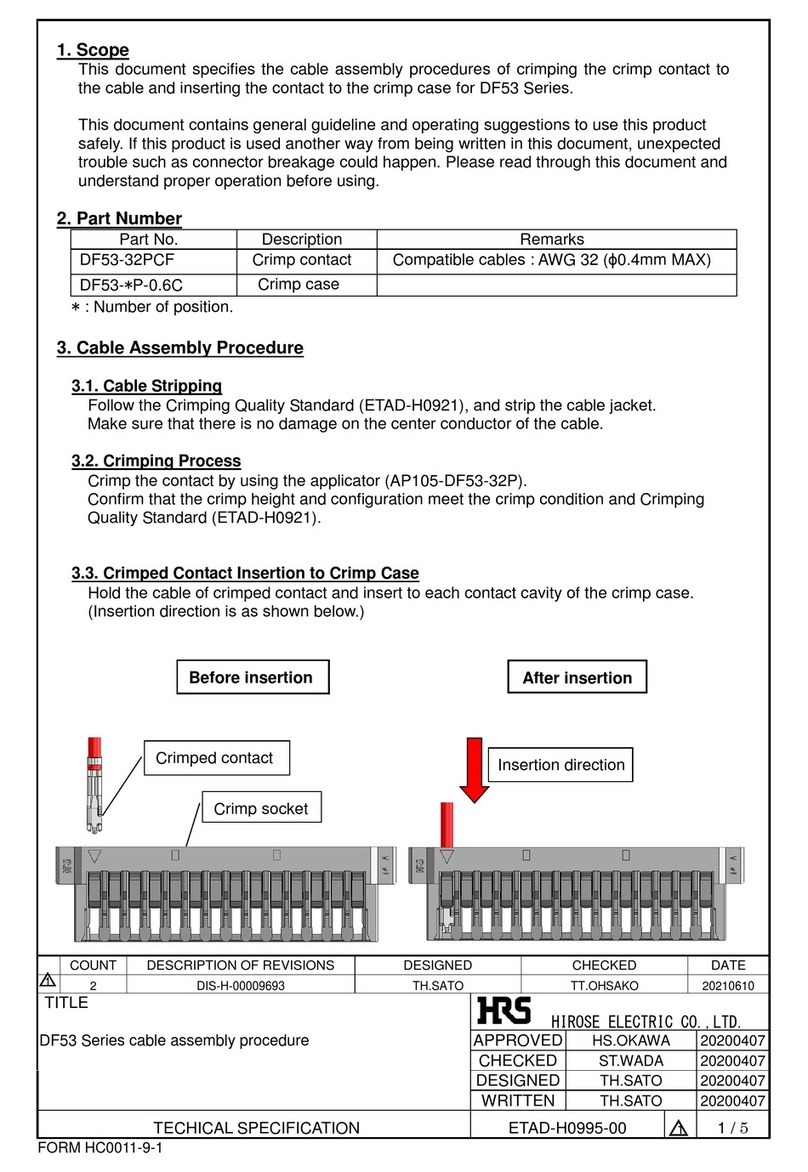

①GT43-1PS-CSB/CRAD (shielding plate assembly jig)

This jig consists of the jig main body and the control box.

②WGT43-SHIELD/CRAD (shielding plate cable transfer 1 set)

This jig consists of the jig main body, the control box and the start switch.

Terminal guide

Air pressure sensor

Control box

Hirose genuine: shielding

plate assembly jig

Start SW

Cable clamp transfer section

Cable clamp set section

Terminal feeder

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

3

3. INSTALLATION

CAUTION

As this product is heavy, handle bytwo people and take sufficient safetymeasures

so that falling or dropping of the machine can be avoided during installation.

■Precaution for installation

Place the cable strip process equipment and the control box on a flat surfaced workbench which can

withstand heavy weight.

CAUTION: Do not install the machine in a place as described below.

(1) A place under direct sunlight.

(2) A dusty place.

(3) A place where temperature or humidity changes drastically.

(4) A place near a fire.

(5) A place near a volatile substance.

(6) A vibrating place.

(7) A place where the machine may get wet.

■Installation area (including working/maintenance area): 2 m x 2 m

CAUTION

In order to avoid accidents due to sudden unexpected start of the machine, start

working after turning the power OFF.

