INSTALLATION INSTRUCTIONS

62-0282-02

P7640U Differential Pressure Sensors

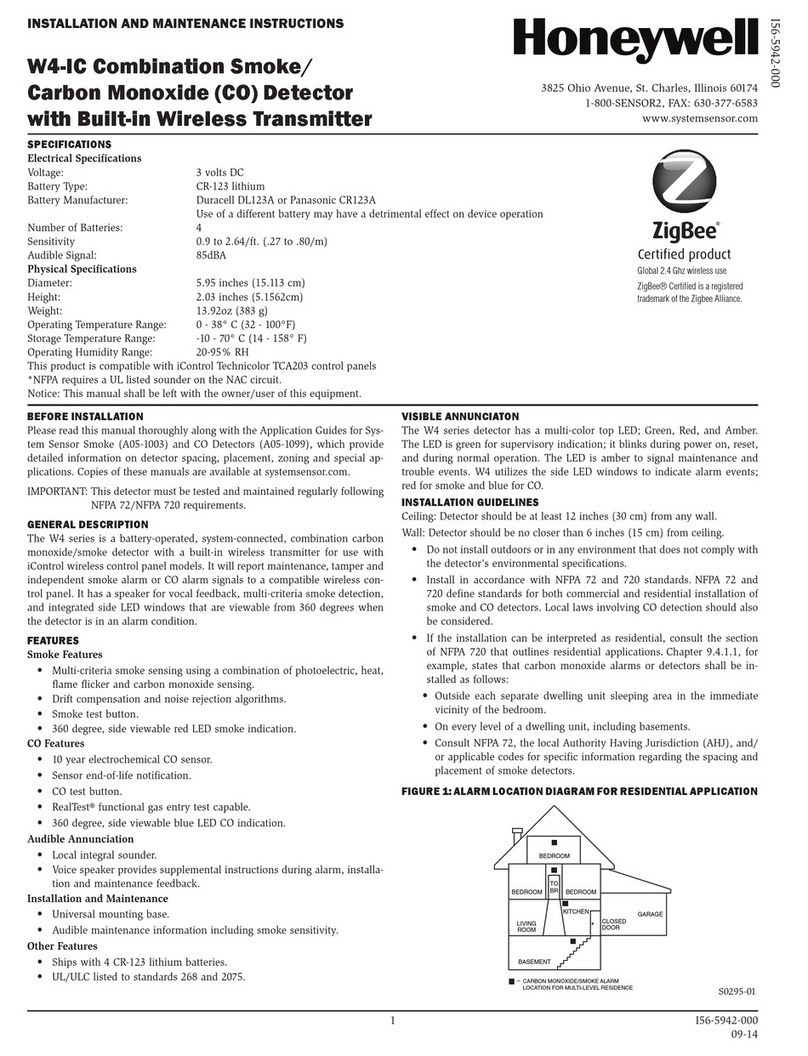

APPLICATION

The P7640U Universal Differential Pressure Sensors

provide reliable, accurate measurement and control.

Proper applications include measurement of extremely

low pressure applications such as: building/room

pressure, air flow, variable air volume, filter status, and

duct pressure. They are ideal for clean rooms, hospitals,

fume hoods, and computer rooms.

The P7640 Pressure Sensors are designed with field-

selectable 4-20 mA, 0-5 Vdc, or 0-10 Vdc output. The

pressure ranges fall between 0–10 in. w.c./0–2500 Pa.

See Table 2.

Accessory

32003169-001 Duct Pressure Pick-up Probe, 4 in.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazard-

ous condition.

2. Check ratings given in instructions and on the

product to ensure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

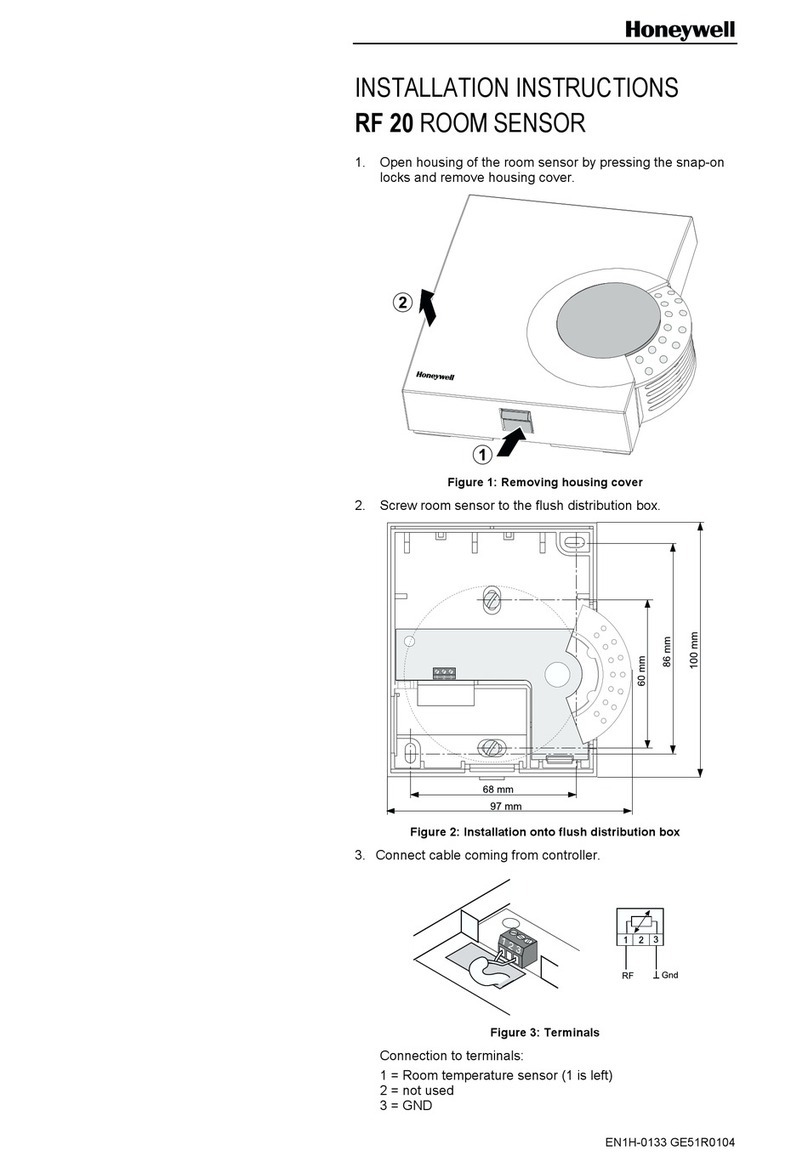

Mounting

Screw holes are accessed inside the enclosure (with the

cover removed) and are located in the upper left and

lower right corners.

Panel Mount

Run tubing from one (static) or both (differential) barb

fittings, making sure the typically higher pressure source

is connected to the port labeled HI, and the typically

lower pressure source is connected to the port labeled

LO.

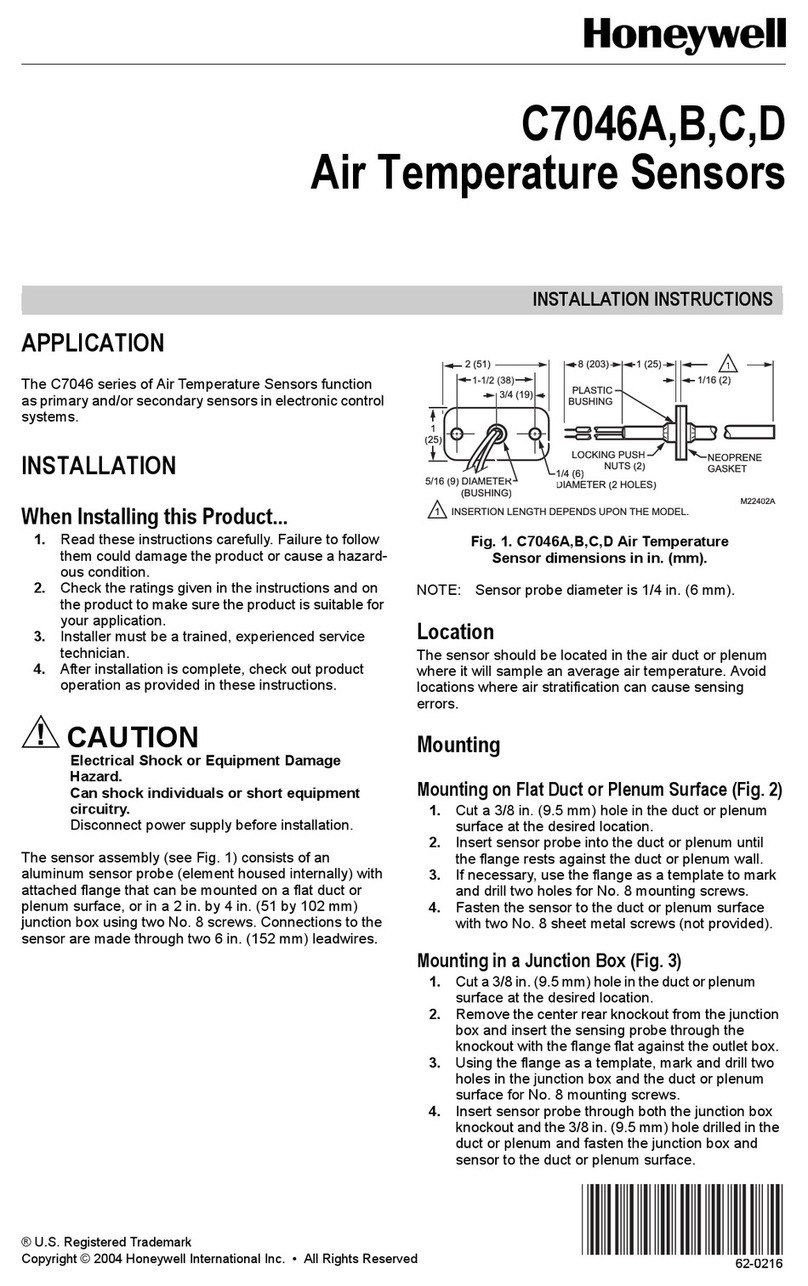

Configure the internal tubing as shown in Fig. 1. Use

small diameter tubing for panel mount configuration.

Duct Mount

1. Thread probe into the back of the housing.

2. Configure internal tubing as shown in Fig. 2. Use

large diameter tubing for duct mounting

configuration.

3. Unit is typically mounted at the high pressure loca-

tion when used for differential control.

CONFIGURATION

Select the proper output, mode, and pressure range

using the switches and jumpers:

1. Select output using the output switch:

a. Current: mA (then skip to step 3), or

b. Voltage: Volt.

2. Select 0-10 Vdc or 0-5 Vdc using jumper J4.

3. Select bi- or uni-directional mode using jumper J5.

NOTE: Setting for 0 to 10 in. w.c. and bi-direc-

tional will give output from -10 to 10 in.

w.c.

4. Select inches w.c. or Pascal scale using jumper J7.

5. Select fast or standard response time using jumper

J8.

6. Select appropriate full-scale pressure range using

the rotary switch. Align arrow (not the slot) to the

desired range. See Table 2 for the range selection

guide.

NOTE: The universal model is marked full scale.

When the range is changed, the LCD

models momentarily indicate selected

range.

7. Set output according to Table 1.