Quick Start Guide for UDC2500 Universal Digital Controller

51-52-25-124

For detailed instructions see UDC2500 Product Manual 51-52-25-127.

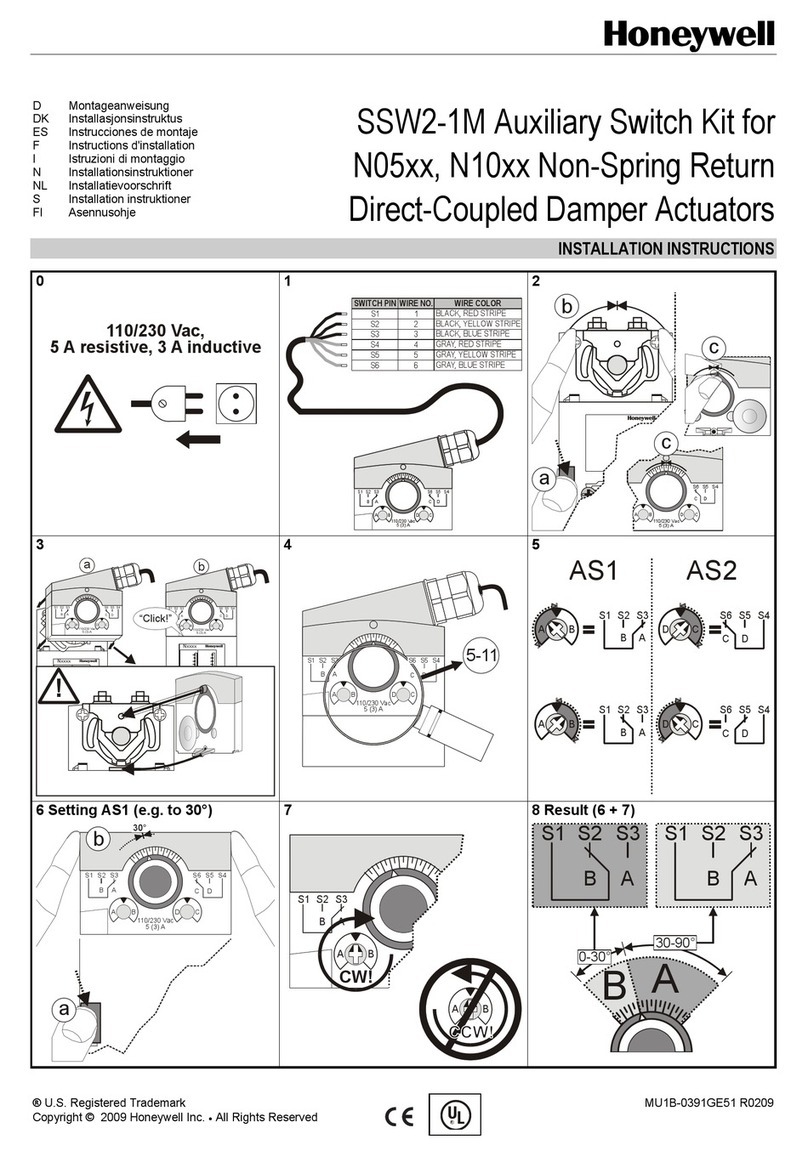

1. Model Number Interpretation

Write your controller model number in the boxes. Then refer to Tables I, II, and III and circle the corresponding options to identify your controller’s features.

- - - - X X X X X - X X

Key Number Table I Table II Table III Other options

Instructions

Select the desired key number. The arrow to the right marks the selection available.

Make the desired selections from Tables I through V using the column below the

proper arrow. A dot ( ) denotes availability.

Key Number -- - -

_ _ _

-

_ _ _ _ _

_

I

_

IIIII IV

_

V

_

KEY NUMBER - UDC2500 Single Loop Controller Selection

Digital Controller for use with 90 to 264Vac Power DC2500

Digital Controller for use with 24Vac/dc Power DC2501

TABLE I - Specify Control Output and/or Alarms

Description

_ B

One Alarm Relay Only

0 _

C _

E _

None (Can be used as an indicator only)

Current Output (4 to 20ma, 0 to 20 ma)

Electro Mechanical Relay (5 Amp Form C)

Solid State Relay (1 Amp)

_ A

_ T

Output #2 and Alarm

#1 or Alarms 1 and 2

_ 0

E-M Relay (5 Amp Form C) Plus Alarm 1 (5 Amp Form C Relay)

Solid State Relay (1 Amp) Plus Alarm 1 (5 Amp Form C Relay)

