III

CONTENTS

Important Information ............................................................................................I

Safety Precautions....................................................................................................II

1. Before You Begin

1-1 Specifications......................................................................................................2

1-2 Machine Descriptions ........................................................................................3

1-2-1 Machine Descriptions and Functions .............................................................3

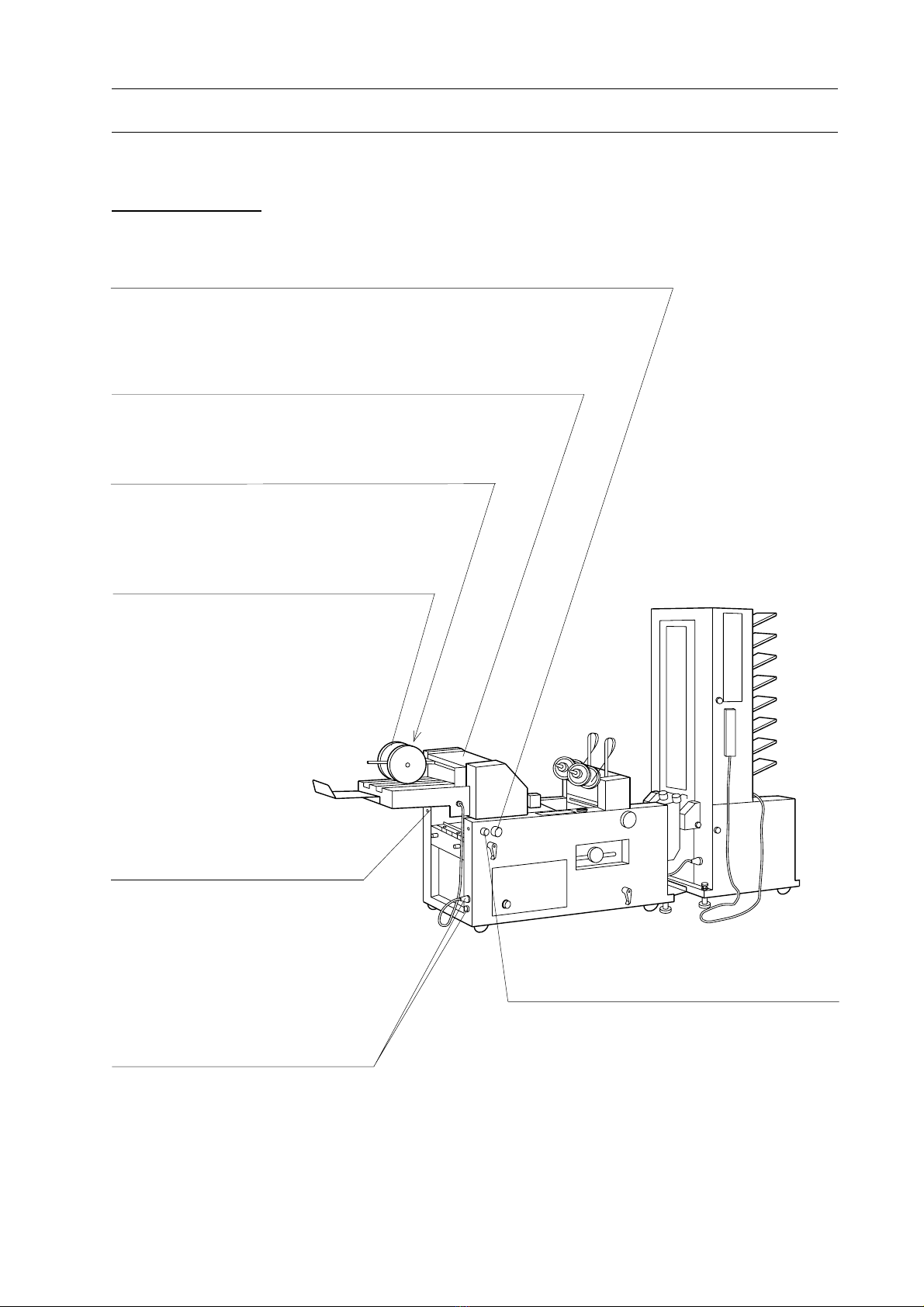

[1] General View 1................................................................................................3

[2] General View 2................................................................................................4

