Honeywell L482A User manual

Other Honeywell Controllers manuals

Honeywell

Honeywell 7800 SERIES User manual

Honeywell

Honeywell HCE80R User manual

Honeywell

Honeywell MO953 Series Mounting instructions

Honeywell

Honeywell AQUASTAT L4188A User manual

Honeywell

Honeywell UDC2800 User manual

Honeywell

Honeywell ML6185 User manual

Honeywell

Honeywell S9200U1000 User manual

Honeywell

Honeywell Experion PKS Instruction manual

Honeywell

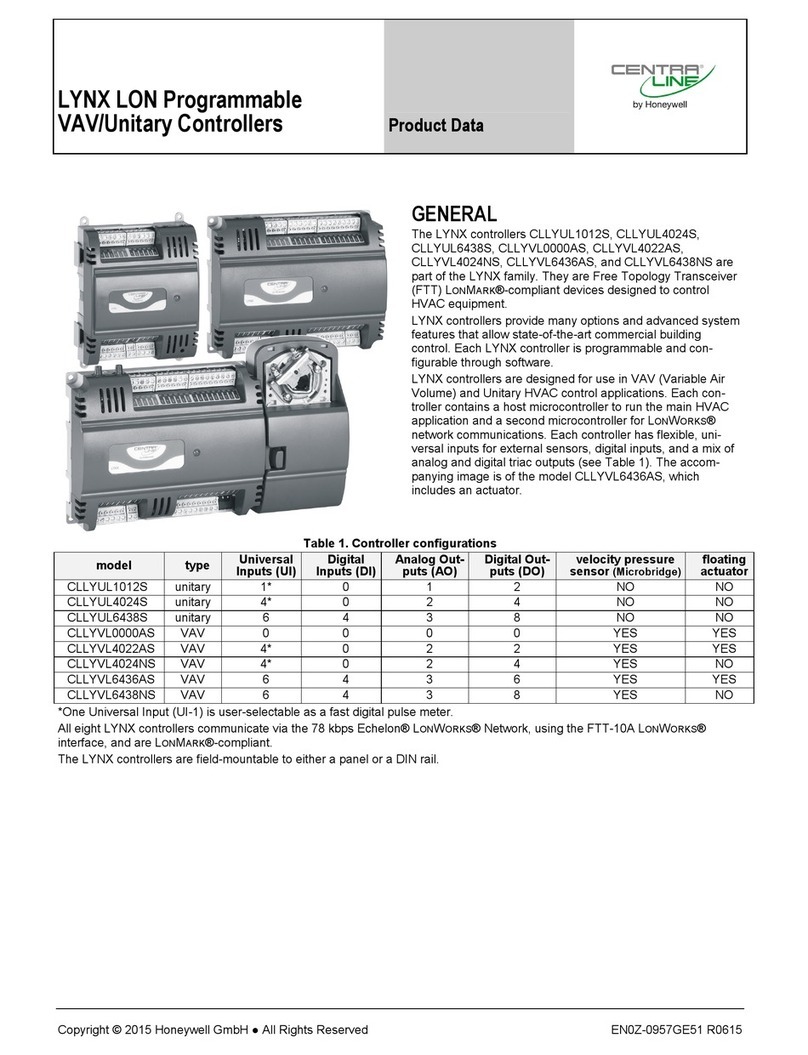

Honeywell CentraLine LYNX LON CLLYUL1012S Operation manual

Honeywell

Honeywell UDC100 User manual

