Honeywell Aquastat L7224U User manual

Other Honeywell Controllers manuals

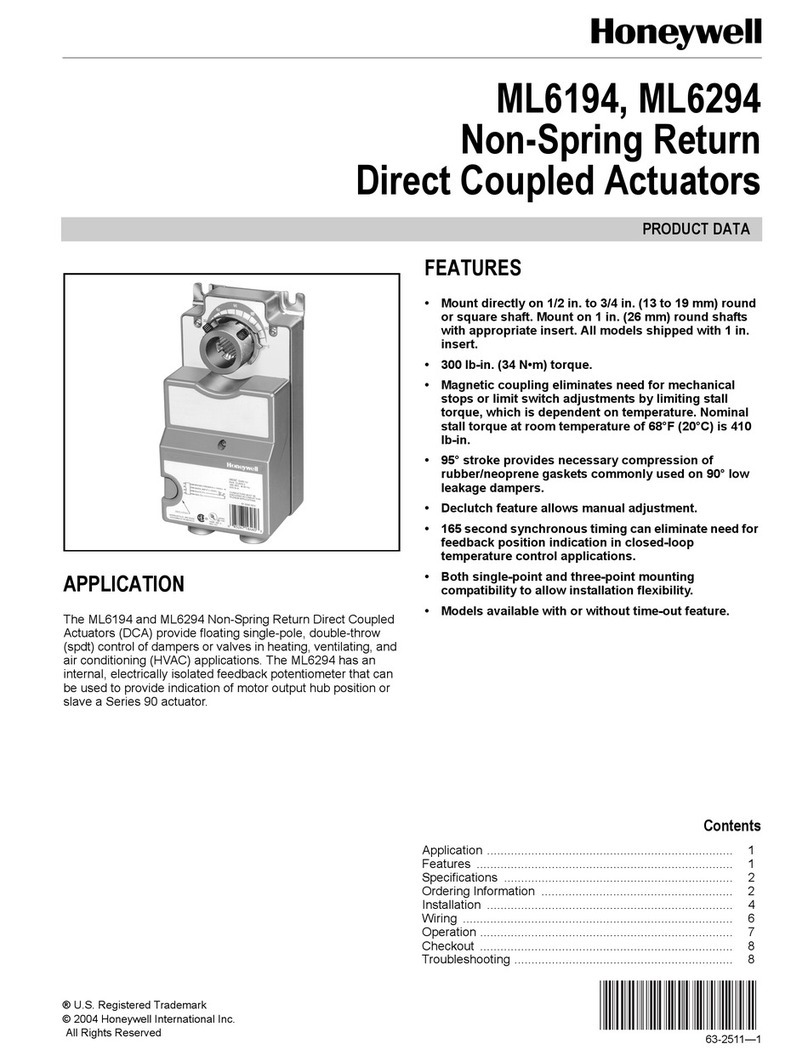

Honeywell

Honeywell Excel 10 User manual

Honeywell

Honeywell UDC3300 User manual

Honeywell

Honeywell HW-AV-LTE-M User manual

Honeywell

Honeywell V8200 User manual

Honeywell

Honeywell T775U Series User manual