Availability

A _

T _

R _

_ E

Output #1

Open Collector transistor output

Dual 2 Amp Relays (Both are Form A) (Heat/Cool Applications)

No Additional Outputs or Alarms

Open Collector Plus Alarm 1 (5 Amp Form C Relay)

TABLE II - Communications and Software Selections 0 _ _

1 _ _

2 _ _

3 _ _

4 _ _

5 _ _

_ 0 _

_ A _

_ B _

_ L _ aa

_ _ 0

_ _ R

Software Selections

Standard Functions, Single Display

Dual Display with Auto/Manual

Set Point Programming (12 Segments) Dual Display, Auto/Manual

Limit Controller

Infrared Interface Included (Can be used with a Pocket PC)

Infrared interface

Communications

None

Device Net Plus Auxiliary Output/Digital Inputs (Future Release)

Auxiliary Output/Digital Inputs (1 Aux and 1 DI or 2 DI)

RS-485 Modbus Plus Auxiliary Output/Digital Inputs

10 Base-T Ethernet (Modbus RTU) Plus Auxiliary Output/Digital Inputs

Profibus-DB Plus Auxiliary Output/Digital Inputs (Future Release)

None

D

2500 2501

TABLE III - Input 1 can be changed in the field using external resistors Selection

1 _

2 _

3 _

_ 0

_ 1

Input 2 None

0-5V, 1-5V, 0-20mA, 4-20mA

Input 1 TC, RTD, mV, 0-5V, 1-5V

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA, 0-10V

Availability

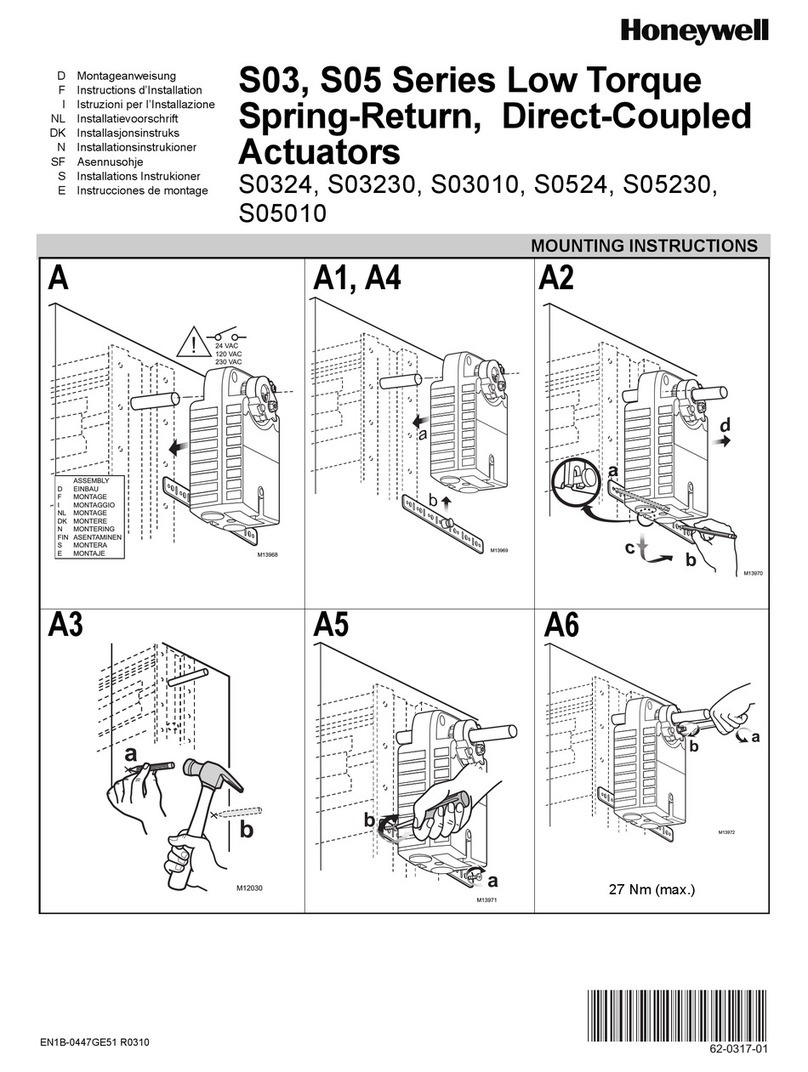

2. Dimensions and mounting

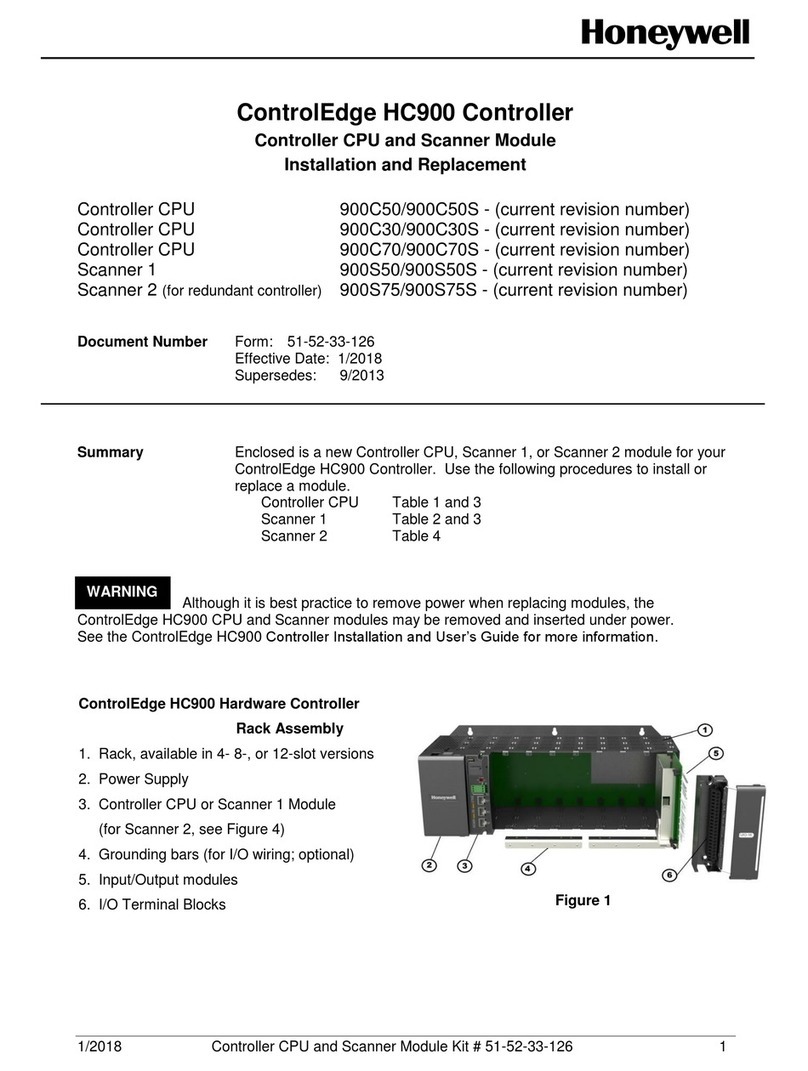

3. Wiring

L1

L2/N

4

5

6

10

11

12

13

14

15

16

17

7

8

9

20

21

22

23

24

25

26

27

18

19

RS-485 or Ethernet10BaseT

DIGITAL INPUTS AND AUX OUT

+

-Input #1

Input #2

+

-

larm #1

Output #2 or

larm #2

Output #1

C/DC

Line

oltage

Ground

Hot

Neutral

+

-

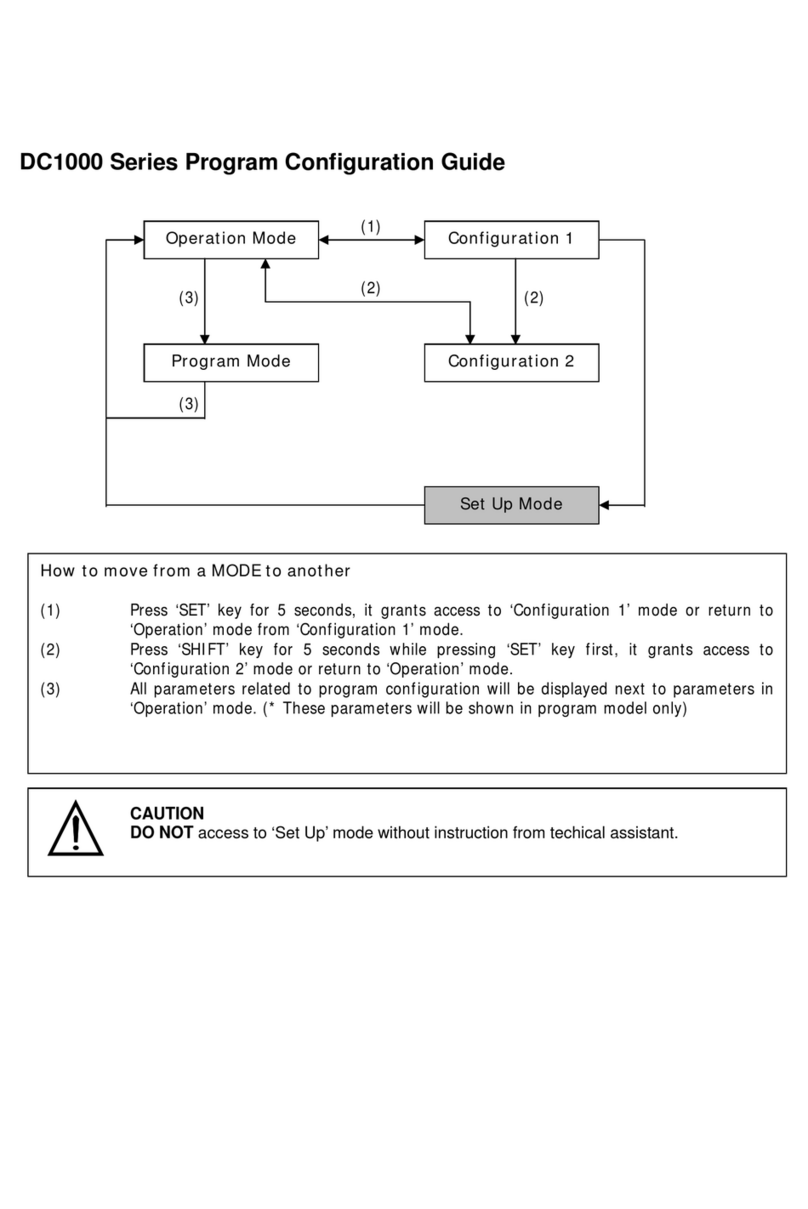

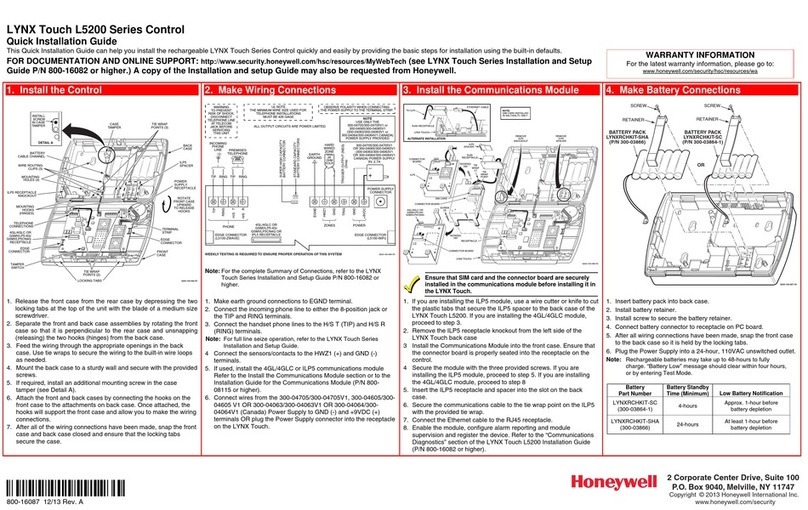

4. Configuration Procedure

Step Operation Press Result

1 Enter Set Up

Mode SET UP Upper Display = SET

Lower Display =TUNING (This is the first Set Up Group title)

2 Select any Set Up

Group SET UP Sequentially displays the other Set Up group titles shown in the prompt hierarchy. (See 5. Configuration Record Sheet for prompts.)

You can also use the or keys to scan the Set Up groups in both directions. Stop at the Set Up group title that describes the

group of parameters you want to configure. Then proceed to the next step.

3 Select a Function

Parameter FUNCTION Upper Display = the current value or selection for the first function prompt of the selected Set Up group.

Lower Display =the first Function prompt within that Set Up group.

Sequentially displays the other function prompts of the Set Up group you have selected. Stop at the function prompt that you want to

change, then proceed to the next step.

4 Change the Value

or Selection or Increments or decrements the value or selection that appears for the selected function prompt. If you change the value or selection of a

parameter while in Set Up mode then decide not to enter it, press [MAN-AUTO/RESET] once—the original value or selection is recalled.

5 Enter the Value

or Selection FUNCTION Enters value or selection made into memory after another key is pressed.

6 Exit Configuration LOWER

DISPLAY Exits configuration mode and returns controller to the same state it was in immediately preceding entry into the Set Up mode. It stores any

changes you have made.

If you do not press any keys for 30 seconds, the controller times out and reverts to the mode and display used prior to entry into Set Up

mode.