2 P5416543

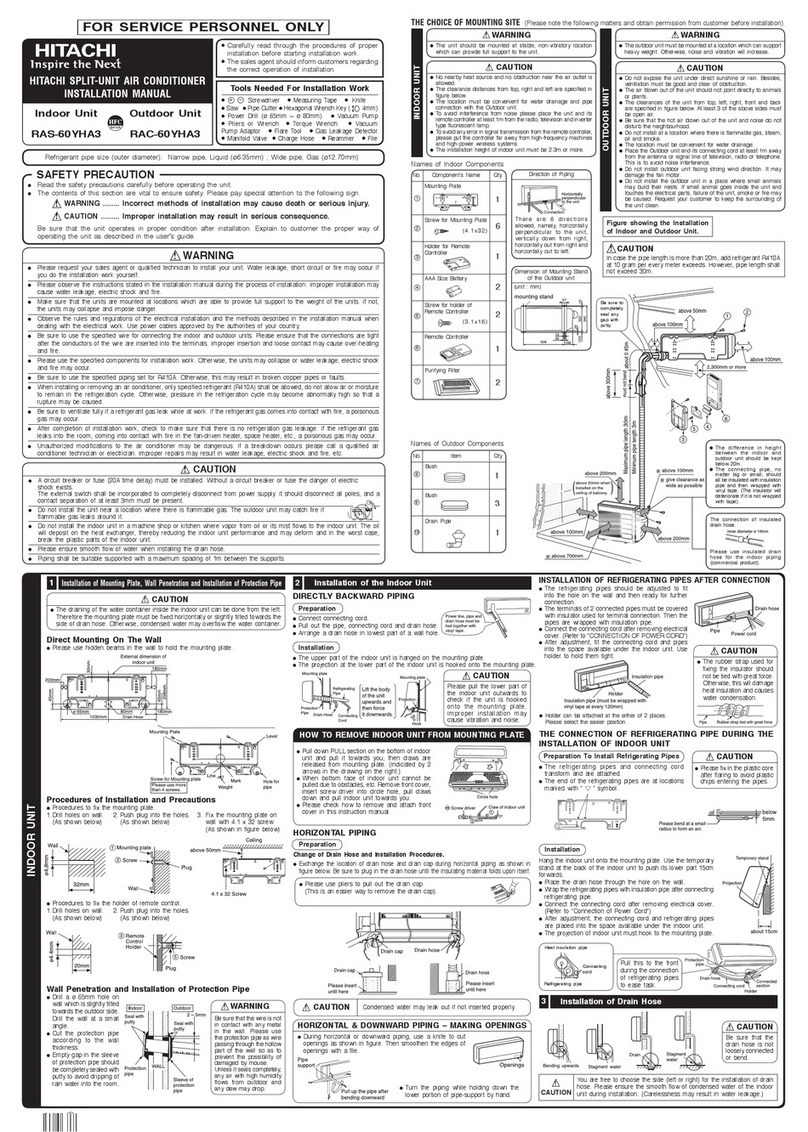

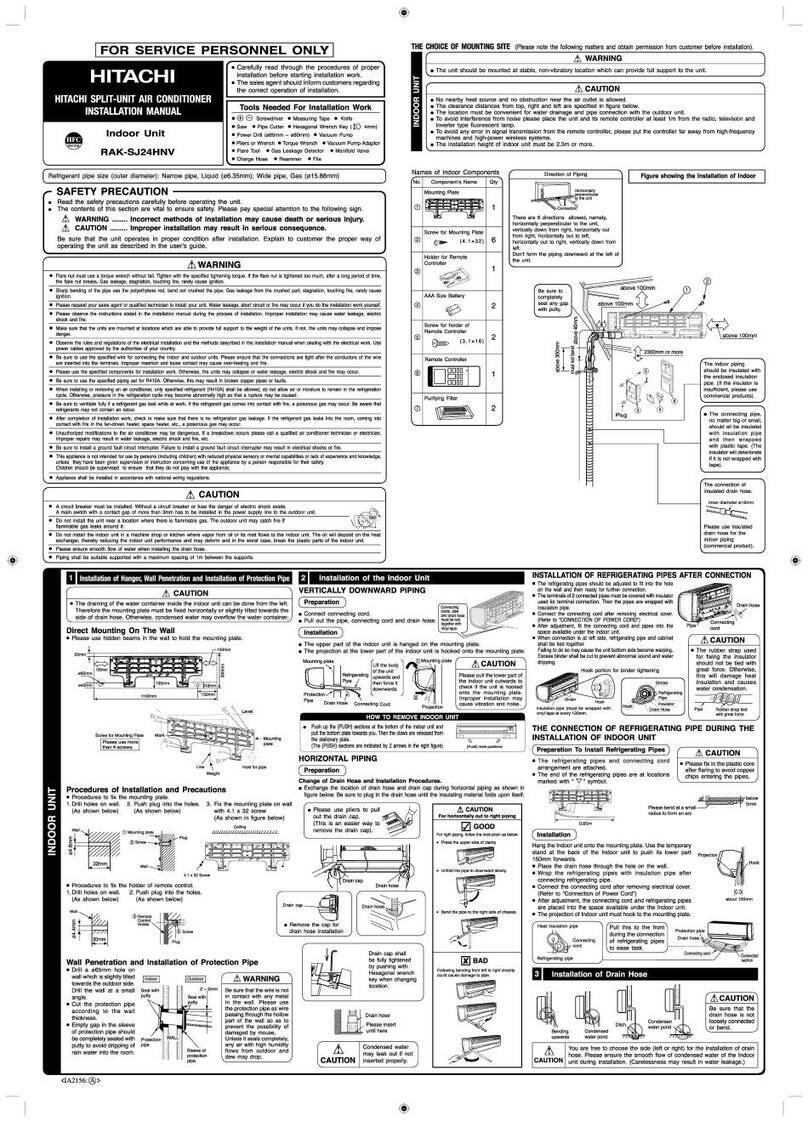

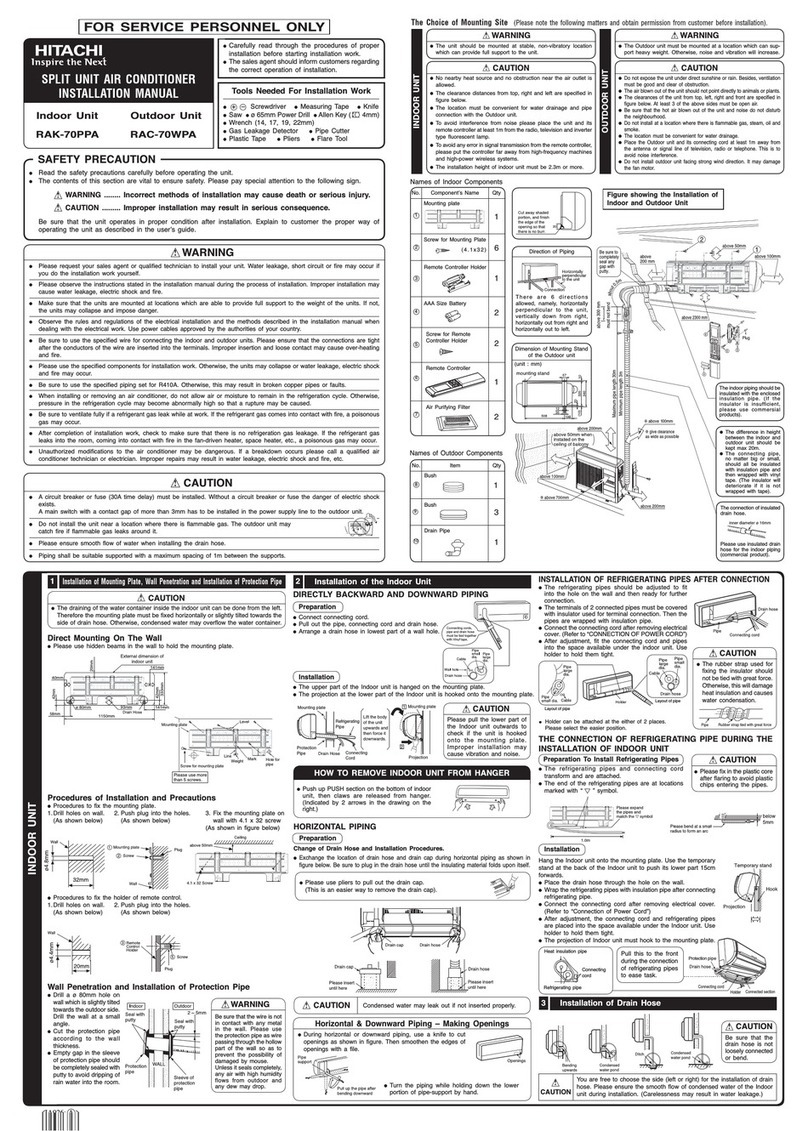

l Do not perform the installation work, refrigerant piping work, drain pump, drain piping and electrical wiring

connection without referring to our installation manual. If the instructions are not followed, it may result in

a water leakage, electric shock or a re.

l Use the specied non-ammable refrigerant (R410A) to the outdoor unit in the refrigerant cycle.

Do not charge material other than R410A into the unit such as hydrocarbon refrigerants (propane or etc.),

oxygen, ammable gases (acetylene or etc.) or poisonous gases when installing, maintaining and moving.

These ammables are extremely dangerous and may cause an explosion, a re, and injury.

l Do not pour water into the indoor unit. These products are equipped with electrical parts.

If poured, it will cause a serious electrical shock.

l Do not open the service cover or access panel for the indoor or outdoor unit without turning OFF the main

power supply.

l Do not touch or adjust safety devices inside the indoor unit or outdoor unit. If these devices are touched

or readjusted, it may cause a serious accident.