Honeywell

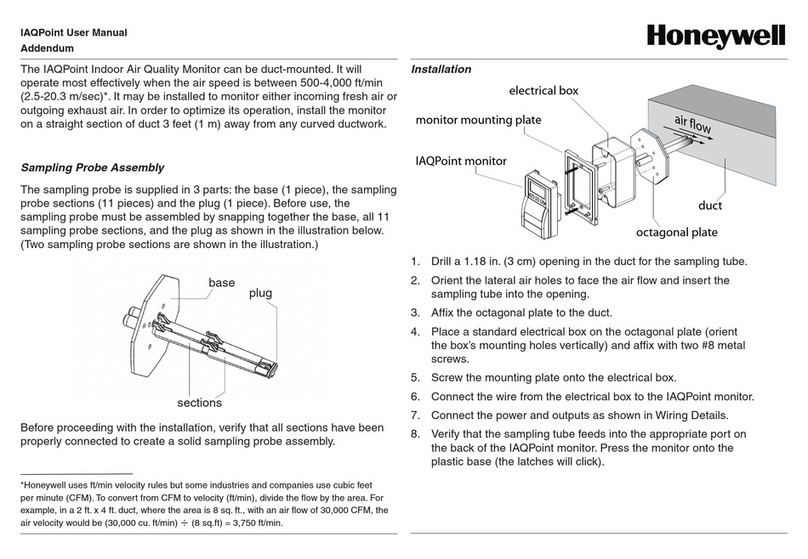

Honeywell IAQ Poin User manual

Honeywell

Honeywell C7150B Operation manual

Honeywell

Honeywell LeakFilm MC User manual

Honeywell

Honeywell Pressuretrol P7810A Operation manual

Honeywell

Honeywell CIPer 50 User manual

Honeywell

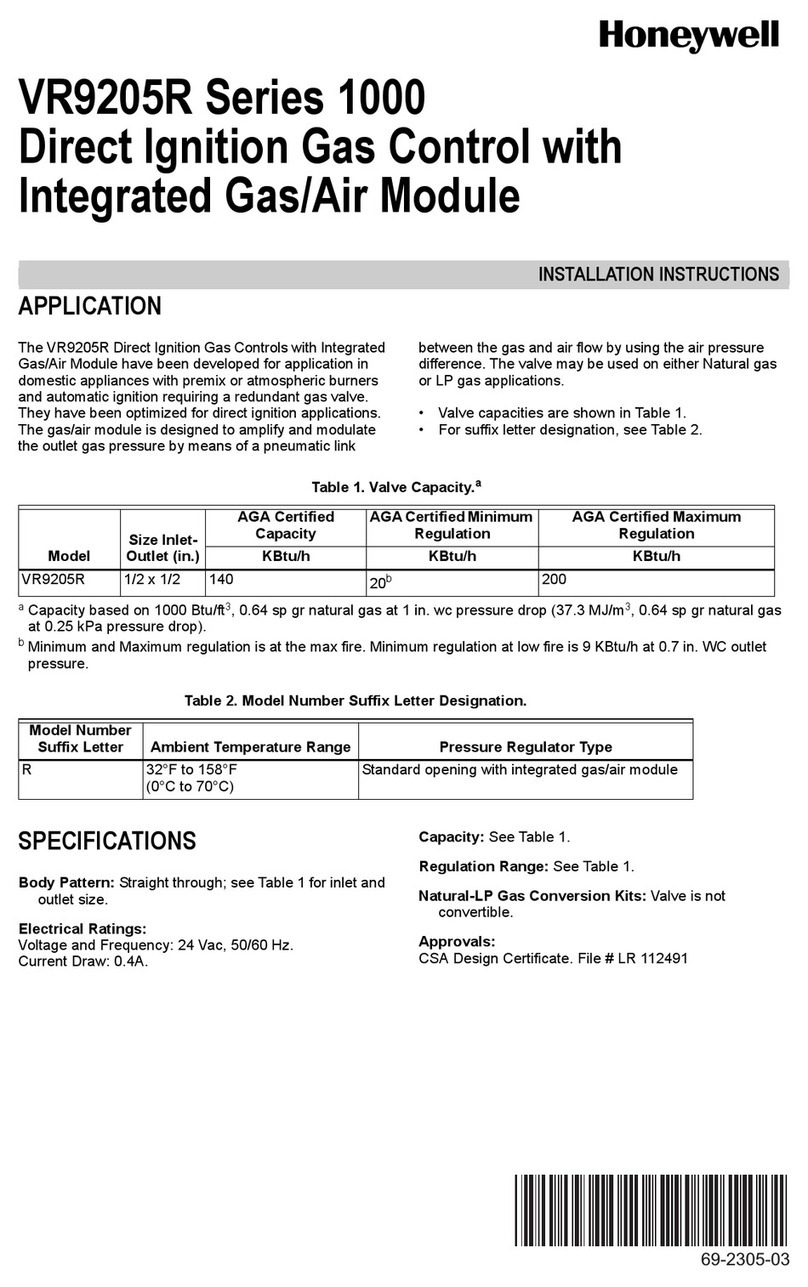

Honeywell 1000 Series User manual

Honeywell

Honeywell UDC100 User manual

Honeywell

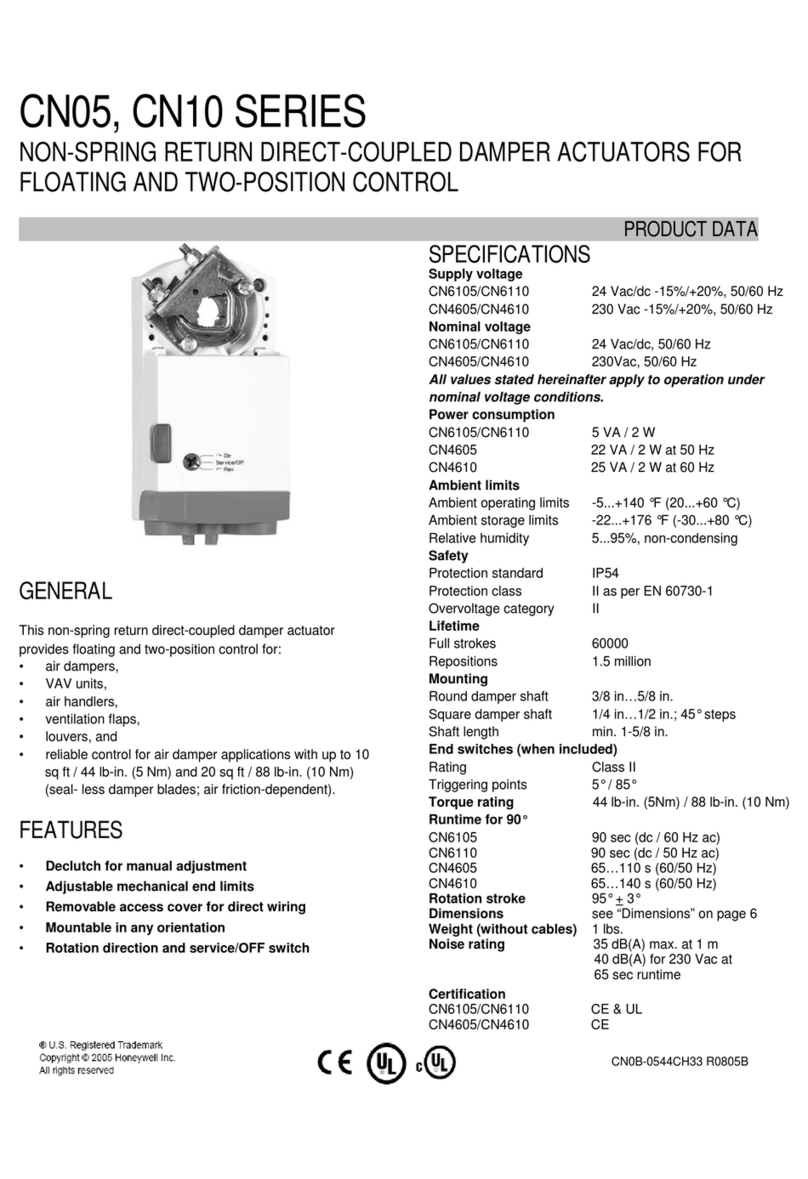

Honeywell CN05 Series User manual

Honeywell

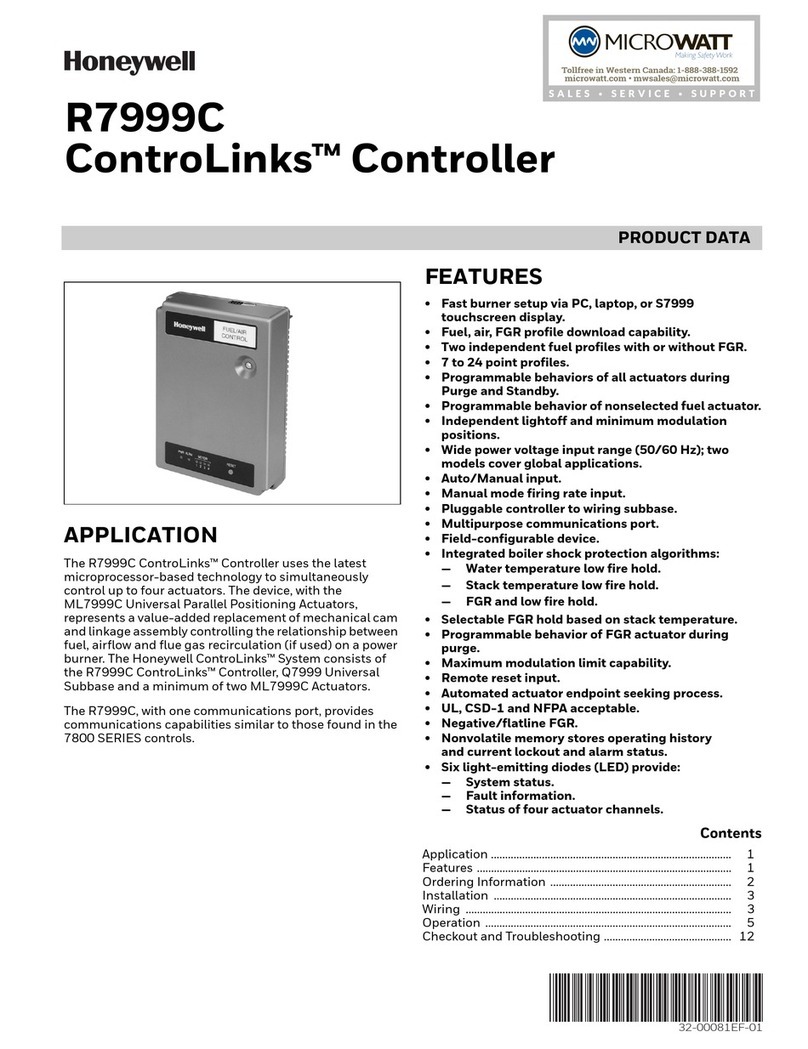

Honeywell ControLinks R7999C User manual

Honeywell

Honeywell L4188 User manual

Honeywell

Honeywell MIWI350 Operating instructions

Honeywell

Honeywell Mini-AT User manual

Honeywell

Honeywell Vista Automation Module User manual

Honeywell

Honeywell Unipoint 2306B1000 User manual

Honeywell

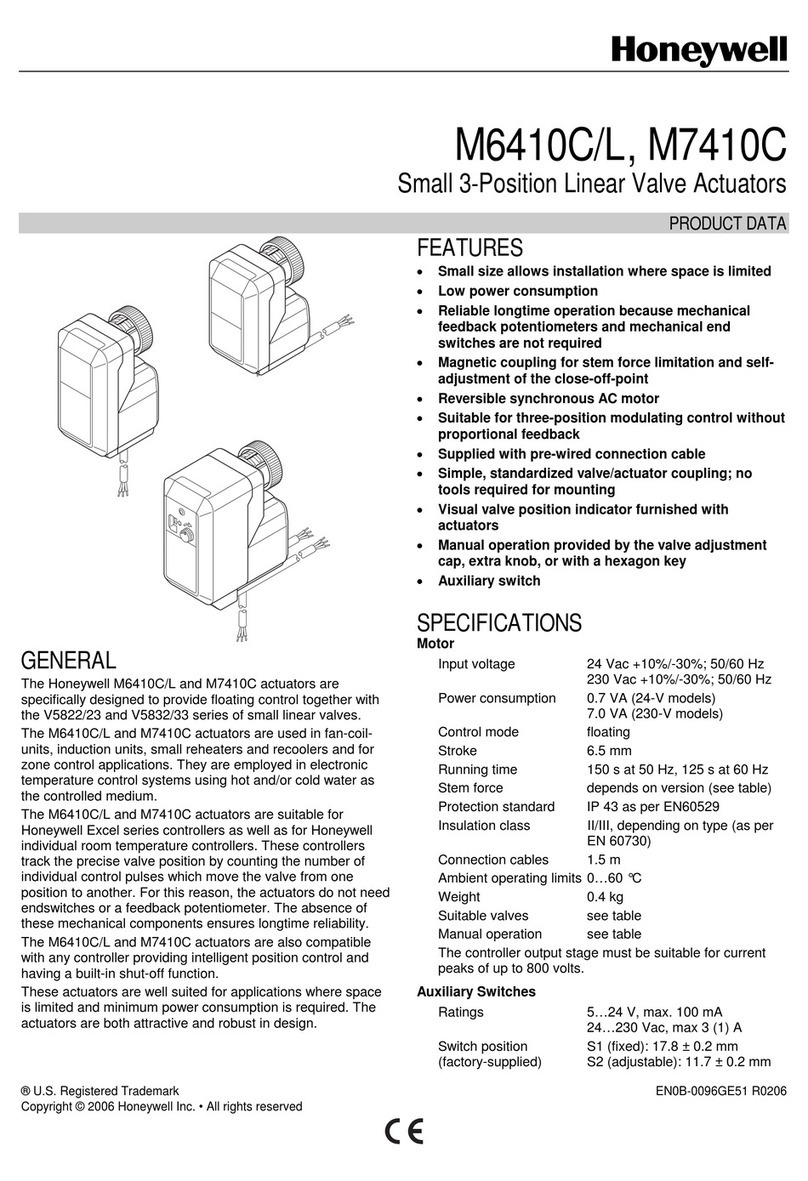

Honeywell M6410C/L Operation manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions