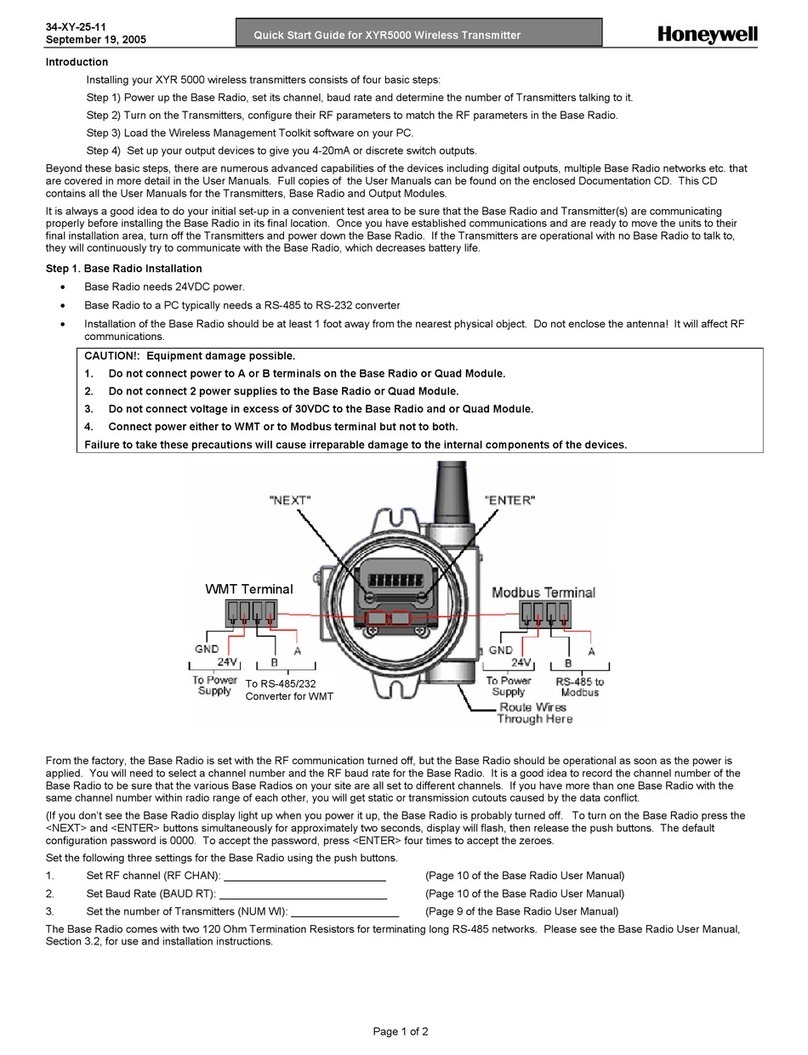

STT850/750 Quick Start Guide 4

Digital Output Wiring

Digital Output is available only on HART transmitters. The Digital Output should not use the

same power supply as used to support the 4-20mA transmitter output. See Figure 13 and

Figure 14.

For Intrinsically Safe (IS) applications, the 4-20mA and the Digital Output must use

separate IS Barriers.

Figure 13: Digital Output Connections for mA Load (HART only)

For best performance, it is recommended that:

•Digital Output wires should be in a separate shielded twisted pair cable, do

not use the same cable as used for the Loop or the Sensor wires

•If using the same power supply to operate both the 4-20mA Loop and the

Digital Output, then make the interconnections to the power supply terminals

directly at the power supply

NOTE: Intrinsically Safe Installations require the use of separate IS Barriers for the

4-20mA output and for the Digital Output connections

Figure 14: Digital Output Connections for PLC Counting Input (HART

only)

Explosion-Proof Conduit Seal

When installed as explosion proof in a Division 1 Hazardous Location, keep

covers tight while the Transmitter is energized. Disconnect power to the

Transmitter in the non-hazardous area prior to removing end caps for service.

When installed as non-incendive equipment in a Division 2 hazardous location,

disconnect power to the Transmitter in the non-hazardous area, or determine that the

location is non-hazardous before disconnecting or connecting the Transmitter wires.

Transmitters installed as explosion proof in Class I, Division 1, Group A Hazardous

(classified) locations in accordance with ANSI/NFPA 70, the US National Electrical

Code, require a LISTED explosion proof seal to be installed in the conduit, within 18

inches (457.2 mm) of the Transmitter. Crouse-Hinds type EYS/EYD or EYSX/EYDX are

examples of LISTED explosion proof seals that meet this requirement. Transmitters

installed as explosion proof in Class I, Division 1, Group B, C or D hazardous

(classified) locations do not require that explosion proof seal be installed in the conduit.

