Hirose GT50 Series User manual

GT50 Series

Handling Manual

COUNT

DESCRIPTION OF REVISIONS

DESIGNED

CHECKED

DATE

0

0

名称TITLE

GT50 SERIES HANDLING MANUAL

APPROVED

AH.EDASHIGE

20230207

CHECKED

HH.TSUKUMO

20230207

DESIGNED

RS.TAKAGI

20230206

WRITTEN

RS.TAKAGI

20230206

技術指定書TECHICAL SPECIFICATION

ETAD-T0979-00

0

1 / 20

FORM HC0011-9-1

HIROSE ELECTRIC CO.,LTD.

△

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

2/20

FORM HC0011-9-2

TABLE OF CONTENTS

1. SCOPE.....................................................................................................................................................3

2. PARTS DESCRIPTION .........................................................................................................................4

2.1 DESCRIPTION........................................................................................................................................4

2.2 PART NUMBERS ...................................................................................................................................5

2.3 MATERIALS ............................................................................................................................................6

3. PACKAGING ...........................................................................................................................................7

4. MECHANICAL PERFORMANCES ......................................................................................................8

5. STORAGE - HANDLING OF COMPONENTS ...................................................................................9

5.1 STORAGE CONDITIONS .....................................................................................................................9

5.2 HANDLING OF COMPONENTS..........................................................................................................9

6. ASSEMBLY PROCESS.......................................................................................................................11

6.1 CRIMPING OF TERMINALS...............................................................................................................11

6.2 CONNECTOR ASSEMBLY INSTRUCTIONS..................................................................................12

7. WIRING HARNESS ASSEMBLY RECOMMENDATIONS.............................................................14

8. REPAIR PROCESS..............................................................................................................................15

9. ELECTRICAL TEST.............................................................................................................................16

9.1 CLAMPING AREAS OF CONNECTORS..........................................................................................16

9.2 LOCATION OF TEST PROBES.........................................................................................................16

9.3 DEFINITION OF TEST PROBES.......................................................................................................17

9.4 RECOMMENDATIONS FOR ELECTRICAL TESTS.......................................................................17

10. CRIMP QUALITY STANDARD...........................................................................................................18

10.1 SCOPE...................................................................................................................................................18

10.2 APPLICABLE WIRE.............................................................................................................................18

10.3 QUALITY STANDARD.........................................................................................................................18

11. CRIMP PARAMETERS........................................................................................................................20

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

3/20

FORM HC0011-9-2

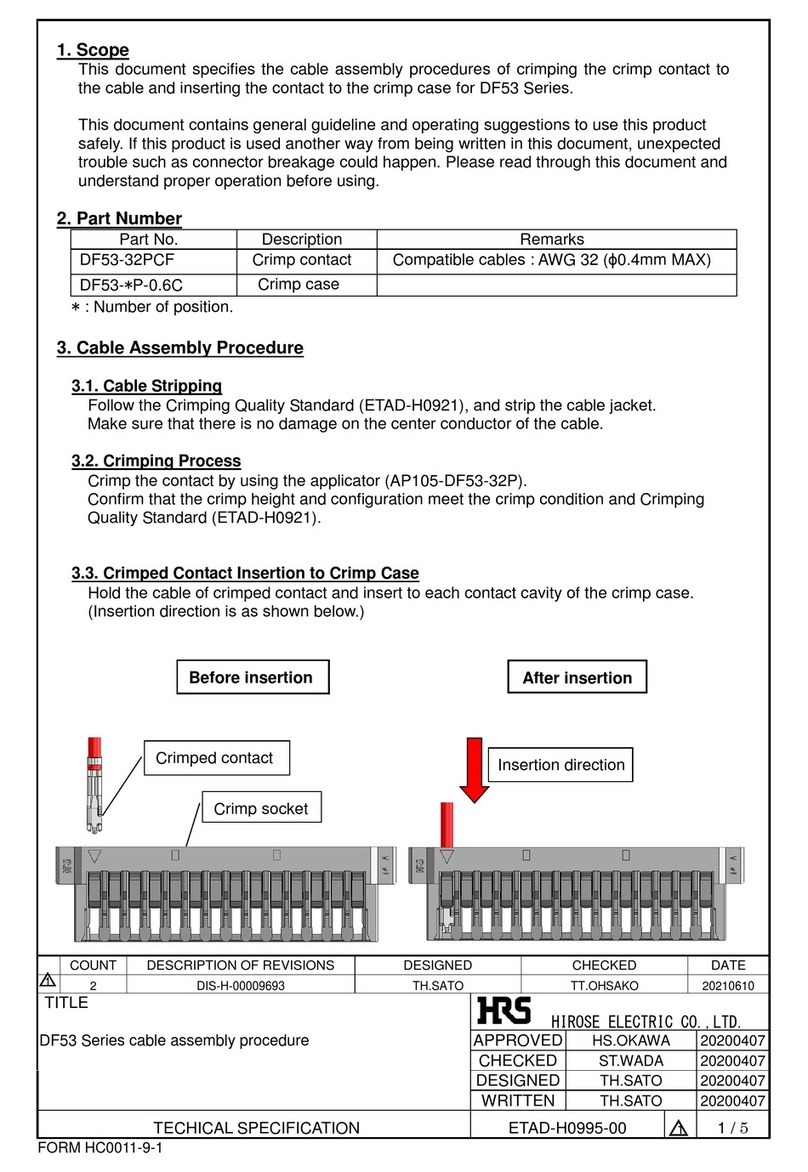

1. SCOPE

This harness operation manual describes the procedures for wiring, assembling and

disassembling the GT50 connectors.

