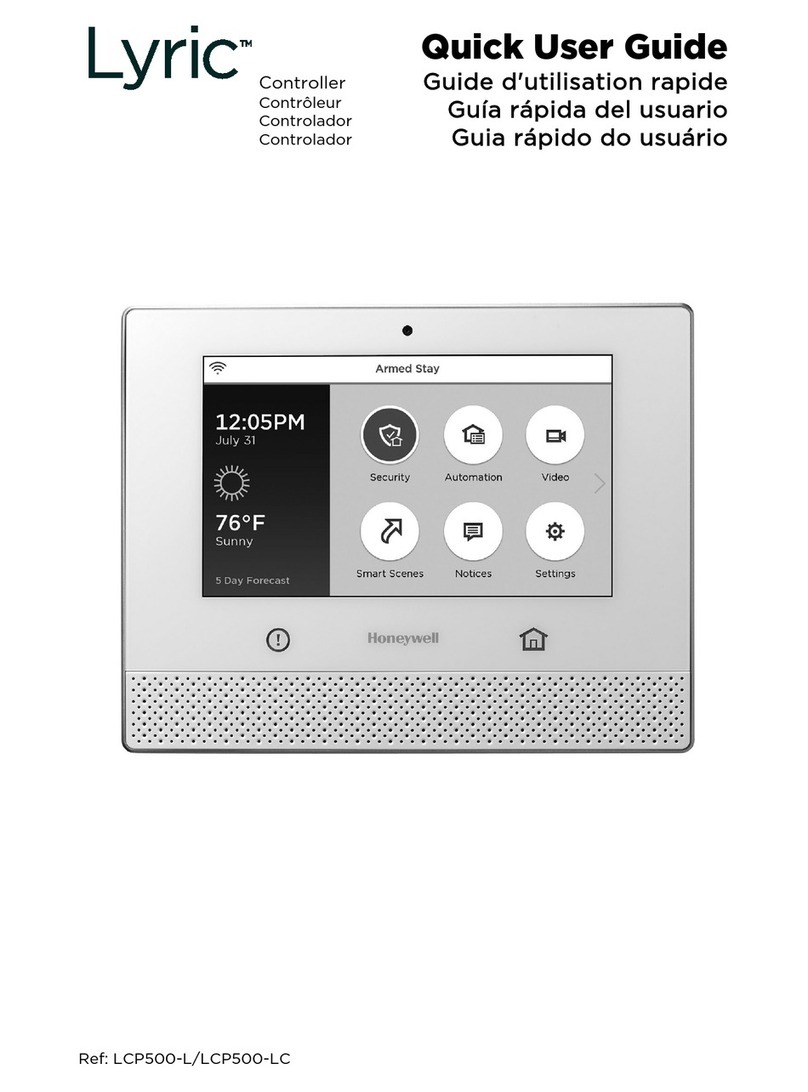

Honeywell LKS 160 User manual

Other Honeywell Controllers manuals

Honeywell

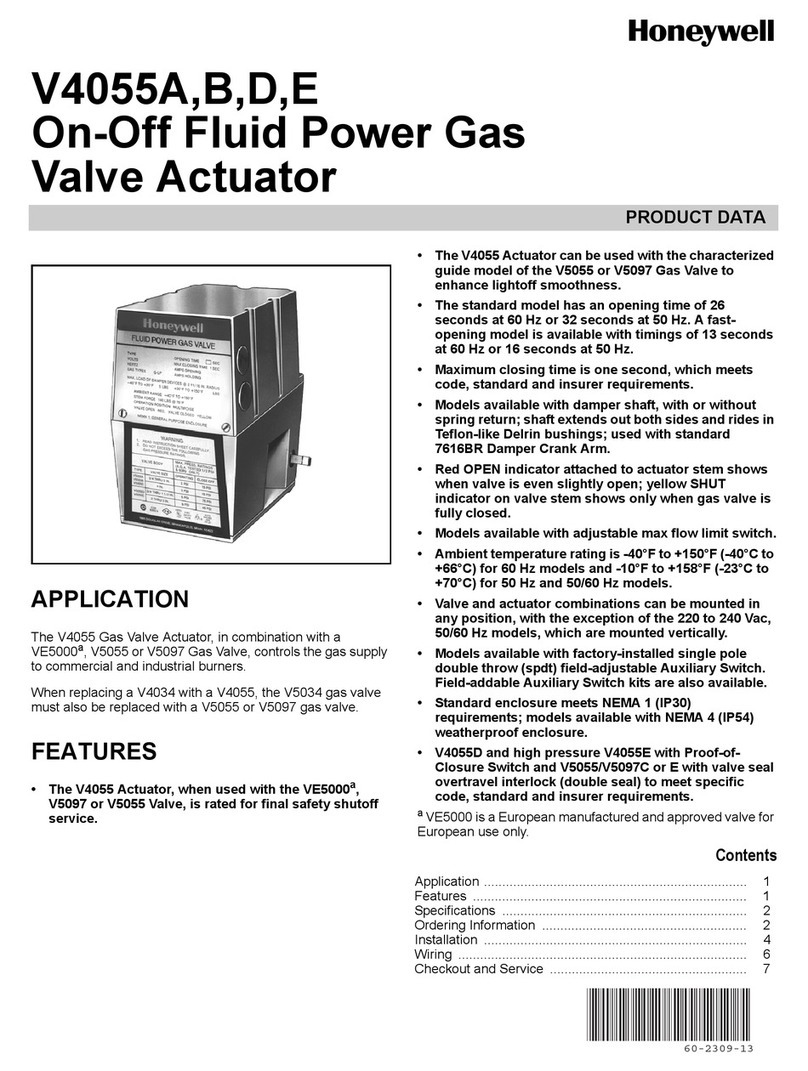

Honeywell V4055A Operation manual

Honeywell