Honeywell

Honeywell PW6K1ICE Operator's manual

Honeywell

Honeywell MS4620F User manual

Honeywell

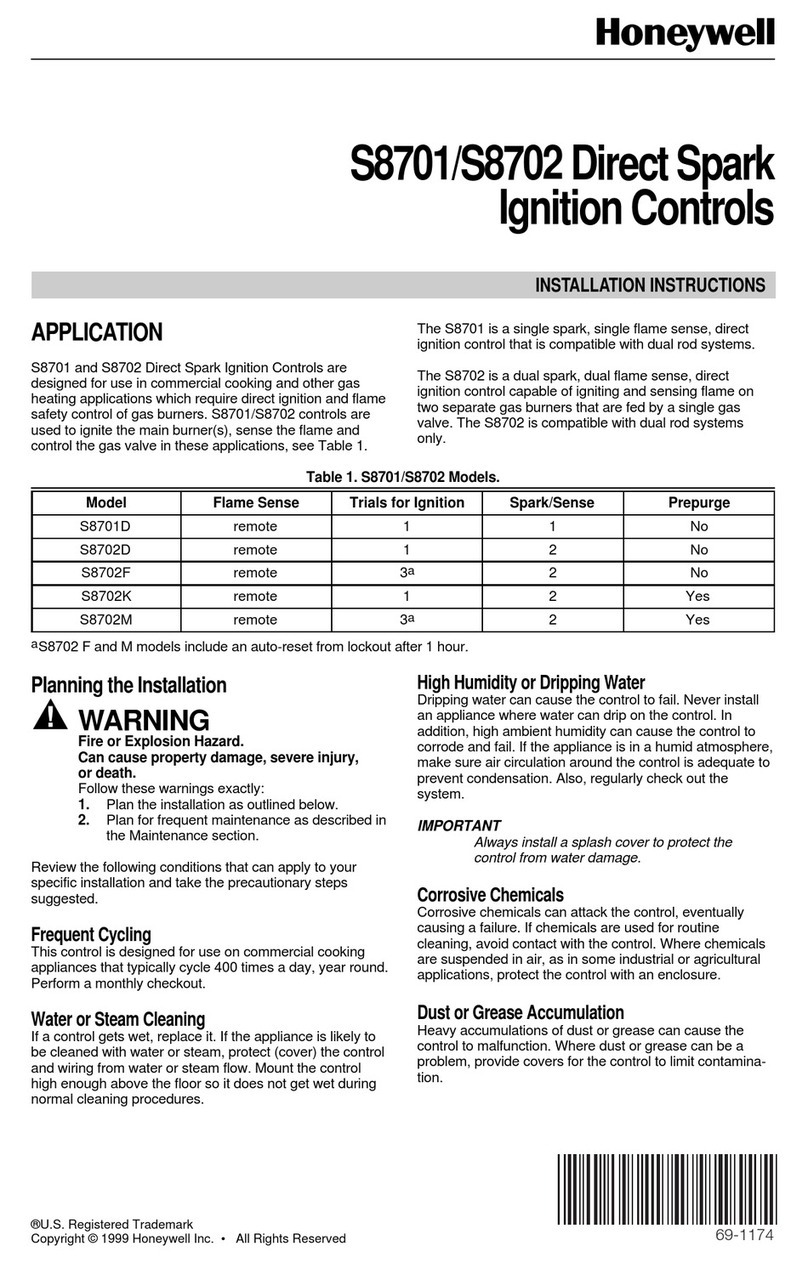

Honeywell S8701 User manual

Honeywell

Honeywell HercuLine 10260A User manual

Honeywell

Honeywell MS4120F Operation manual

Honeywell

Honeywell Spyder PUL1012S User manual

Honeywell

Honeywell 4000 Series Operation manual

Honeywell

Honeywell UDC2500 User manual

Honeywell

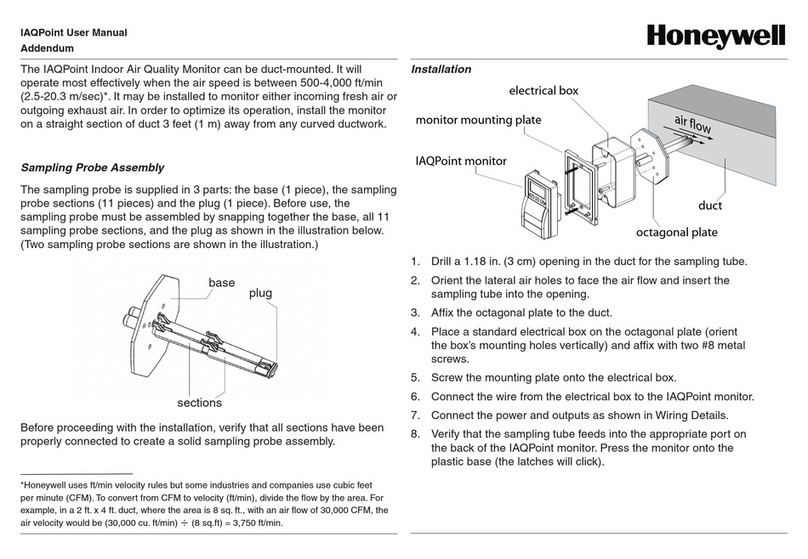

Honeywell IAQ Poin User manual

Honeywell

Honeywell T2798I2000 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions