EN-3

1. Overview

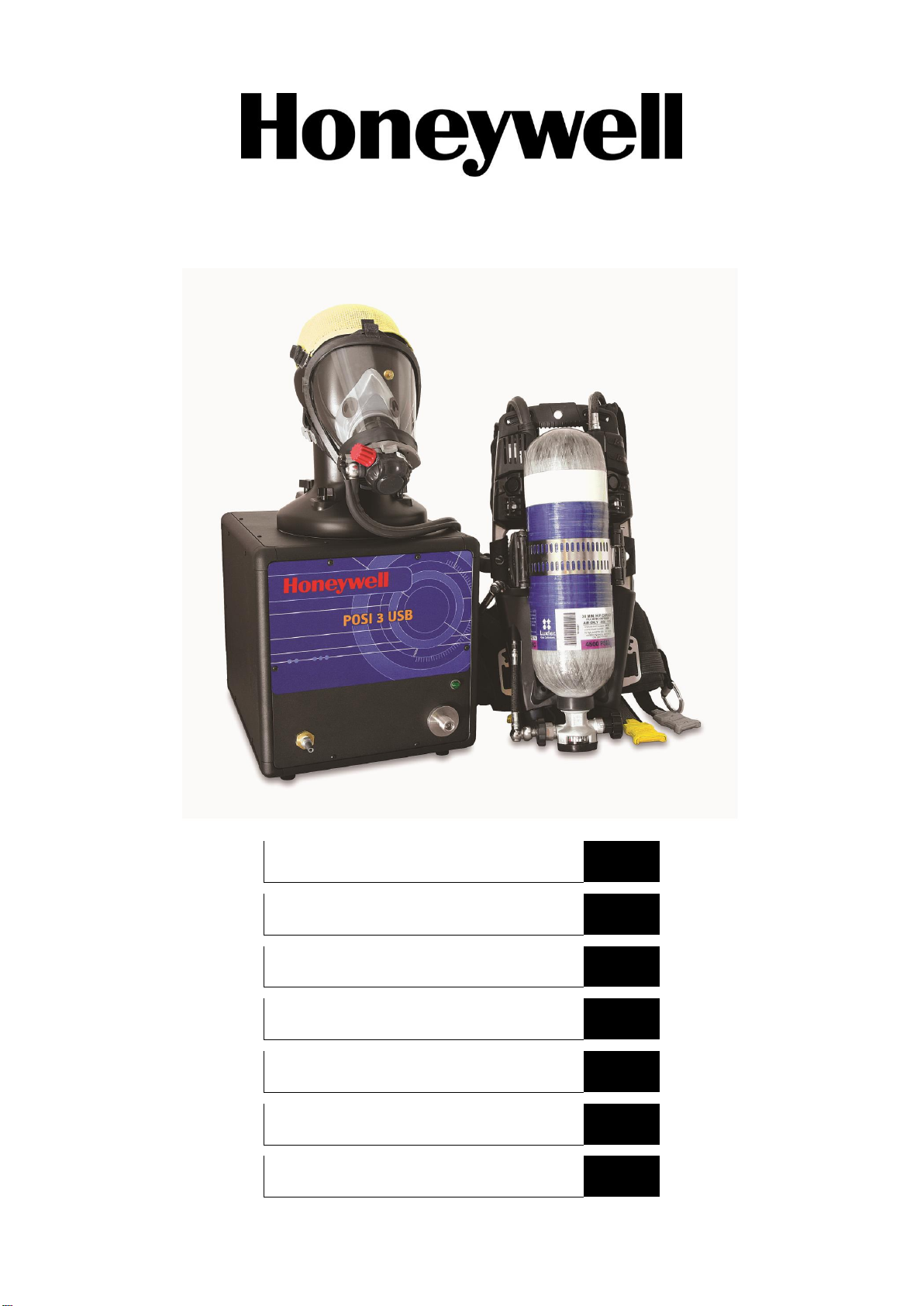

The TestAir 4 is a computerized test bench designed

to evaluate the performance of a completely

assembled self-contained breathing apparatus (SCBA)

and other types of air-supplied respiratory protective

equipment.

This Setup Guide is designed to provide the user with

step-by-step instructions for the initial setup of the

TestAir 4.

Instructions for running tests are contained in the

TestAir 4 Help File.

1.1 Installation Overview

Prior to performing tests, the following items must be

accomplished:

1. Remove the TestAir 4 and the accessories from

the shipping box and verify that all parts are

present. See section 2 for the complete parts list.

Do not discard the shipping box and packing

materials –they are necessary for returning the

TestAir 4 to Honeywell Respiratory Safety

Products (HRSP) for its annual calibration or

maintenance.

2. Verify that your PC meets the OS and hardware

requirements as described in sections 3.1 and 3.2

below.

3. Install the software (see section 4 below).

4. Launch the software (see section 6 below). If this

is the initial use of the software, “Setup” is both

the user name and the password for the initial

opening of the software.