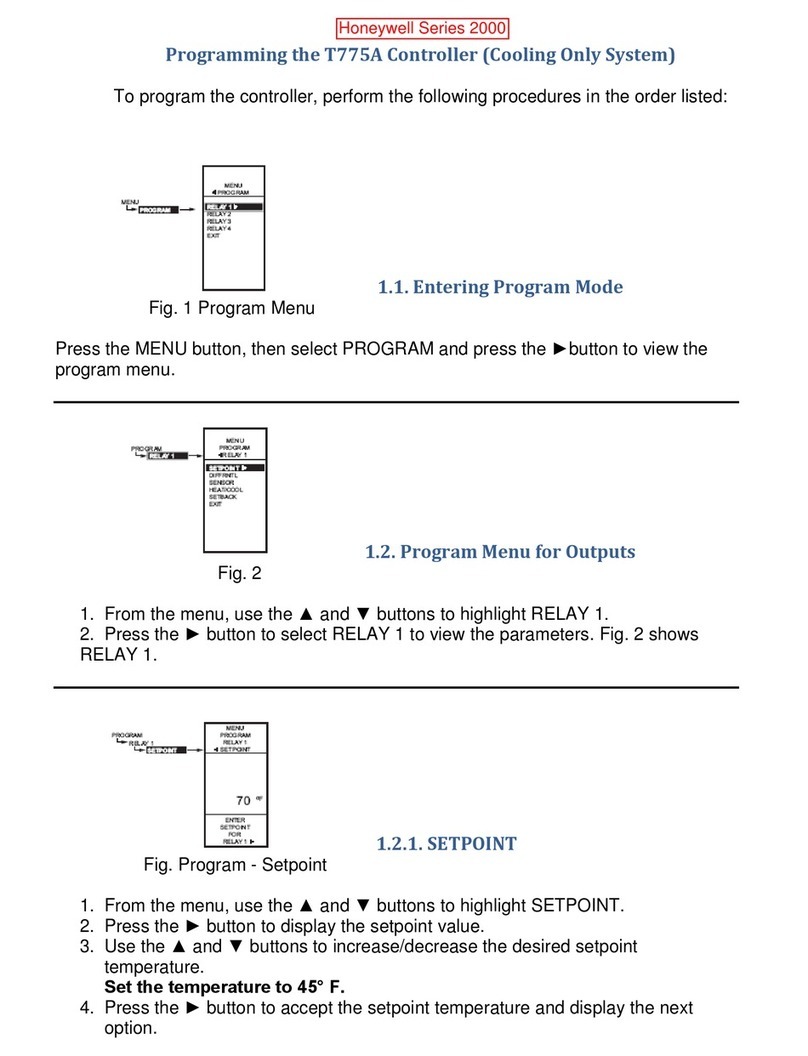

Honeywell T775A User manual

Honeywell

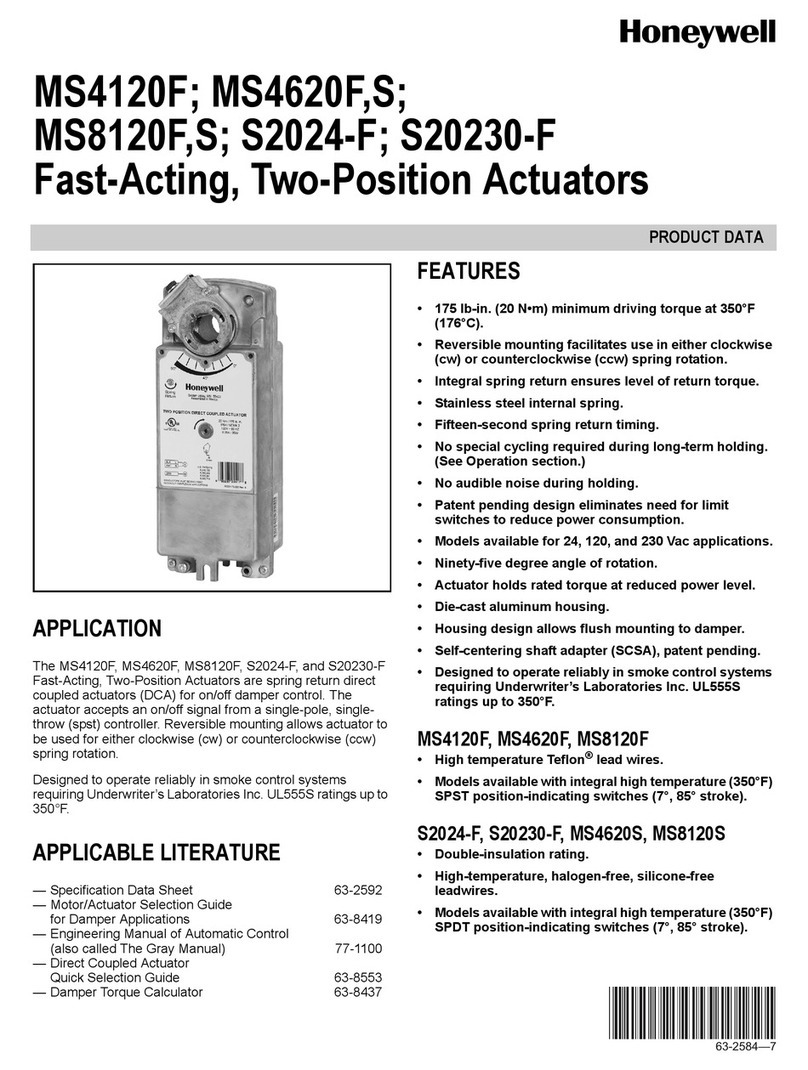

Honeywell MS4120S Operation manual

Honeywell

Honeywell Excel 50 User manual

Honeywell

