T775L SERIES 2000 ELECTRONIC STAND-ALONE STAGING CONTROLLER

3 62-0257—11

BEFORE INSTALLATION

Review the “Specifications” on page 37 before

installing the controller.

When Installing This Product

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazard-

ous condition.

2. Check ratings given in instructions and on the prod-

uct to ensure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

INSTALLATION AND SETUP

The following installation procedures are typically

performed in the order listed:

1. Mounting – see “Mounting” below.

2. Wiring – see “Wiring” on this page.

3. Checkout – see page 8.

4. Interface and Programming overview – see page 9.

5. Setup – see page 11.

6. Programming the Controller with no Reset – see

page 22

or

Programming the Controller with Reset – page 25.

7. Scheduling (optional) – see page 31.

Additional topics are:

• Temperature sensor calibration begins on page 8.

• Interface overview begins on page 9.

• Summary menu begins on page 36.

• Troubleshooting begins on page 36.

MOUNTING

This section describes the mounting procedures for the

controller and temperature sensor(s).

Controller Mounting

IMPORTANT

Avoid mounting in areas where acid fumes or

other deteriorating vapors can attack the metal

parts of the controller circuit board, or in areas

where escaping gas or other explosive vapors

are present.

IMPORTANT

The controller must be mounted in a position that

allows clearance for wiring, servicing, and

removal.

Use a screwdriver to pry out only the knockouts that you

will use.

If mounting on DIN rail, be sure to remove the knockouts

before mounting. See “Controller Wiring” on page 5 and

Fig. 7 on page 6 for recommended knockout usage and

locations. If you do not use an opened knockout be sure

to cover it.

Mount the controller on any convenient interior location

using the four mounting holes provided on the back of the

enclosure using #6 or #8 screws (screws are not provided

and must be obtained separately). Use controller

dimensions in Fig. 1 on page 2 as a guide.

The controller may be mounted in any orientation.

However, mounting in the orientation shown in Fig. 1

permits proper viewing of the LCD display and use of the

keypad.

Temperature Sensor(s) Mounting

and Location

Temperature sensors may be located up to 1,000 feet

(304 m) from the T775L controller. See Table 3 on page 8

for calibration guidelines.

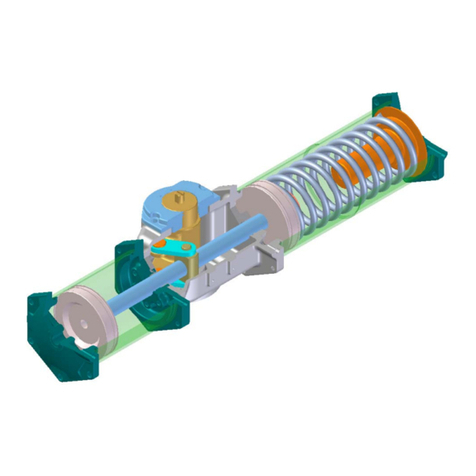

The sensors may be mounted on a wall or panel for

sensing space temperature, strapped to a pipe or inserted

in an immersion well (see Fig. 2) for hot or cold water

sensing, or taped to a standard cap or bulb holder for duct

air sensing. To prevent moisture or condensation entering

the sensor through the lead wire holes, mount the sensor

with the lead wires exiting the bottom of the sensor.

NOTES:

1. The included sensor is not designed for very

wet applications. For immersion applications,

an immersion well is used.

2. Heat conductive compound must be used in

immersion wells.

3. See “Temperature Sensors” on page 2 for this

type of installation.

Fig. 2. Sensor inserted in immersion well.

NOTE: Multiple sensors may be parallel-series wired to

sense average temperatures in large spaces.

See Fig. 3 on page 4.

WIRING

All wiring must comply with applicable electrical codes

and ordinances, or as specified on installation wiring

diagrams. Controller wiring is terminated to the screw

terminal blocks located inside the device.

The remainder of this section describes the temperature

sensor wiring and the T775L controller wiring.

Wiring Connections Access

To access the wiring connections, remove the two screws

on the left side of the enclosure and gently swing open the

top. Be careful to not stress the ribbon cables that

connect the keypad and LCD display to the controller

circuit board.

SENSOR

PLACED

IN WELL

IMMERSION

WELL

1/2 NPT

USE HEAT

CONDUCTIVE

COMPOUND

M24379