Hirose DF62WZ-6P-2.2DSA(20) User manual

Other Hirose Cables And Connectors manuals

Hirose

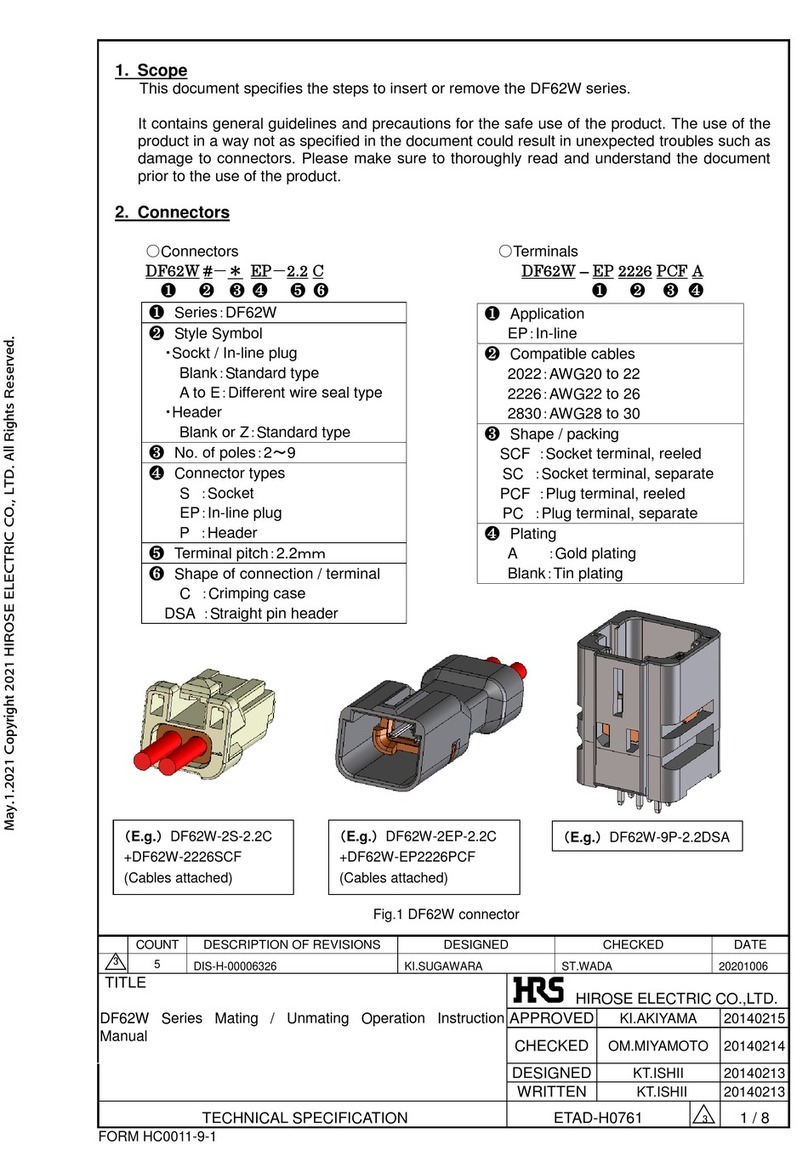

Hirose DF62W Series Manual

Hirose

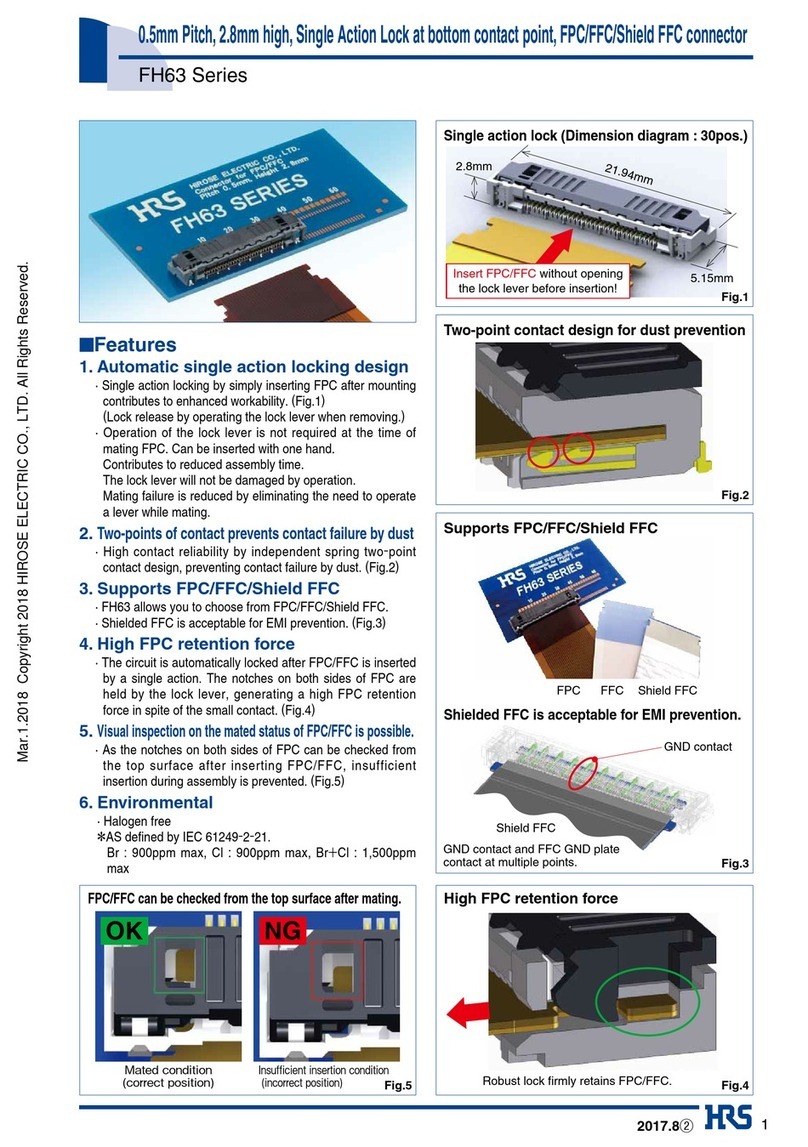

Hirose FH63 Series Manual

Hirose

Hirose BM56G Series Instruction Manual

