Instructions –PRO Forklift Service Body Rack

For Technical Support Call: 800-343-7486, Monday-Friday, 7AM - 4 PM (PST) Page 4

Table of Contents

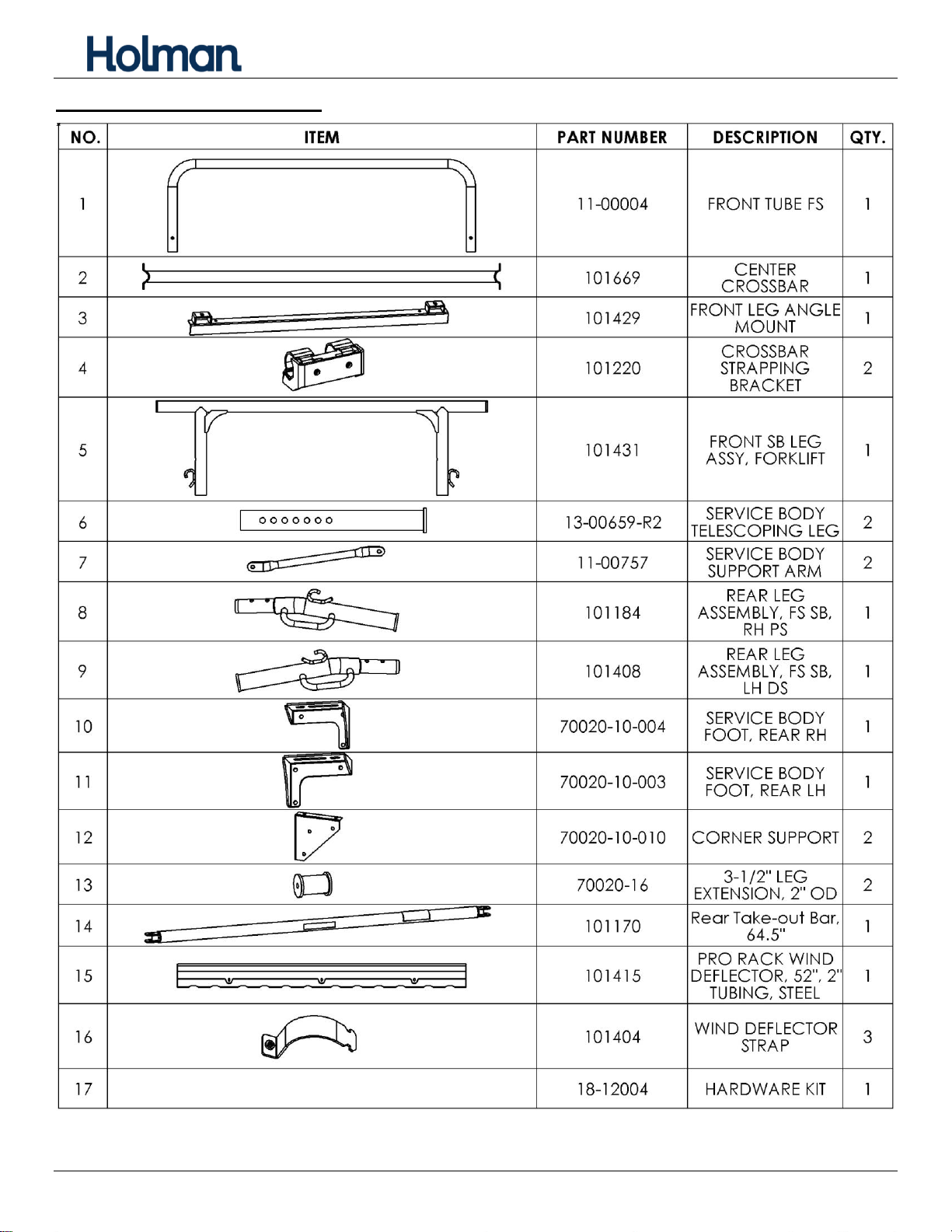