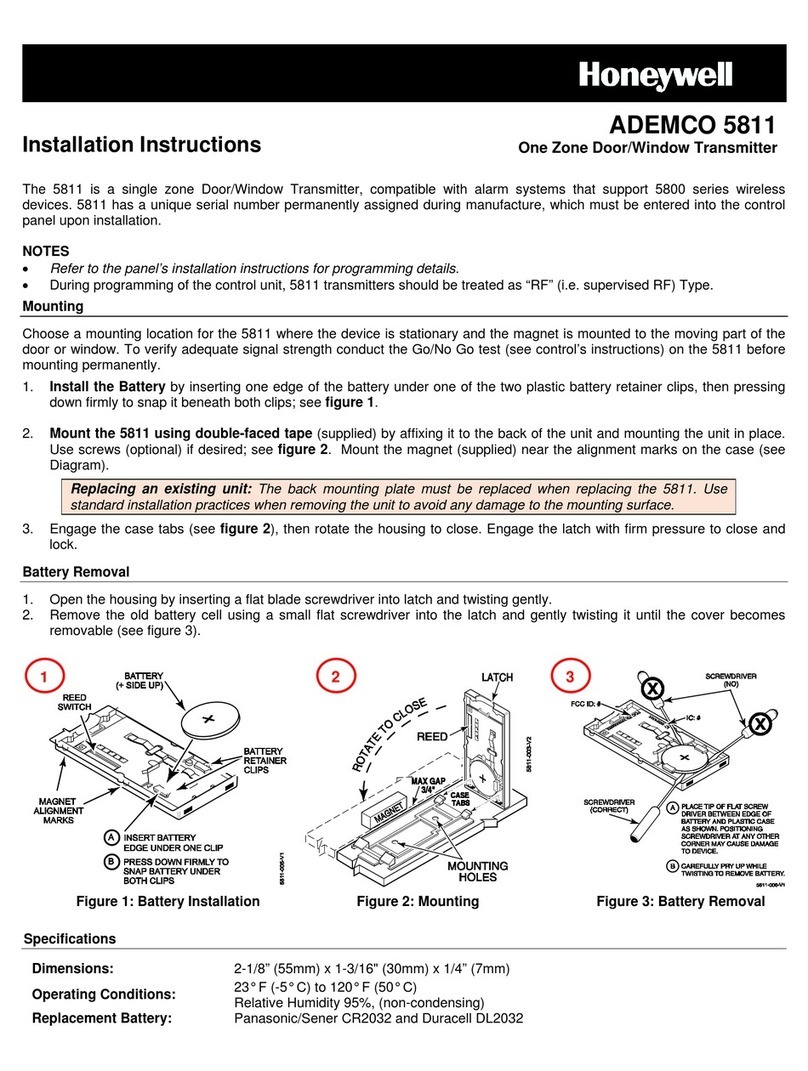

1 See Figure 8, above, for parts locations. Loosen the end cap lock

using a 1.5 mm Allen wrench.

Remove the end cap cover from the terminal block end of the

Electronics Housing

Feed loop power leads through one end of the conduit entrances on

either side of the Electronics Housing. The Transmitter accepts up to

16 AWG wire.

4

Connect the positive loop power lead to the positive (+) terminal and

the negative loop power lead to the negative (-) terminal. Note that

the Transmitter is not polarity-sensitive.

Shielded, twisted-pair cable such as Belden 9318 or equivalent must

be used for all signal/power wiring.

Note: If solid core wire is used strip insulation 1/4 in (6 mm). Once

inserted under the square washer the stripped portion should be

contained under the square washer. If multi-stranded wire is used, a

ferrule is to be used and the stripped wire should be in the insulated

portion of the ferrule. The ferrule can be also be used on the solid

core wire.

After wiring the Transmitter as outline in the next sections, torque the

screws to 1.1 Nm (10 lb-in)

5 Feed input sensor wires through the 2nd conduit entrance and

connect wire per wiring diagrams

Replace the end cap, and secure it in place

Configuration Guide

This transmitter comes with a standard factory configuration. Consult the nameplate for

basic information.

Reconfiguration for your particular application can be accomplished by following

instructions in the Transmitter User’s manual.