5. Create a user that has the rights to create and

modify apparatus data in the software. (see

section 6.2)

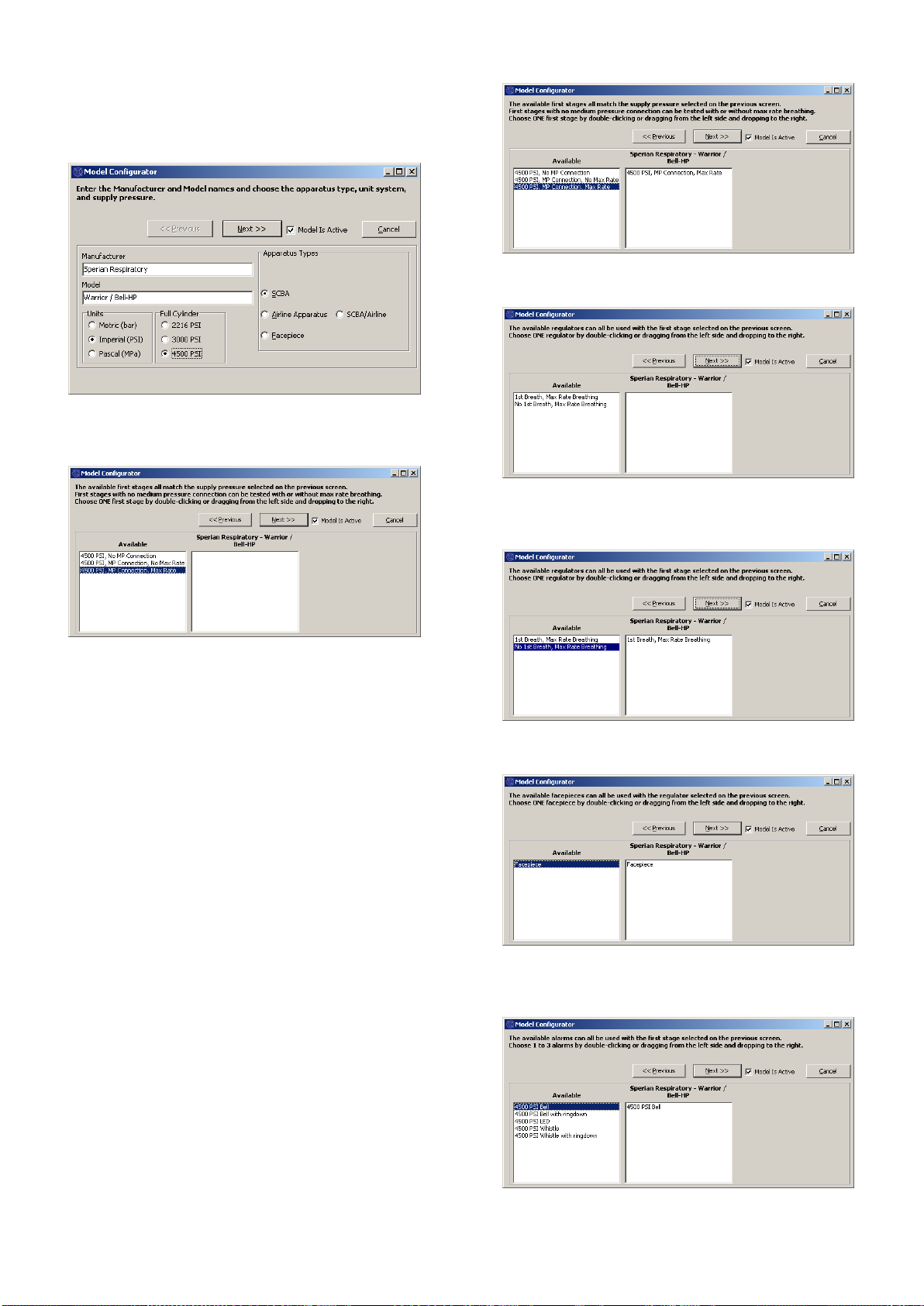

6. Enter information about the breathing apparatus

models into the software. This section can be

disregarded by users with manufacturer-specific

software. See section 6.3.

7. Assign the serial number of the breathing

apparatus to the model/apparatus info that was

created.

8. Attach the breathing apparatus to the TestAir 4

(see section 7 below).

9. Perform Tests. See the TestAir 4 Help File for

further information about testing.

1.2 Note on Brand-Specific Software

The TestAir 4 is the Honeywell Safety Product Original

Equipment Manufacturer (OEM) version of software

available in Europe.

For more information on the different OEM, please

refer to the PDF file ”Setup Guide Posi3 USB”

paragraph 1-2, attached to the TestAir 4.

Use of the first stage manifold in conjunction with

brand-specific software allows the user to test

specific breathing apparatus to the tolerances

specified by the SCBA manufacturer and allows the

user to easily isolate problem components.

1.3 Calibration Requirement

The TestAir 4 must be calibrated annually to maintain

the accuracy of the internal transducers. Calibration

must be performed either by HRSP, or by a

Honeywell-authorized Service Center.

1.4 Software License

Each copy of TestAir 4 Software is licensed to the user

who purchased it. The name of the registered user will

appear during the software installation procedure.

The license information may be viewed at any time

through the Help - About screen.

The software license information is stored in the record

of each breathing test that is performed, and will be

displayed on the breathing test results when printed.