Hirose

Hirose GT43 User manual

Hirose

Hirose GT16GM Series User manual

Hirose

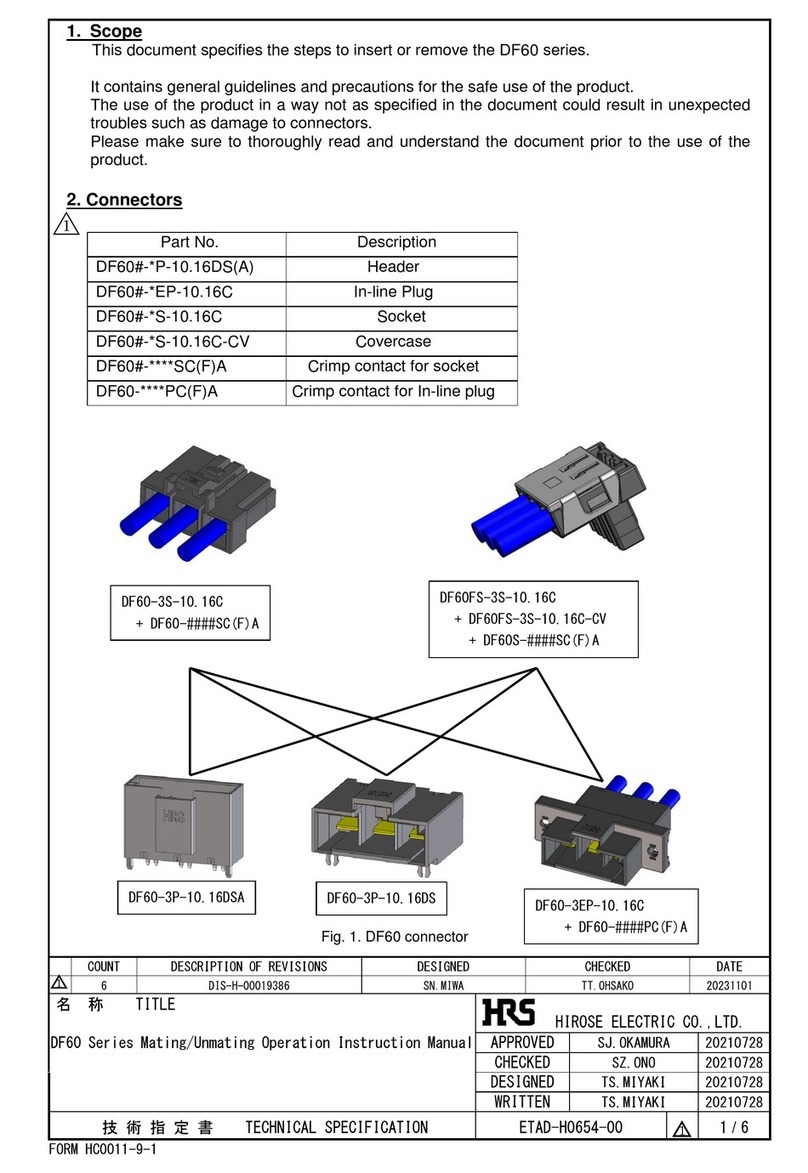

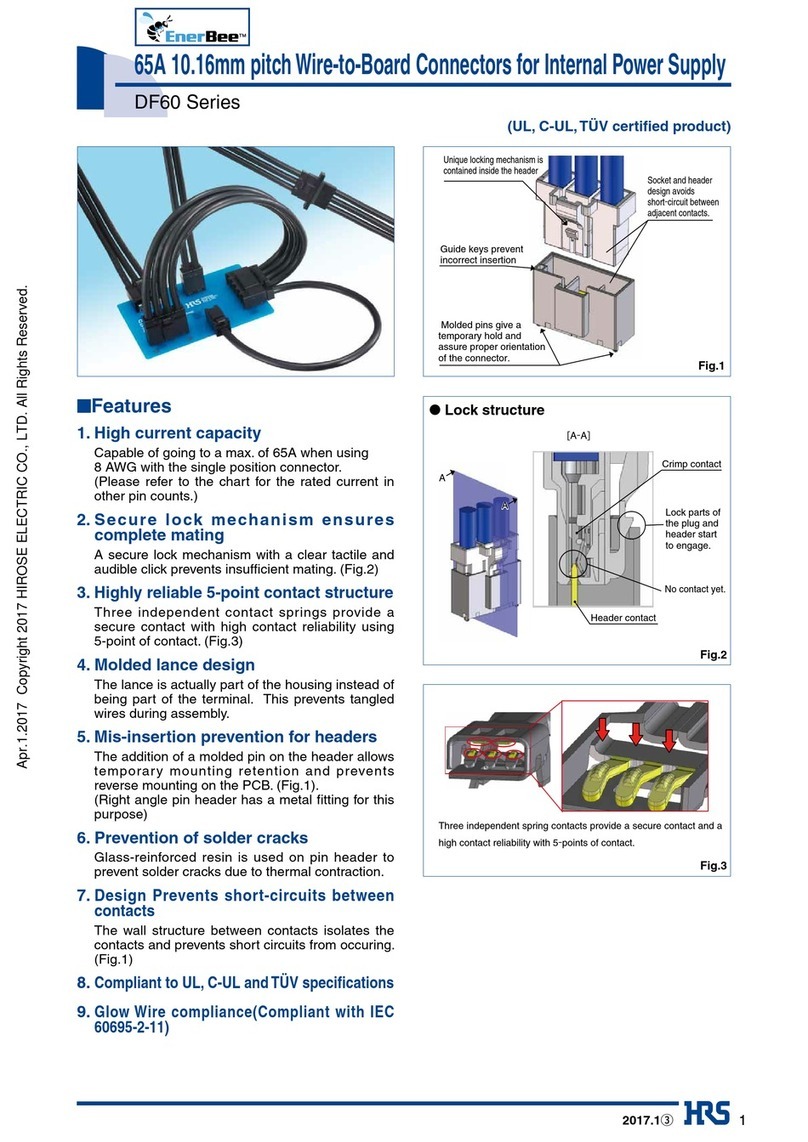

Hirose EnerBee DF60 Series User manual

Hirose

Hirose EnerBee DF60 Series User manual

Hirose

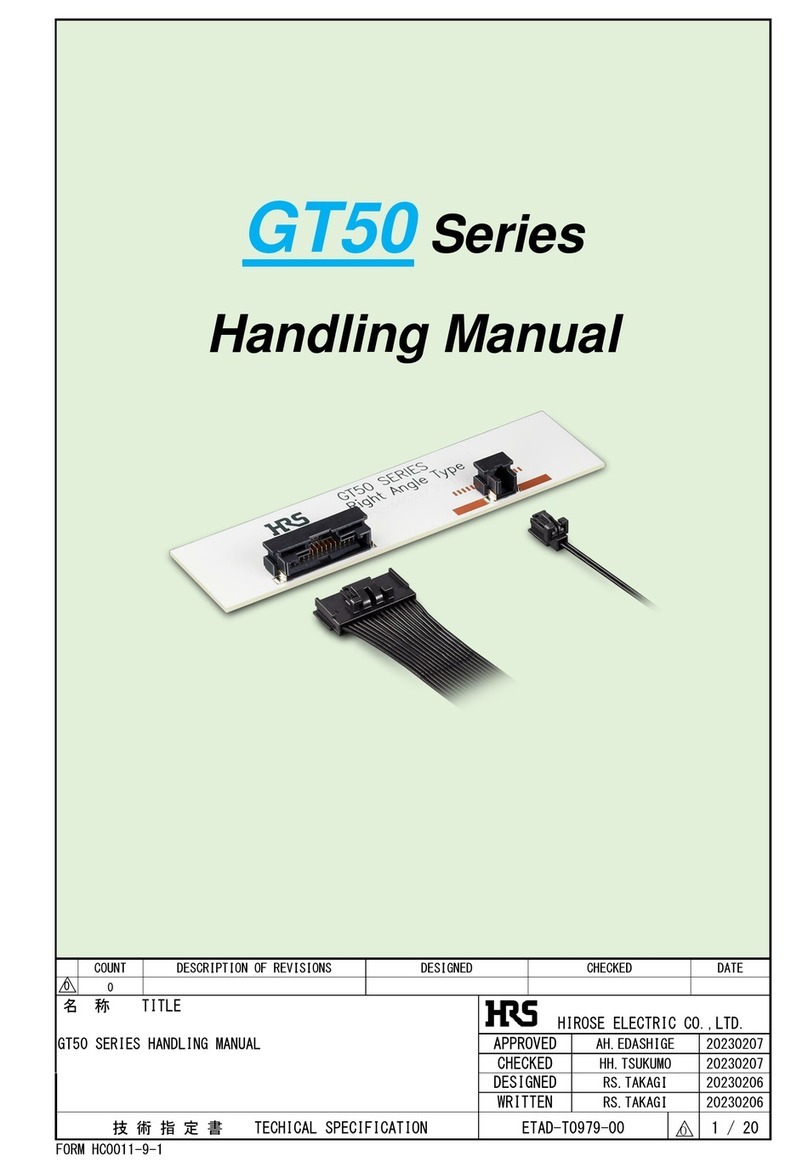