This can be found by following the website URL or QR code on page 1 of this

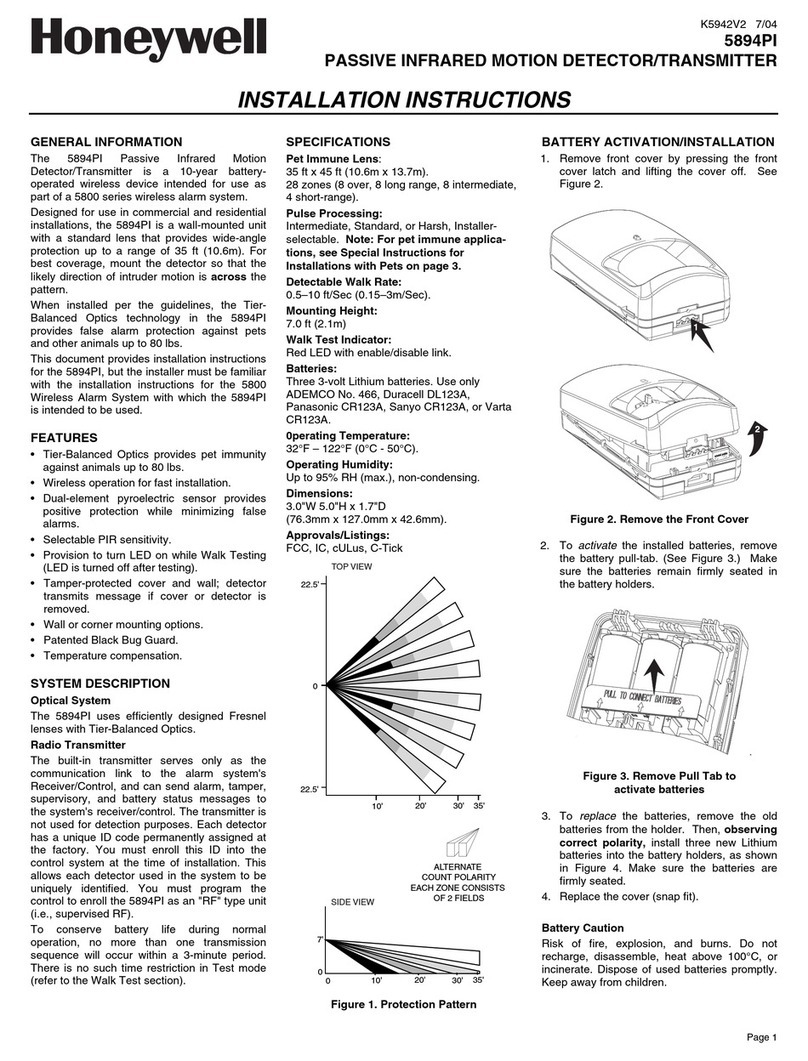

Set the Jumpers For HART/DE

Setting Failsafe Direction and Write

Protect Jumpers

The SmartLine Temperature Transmitter

(DE or HART) provides two jumpers to

set the desired failsafe action andWrite

Protect option. See

Figure 15

The top jumper on the electronics

module sets the Failsafe direction. The

default setting is up-scale failsafe.

Up Scale drives the loop to a value

greater than 21mA while Down Scale

drives the loop to a value less than

3.8mA.

You can change the failsafe direction by

moving the Failsafe Jumper (top jumper)

to the desired position (UP or DOWN).

If your transmitter is operating in DE

mode, the upscale failsafe action will

cause the transmitter to generate a

“+ infinity” digital signal, while a

downscale failsafe will cause the

transmitter to generate a “– infinity”

digital signal.

The bottom jumper sets the Write

Protect. The default setting is OFF (Un-

protected).

When set to the On (Protected) position,

Changed configuration parameters

cannot be written to the transmitter.

When set to the OFF (Un-protected)

position, Changed configuration

parameters can be written to the

transmitter.

ATTENTION: Electrostatic

Discharge (ESD) hazards. Observe

precautions for handling

electrostatic sensitive devices

Turn OFF Transmitter power.

2

Loosen the end-cap lock, and

unscrew the end cap from the

Electronics side of the Transmitter

If there is a Display module,

carefully depress the tabs on the

sides of the Display Module and

pull it off.

If necessary, move the interface

connector from the Communication

Module. Do not discard connector

Set the Failsafe Jumper (top

jumper) to the desired action (UP

or DOWN). And the Write Protect

jumper (Bottom jumper) to the

desired behavior (Protected or

Unprotected) See Figure 16 for

If applicable, re-install the Display

module as follows:

• Orient the display as desired.

• Install the Interface Connector in

the Display module such that it will

mate with the socket for the display

in the Communication module.

• Carefully line up the display,

and snap it into place. Verify that

the two tabs on the sides of the

display latch.

Screw on the end cap and tighten

the end-cap lock. Turn ON

Figure 15: Jumper Location HART/DE

Failsafe = UP (High)

Write Protect = OFF (Not Protected)

Failsafe = DOWN (Low)

Write Protect = OFF (Not Protected)

Failsafe = UP (High)

Write Protect = ON (Protected)

Failsafe = DOWN (Low)

Write Protect = ON (Protected)

Figure 16: Jumper Settings