Document: I56-6584-001 (33797_01)

One Fire-Lite Place, Northford, CT 06472-1601 USA

USA - Phone: (203) 484-7161

Canada - Phone: (905) 856-8733

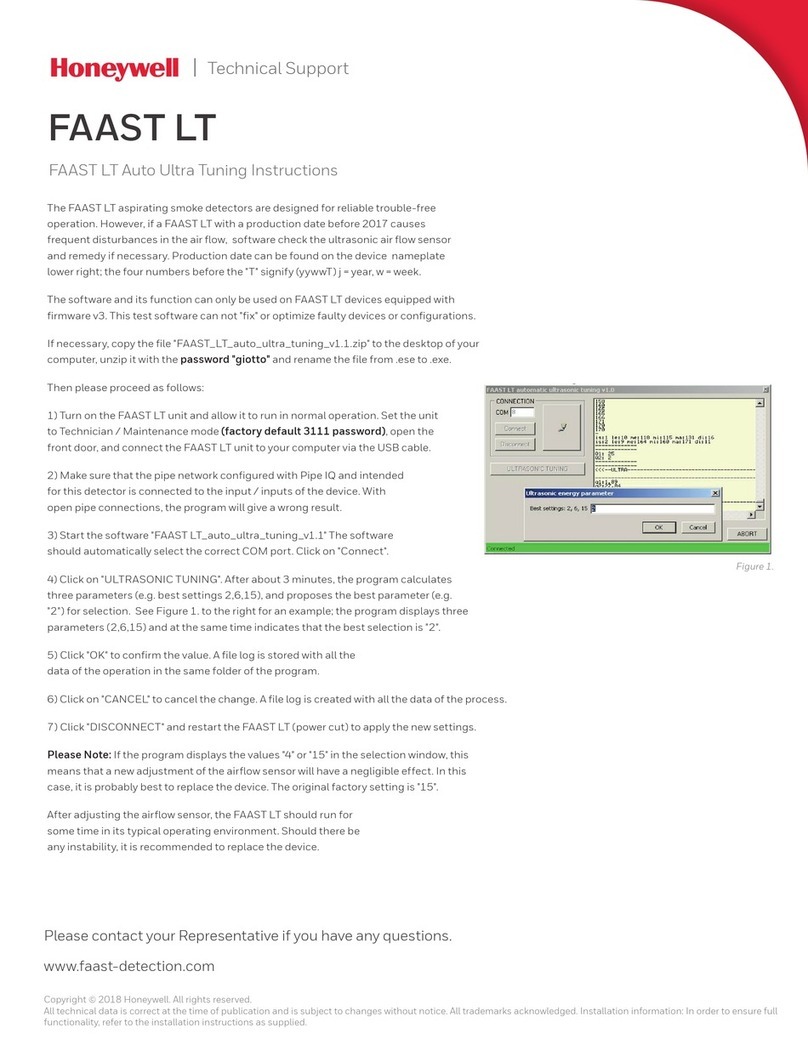

www.relite.com

7

8

9

Operation after a Power Failure

After a power failure of any duration, when the supply is restored, the detector will check the possible new

situation versus it memorized data.

If the reector is found in the same position and all parameters are within acceptable limits, the detector will

resume its operation and go out of fault condition.

If any signicant parameters have changed, it will remain in a fault condition and a re-initialization will be required.

Imager reset

The fault LED is non-latching but the alarm LED can be set to latching by the FACP. The Imager alarm can be

reset from the FACP.

6Testing the installation

After the commissioning, the detector must be tested for correct alarming by using the OSP-004 test lter at the

reector or using the remote test station. When using the RTS151KEY for testing the detector, the remote fault

LED will blink the set sensitivity of the detector. The number of blinks, similar to section 5, will represent the set

sensitivity and the sequence is repeated every 3 seconds till the detector is reset.

5Initialization and commissioning

Ensure that neither you nor any other objects are in the line of sight between the detector and the reector and

start to manually align the Imager to the reector.

The OSP-002 Laser Alignment Tool can be used for the rough alignment if the system is to be installed at longer

distances or in heavy lit environments.

Follow these steps to adjust the optical sphere of the detector component to align the system:

• Make sure the lever is the 3 o’clock position.

• The 4 arrows will intuitively guide the user to optimal eyeball alignment.

Likely the alignment process will start with all arrows red.

• Gently move the eyeball until all arrows and the middle green LED blink green for the eyeball to be optimal

aligned.

• When all arrows are green, gently lock the eyeball by moving the lever down till the eyeball is solidly locked.

The lever is now in the 5 o’clock position and you feel the resistance of the locked position.

By locking the eyeball an internal switch is activated and the detector will now start its initiation or commissioning

process. A normal commissioning process takes roughly 10 seconds. During the commissioning process, the

beam path must remain clear from object intrusions.In this process cycle, the detector will measure the size of the

reector in the FOV and set the sensitivity automatically to the optimum sensitivity for the specic distance.

Before going in operational mode, the detector will show its set sensitivity. This is shown by blinking the 4 arrows

to the color yellow, reecting the % of selected obscuration/sensitivity. The key is; 1 blink = 25%, 2 blinks = 30%,

3 blinks = 40% and 4 blinks = 50%. After 5 seconds, the scenario will be repeated a second time and the arrows

LEDs go out and the front OK LED blinks green. The detector is now in operation and working correctly.

The paintable rim can now be snapped over the front to secure the locking lever and to hide the alignment LEDS

and locking mechanism.

Applying the cover also secures the locking lever in position.

Operation Modes and Troubleshooting Guide OSI-RI-FL

Modes Red and

Remote Alarm

output

Yellow and Remote

Trouble Output

Green Initiating means Comments &

Troubleshooting Tips

Power on Off Blink Off Apply Power from

discharged state

• All wiring correctly done.

• Address switches set.

Alignment Off Blink Off Lever in 3:00 position

and commissioning is

active

• Ready to perform

alignment.

• Follow guidance from the

4 arrows to correctly align.

Initializing/

Commissioning

Off Blink Off Lock lever in 6:00

position to start

commissioning

• Commissioning and

setting sensitivity.

• Do not interrupt beam.

Normal Off Off Blink Successful completion

of initialization or

detector reset

• Initializing nished.

• Detector operates normal

in quiescent condition.

• Detector successfully

reset.

Alarm On Off Off Smoke, Test Filter

or RTS151KEY Test

Station

• Blinks till reset from FACP.

Trouble-Drift

Compensation

Off 3 Quick Blinks Blink Long Term Drift

Reference Out of 20%

Range

• Reduced IR Signal

• Clean detector and

reector.

Trouble-Beam

Blockage

Off 4 Quick Blinks Blink Beam blockage

or detector out of

alignment

• Remove blockage or re-

align detector

• Faulty unit.

Trouble-Imager

saturation

Off 5 Quick Blinks Blink Imager saturated • Sunlight or very strong

light into detector or

reector.

• Re-position detector or

reector.

• Remove light source.

Test activated-Pass

Result

On Blinks the set

sensitivity by

number of blinks (1-

4). Repeats every 3

seconds till reset.

Off FACP or RTS151KEY • Remains in alarm until

reset by FACP.

• Number of lit arrows

indicates sensitivity

level that was selected

automatically.