HiWeigh PH User manual

PHS

1

Warning

In electrical connection of controller, please cut off the power

supply in advance. Wait for 30 seconds between power-on of the

controller for 2 times.

Pay Attention to Static Electricity

The controller is a device sensitive to static electricity, thus please

take anti-static precautions in use and maintenance.

Warning

Ask professional personnel to debug, detect

and repair controller.

Warning

Please keep good grounding of controller.

2

Contents

ITECHNICAL INDICATORS.......................................................................................................3

II MAIN FUNCTION......................................................................................................................3

III BOUNDARY DIMENSION ......................................................................................................3

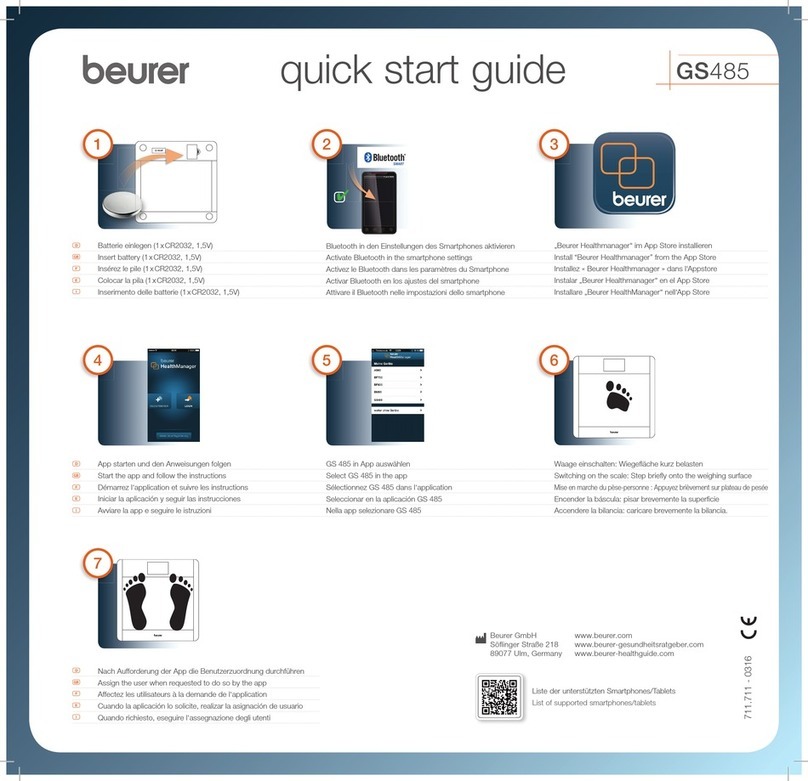

IV INTRODUCTION TO PANEL .................................................................................................4

VPARAMETER SETTING ...........................................................................................................5

SETTING ENTRY................................................................................................................................5

F1 Parameter Setting of Sca ............................................................................................ 5

F2 APPLICATION FUNCTION SETTING ....................................................................................7

F3 ENERGY-SAVING PARAMETER SETTING ...........................................................................8

F4 SERIAL-PORT SETTING...........................................................................................................8

F5 MAINTENANCE AND SERVICE .......................................................................................................9

VI FUNCTION DESCRIPTION ..................................................................................................10

VII Prompt Message of Instrument..............................................................................................11

APPENDIX 1. CONTINUOUS OUTPUT FORMAT SPECIFICATION ................................12

APPENDIX 2. PRINTING FORMAT SPECIFICATION .........................................................14

3

I Technical Indicators

●6-digit 1.2-inch LED display, 7 state indicator lamps. Long service life and shock

resistance

●7functionkeys.Operationissimple and convenient

●Protectionlevel:IP5x

●Excitationvoltage:+5VDC

●Loadcapacityofsensor:atmost4350Ωsimulation sensors

●Inputsignalrangeofnullpoint:0-5mV

●Inputsignalrangeoffullscale:1-10 mV

●Innerresolution:1million

●Weightupgradingrate:40timespersecond

●Powersupplymode

Battery: 6V4Ah

Adapter: voltage 100-240VAC Current 0.1A Frequency 50-60Hz.