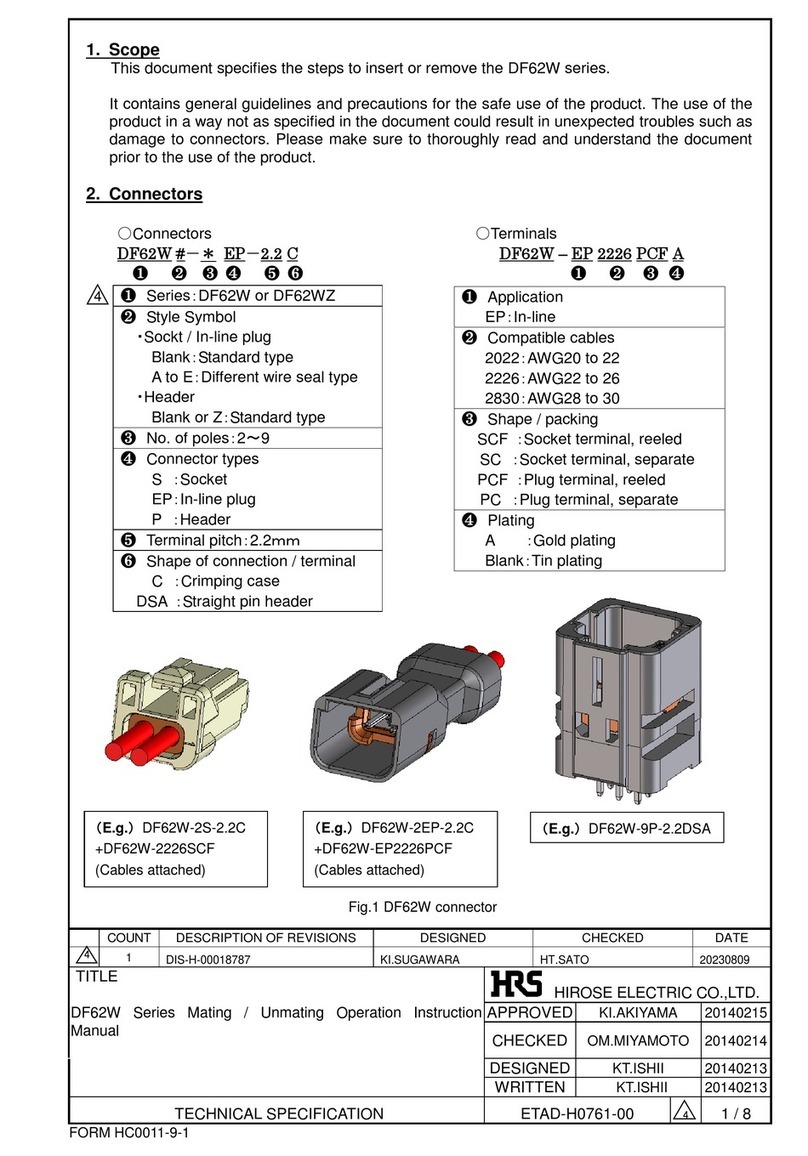

3-1. Cable connection, air tube connection, power connection

①Connect 2 rectangular connectors

of the control box for the shielding

plate assembly jig to the shielding

plate assembly jig.

②Connect the metal connector

connected to the electrical

component plate to the shielding

plate assembly jig and the control

box for the shielding plate

assembly jig.

③Connect the receptacle of the

control box for the shielding plate

assembly jig to 100 V power

supply.

Control box

(With a label for

conforming equipment)

Connection of rectangular

connector (small)

Connection of rectangular

connector (large)

Connection of metal

connector

(Connect with the electrical

component plate.)

Not used

Electrical

component plate

Control box

rear face

Shielding plate assembly

jig main body

rear face

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

4

④Connect 2 rectangular connectors

of the control box for shielding plate

cable transfer 1 set and round

shaped connector of the red box to

the electrical component plate.

⑤Connect the receptacle of the

control box for the shielding plate

cable transfer 1 set to 100 V power

supply.

* 100 V service power supply is

provided on the rear face of the

control box.

⑥Connect the start SW to the rear

face of the control box for shielding

plate cable transfer 1 set.

⑦Supply air to the regulator of the

electrical component plate and the

shielding plate assembly jig main

body.

⑧Open both finger valves and verify

that the indication of each pressure

gauge is 0.5 MPa - 0.6 MPa.

* Whenelectricalcomponentplateis

not used, close the valve so that

the air pressure will be zero.

Connect to the control box for the shielding plate

cable transfer 1 set.

Connection of rectangular

connector (small)

Connection of rectangular

connector (large)

Connection of round

shaped connector

Details of electrical

component plate connection

Red box

Control box

(With a label for

conforming equipment)

Electrical

component plate

Start SW

Electrical

component plate

Regulator

Finger valve

Air connection

Pressure gauge

Air connection

Shielding plate

assembly jig

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

5

4. OPERATING PROCEDURE

4-1. Pre-working preparation

CAUTION

In order to avoid accidents due to sudden unexpected start of the machine, turn

OFF the power of the jig main body before starting the work.

Before starting to work, check air pressure, and make sure that there is no missing connector

connection.

①Lift up the knob lever, rotate it to make a

gap, then insert the shielding plate.

* By rotating the knob, the pin will be lifted

up, and the lever can be fixed in the

raised state.

②Lift up the pin and let the shielding plate

pass through, and then set the shielding

plate as is straight above the fabrication

section (assembly section).

The guideline for the setting position is

the position that the 3rd shielding plate is

inserted half way after the first shielding

plate has been inserted into the jig.

③Lower the feed pin, and make sure that

the pin is set inside the carrier hole of the

shielding plate.

④Rotate the knob lever, and then lower it

down.

Put the shielding

plate through

Knob lever

Lever detail

Put the shielding

plate through

Lift up

feed pin

Fixed in the state that the

3rd piece is half in.