It also details the crimping information and common practices of general crimps for the

GT50 terminals.

All measurements are in millimeters and Forces in Newtons unless otherwise specified.

In addition, photographs and illustrations described are representative products of HRS

GT50 series, so they differ depending on products.

Information of this manual is subject to change without notices.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

4/20

FORM HC0011-9-2

2. PARTS DESCRIPTION

2.1 DESCRIPTION

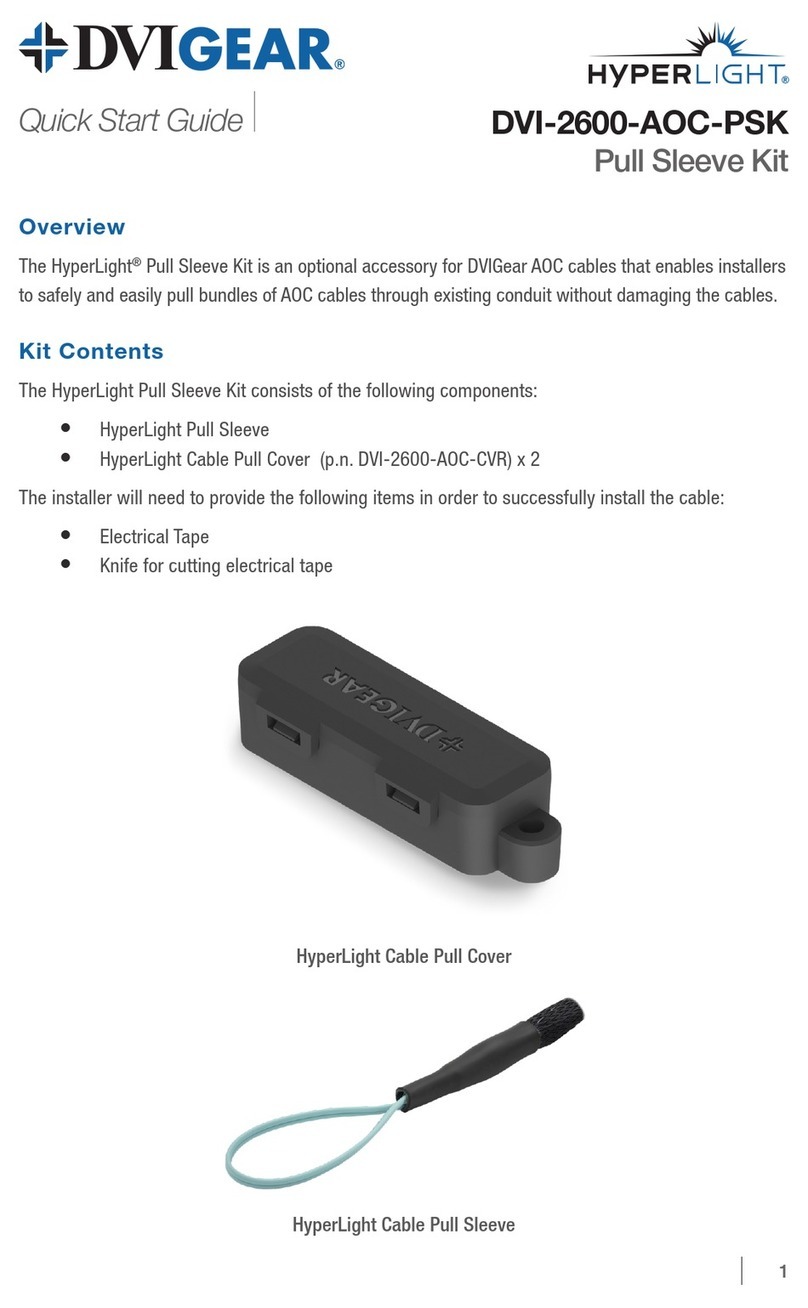

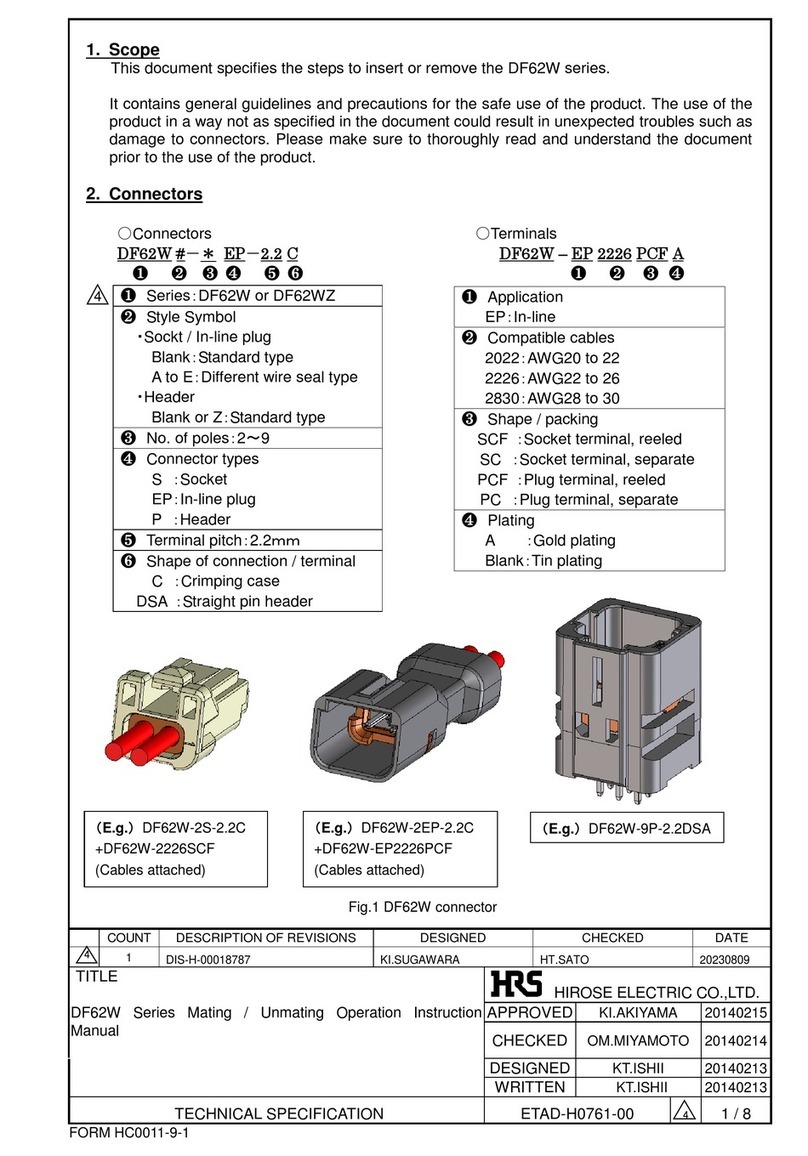

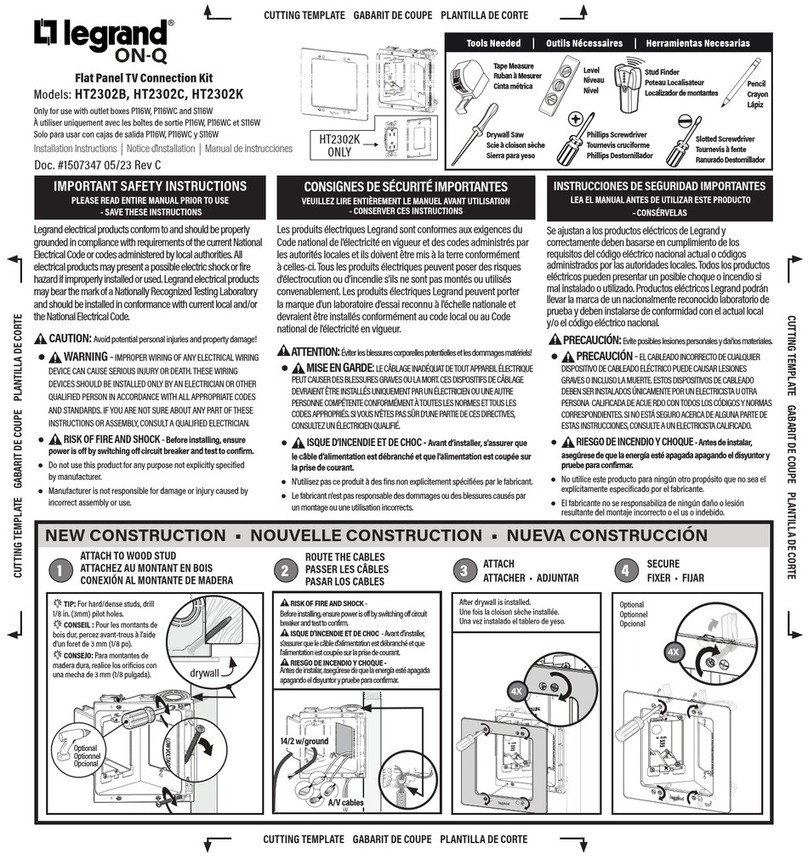

【Plug】

【Receptacle】

Receptacles exist only in right angle version with SMT metal hold down.