●2RS232ports

●Operatingtemperature:-10-40, relative humidity is below 85 %

●Storagetemperature: -20-60, relative humidity is below 85 %

●Conformingtostandard:GB/T7724-1999

II Main Function

●Basicweighingfunction:resetting,removingthepeelandclearingthepeel

●Weightdetectionfunction,countingfunction,animal scale function

●Weightkeepingfunction,weightaccumulationfunction,percentagedisplay

●Setredundantbackupfunctionofparameters

●Automaticscreenprotectionandautomaticshutdownenergy-saving function

●Richprinting formats and communication protocol

III Boundary Dimension

Instrument size: detailed in the following figure (mm); instrument weight: 1.5kg

4

IV Introduction to Panel

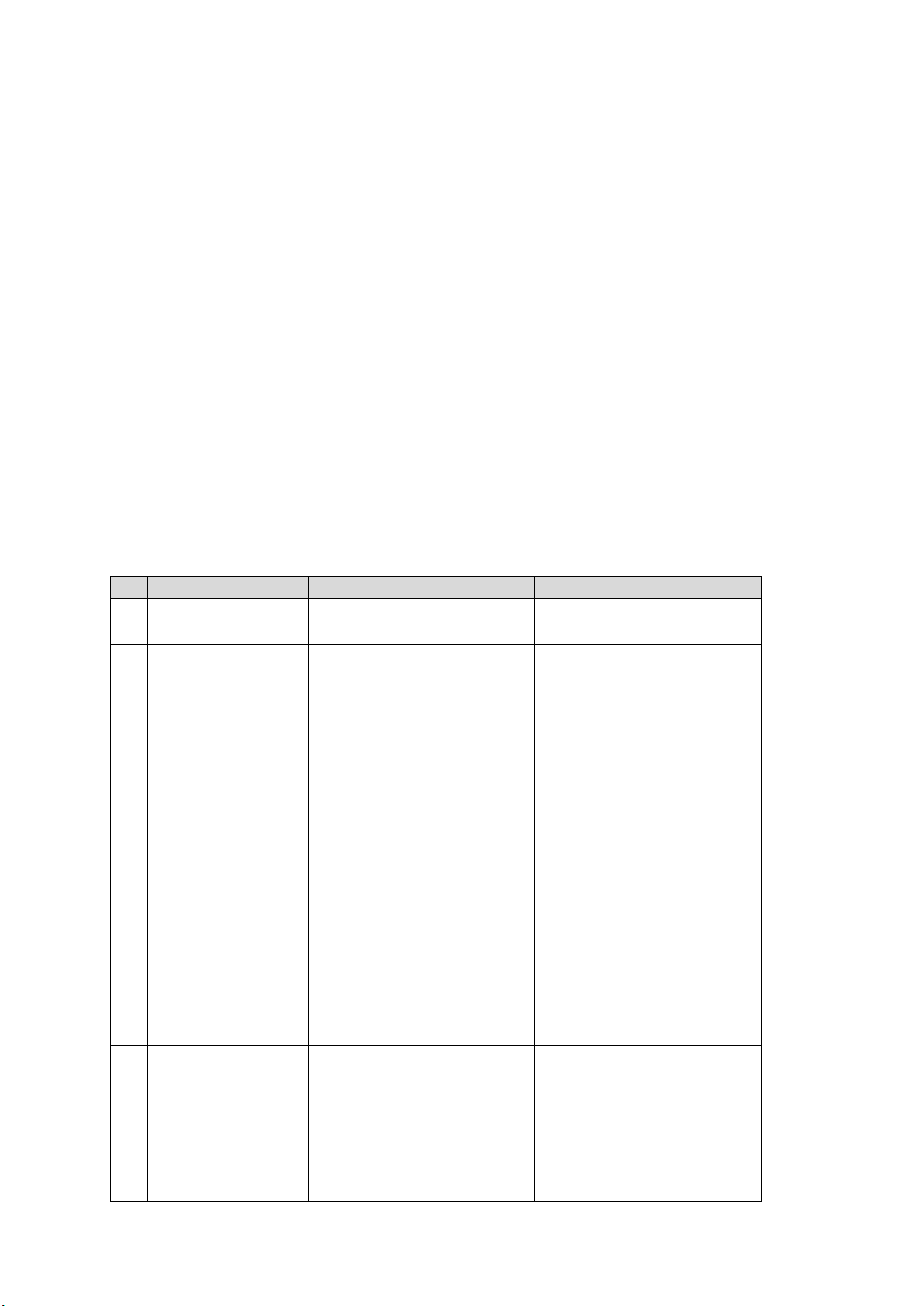

●Introductiontoindicatorlamps

Identificati

on

Analysis

Remark

6

Dynamic and static indication

The lamp is on when scale is in dynamic state, otherwise, the

lamp is off

Zero center indication

The lamp is on when the absolute value of weight on the scale

is less than ±0.2d, otherwise the lamp is off

Net

Identification of gorses weight and

net weight

The lamp is on in net weight and off in gross weight

lb

Weight unit

For indicating current unit

kg

Hold

Weight maintenance

The lamp is on when the weight is locked, otherwise it is off

Ac

Voltage indication of battery and

power supply

The green lamp is on when the voltage of the adapter and

battery is normal, and the red lamp is on in undervoltage state

Introduction to operation keys

Operation without special specification refers to short press on keys.

Key symbol

Normal weighing state

Set stage

Weight maintenance key

Short press→F2.1 = 1, keep/cancel.

F2.1 = 2, switch between percentage and

weight.

F2.1 = 5, switch between quantity and

weight.

Long key→enter setting menu.

Return to the last menu.

Accumulation key

Short key →F2.1 = 4, include display weight in

accumulation value.

Long key →F2.1 = 3, select scale to sample target

weight.

F2.1 = 4, accumulate weight of scale

display.

F2.1 = 5, count sampling of scale.

No definition.

Unit conversion key

Short key →in weighing state, switch weight unit.

The corresponding unit indication lamp is

on.

Flicker bit is on the left.

5

Skin removal key

Short key →net weight turns to gross weight;

induction lamp of net weight “Net” is off.

Flicker bit is on the right.

Skin removal key

Short key →gross weight turns to net weight.

Indication lamp of net weight “Net” is on. Conduct

skin removal operation for multiple times.

Digit flicker position

reduces.

Zero clearing key

Gross weight state resets weight. When the scale is

in net weight, dynamic state, saving state and out of

resetting range, zero clearing operation is invalid.

In setting, digit of flicker

position increases. In

adjustment of display,

accumulation is cleared.

Printing key

Short key →start up or print.

Printing format refers to Appendix1.

Long key →shut down.

Confirm operation, to save

setting data.

V. P a r a m e t e r S e t t i n g

Setting entry:

Press the [Hold] button on the operating panel in the state of normal weighing.

If F1.14 = 0, you can set all the parameters within F1~F5.

If F1.14 = 1, you can only set all parameters within F2~F5.

If F1.14 = 1 and you need to set the parameters within F1 menu, you can press the

calibration switch button until the F1 menu is entered.

F1 Parameter Setting of Scale

F1.1 Measuring Range

Selectable parameters: 3~200000 (default value: 6)

F1.2 Decimal Places

Selectable parameters: 0 ---- no decimal point

0.0 ---- 1 decimal place

0.00 ---- 2 decimal places

0.000 ---- 3 decimal places (default value)

0.0000 ---- 4 decimal places

F1.3 Number of Divisions

6

Selectable parameters: 1 (default value), 2, 5, 10, 20, 50

F1.4 Calibration Unit

Selectable parameters: 0 ---- kg (default value)

1 ---- lb

F1.5 Gravitational Acceleration

Selectable parameters: 9.7000069.99999. Default value = 9.79455.

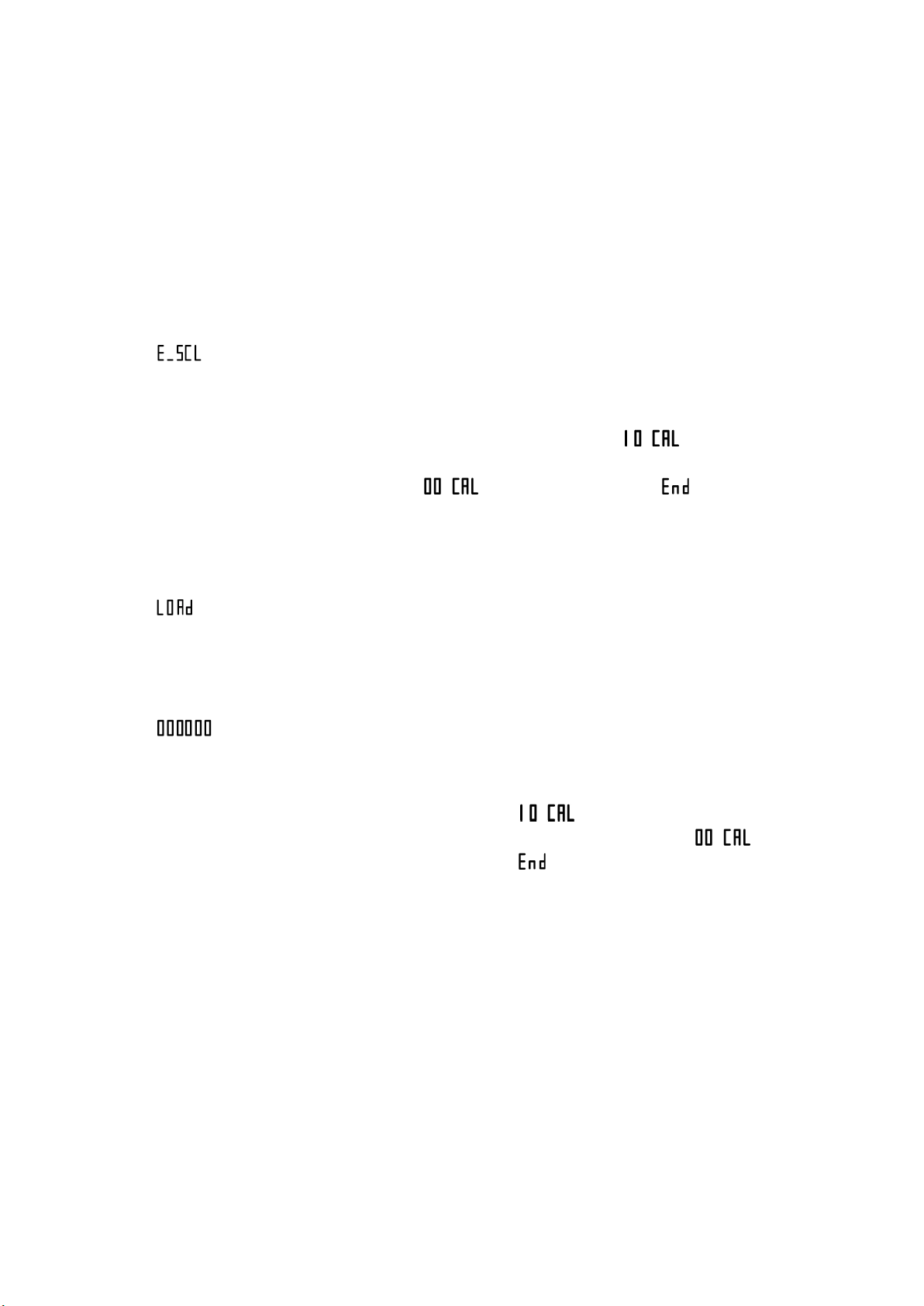

F1.6 Null-point Calibration

Keeping empty the scale

Remove the weights on the weighing platform to

guarantee the scale is in the empty state. Press the [Print]

key and the meter will display [ ]. The displayed

digits will reduce slowly until the meter displays

[]. In the end it will display [ ] for one

second, which indicates the end of null-point

calibration.

F1.7 Load-point Calibration

Loading weights

Load weights on the weighing platform to ensure that 10% of full-scale value ≤weight of weights

≤full-scale value, and then press the [Print] key to start the

next step.

Entering the same weight value as that of the loaded weights.

Entering the same weight value as that of the loaded weights,

please press the [Print] key after the scale becomes stable, and

the meter will display [ ]. After that, the displayed

digits will reduce slowly until the meter displays [ ]. In

the end it will display [ ] for one second, which

indicates the end of null-point calibration.

F1.8 Automatic Null Tracking

Selectable parameters: OFF, 1 d, 2 d, 3 d (default value)

F1.9 Automatic Reset Range at Startup

Selectable parameters: OFF, 2 %, 10 %, 20 % (default value)

F1.10 Button Reset Range

Selectable parameters: OFF, 2 %, 10 % (default value), 20 %

F1.11 Digital Filter

Selectable parameters: 0 ---- Mild Filtering

7

1 ---- Moderate Filtering (default value)

2 ---- Severe Filtering

F1.12 Steady Range

Selectable parameters: 1 d, 2 d, 3 d (default value)

F1.13 Overload Display Range

Selectable Parameters: 9d, 5% (default value), 10%, 20%

F1.14 F1 Menu Protection

Selectable Parameters: 0 ---- Enter F1 menu by keyboard operation

1 ---- Enter F1 menu by pressing the calibration

button

F1.15 Restoring Factory Default

Set the parameters within F1~F4 as the defaults, which can’t impact the parameters of

standard scale.

F2 Application Function Setting

F2.1 Function Selection

Selectable Parameters: 0 ---- Close the application functions (default value)

1 ---- Weight keeping function

2 ---- Percentage display function

3 ---- Weight checking and sorting function

4 ---- Accumulative scale function

5 ---- Counting scale function

6 ---- Animal scale function

F2.2 Empty-scale threshold value

Selectable Parameters: 0~ full range (default value: 0.001)

F2.3 Target Weight for Weight Checking and Sorting

Selectable Parameters: 0~ full range (default value: 2.000)

F2.4 Positive Error for Weight Checking and Sorting

Selectable Parameters: 0~ full range (default value: 0.100)

F2.5 Negative Error for Weight Checking and Sorting

Selectable Parameters: 0~ full range (default value: 0.100)

F2.6 Access to Target Weight for Weight Checking and Sorting, and Counting

Sample Weight

8

Selectable Parameters: 0 ---- Access to Platform Weighing (default value)

1 ---- Manual Input Access

F3 Energy-saving Parameter Setting

F3.1 Time-out Screensaver Time Setting

Selectable Parameters: 0~ 99 minutes, (default value: 30 minutes)

If set to be 0, this function shall not be allowed.

During the screen protection, the display will randomly show “ ”.

F3.2 Energy-saving Time Setting for Auto Power-off

Settable Parameters: 0~250 minutes. (default value: 150 minutes)

If set to be 0, this function shall not be allowed.

F3.3 Display Brightness Control

Selectable Parameters: 0---- low light level

1 ---- middle light level (default value)

2 ---- high light level

F4 Serial-port Setting

F4.1 Setting of UART0 Communication Interface Parameter

F4.1.1 Communication Mode

Selectable Parameters:

---- no output (default value)

---- continuous output protocol A

---- continuous output protocol B

---- continuous output MT

---- firm output protocol A

---- firm output protocol B

---- key dispatch protocol A

---- key dispatch protocol B

F4.1.2 Setting of Data and Check Pit

Selectable Parameters: 8_N_1 ---- 8-pit no parity check (default value)

7_E_1 ---- 7-pit odd parity check

7_O_1 ---- 7-pit even parity check

8_E_1 ---- 8-pit odd parity check

9

8_O_1 ---- 8-pit even parity check

F4.1.3 Baud Rate

Selectable Parameters: 1200, 2400, 4800, 9600 (default value)

F4.1.4 Continuous Output & Delivery Parity Check and Character (only for F4.1=3)

Selectable Parameters: 0 ---- no delivery (default value)

1 ---- delivery

F4.1.5 Bluetooth Node Setting (effective only when Bluetooth module option

is configured)

Selectable Parameters: xxxxi01~xxxx99 (default value: xxxx01)

F4.2 Parameter Setting of UART1 Printing Interface

F4.2.1 Whether to connect the printer

Selectable Parameters: 0 ---- not connected to the miniprinter (default)

1 ---- connected to the miniprinter

F4.2.2 Printing Carriage Return Character

Selectable Parameters: 0~9 carriage return characters (default value: 3)

F4.2.3 Printing Setting of Accumulative Scale

Selectable Parameters: 0 ---- total accumulative data for printing

(default value)

1 ---- printing detail + total accumulative data

F5 Maintenance and Service

F5.1 Key test

Instrument display , pressPrint, Zero, Tare,

Gross, lb/kgand Totalin order, and the instrument displays

, , , , and

, press Holdto quit key test.

F5.2 Display screen test

All strokes of meter display will have self-inspection, to observe

whether there is lacks of strokes.

Press Holdor Printto quit test of display screen.

F5.3 Display current internal code

The display will show internal code of current instrument after

smoothing. Press Holdor Printto quit the interface.

10

VI Function Description

●Weight maintenance function F2.1 = 1

Operation method

In normal weighing state, press Holdon the operation panel, the will

instrument lock display weight of the current scale, and “Hold” indication

lamp is on. Only when weight setting value≥F2.2 is displayed, weight

maintenance operation is effective. Otherwise, it will return to weighing state

after invalid operation information ] is shown for a second.

If weight is in locked state, pressHoldagain to cancel locking of weight and

return to normal weighing state, and “Hold” indication lamp is off.

If it is in weight locking state, refuse to remove skin, clear skin and zero setting

operation.

●Percentage display F2.1 = 2

Display specification

Display , representing 20.5 %.

Pr = current actual weight / range ×100%.

Press Holdto display switch in percentage and weight.

●Check weight and selection scale function F2.1 = 3

Function description

Set parameters such as F2.2 = A, F2.3 = B, F2.4 = C and F2.5 = D.

When display weight is X.

If X ≤A, do not conduct check weight and selection. 7

If X 4(B – D), it lacks of weight, and the display flickers.

If (B – D) ≤X ≤(B – C), it is qualified and the display has normal display

If X 5(B – C), it is overweight and the display flickers.

Acquisition of target value

Press Totallong until the display showsTARGET, and then pressPrint

to show current target value and flicker.

If F2.6 = 0, press Print, the instrument will take the weight on current scale as

the new target value and quit the setting interface.

If F2.6 = 1, the display shows , to request manual change of target value.

After change, press Printto save setting data and quit setting interface.