Knob lever spring

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

6

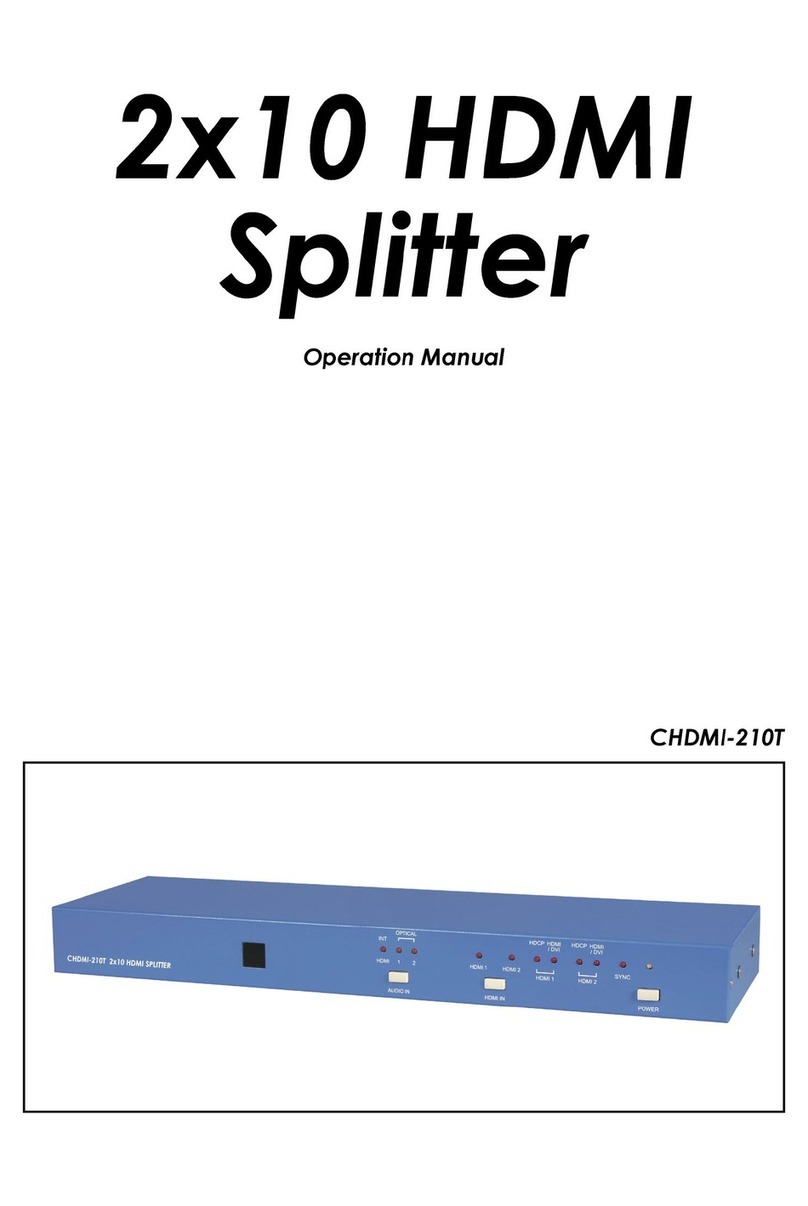

⑤Set the monitor select switch of the

control box for the shielding plate

assembly jig to “9”.

⑥Set the dial of the Vol.2 rotary switch of

the control box for the shielding plate

assembly jig to “F”.

⑦Press the yellow reset button.

(This operation makes the machine to be

in “shielding plate existing” mode, and the

operation is enabled.

⑧Verify that IN 1 - 4 lamps on the control

box of the shielding plate assembly jig are

lit.

⑨Set the dial of the Vol.2 rotary switch of

the control box for the shielding plate

assembly jig to “0”.

(This state means preparation is

complete.)

* If “F”+ reset is not selected, 4 times blank

feed will take place. Blank feed will result

in the shielding plate loss, and there is a

possibility that the carrier cut section will

cause a trouble.

4-2. Working method

WARNING

Be careful not to have your hand, finger, hair or clothes get caught in the moving

section of the machine.

Prepare a cable completed in the external cylinder terminal crimping process (cable is set to the cable

clamp).

Do the work according to the following procedure.

①Turn ON the power of the 2 control boxes.

②Open the finger valve of the shielding plate

assembly jig main body of the electrical

component plate, and supply air.

