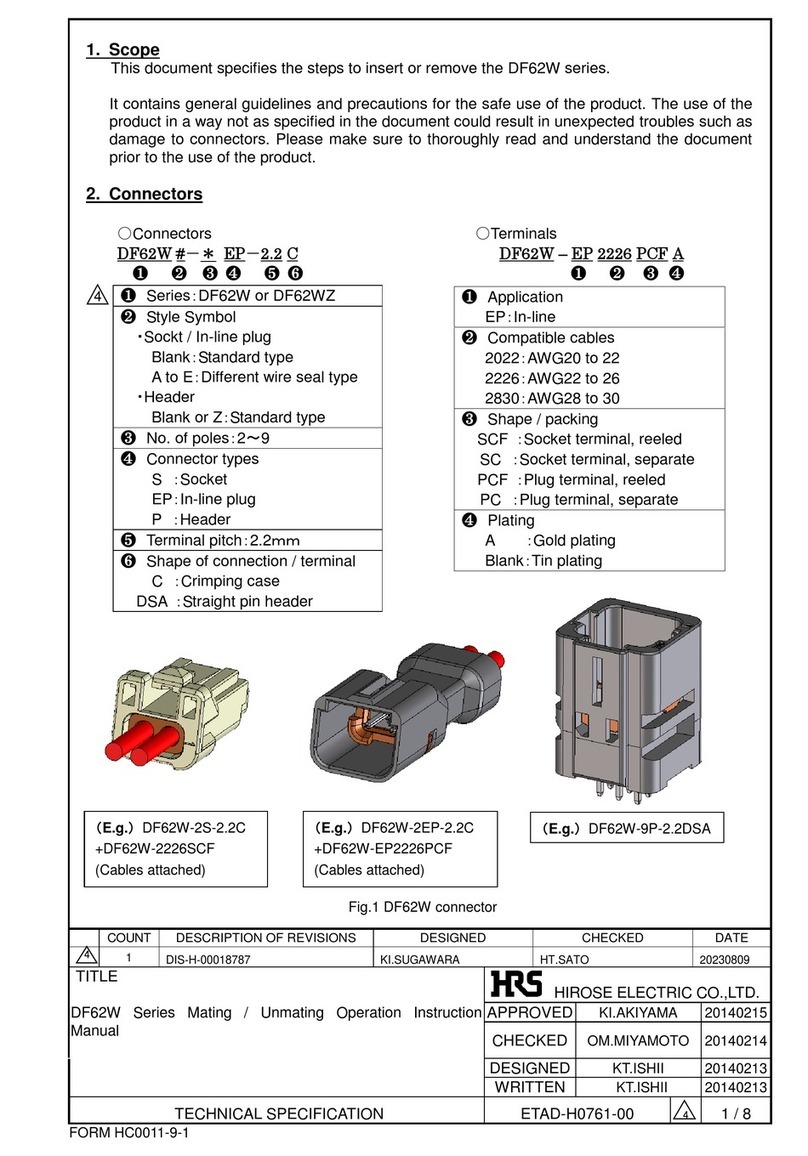

Hirose DF62W Series Manual

Other Hirose Cables And Connectors manuals

Hirose

Hirose HIF Series User manual

Hirose

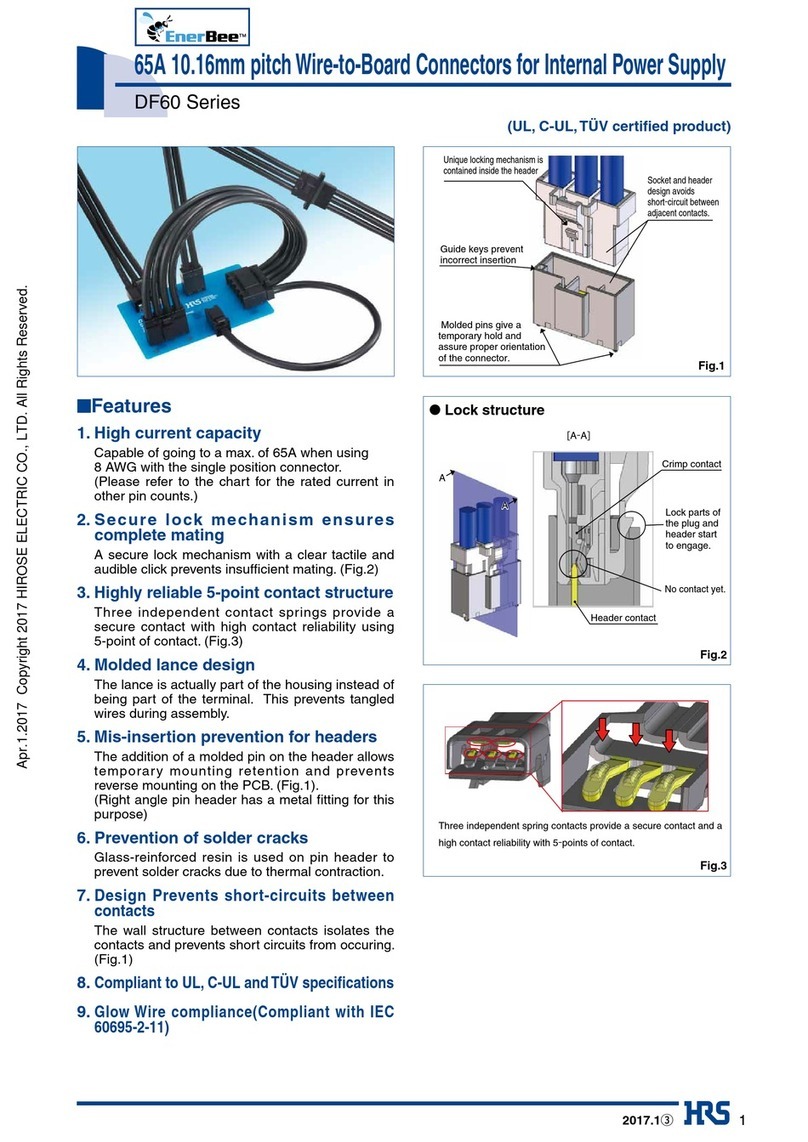

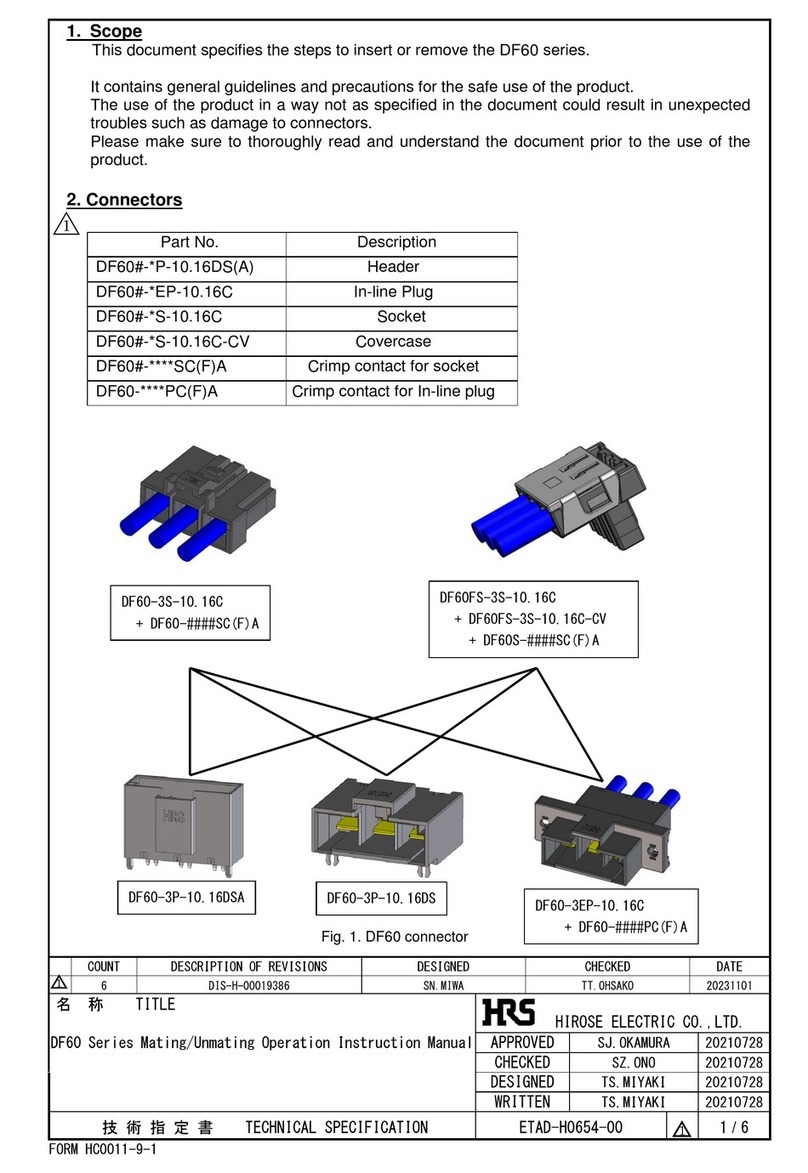

Hirose EnerBee DF60 Series User manual

Hirose

Hirose GT43 User manual

Hirose

Hirose EnerBee DF60 Series User manual

Hirose

Hirose GT16GM Series User manual

Hirose

Hirose BM10 Series User manual

Hirose

Hirose BM56G Series Instruction Manual

Hirose

Hirose DF62WZ-6P-2.2DSA(20) User manual

Hirose

Hirose GT50 Series User manual

Hirose

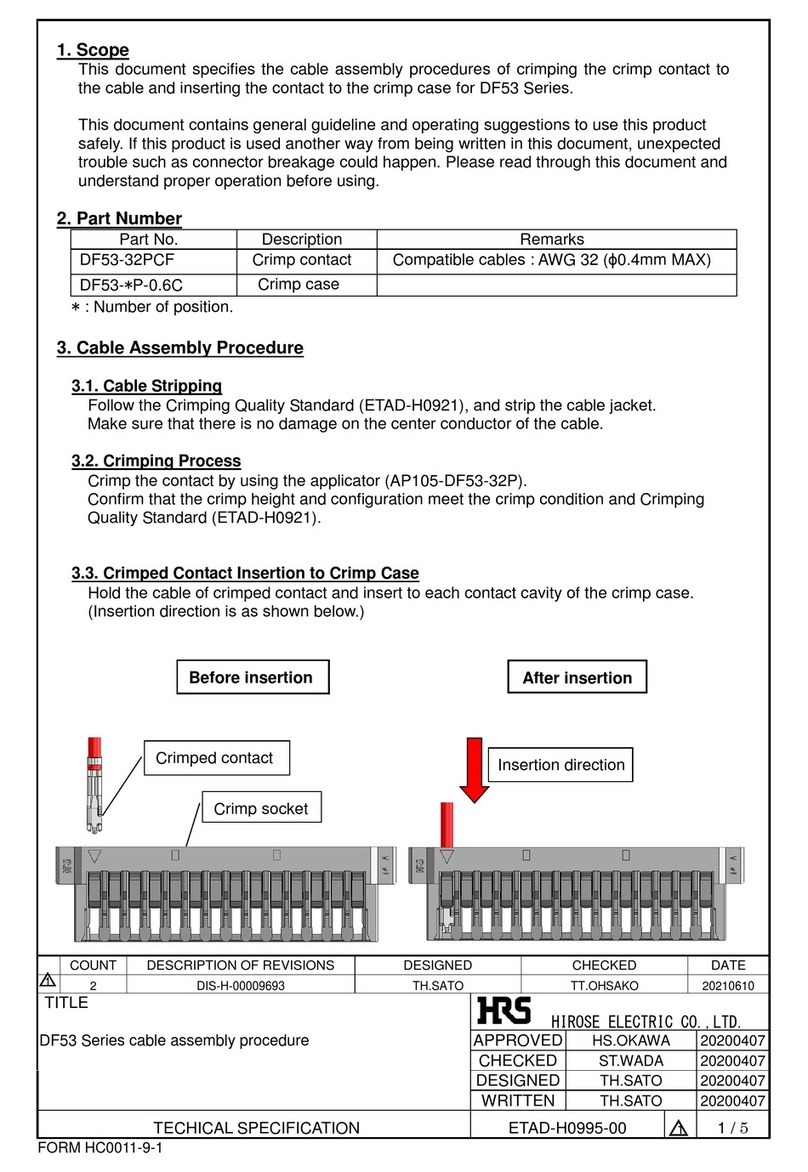

Hirose DF53 Series Manual

Popular Cables And Connectors manuals by other brands

Speaka Professional

Speaka Professional 67 43 52 operating instructions

Monacor