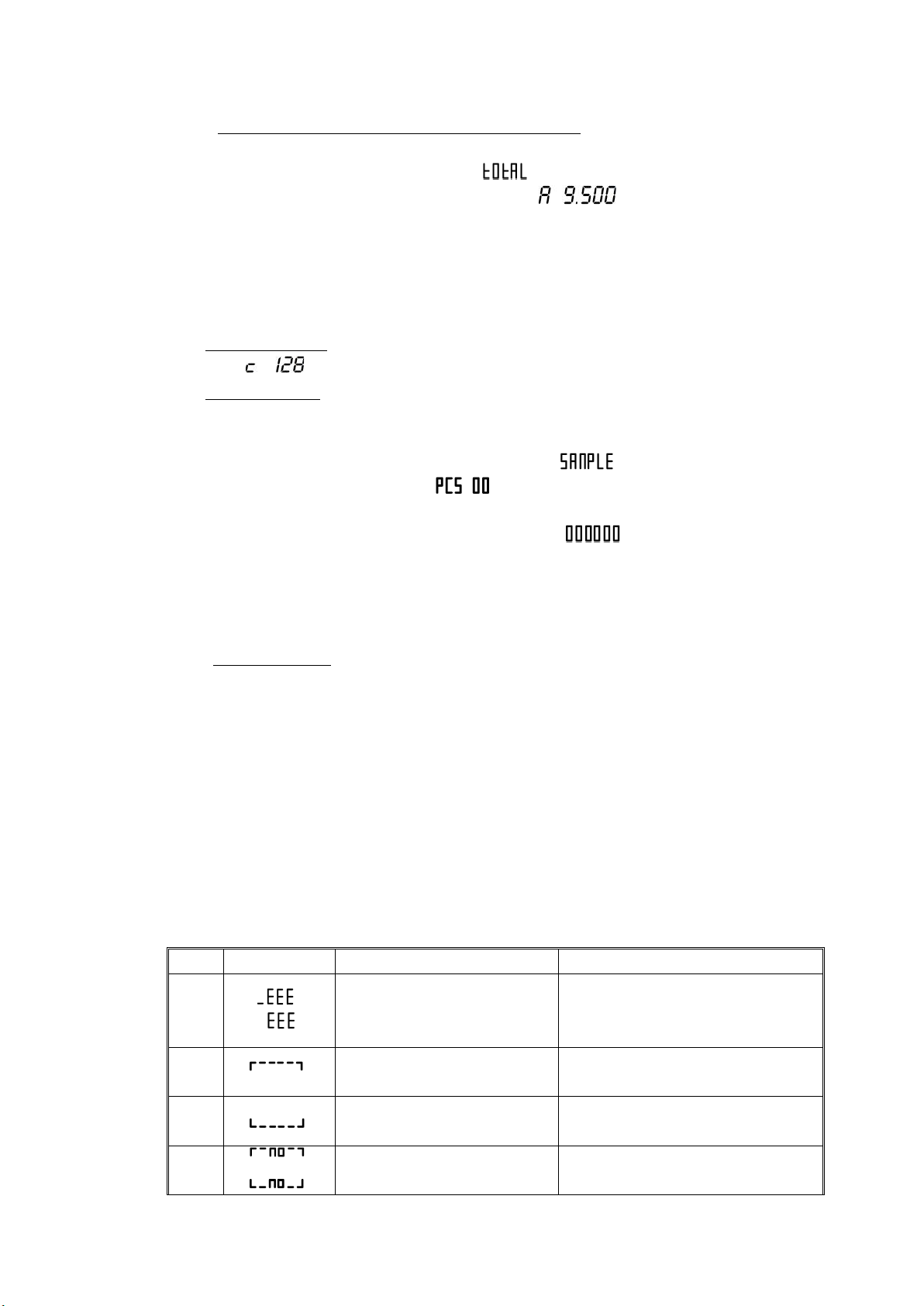

Function of accumulation scale F2.1 = 4

Operation method

In normal weighing state, when the scale is in zero, add weight to the scale and

pressTotalon operation panel, if the display shows progress

bar, it indicates that the current display weight is included accumulated value,

and then it returns to normal weighing state. If the display shows

for a second, and returns to the normal weighing state, it indicates operation is

invalid. Reason: 1. Between two accumulation operations, the scale must have

back-to-zero process, otherwise, accumulation is refused. 2. Accumulation

operation is effective only when display weight≥F2.2 is set. 3. The scale is in

11

dynamic state.

Adjustment, clearing and printing of accumulated value

In normal weighing state, press Totalon operation panel for more than 2

seconds, the display will show for a second, and then the display

shows current total accumulated value and flickers. To clear

accumulated value, press Zero, to make flicker weight be 0. Press Print

to print accumulated data. Press Holdto quit the interface.

Attention: set whether to be over detailed data or accumulated data in F4.6.

Function of counting scale F2.1 = 5

Instrument display

, showing current quantity.

Sampling method

1. Check whether the scale is in zero, if not, press Zerofor zero setting.

2. Place materials counted on the scale.

3. PressTotallong until the display shows , and then pressPrint.

If F2.6 = 0, the display shows . Input the quantity counted just now, and

press Printfor confirmation. The instrument saves sampling data and quits the

sampling interface. If F2.6 = 1, the display shows , input sample weight.

Press Print, the instrument saves setting data and quits sampling setting interface.

4. In this function, pressHoldto display switch between quantity and weight.

Function of animal scale F2.1 = 6

Operation method

In normal weighing state, place the animal on the weighing platform and its

weight must be ≥threshold value set in F2.2. Press Total, instrument will collect

data sampling. After sampling, the average value of sampling data will be locked,

showing A X.XXX. PressPrintto print; press Holdor Totalto quit the

interface.

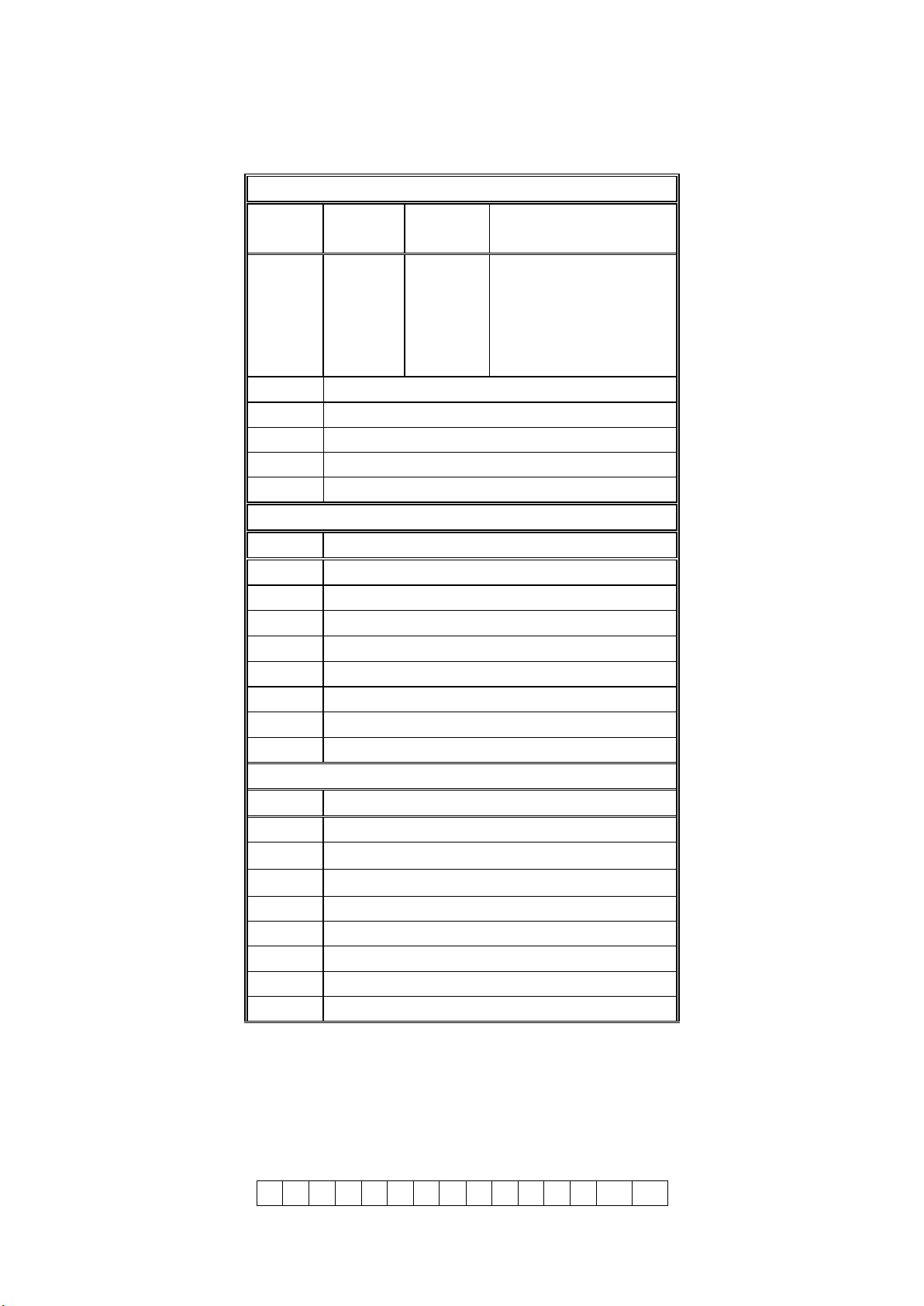

VII Prompt Message of Instrument

The instrument has extremely high stability and reliability, thus is not easy to have error in

general situation. Once an error occurs, please make clear the error first and observe whether the

instrument still has error after power-on. Do not hurry to repair the scale body or instrument.

Repair the instrument according to error code of the instrument as possible.

No.

Symbol

Analysis

Treatment Method

1

Unable to reset after startup

1. Determine it is no-load state in

startup;

2. Make zero calibration again.

2

The weighed object is over full

range for 9 days

Reduce weight on weighing platform

3

The weighed object is below 0

for 5 days

Press Zeroto reset

4

Out of zero clearing range

Check whether the weighing platform

has weight.

12

Remove weight.

5

Invalid operation

6

EEPROM checksum and error

Press Printreprint factory value.

Start up again. If the information

occurs again, return to factory for

repair. Please calibrate the scale

again if the situation does not occur;

Attention: this place is provided with

all parameters of instruments of the

factory.

7

The calibration input weight is

too small

Input≥10 % weight of full range

8

The weight in calibration is too

light

Load≥10% weight of full range

9

The scale is dynamic in scale

Inspect the scale body

10

Setting error of date and time

Set according to specification of date

and time

11

Error of AD initialization

If the error occurs after restarting,

return it to the factory for repair

12

In loading scale, it indicates to

loading weight;

Load weight according to

requirements;

13

It has enters menu setting

Press Printto continue setting.