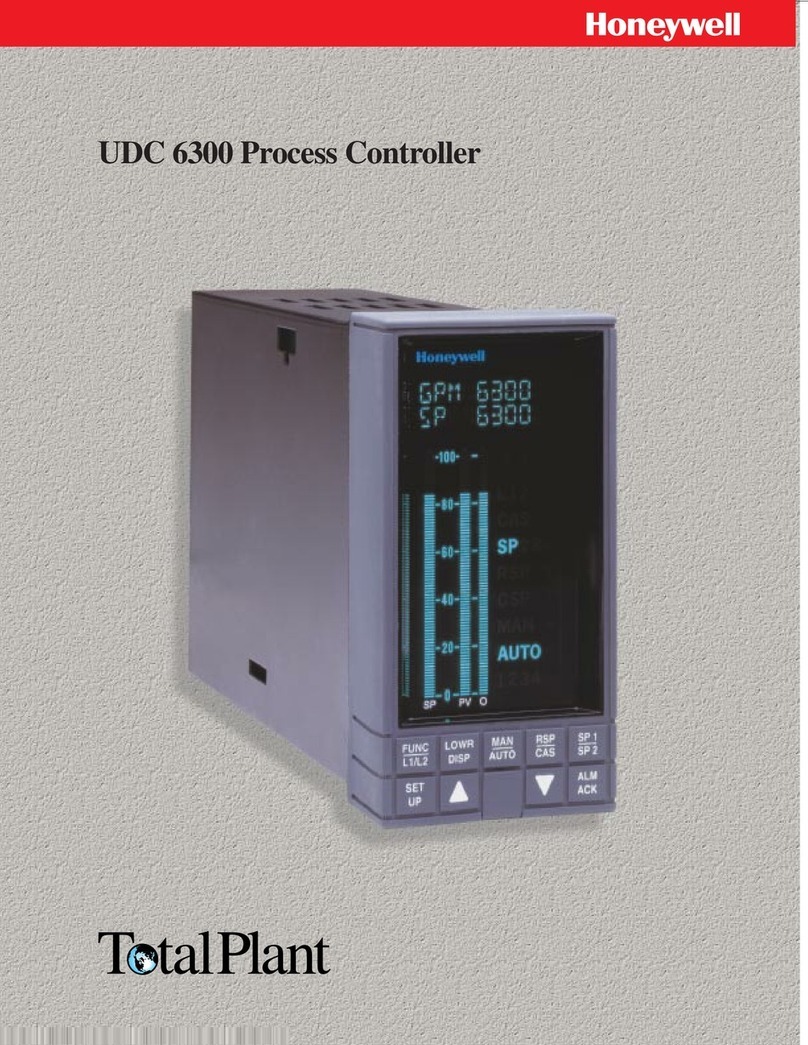

Honeywell UDC 6300 User manual

Honeywell

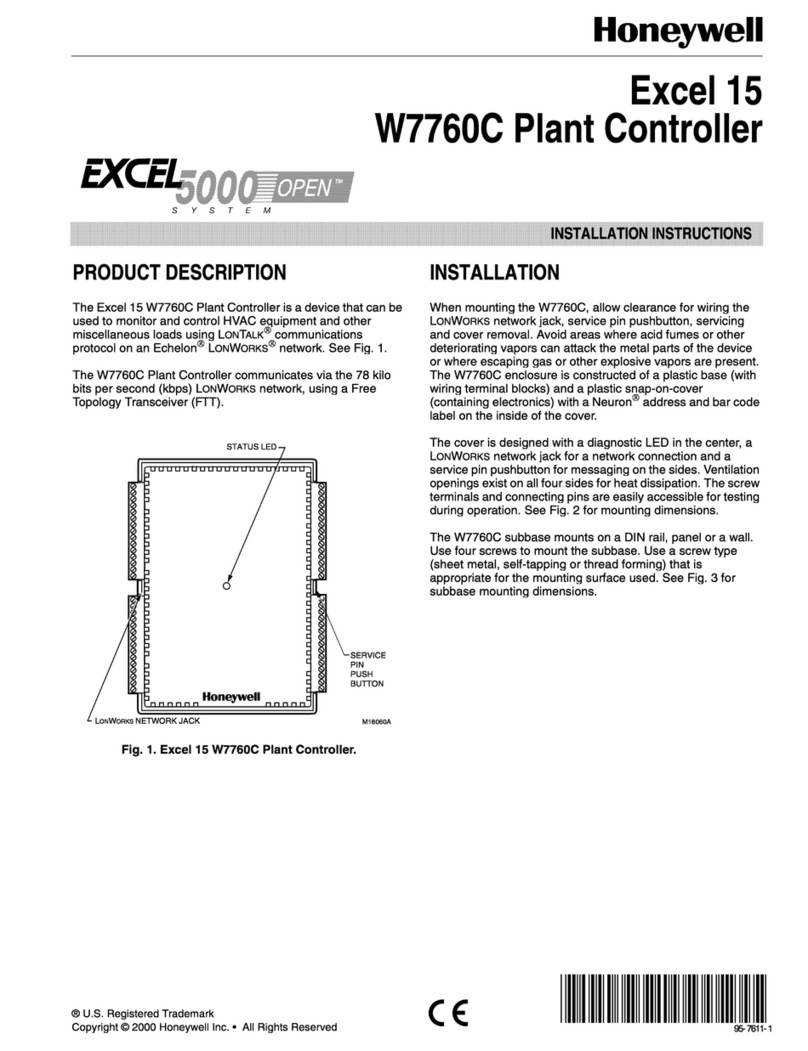

Honeywell EXCEL 5000 OPEN ZAPP User manual

Honeywell

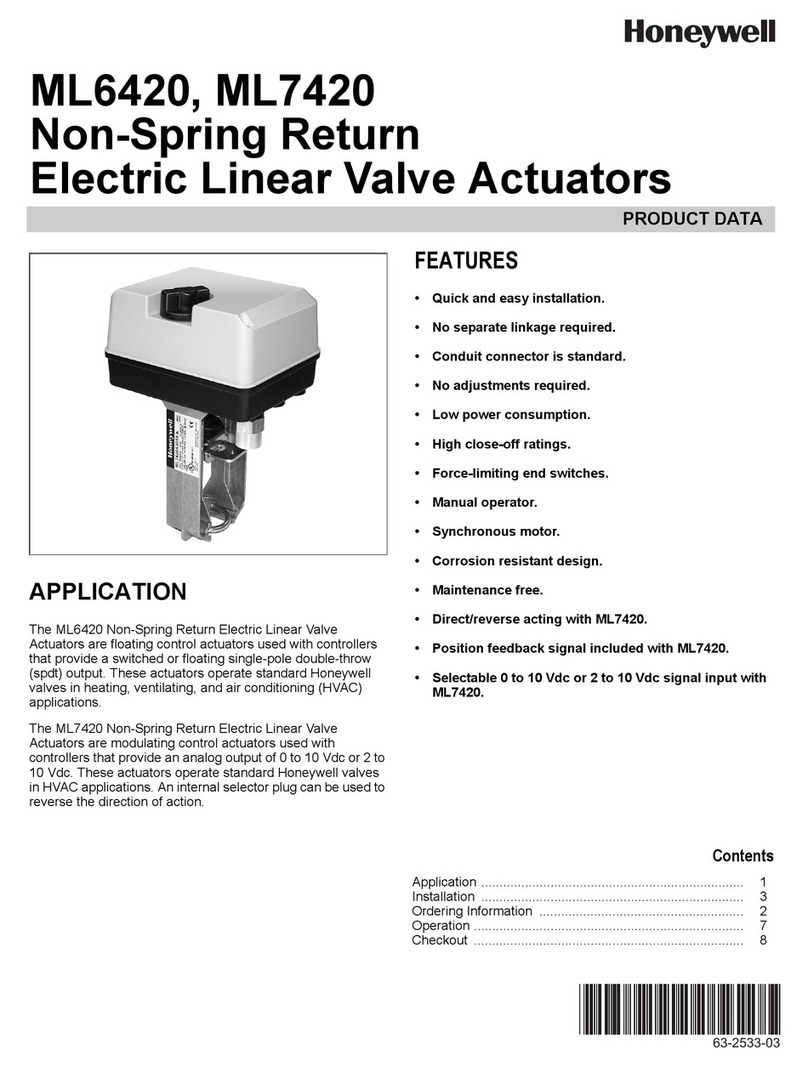

Honeywell ML6420 Operation manual

Honeywell

Honeywell PRO 2000 Series Owner's manual

Honeywell

Honeywell Z11S User manual

Honeywell

Honeywell Touchpoint Plus Release Note

Honeywell

Honeywell ML6185 User manual

Honeywell

Honeywell RA890G User manual

Honeywell

Honeywell VK41 R Series User manual

Honeywell

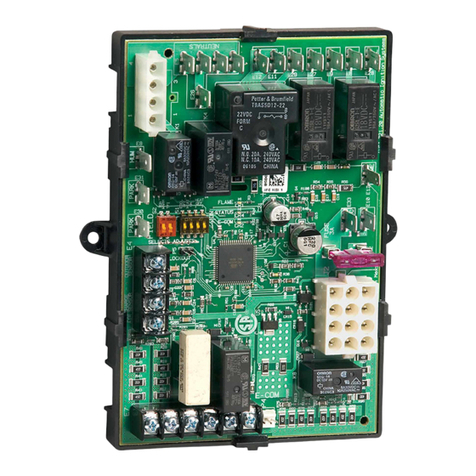

Honeywell S9200U1000 User manual

Honeywell

Honeywell Ex-Or MLS2000DALIHBW Installation and operation manual

Honeywell

Honeywell Aquastat L4006 User manual

Honeywell

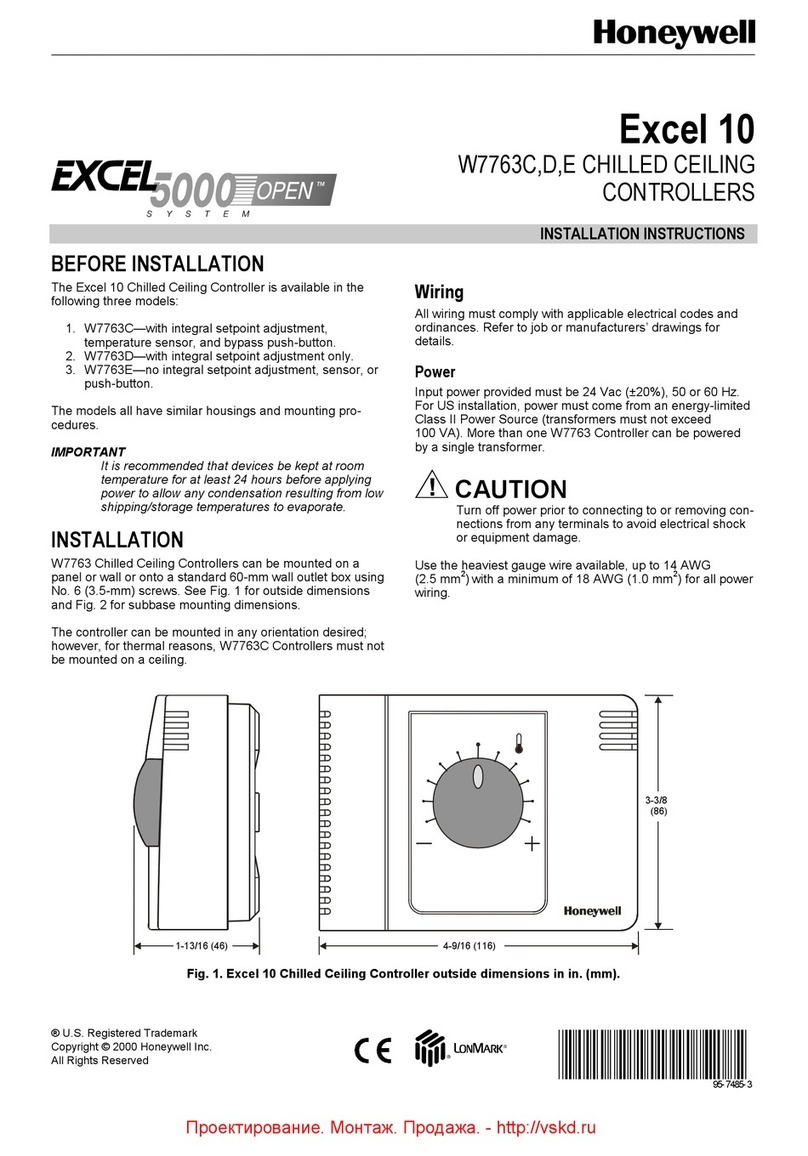

Honeywell Excel 10 User manual

Honeywell

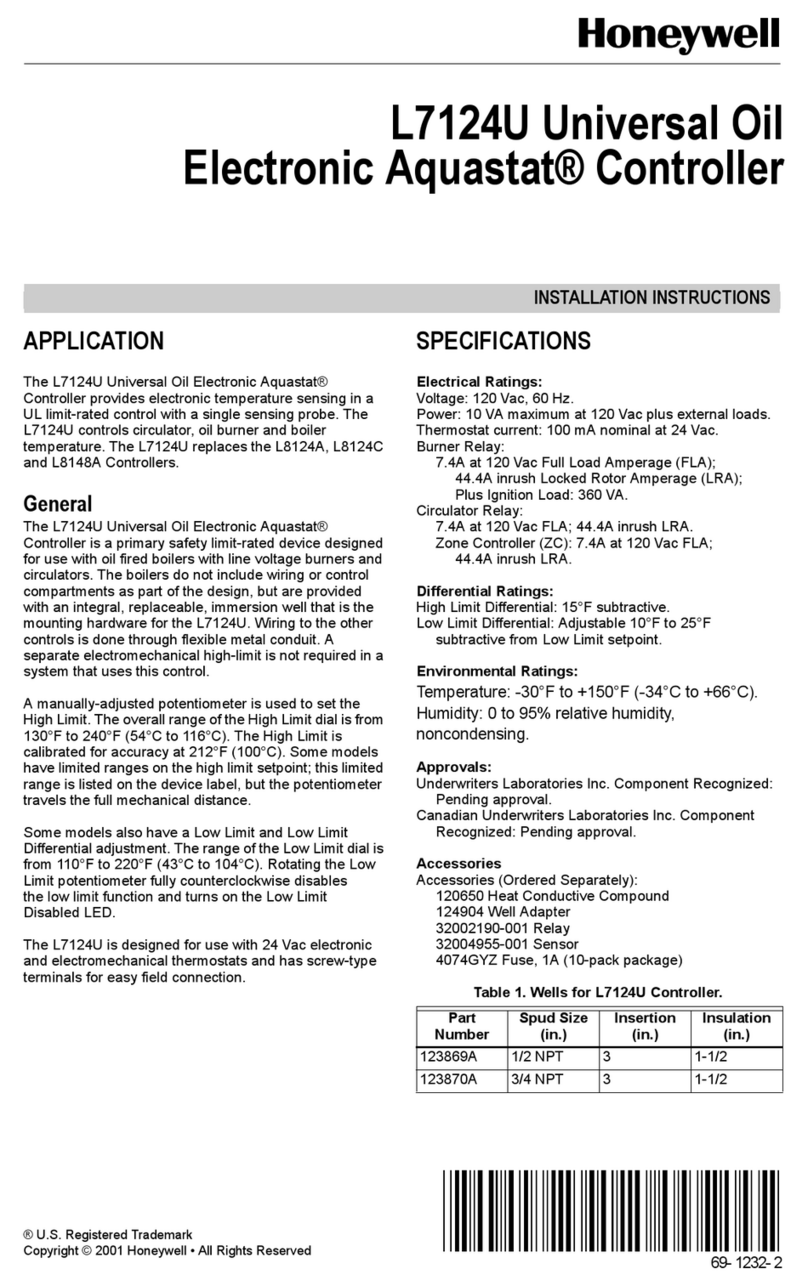

Honeywell L7124U User manual

Honeywell

Honeywell TRADELINE SV9501 User manual

Honeywell

Honeywell ML7425A Series Operation manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions