I 0667 -5

Sp r i n g

DC WD Co n e

4

GB

3 - START - UP

3.1 - ELECTRICAL CONNECTION

THE ELECTRICAL CONNECTION MUST BE MADE BY SPECIALIZED PERSONNEL. CONNECTION TO THE SINGLE PHASE MAINS MUST

BE MADE BETWEEN PHASE AND NEUTRAL, AND NEVER, UNDERANY CIRCUMSTANCES, BETWEEN PHASE AND EARTH (GROUND).

EFFICIENT EARTHING (GROUNDING) IS ESSENTIAL FOR CORRECT MACHINE OPERATION. THE MANUFACTURER DECLINES

ALL RESPONSIBILITY AND WARRANTY IN THE EVENT OF INCORRECT CONNECTION.

Before connecting the machine to the mains through relative cable, check that the mains voltage matches the one

shown on the nameplate at the back of the balancing machine. Rating of the electrical connection should be on the

basis of the machine electrical power consumption (see nameplate).

The machine mains supply cable should be fitted with a plug conforming to current regulations.▪

It is recommended to provide the machine with its own electrical connection through a slow acting safety switch▪

rated at 4 A (230 V) or 8A (115 V).

When connection is made directly to the main control panel without using any plug, it is advisable to padlock the▪

main switch of the balancing machine in order to limit its use to authorized personnel only.

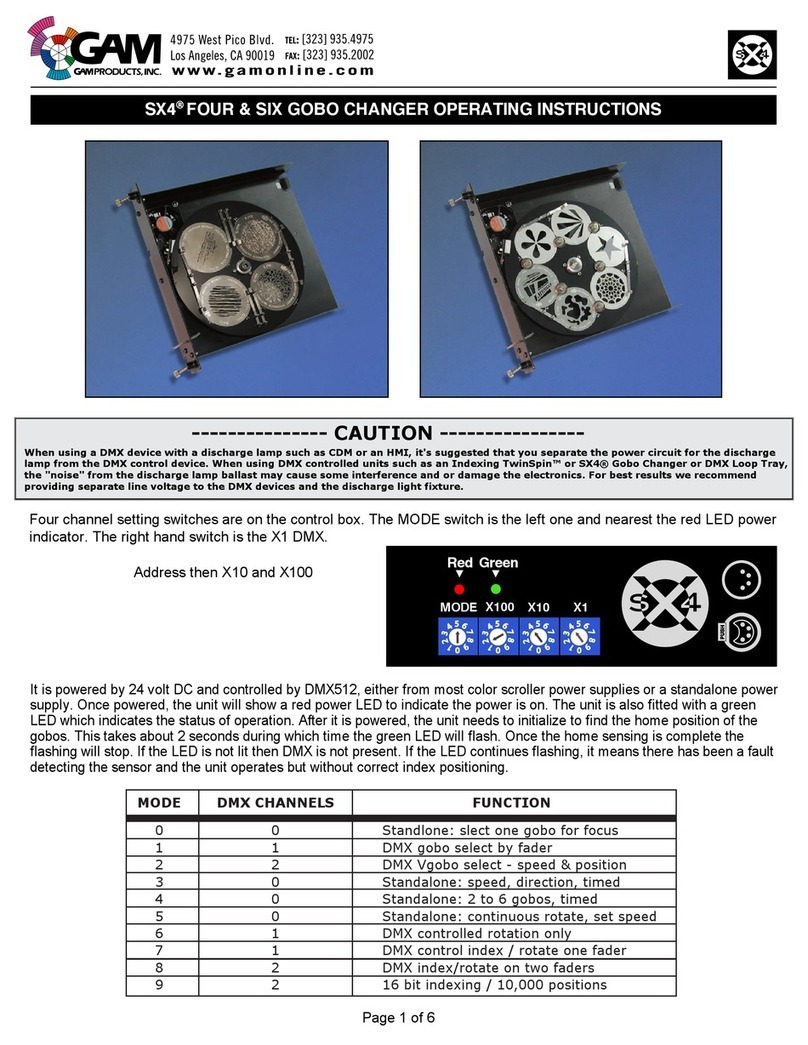

3.2 - ADAPTER MOUNTING

The wheel balancer is supplied complete with cone►

type adapter for fastening wheels with central bore.

The threaded terminal is fitted according to the dra

wing; it can be removed to fit optional adapters.

It can be removed to fit optional adapters.

3.3 - WHEEL MOUNTING

The wheels should be fastened with one of the numerous adapters manufactured by the manufacturer (see enclosed

brochures). Incorrect centering inevitably causes unbalance.

3.4 - WHEEL GUARD ASSEMBLY AND ADJUSTMENT (option)

a) Fasten the components to the base as illustrated in the specific exploded drawing.

b) N.b.: The tip of the microswitch must fit into the relative seat when the guard is closed.

Note: Do not lean on the guard during the wheel balancing cycle.

3.5 - WD/DC SPACER (option)

When balancing very wide wheels (9”), there might be not enough space to turn the distance gauge. To move the

wheel away from the machine side, fit the WD spacer on the flange body and secure it with the standard issue nuts.

When centring the wheel with cone from the inside, mount the DC spacer to obtain spring thrust.