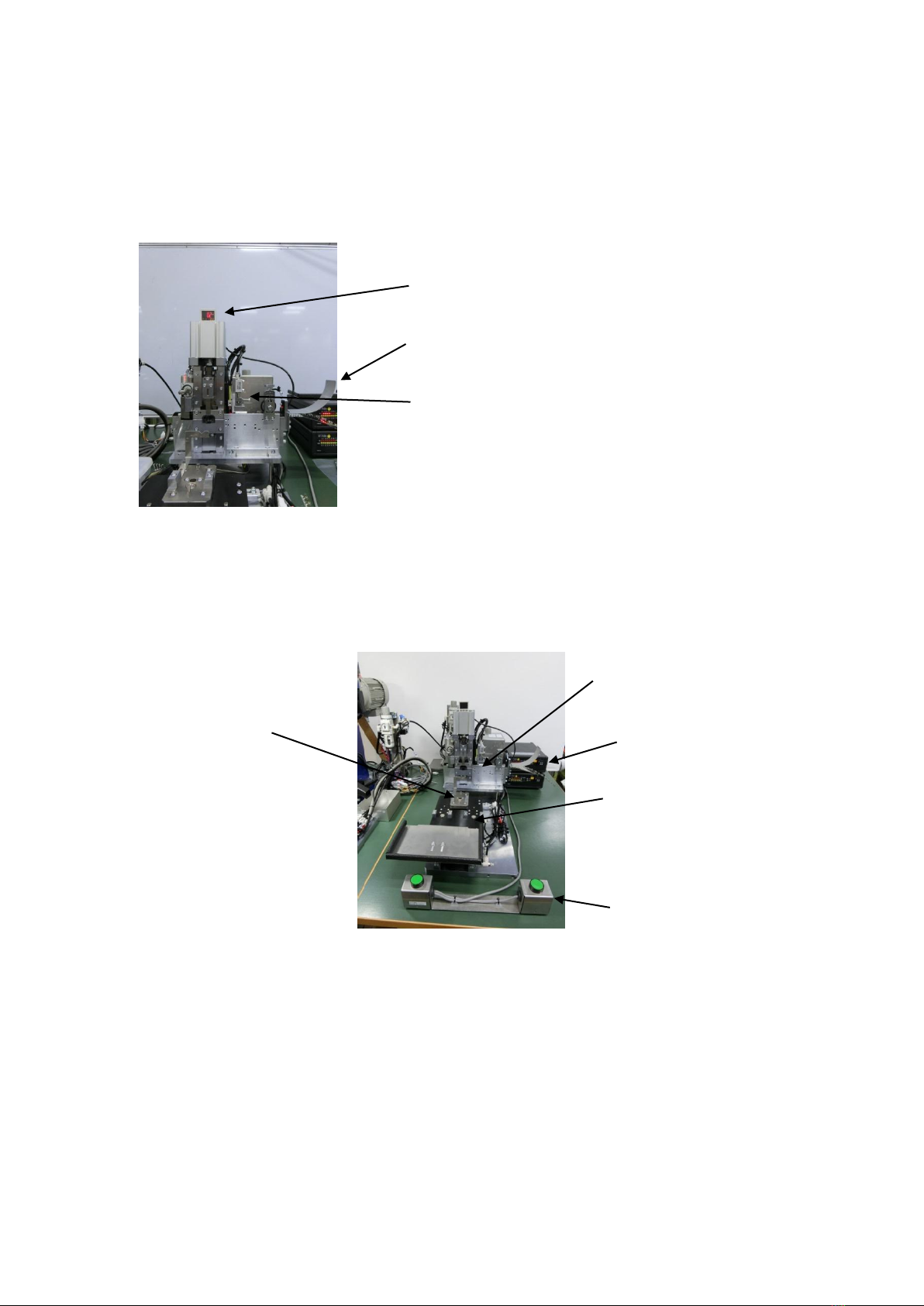

③Set the cable clamp (external cylinder crimping

completed product) to the base of the cable clamp

set section.

Note: Because the proximity sensor, which detects that

the cable clamp is properly set, is incorporated in

thebase section,thejigwillnotoperateif thecable

clamp is not properly set.

⑤ Set the monitor select switch to “9”.

⑥Set VOL2 rotary switch to “F”.

⑦Push the reset button.

⑨ Set to “0”.

⑧Make sure that the lamp is ON.

OK

NG

Not firmly seated.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

7

④Press the start SW.

The shielding plate table advances and moves the

external cylinder terminal crimped product to the

home position at the shielding plate assembly

section.

Next, the shielding plate assembly jig will operate.

⑤After completion of 1 cycle, remove the cable

clamp, which completes the work.

* In case the operation is stopped by the reset button due to incorrect crimping, press the Reset button.

By pressing the Reset button, origin point return will take place.

After pressing the Reset button, dispose the defective parts in the red box.

The design is made in a way that the equipment will not operate unless the transmission sensor in the

red box is made to respond once after resetting.

4-3. Ending work

①Turn OFF the power of the 2 control boxes.

②Close the finger valve.

③Remove the waste in the shielding plate carrier cut waste receiving box.

5. CONFIRMATION OF THE QUALITY

Check each item.

Refer to the latest GT43 terminal instruction manual for the details.

5-1 Checking the shielding plate assembly dimensions

Wide and height

After completion of the shielding plate assembly

work, verify the dimensions (shape) of the 2

locations as shown in the illustration on the left

using a toolmaker’s microscope or the like.

Location

Dimension

S

Wide

5 ±0.1

X2

Height

2.855 ±0.075

P,Q<X2

How bending is

made

Visually check

inside.

5-2. Checking the dimension of the shielding plate assembly

position

Assembly position

After completion of the shielding plate assembly

work, verify the dimension of 1 location as shown

in the illustration on the left using a toolmaker’s

microscope or the like.

Location

Reference value

M

0.1 ±0.1

* Reference value is shown for M.

There is no problem if there is no interference

between the shielding plate plastic section and the

terminal plastic section and if a gap can be

observed.

(NG in case the above cannot be satisfied.)

Cross section XX (case 1)

Cross section XX (case 2)

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

8

• Make sure that the crimping barrel of the

shielding plate is covering the outer periphery of

male and female terminals.

• NG if the mating joints of the barrel is misaligned

for half of the barrel width or more or if the left and

right barrels are not contacting the terminal.

5-3. Checking the shielding plate cut off tab dimension

Cut off tab

Location

Reference value

N

Within 0.3

5-4. Appearance Inspection

Control the cut made during the crimping work to be within the level not affecting the connection

performance.

In case a cut affecting the connection performance is made, replace the crimper or the anvil etc. as

necessary.

6. SETTING METHOD AND OPERATIONAL FLOW

Setting to the operational modes below can be made by turning the dial of VOL.2 using a micro-driver or

the like.

When shipped out of the factory, dial setting is made to zero (line/auto).

Shielding plate assembly jig

VOL.2 dial

Specifications

Operational

mode

Operational details

0

Line

Auto

When the start switch is pressed,

operation will be made for 1 cycle.

1

Line

Step

Each time the start switch is pressed,

the motion will change in the order of

slide advance ⇒shielding plate

operate ⇒slide return.

2

Stand-alone

Auto

When the start switch is pressed, slide

only will operate for 1 cycle.

3

Stand-alone

Step

When the start switch is pressed, the

slide will advance, and when the start

switch is pressed again, the slide will

return.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

9

Shielding plate cable transfer 1 set

VOL.2 dial

Specifications

Operational

mode

Operational details

0

Line

Auto

When the start switch is pressed, slide

only will operate for 1 cycle.

1

Line

Step

When the start switch is pressed, the

slide will advance, and when the start

switch is pressed again, the slide will

return.

F

–

–

* Initial position setting

* Refer to the initial position setting method for the jig at the time of newly inserting the shielding plate

as described in section 4-1 of this instruction manual.

Operational flow diagram

Seated sensor

Start SW

Pallet advance

Front edge sensor

Pallet descend

Crimping jig operation

Internal timer

Vol.1

Numeral x 0.1sec

In the case of Vol.2 0,1

In the case of Vol.2 2,3

Pallet ascend

Pallet return

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

10

7. ADJUSTMENT AND SUPPLEMENTAL SPECIFICATIONS

CAUTION

When making adjustment of this machine, be sure to make adjustment after

confirming that the quality of the previous process is satisfactory.

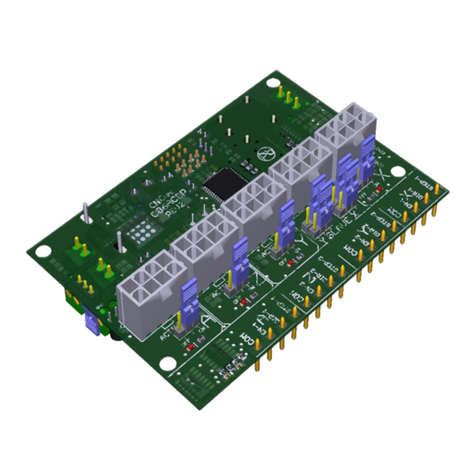

7-1. Adjustment of various speed controllers

Because the speed controller is adjusted to the optimum level at the time of shipment from the factory,

adjustment is basically not required.

Reference value of the control level for various speed controllers are described as a guideline.

〇Shielding plate cable transfer 1 set

Transfer cylinder forward side…2 turns release from fully closed state.

Transfer cylinder return side…2 turns release from fully closed state.

Transfer top/bottom cylinder top side…1 turn release from fully closed state.

Transfer top/bottom cylinder bottom side…1 turn release from fully closed state.

〇Shielding plate assembly jig

* When adjusting the speed controller, it will be necessary to remove the rear cover.

For that purpose, be sure to do the work while the air source and power supply are turned OFF.

The photo below is taken with the cover removed.

Terminal cut cylinder forward side…4.5 turns release from fully closed state.

Terminal cut cylinder return side…4.5 turns release from fully closed state.

Transfer top/bottom cylinder top side

speed controller

Transfer top/bottom cylinder bottom

side speed controller

Transfer cylinder forward side speed

controller.

Transfer cylinder return side speed

controller.

Terminal cut cylinder forward side

Terminal cut cylinder return side

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

11

Shielding plate cut and push cylinder top end side…6 turns release from fully closed state.

Shielding plate cut and push cylinder lower end side…6 turns release from fully closed state.

Terminal feed cylinder forward side…3 turns release from fully closed state.

Terminal feed cylinder return side…3 turns release from fully closed state.

Pilot pin cylinder…2 turns release from fully closed state

7-2. Adjustment of cable clamp transfer amount

Because the cable clamp transfer amount is adjusted to the optimum level at the time of shipment from

the factory, adjustment is basically not required.

When making fine adjustment, make fine adjustment for the protruded amount of the adjustment screw

in the photo below.

Transfer amount adjustment screw

Shielding plate cut and push cylinder

lower end side

Shielding plate cut and push cylinder

top end side

Terminal feed cylinder return side

Terminal feed cylinder forward side

Pilot pin cylinder

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

12

7-3. Control box default state

Control box display, in the case of correct origin point return, is described below.

(The displayed number will change depending on the number of the monitor select switch.)

〇Shielding plate assembly jig

* While VOL.1 dial is used for internal timer between each operation, change from “5” position, which

is the default setting, is not required.

* In the case of monitor select switch “3 - 8”, there will be no lamp lighting.

In case monitor select switch is “0”.

In case monitor select switch is “1”.

In case monitor select switch is “2”.

In case monitor select switch is “9”.

Dec.1.2023Copyright2023HIROSEELECTRICCO.,LTD.AllRightsReserved.