Hirose GT50 Series User manual

Hirose

Hirose HIF Series User manual

Hirose

Hirose BM10 Series User manual

Popular Cables And Connectors manuals by other brands

Metra Electronics

Metra Electronics CS-1X2HDMSPL3 user manual

Festo

Festo NEBM-M12G8-E Q5 Series Assembly instructions

Philips

Philips Sonicare 300 SerieS user manual

Transmedia

Transmedia CS 23-8 L Quick installation guide

id-Technik

id-Technik KS 25/36 Assembly instructions

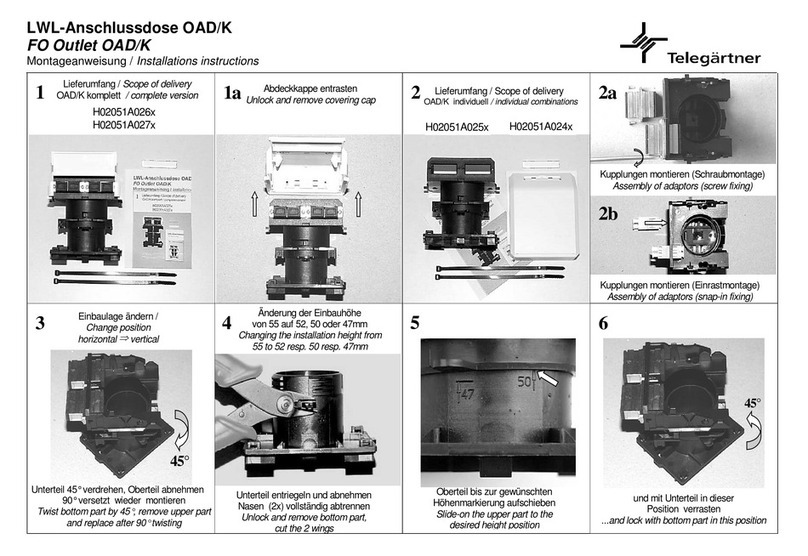

Telegärtner

Telegärtner H02051A026 Series installation instructions