SAFETY SUMMARY 1

1

ENGLISH

1. SAFETY SUMMARY

ÕWARNING:

-This product is used for BMS connection adapter for HITACHI Water Chilling Units.

-Do not place the adapter in a place where flammable gas, or oil mist may stay exit, it will

cause a fire, a fire disaster, deformation of machines, corrosion or breakage

-a place where oil mist or steam drifts.

-a place where sulfide gas form as hot spring drifts.

-In the case that a medical equipment generating electro-magneticwaves is installed near

the Water Chillers, pay an attention to the radiation direction does not occur.

-It is recommended that a space of 3 m or more between HARC70-CE and the medical

equipment, radios, etc. be provided.

-Do not place the adapter in a place to be exposed to direct sunlight.

-Install action:

-Install properly this adapter by following this manual to avoid any electric shock, fire

disaster and injury by falling down HARC70-CE1.

-Check to ensure that the adapter is fixed firmly to avoid injury by falling.

-To avoid the fire or fire disaster, do not install the adapter in a place where there is

possibility of generation or flow of flammable gases.

-Electrical Work:

-To avoid any electric shock, ask for the work to the shop having qualification for

electrical works.

-To avoid any electric shock and disaster, perform electrical wiring according to local

regulations.

-To avoid electric shock, and fire disaster, use the prescribed cable to connect of Water

Chiller units, (model HARC70-CE1)

-Turn off electrical power before electric wiring work when the cover of HARC70-CE1

is opened.

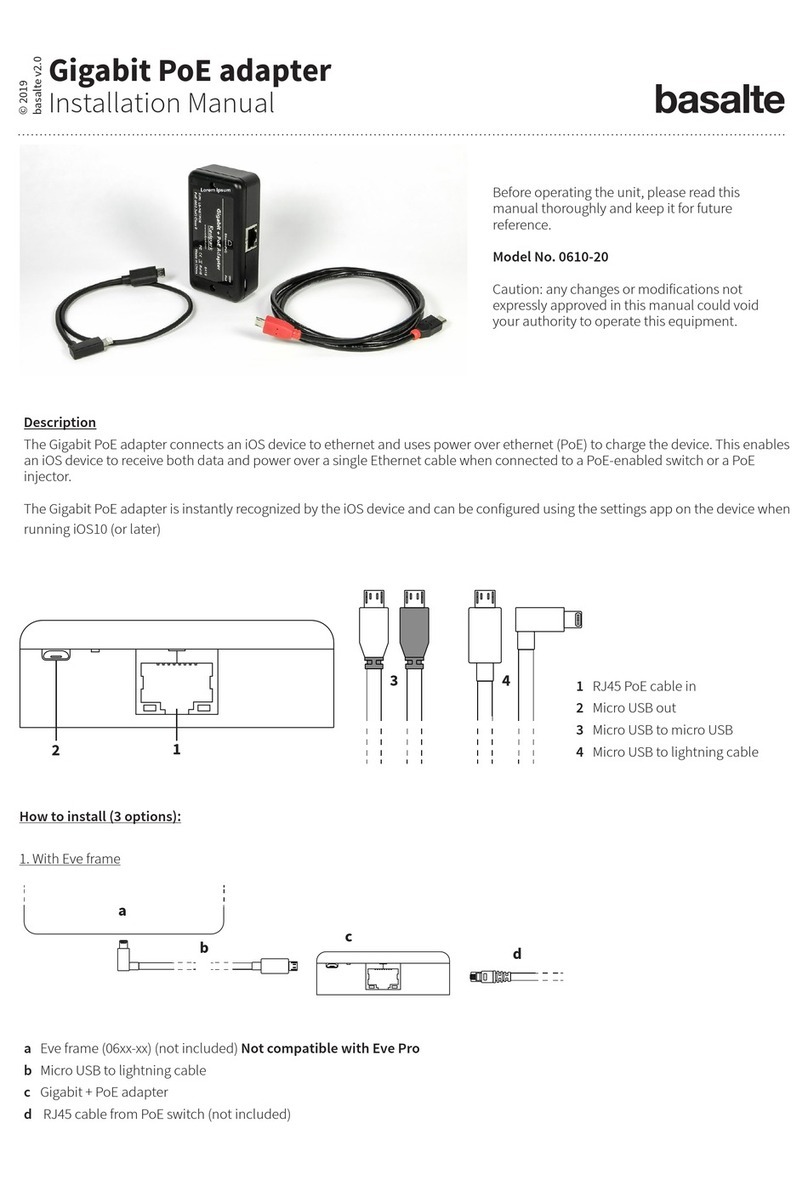

2. SYSTEM CONSTITUTION

2.1. SYSTEM CONSTITUTION

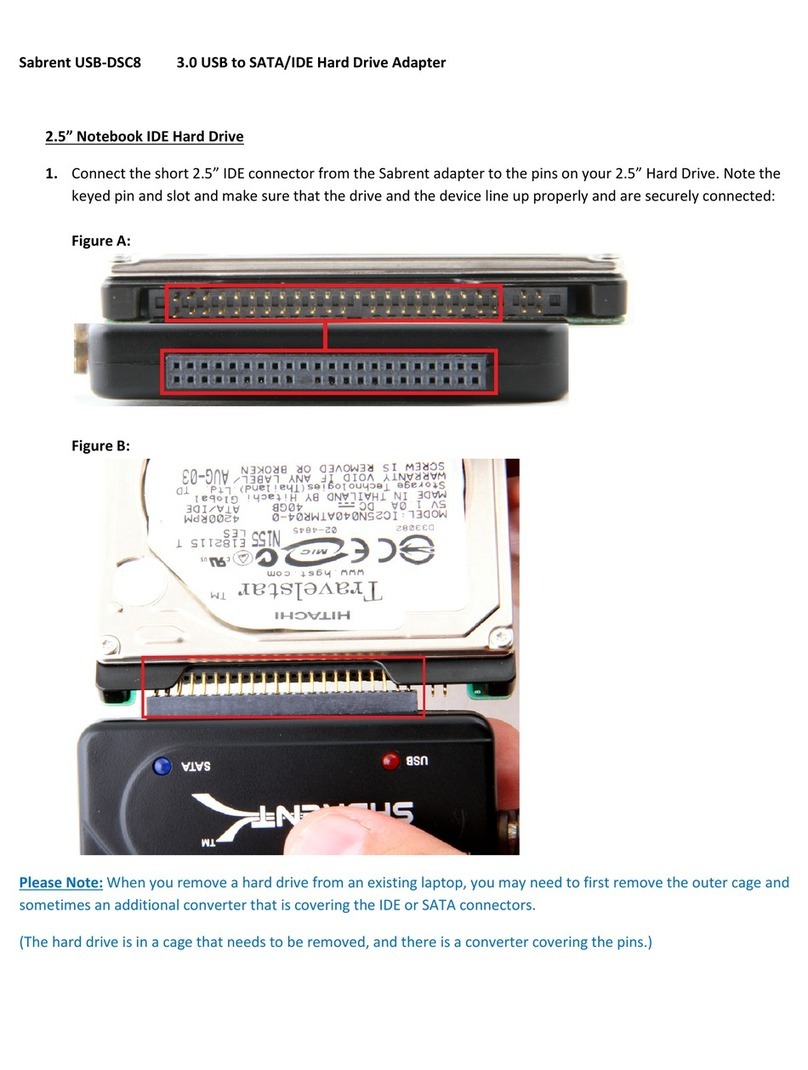

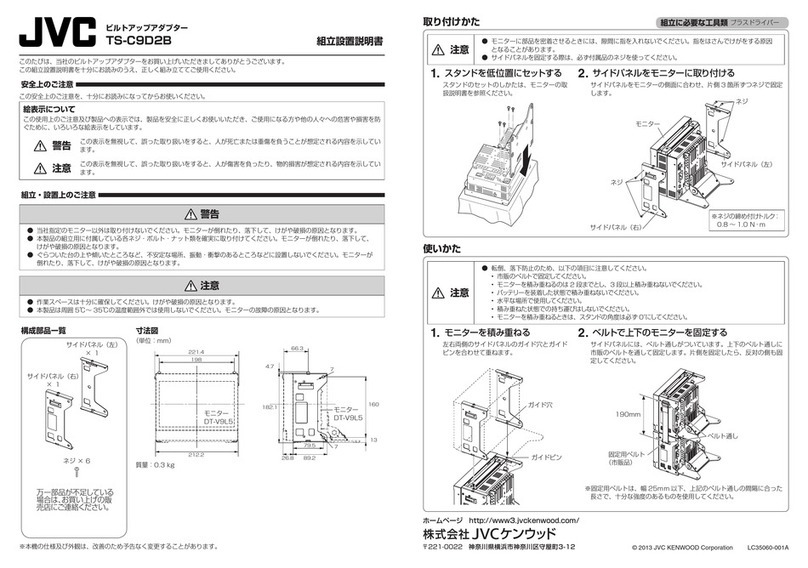

The Internal Constitution of BMS connection using HARC70-CE1 is indicated in the Figure1.1.

Read this manual together with the “Installation & Operation Manual” for other units which are

connected. As for the other equipment which composes the system, read the handling manual

which was attached to each.

(*1) LONWORKS ® is the Register Trade Mark of Echelon Corporation in United States and other countries.

Fig. 1.1. Example of System Constitution

Upper Monitoring System (BMS)

The range which

Hitachi provides

LonWorks ® (*1) Network

HARC70-CE1

Chiller Unit

HARC70-CE1

Chiller Unit Chiller Unit Chiller Unit Chiller Unit