Table of contents

Other Hirose Cables And Connectors manuals

Hirose

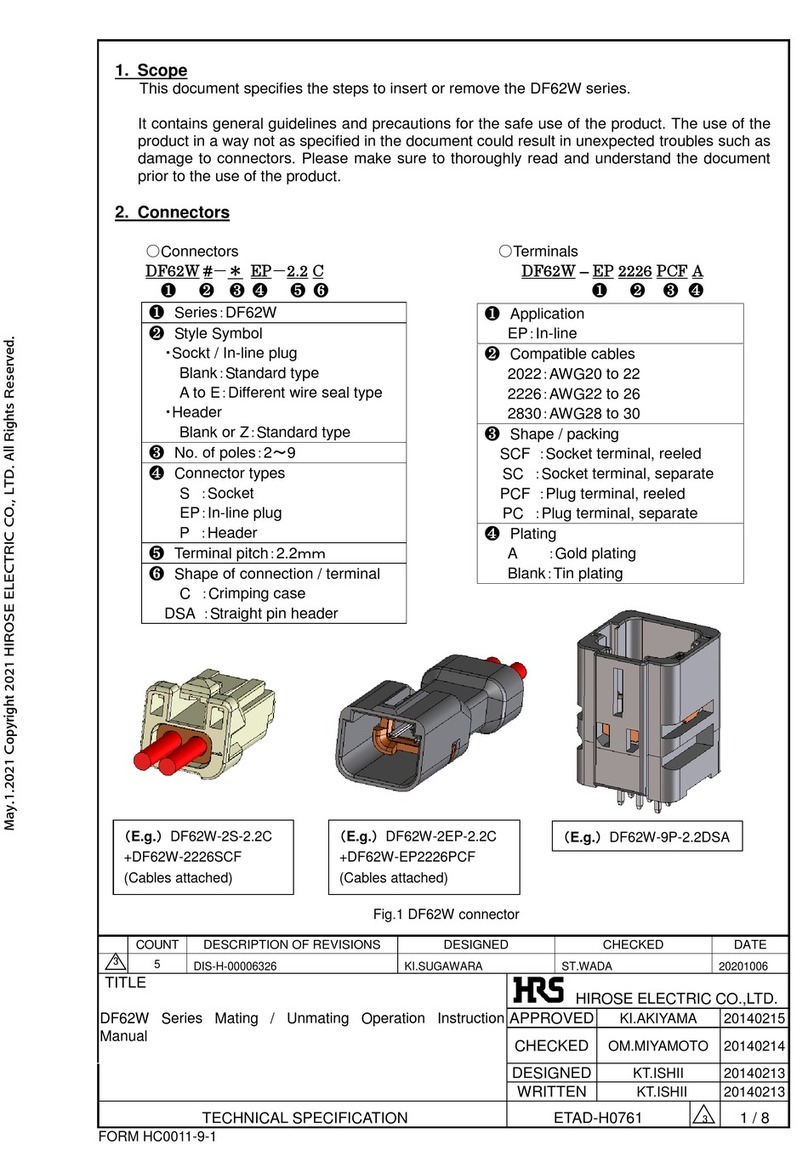

Hirose DF62W Series Manual

Hirose

Hirose HIF Series User manual

Hirose

Hirose BM56G Series Instruction Manual

Hirose

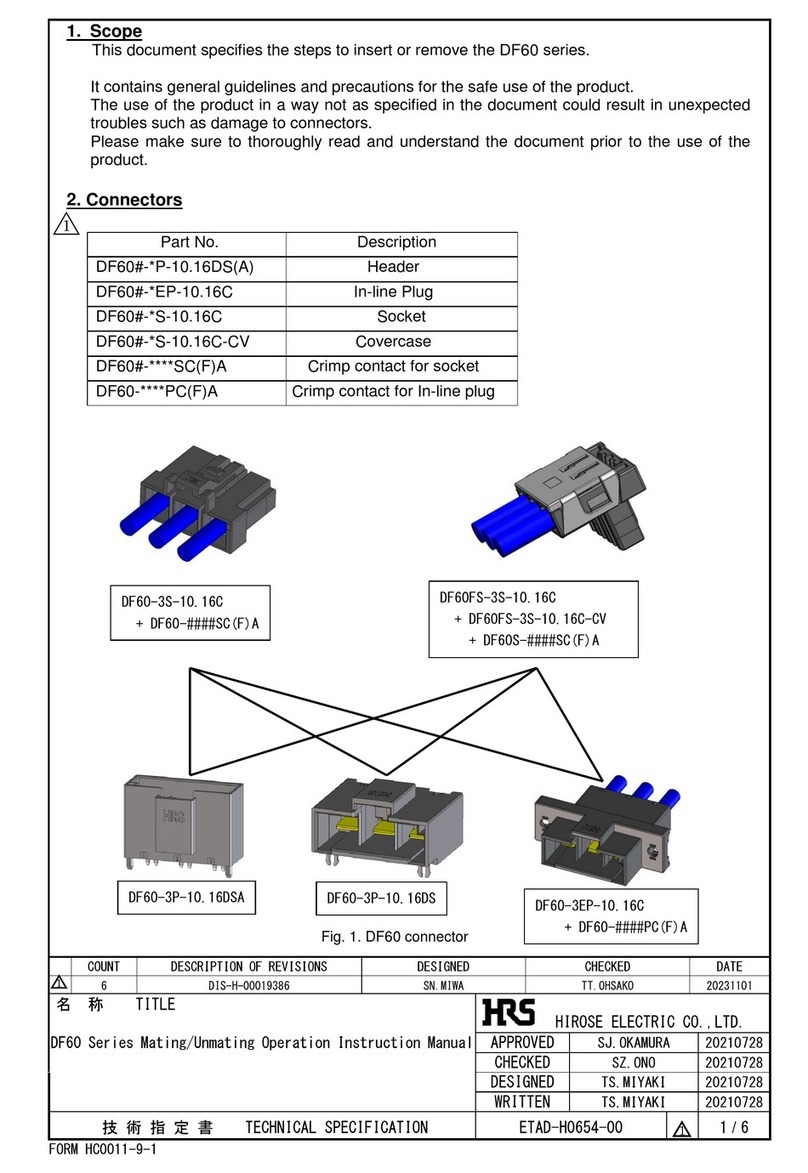

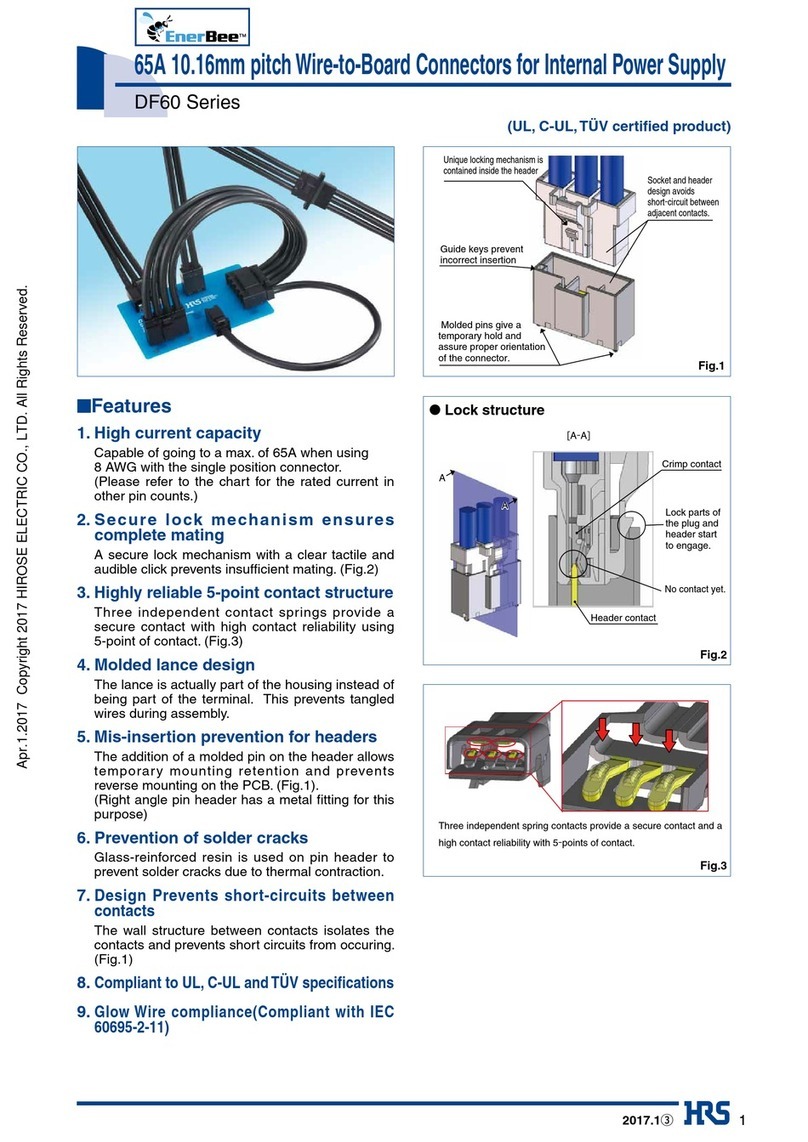

Hirose EnerBee DF60 Series User manual

Hirose