Female housing

Female terminal

(Crimp terminal)

Male contact

SMT Metal hold down

Male housing

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

5/20

FORM HC0011-9-2

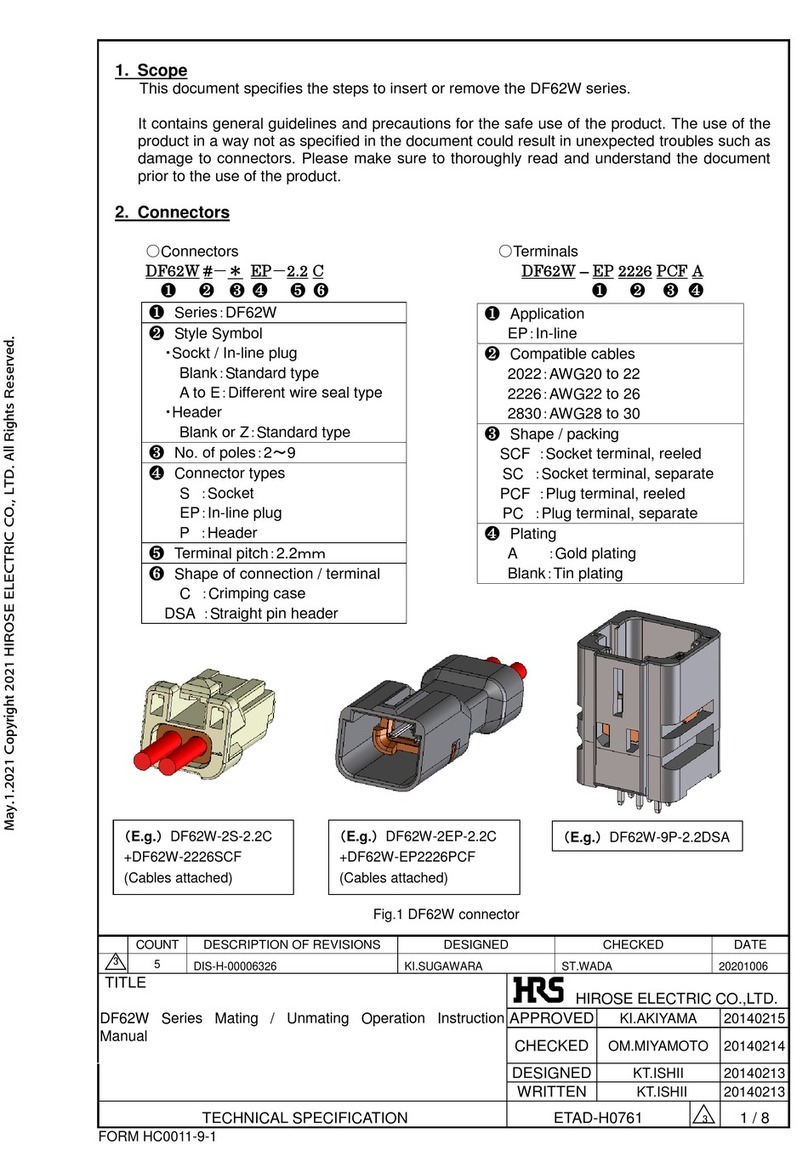

2.2 PART NUMBERS

Description

Part Number

Female terminal

GT50-28SCFA

Plug X positions

GT50-XS-1C

Receptacle X positions

GT50-XP-1H

Note 1: please check with Hirose Sales department for the availability of all part numbers.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

6/20

FORM HC0011-9-2

2.3 MATERIALS

Part

Sub part

Material

Plug

Female housing

PBT

Receptacle

Male housing

LCP

Male contact

Brass

Surface: Gold plating: 0.1µm

min in contact area, 0.05µm min

in solder area

Under: Nickel plating: 1µm min

Metal hold down

Brass

Surface: Tin plating: 1µm min

Under: Copper plating: 0.3µm

min

Female terminal

Metal thickness: 0.12±0.01 mm

Copper alloy

Surface: Gold plating: 0.1µm

min in contact area, Tin plating

1µm min in crimp and carrier

area

Under: Nickel plating: 1µm min

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

7/20

FORM HC0011-9-2

3. PACKAGING

Designation

HRS P/N

Carton box

dimensions

LxWxH (mm)

Type of

packaging

Quantity of parts

per unit

Receptacles

2P and 4P

GT50-XP-1H

405 x 405 x 31

Reel

1000 pcs/reel

Receptacle

16P

GT50-16P-1H

405 x 405 x 51

Reel

1000 pcs/reel

Plugs

GT50-XS-1C

Bags

100 pcs/bag

Female

terminal

GT50-28SCFA

570 x 570 x 55

Reel

28000 pcs/reel

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

8/20

FORM HC0011-9-2

4. MECHANICAL PERFORMANCES

The main mechanical characteristics are as follow:

Test

Value

Tensile strength of the Wire-Terminal link

11N min

Terminal insertion force

2.5N max

Terminal retention force

12N min

Terminal polarization force

4N min

Connector mating force

6.8 ~ 9.9N (2 terminals)

9.6 ~ 13.7N (4 terminals)

13.8 ~ 23.1N (16 terminals)

Connector unmating force

1.0 ~ 1.7N (2 terminals)

1.6 ~ 2.2N (4 terminals)

7.9 ~ 12.2N (16 terminals)

Connector retention force

25N min

Connector polarization force

100N min

Mating / unmating cycles number

10 times

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

9/20

FORM HC0011-9-2

5. STORAGE - HANDLING OF COMPONENTS

5.1 STORAGE CONDITIONS

Store in a well ventilated environment with the following relative temperature and

humidity range: -10° to 60°C ; 85% HR maximum.