l Refrigerant leakage can cause difculty with breathing due to insufcient air. Turn OFF the main switch,

extinguish any naked ames and contact your service contractor, if refrigerant leakage occurs.

l Make sure that the refrigerant leakage test should be performed.

Refrigerant (Fluorocarbon) for this unit is non-ammable, non-toxic and odorless.

However if the refrigerant is leaked and is contacted with re, toxic gas will generate.

Also because the uorocarbon is heavier than air, the oor surface will be lled with it, which could cause

suffocation.

l The installer and system specialist shall secure safety against refrigerant leakage according to local

regulations or standards.

l Use an ELB (Earth Leakage Breaker).

In the event of fault, there is danger of an electric shock or a re if it is not used.

l Do not install the outdoor unit where there is high level of oil mist, ammable gases, salty air or harmful

gases such as sulfur.

l For installation, rmly connect the refrigerant pipe before the compressor starts operating.

For maintenance, relocation and disposal, remove the refrigerant pipe after the compressor stops.

l Do not perform a short-circuit of the protection device such as the pressure switch when operating.

It may cause a re and explosion.

l Do not alter the product and the electrical wiring. It will cause a serious accident.

l Do not install the indoor unit in ammable environment to avoid re or ab explosion.

l As the new refrigerant (R410A) is adopted, the refrigerant oil has been also changed, which tends to be

affected by foreign matters such as moisture, oxide lm, fat. Perform the installation work with care not

to enter moisture, dust or old refrigerant into the refrigerant cycle, otherwise the parts such as expansion

valve bite foreign matter and the operation may be unavailable.

l Do not insert the drain pipe to the drainage trench where corrosive gases occur. Poisonous gases ow

into the room, so that may cause the poisoning.

l Cleaning inside Existing Refrigerant Pipe

* Non-ammable and nontoxic detergent shall be used to clean the pipe. If not, it may cause a re.

* Ventilate well, otherwise cleaning the pipe in the sealed room may cause suffocation. Additionally, if the

detergent contacts a re and is under high temperature, it may cause generation of toxic gas.

* The detergent after cleaning shall be recovered. It is prohibited to emit uorocarbons to the atmosphere

without permission.

DANGER