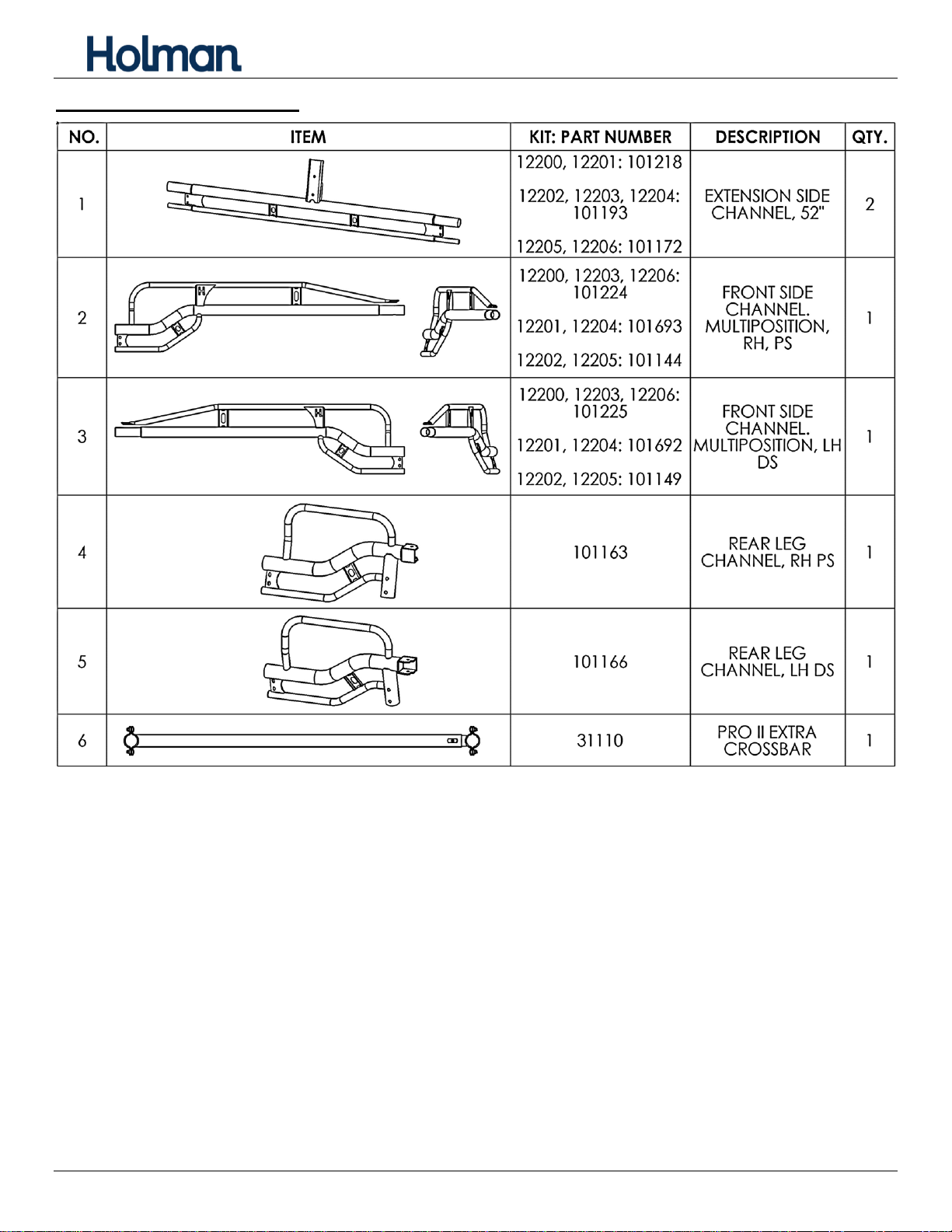

Leg and Bar Kit Parts List................................................................................................................5

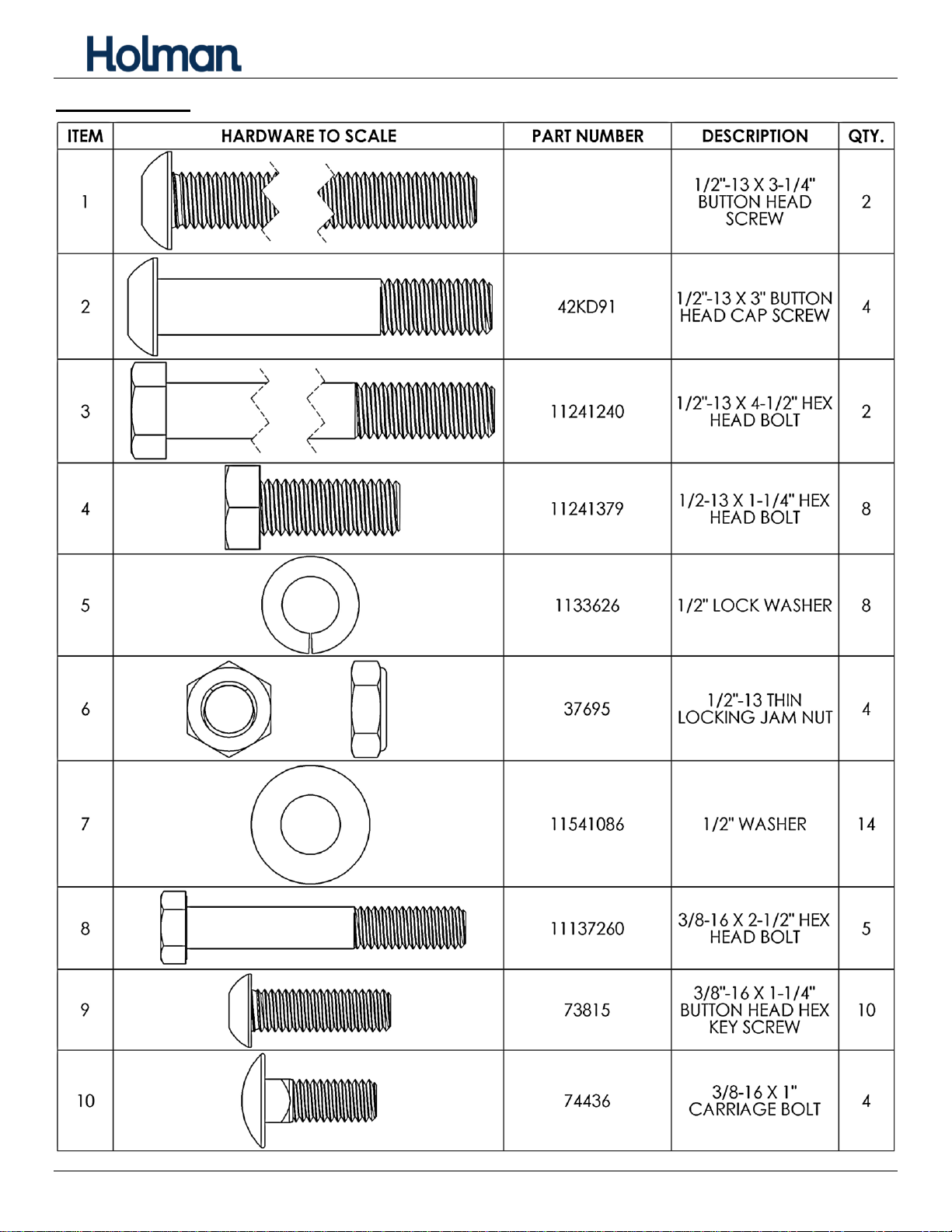

Hardware Kit....................................................................................................................................7

Hardware (Continued) .....................................................................................................................8

Sealant Application..........................................................................................................................9

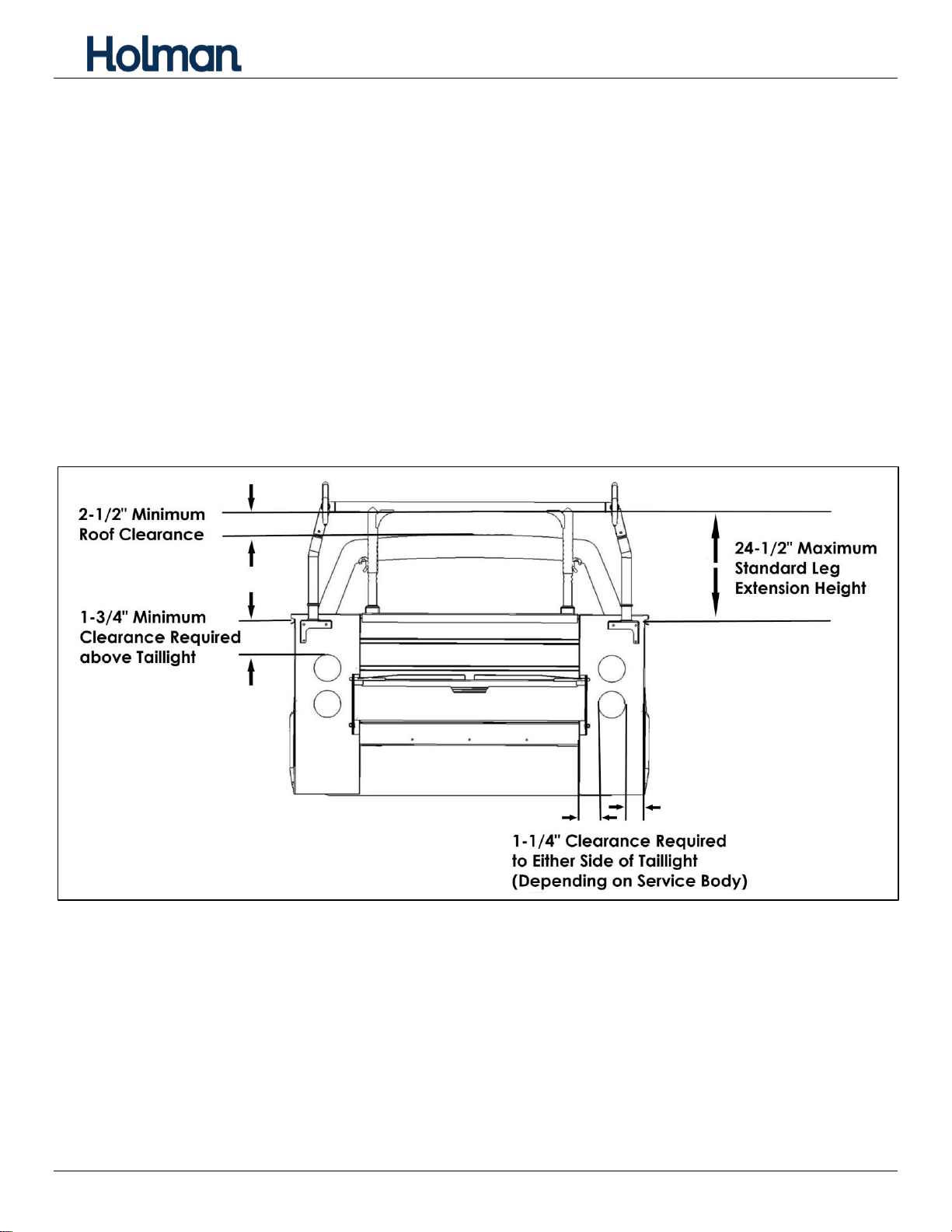

Step 1 –Measure Service Body and Truck .....................................................................................9

Step 2 –Install Front Leg Angle Mount .........................................................................................10

Step 3 –Install Bulkhead Bracing..................................................................................................10

Step 4 –Assemble Front Leg Assembly........................................................................................11

Step 5 –Join Side Channels .........................................................................................................11

Step 6 –Attach Wind Deflector......................................................................................................12

Step 7 –Attach Front Tube............................................................................................................13

Step 8 –Attach Center Crossbar...................................................................................................13

Step 9 –Attach Rear Take-out Bar................................................................................................13

Step 10 –Attach Rear Legs...........................................................................................................14

Step 11 –Attach Front Legs..........................................................................................................14

Step 12 –Install Foot to Rack........................................................................................................16

Step 13 –Install Rack onto Service Body......................................................................................17

Step 14 –Install Support Arm........................................................................................................18

Step 15 –Tighten Hardware..........................................................................................................18

Troubleshooting.............................................................................................................................19

Rear Take-out Bar Position Lock...................................................................................................19

Adjust Wind Deflector....................................................................................................................19

Install Extra Crossbar ....................................................................................................................20