Store without contact with the ground, on a pallet or platform, a clean dry surface

until the packages are retrieved for production.

Store packages away from water and direct UV rays.

Store packages away from heat and areas with high temperature variations.

Keep away from high temperature or hygrometry variations to avoid

condensation inside the packages.

Store packages away from dust to keep the components clean.

Keep packages as they are delivered, without undoing the adhesive ribbon until

use.

Do not walk or place heavy objects on packages.

Where packages are stored in racks, place the heavier cartons below and the

lighter ones above not to damage the parts.

5.2 HANDLING OF COMPONENTS

Do not touch the terminal contact points or the interior of the barrel.

In the event that the terminal must be handled, please wear gloves in order to

prevent corrosion.

Placing items on top of a terminal or dropping a terminal may result in shape

deformities or contamination. Please handle terminals with care.

In the event of terminals becoming tangled, please do not forcibly pull or bend

them apart, but disentangle them carefully.

Use caution when handling terminals so as to avoid deformation.

Make sure that the terminals of crimped cables do not become entangled. When

bundling or stacking cables, please prevent the terminals from being subjected to

any external force.

Use caution to ensure that the part is not subjected to any large impacts.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

10/20

FORM HC0011-9-2

Do not place wire harnesses on the floor.

Refrain from any handling that may result in terminal damage or deformation.

Do not use the housing in case it drops.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

11/20

FORM HC0011-9-2

6. ASSEMBLY PROCESS

6.1 CRIMPING OF TERMINALS

1 - Strip the cable

Please refer to the Crimp Quality Standard (§10) for details on strip length.

2 –Crimp wire in terminal

Note 1: Please use the Hirose crimp tool.

Note 2: Please refer to the Crimp Quality Standard (§10) and the crimp parameters (§11) by

cable to check crimp condition.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

12/20

FORM HC0011-9-2

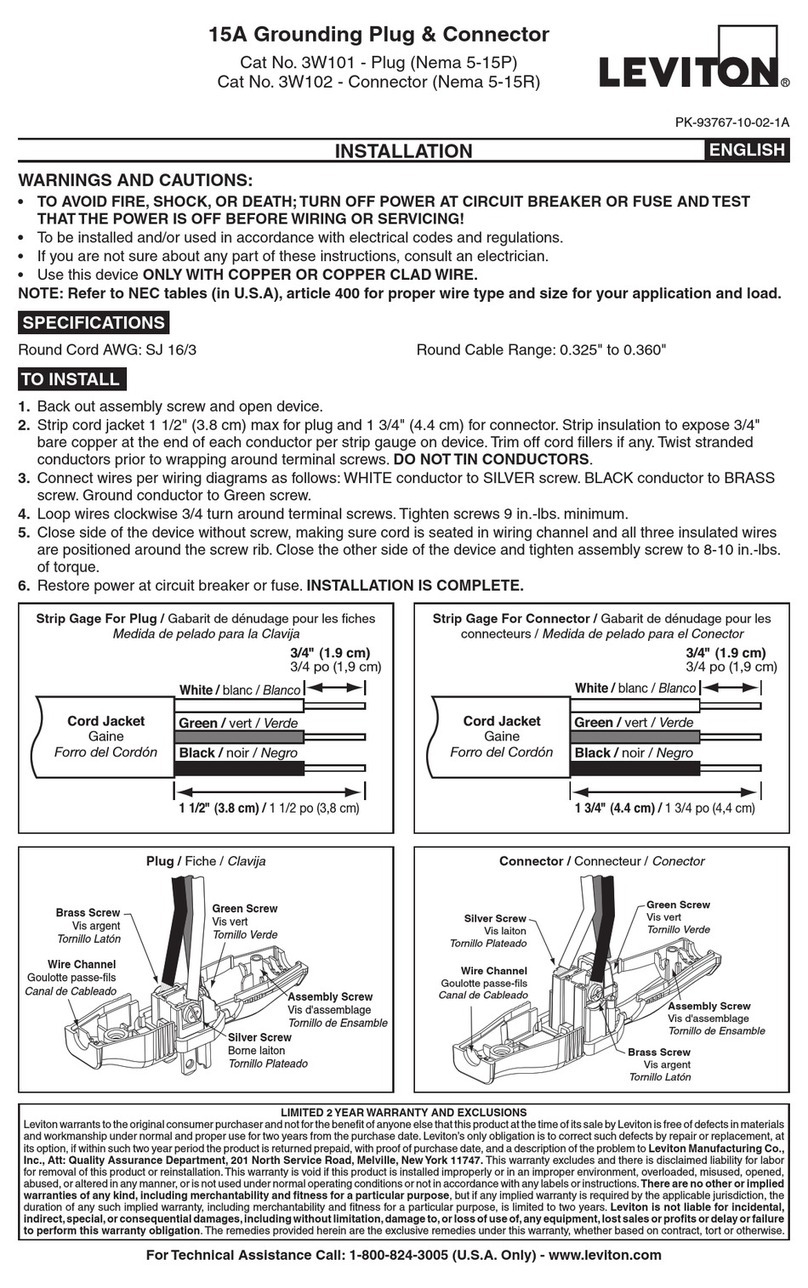

6.2 CONNECTOR ASSEMBLY INSTRUCTIONS

1 –Insert contact and push until a click is heard.