14

End of zero point and loading

point calibration

15

Including current display

weight in accumulated value

16

Accumulated weight overflows

Clear accumulated weight in time

17

Loading default value

18

Printing

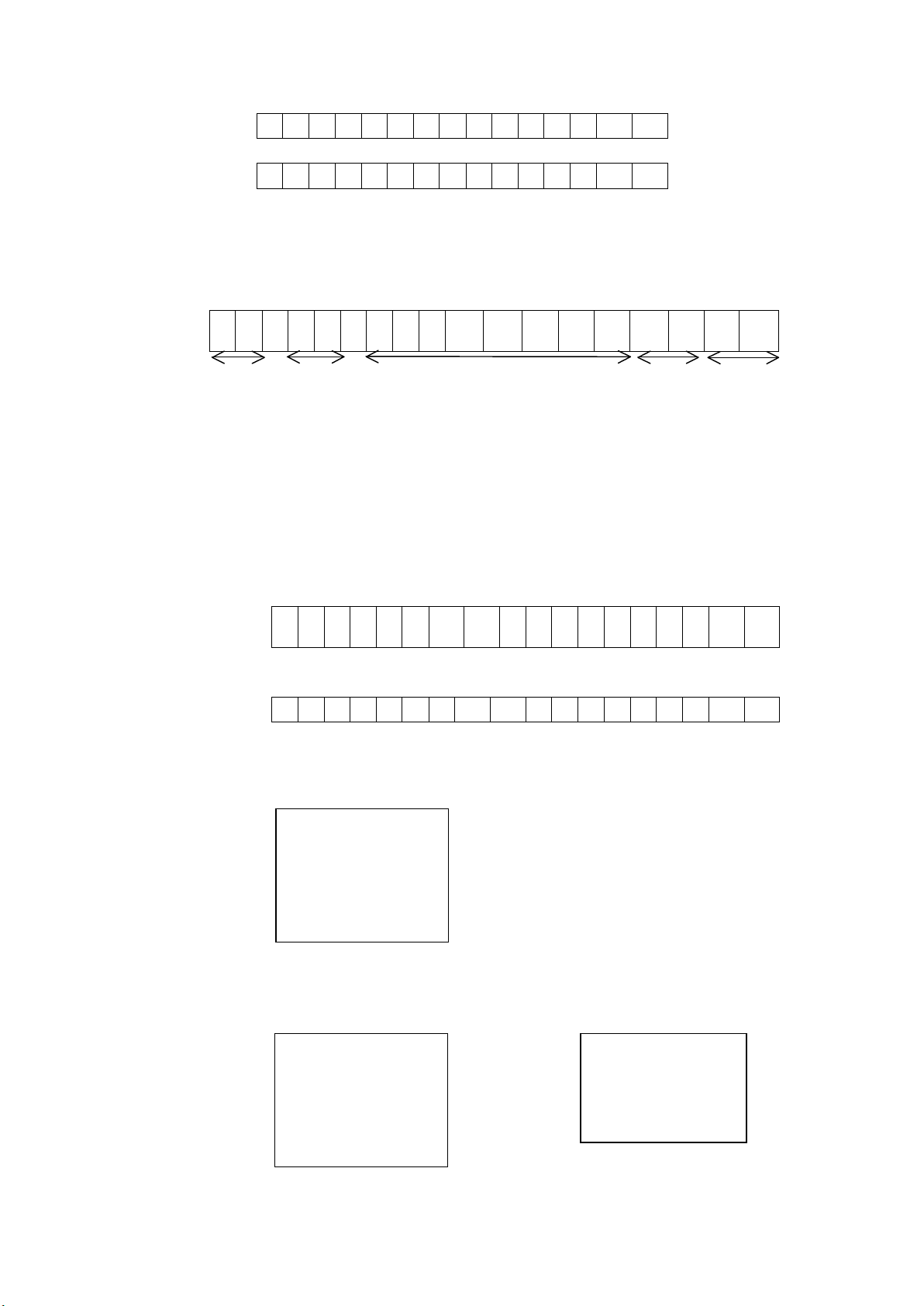

Appendix 1. Continuous Output Format Specification

1. Continuous output MT format

Continuous output MT format has 18 digits.

Continuous output format

ST

X

A

B

C

X

X

X

X

X

X

X

X

X

X

X

X

C

R

CK

S

1

3

6

6

1

1

Where

1. <STX> ASCII02H0

2. Status word: A, B, C

3. Display weight, possibly gross weight or net weight, 6 digits without symbol or

decimal point.

4. Tare weight, 6 digits without symbol or decimal point

13

5. <CR> ASCII carriage return (ODH)

6<CKS> optional checksum and (no output in F4.2.3 = 0)

Status word: A, B, C.

Status word A

Bit 0

Bit 1

Bit 2

Position of decimal

point

0

1

0

1

0

1

1

0

0

1

0

0

1

1

1

XXXXXX

XXXXX.X

XXXX.XX

XXX.XXX

XX.XXXX

Bit 3

Constant 0

Bit 4

Constant 1

Bit 5

Constant 0

Bit 6

Constant 1

Bit 7

Constant 0/check bit

Status word B

Bits

Function

Bit 0

Gross weight = 0, net weight = 1

Bit 1

Symbol: positive = 0, negative = 1

Bit 2

Overload (upper and lower overload) = 1

Bit 3

Static = 0, dynamic = 1

Bit 4

Constant 1

Bit 5

Constant 1

Bit 6

Constant 0

Bit 7

Constant 0/check bit

Status word C

Bits

Function

Bit 0

Unit: kg = 0, lb = 1

Bit 1

Constant 0

Bit 2

Constant 0

Bit 3

Constant 0

Bit 4

Constant 1

Bit 5

Constant 1

Bit 6

Constant 0

Bit 7

Constant 0/check bit

2. Continuous output A format

The data transmitted by continuous output protocol A is present display weight.

Gross weight format: ww0000.000kg or ww0000.000lb

Net weight format: wn0000.000kg or wn0000.000lb

Example: gross weight of 15.000kg

w

w

0

0

0

1

5

.

0

0

0

k

g

0d

0a

14

Net weight of 15.000kg

w

n

0

0

0

1

5

.

0

0

0

k

g

0d

0a

Gross weight-15.000kg

w

w

-

0

0

1

5

.

0

0

0

k

g

0d

0a

Note: the above position of the decimal point is determined according to that in the

instrument.

3. Continuous output B format

Continuous output agreement B format:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

HEAD1 , HEAD2 , DATA UNIT CR/LF

HEAD12OL Upper overload or lower overload, or no zero clearing in startup;

ST the scale is in stable state;

US the scale is in unstable state;

HEAD22GS gross weight3

NT net weight3

DATA2instrument display data3

UNIT2kg or lb3

CR/LF2new line.

Example 12in stale state, gross weight is 18.000kg. sp = space.

S

T

,

G

S

,

sp

sp

1

8

.

0

0

0

k

g

0d

0a

Example 22in unstable state, net weight is -0.200kg. sp = space.

U

S

,

N

T

,

-

sp

sp

0

.

2

0

0

k

g

0d

0a

Appendix 2. Printing Format Specification

F2.1 = 0, 1, 4, 61print current resetting, pressPrint.

F2.1 = 1 weight maintenance function:

Weight is not in maintenance state: Weight is in maintenance state:

or

REPORT

------------------------

Gross 0.200kg

Tare 0.000kg

Net 0.200kg

REPORT

----------------------

Gross 25.000kg

Status Hold

REPORT

------------------------

Gross 0.200kg

Tare 0.000kg

Net 0.200kg

15

F2.1 = 3 selection, check weight, press Print:

Underweight Qualified Overweight

F2.1 = 4 accumulation scale, print detailed statement or format of total weight:

Print details and total weight Only print total weight

F2.1 = 5 counting scale, pressPrint:

REPORT

-----------------------

Gross 1.980kg

State Less

REPORT

-----------------------

Gross 2.000kg

State OK

REPORT

-----------------------

Gross 2.020kg

State Over

REPORT

----------------------

Gross 0.547kg

Amount 55

REPORT

----------------------

Net 25.000kg

Status Hold

REPORT

-------------------------

1 0.200kg

2 0.175kg

3 0.347kg

4 0.375kg

-------------------------

Total 1.097kg

REPORT

-------------------------

Total 1.097kg

APPENDIX 3

GUIDE TO SAFE OPERATION

For safe operation of the truck, please read all warning signs and instructions here and on the truck before using this truck.

Do not operate the pallet truck unless you are familiar with it and have been trained or authorised to do so.

Do not operate the truck unless you have checked its condition. Give special attention to the wheels, the handle

assembly, the forks, lift and the lower control.

Do not use the truck on sloping ground.

Never place any part of your body in the lifting mechanism or under the forks or load. Do not carry passengers.

The operator should wear gloves and safety shoes for protection.

Do not handle unstable or loosely stacked loads.

Do not overload the truck.

Do not subject to unbalanced load, either side to side or along the length of the frame.

The capacity of the truck assumes an evenly distributed load with the centre of the load being at the halfway point

of the length of the forks.

Make sure that length of the forks matches the length of the pallet.

Lower the forks to lowest height when the truck is not being used.

At other specific conditions or places, the operator should operate the pallet truck carefully.

TROUBLE SHOOTING FOR PALLET TRUCK

NO

TROUBLE

CAUSE

ACTION

1

The forks do not lift

to maximum height.

-Not enough hydraulic oil.

-Add more oil.

2

The forks do not lift

up.

-Not enough hydraulic oil.

-The oil has impurities.

-Discharge valve is out of

adjustment.

-Air in the hydraulic oil.

-Pour in more filtered oil.

-Change the oil.

-Adjust the setting screw (B48).

-Expel the air.

3

The forks do not

descend.

-The rod (B101) and the pump

cover (B02) are deformed resulting

from a seriously unbalanced load.

-A part has been broken or been

deformed resulting from

unbalanced load.

-The setting screw (B48) is not in the

correct position.

-Replace the rod (B02) or pump

cover (B101).

-Repair or replace component.

-Adjust the setting screw (B48).

4

Leaks

-Seals worn out or damaged.

-Some parts may be cracked or

worn out.

-Replace seals with new ones.

-Check and replace with new ones.

5

The forks descend

without being

lowered.

-Impurities in the oil cause the

discharge valve (B106) to fail to

close.

-Air in the oil.

-Seals worn or damaged.

-Discharge valve (B106) is out of

adjustment.

-Replace with filtered oil.

-Expel the air.

-Replace with new ones.

-Adjust the setting screw (B48).

2

Figure 1

3

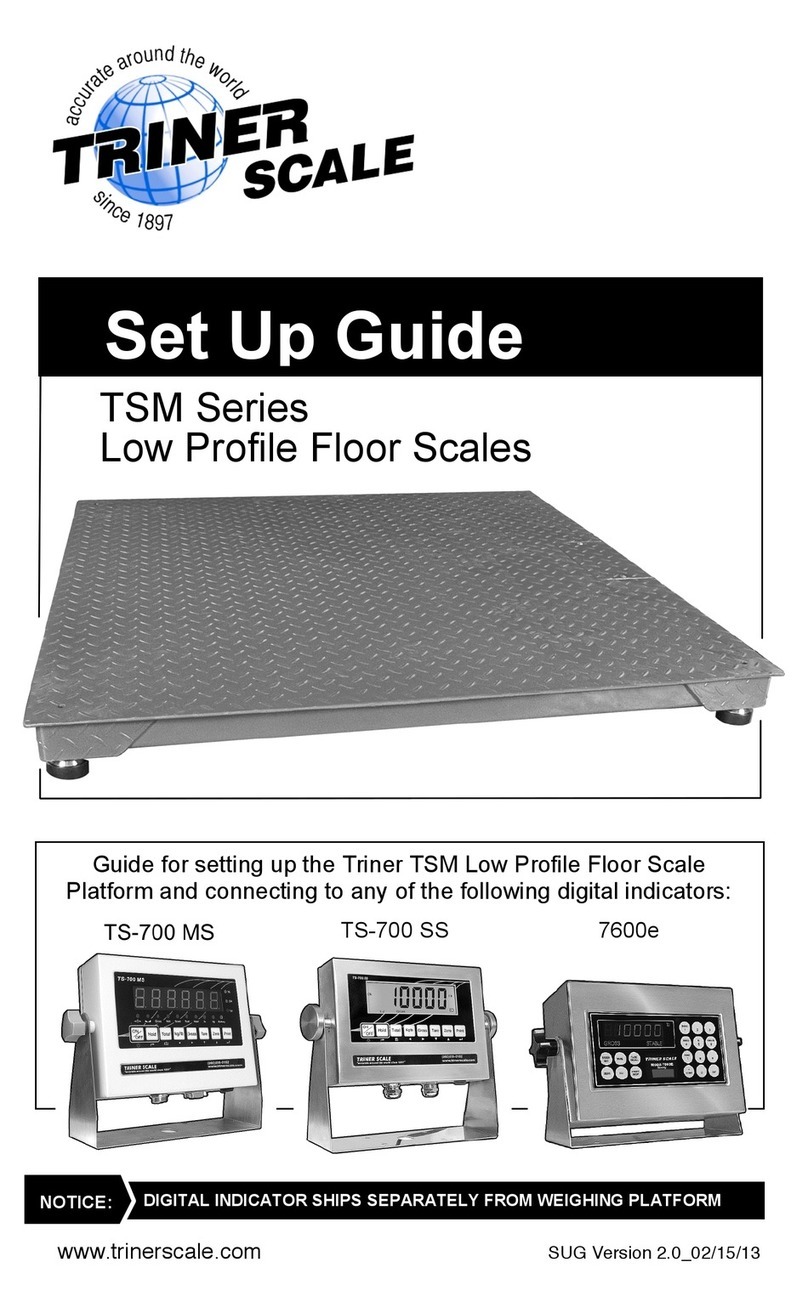

WIRING DIAGRAM OF JUNCTION BOX

L1~L4 Connect sensor connector

GND

silver

-S

white

+S

green

-E

black

+E

red

L0 -Connect meter connector

GND

silver

-S

white

+S

green

-E

black

+E

red

This manual suits for next models

1

Table of contents

Other HiWeigh Scale manuals