Hirose BM10 Series User manual

Hirose

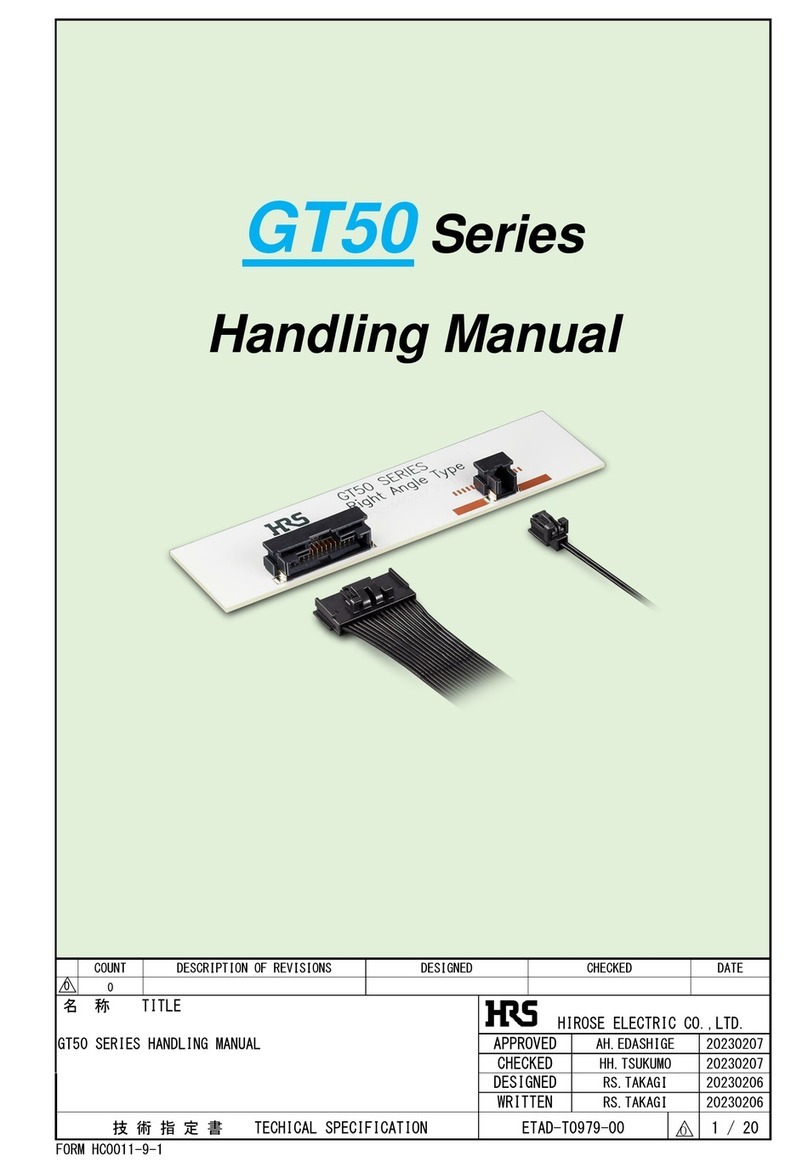

Hirose GT50 Series User manual

Hirose

Hirose GT16G-1S-HU User manual

Hirose

Hirose GT16GM Series User manual

Hirose

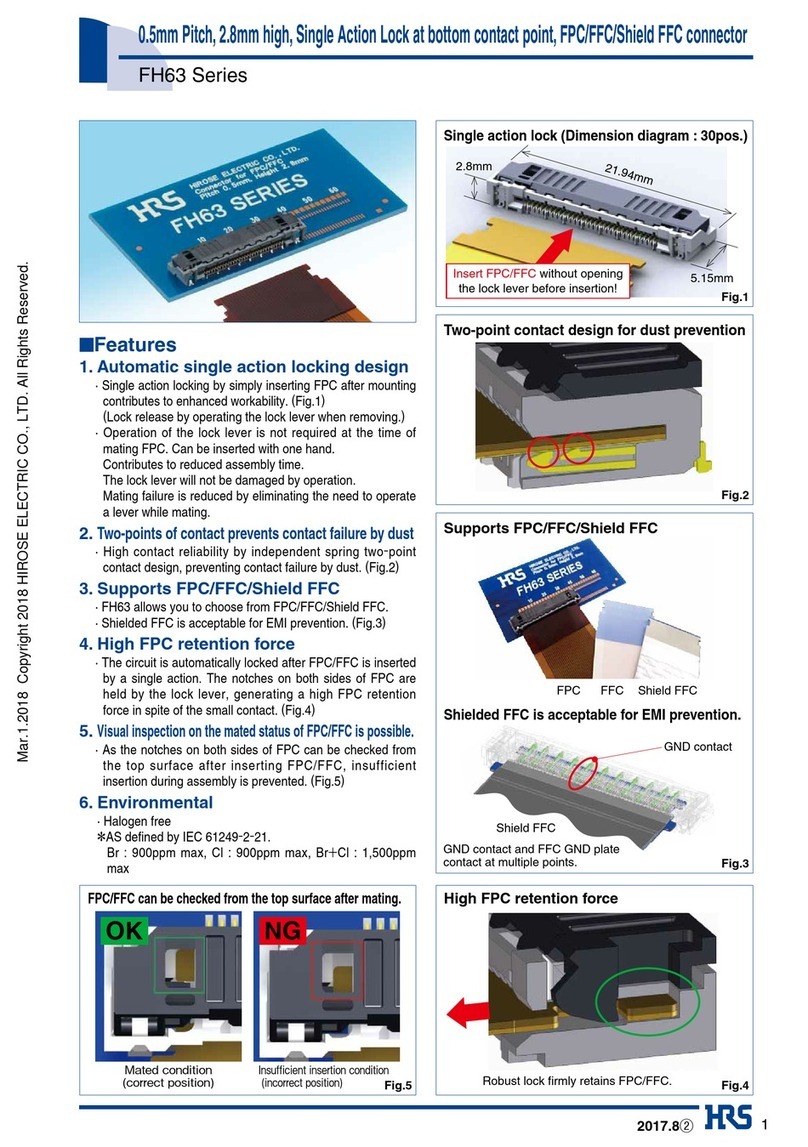

Hirose FH63 Series Manual

Hirose

Hirose EnerBee DF60 Series User manual

Popular Cables And Connectors manuals by other brands