Please take care not to insert the terminal in the opposite orientation.

Straight insertion (Correct):

Note 1: Holding the cable, please insert straight into the housing.

Note 2: If the crimped terminal does not enter the housing smoothly, remove and then re-insert it.

Angled insertion (Incorrect):

Up-down Direction (Incorrect) Right-left Direction (Incorrect)

Scoop and twisted insertion (Incorrect)

Note:Do not use excessive scooping or twisting when inserting terminals.

Scoop Insertion (Incorrect) Twisted (Incorrect)

Crimping Portions Facing Downward

during

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

13/20

FORM HC0011-9-2

<Precautions When Inserting Terminals>

When inserting terminals, hold the socket and insert the terminal without touching the lock lever

(circles in red on the picture below).

2 –Make sure that the contact lance is hooked by the housing lance of the socket.

Lock Lever

Socket

Contact Lance

Insertion

Direction

Housing Lance

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

14/20

FORM HC0011-9-2

7. WIRING HARNESS ASSEMBLY RECOMMENDATIONS

Deformed or damaged parts have to be replaced by a new one.

Apply tape so that every individual wire is subjected to an equal amount of tensile

force to avoid any effect on terminals (like disengagement).

The distance to apply tape from the end of connector is 35mm minimum.

The bending radius for wires should be at minimum 3 times its outer radius to

ensure normal use of our connectors.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

15/20

FORM HC0011-9-2

8. REPAIR PROCESS

For removing the inserted contact from the socket, lift up the housing lance by using a pointed

needle, and pull out the cable.

Once removed, socket cannot be re-used. Please use a new part after repair is completed.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

16/20

FORM HC0011-9-2

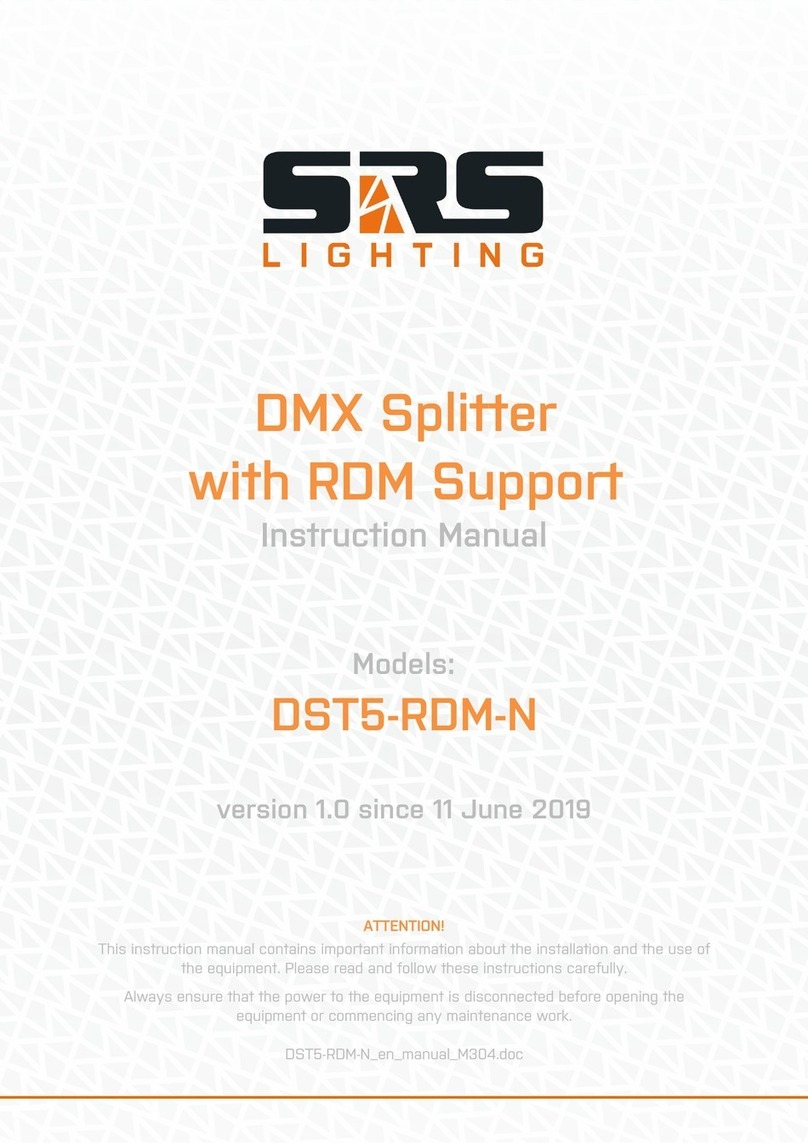

9. ELECTRICAL TEST

9.1 CLAMPING AREAS OF CONNECTORS

During electrical tests, plugs can be clamped in the following areas: (example with GT50-16S-1C)

9.2 LOCATION OF TEST PROBES

The test probes should be located in front face as described below:

(Example with the 16P)

ALLOWEDAREA

(MIDDLEAREAISPROHIBITED)

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

17/20

FORM HC0011-9-2

9.3 DEFINITION OF TEST PROBES

The recommended probe should have the following characteristics:

Diameter: ∅0.30mm maximum

Plating: Gold plated

Spring force: 1N maximum

Stroke: see section below

9.4 RECOMMENDATIONS FOR ELECTRICAL TESTS

Perform test after insertion of terminals.