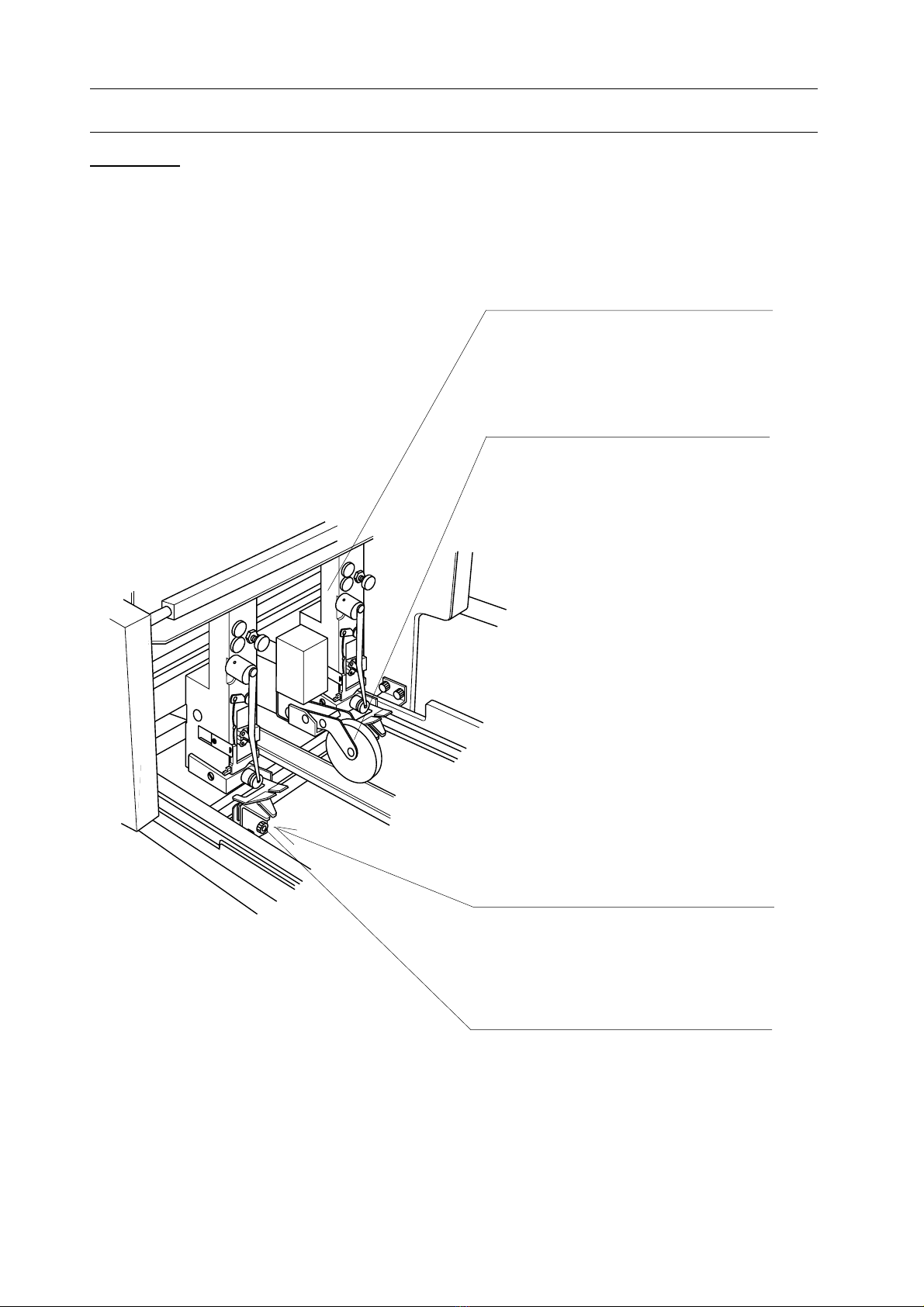

[3] Front and Side Joggers ....................................................................................5

[4] Stitcher ............................................................................................................6

[5] Wire Coil .........................................................................................................7

[6] Sheet Transport Section ..................................................................................8

[7] Stitcher Head 1 ................................................................................................9

[8] Stitcher Head 2 ................................................................................................10

1-2-2 Operation Panel ..............................................................................................11

1-3 Accessories..........................................................................................................12

2. Operation Procedure

2-1 Stitching and Folding Operations ....................................................................16

2-1-1 Stitching Section.............................................................................................16

2-1-2 Folding Section...............................................................................................18

2-2 Top and Side Stitching Operations ..................................................................21

2-3 Folding Operations ............................................................................................22

2-4 Corner Stitching Operations ............................................................................23

2-5 Collating Operations .........................................................................................24

2-6 Operation Procedure .........................................................................................25

2-7 For Efficient Operations ...................................................................................26

2-7-1 Adjusting Parts ...............................................................................................26

[1] Adjusting Jogging Stroke of Side Jogger ........................................................26

[2] Adjusting Square of Folding End Stopper ......................................................26

[3] Adjusting Knife Height ...................................................................................26

[4] Adjusting Foding Roller Clearnce...................................................................26

[5] Adjusting Folding Roller Pressure ..................................................................27