Monoprice

Monoprice 14526 user manual

OUNEVA

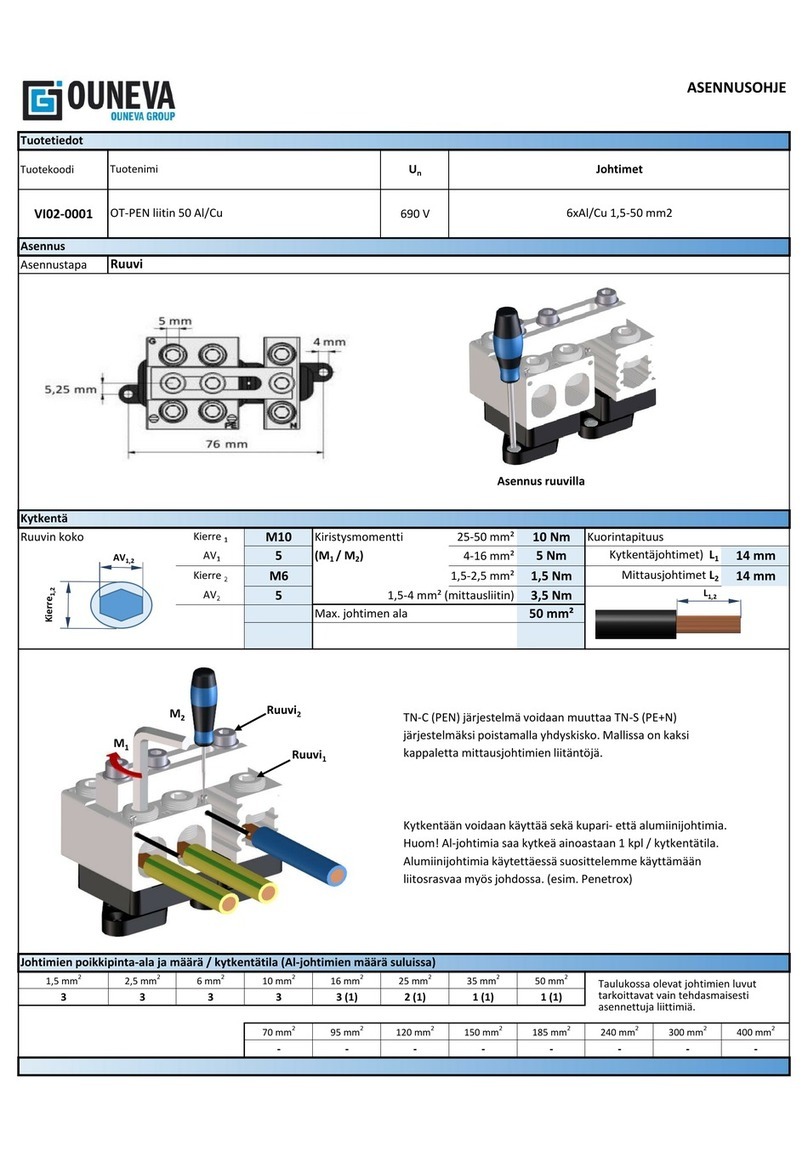

OUNEVA VI02-0001 installation guide

Eaton

Eaton COOPER POWER SERIES installation instructions

SCHURTER

SCHURTER 4795 Series Assembly instruction

Splitvolt

Splitvolt Splitter Switch SPS 01-011 Quick start user guide

Burndy

Burndy Continental Industries ThermOweld CB-8 instructions