Avoid any deformation on housing or terminal during electrical test.

Replace any damaged housing or terminal with a new one.

∅0.3mm max

Gold plated

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

18/20

FORM HC0011-9-2

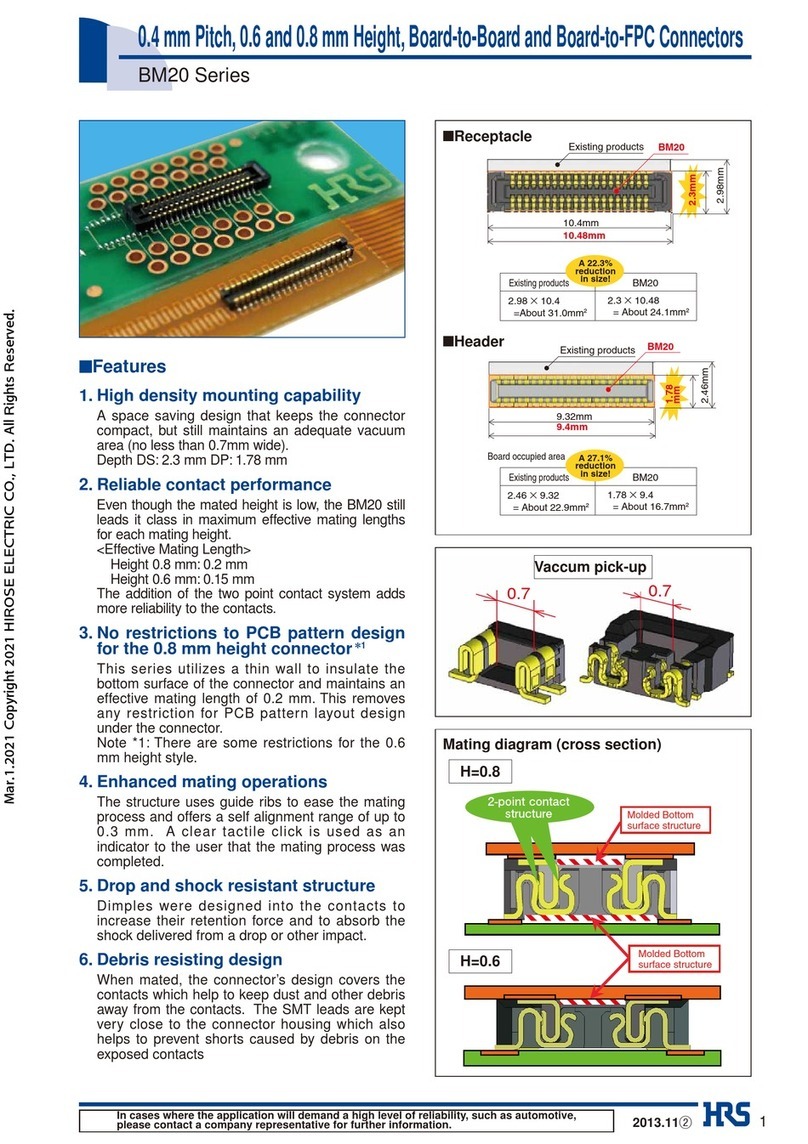

10. CRIMP QUALITY STANDARD

10.1 SCOPE

This technical specification prescribes crimp condition of GT50-28SCFA (CL760-1001-0).

10.2 APPLICABLE WIRE

Applicable wire size: 0.08mm² ~ 0.09mm²

Applicable insulation size: 0.66 ~ 0.8mm max.

10.3 QUALITY STANDARD

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

19/20

FORM HC0011-9-2

CHECK POINT

MEASURE (mm)

Remarks

Cover location

A

0.3 + /-0.15

Location of tip of the core

B

0.35 +/-0.23

Front bell-mouth

C1

0.15 max

Rear bell-mouth

C2

0.175 +/-0.075

Bend-up

D

2° max

Bent-up is measured

angle at Z2 from

datum plane Z1

Bend-down

E

2.5° max

Bent-up is measured

angle at Z2 from

datum plane Z1

Twist

F

±2° max

Twist is measured

angle at Z4 from

datum plane Z3

Rolling

G

±3° max

Cut-off tab

H

0.15 max

Strip length

I

2.1 +/-0.15

This dimension is for

reference.Please

adjust it to meet

specified dimensions

after the crimping.

Burr height

J

0.12 max

Width

Wire barrel

C/W

0.70 max

Insulation barrel

I/W

0.76 max

Stabilizer

S/W

0.76 max

Stabilizer height

S/H

1.65 +/-0.05

Crimping step

Apply only to bend-up

K

0.12 max

Gap

L

0.025 +/-0.02

Note 1: Refer to a Crimping condition list for the crimp height and insulation height.

Note 2: Please confirm that the crimped contact can be inserted to the socket.

Note 3: Bell mouth can’t be at the side of wire crimp part and must be within the crimp wide

standard.

HIROSE ELECTRIC CO.,LTD.

ETAD-T0979-00

0

20/20

FORM HC0011-9-2

11. CRIMP PARAMETERS

WIRE

TYPE

SEC AREA

(mm²)

/

AWG

CONDUCTOR

INSULATION

Tensile

strength of

the

wire-terminal

link

(minimum)

C/H

C/W

C/H

C/W

SEA

0.08 / 28

0.50 ~0.56

0.70 max

1.10 ~1.20

0.76 max

11N

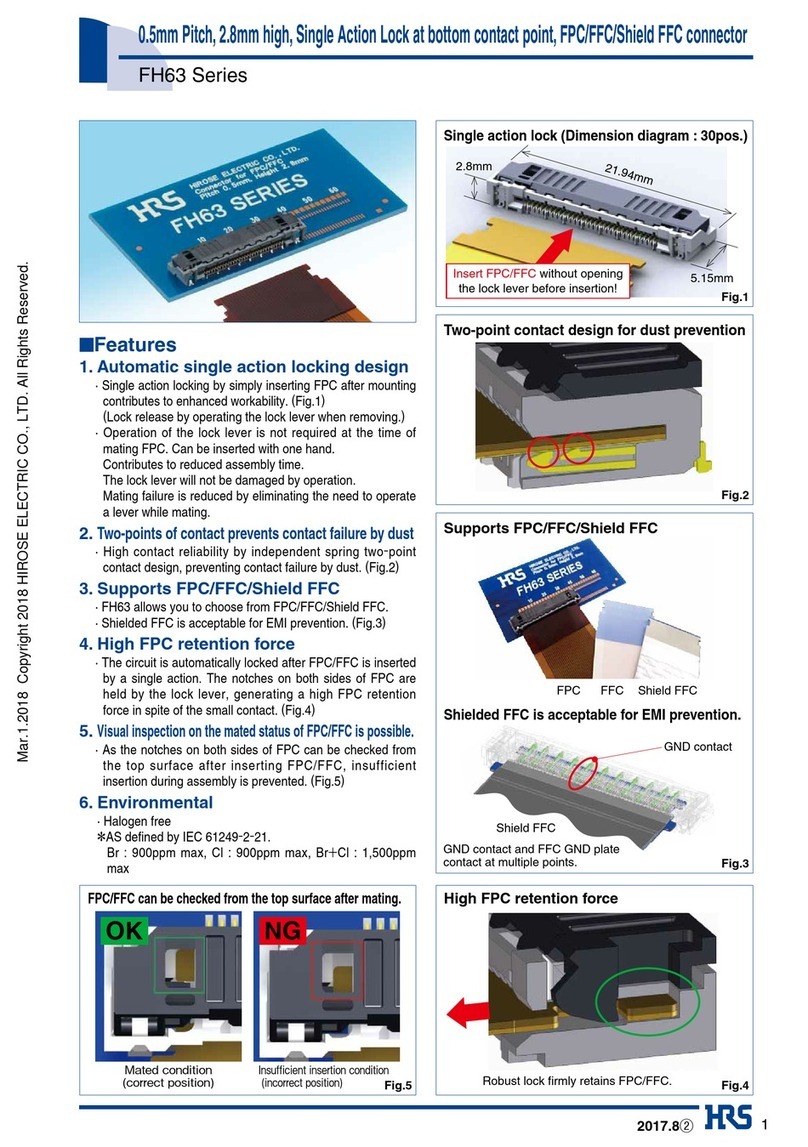

Table of contents

Other Hirose Cables And Connectors manuals

Hirose

Hirose DF62WZ-6P-2.2DSA(20) User manual

Hirose

Hirose EnerBee DF60 Series User manual

Hirose

Hirose DF62W Series Manual

Hirose

Hirose GT43 User manual

Hirose

Hirose BM56G Series Instruction Manual

Hirose

Hirose EnerBee DF60 Series User manual

Hirose

Hirose GT16G-1S-HU User manual

Hirose

Hirose HIF Series User manual

Hirose

Hirose DF53 Series Manual

Hirose

Hirose FH63 Series Manual

Popular Cables And Connectors manuals by other brands

LEGRAND

LEGRAND ON-Q HT2302B quick start guide

Falltech

Falltech SRD User instruction manual

Eraser

Eraser R1S operating manual

Gleason Reel

Gleason Reel Direct Drive Hazardous Duty Electric Cable Reels... Installation and maintenance instructions

Axis

Axis T8127 installation guide

Philips

Philips SWV3412W Specifications