Monacor HDMS-1044K instructions

nvent

nvent Raychem HAK-C-100 installation instructions

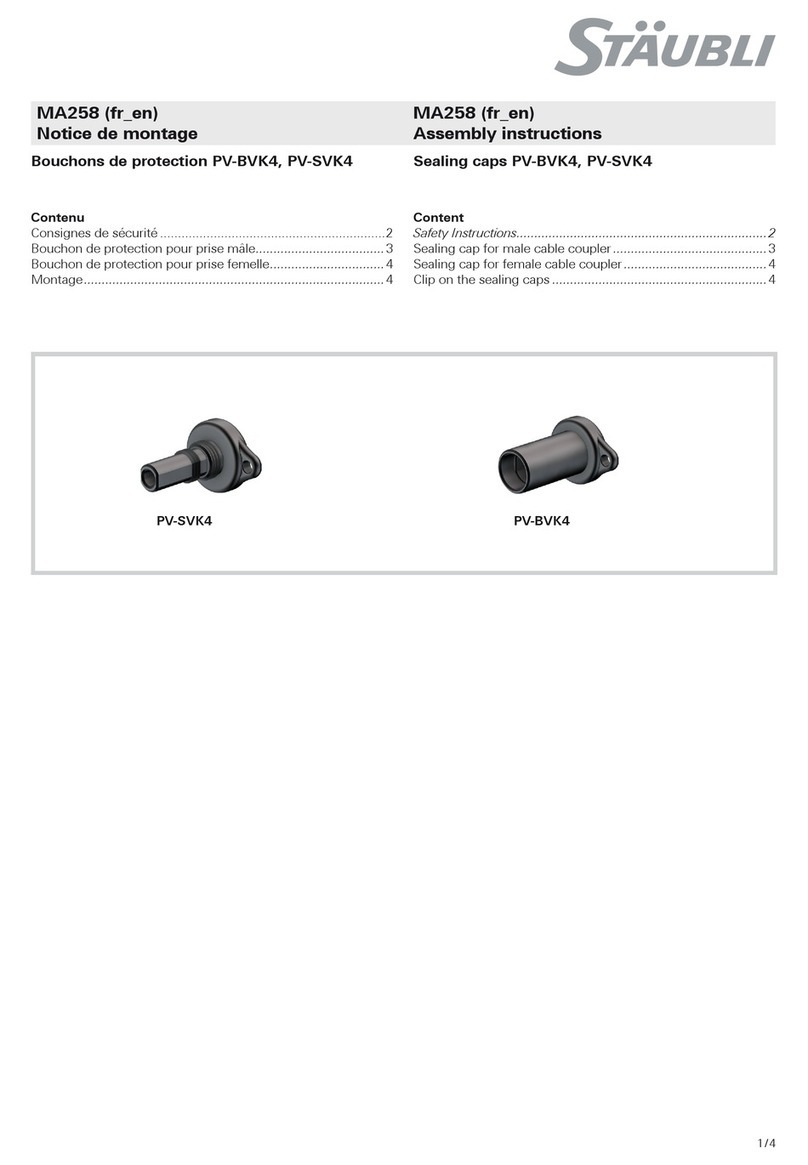

Staubli

Staubli PV-BVK4 Assembly instructions

Panduit

Panduit DP6 PLUS installation instructions

Thermon

Thermon Terminator DP Installation procedures