HORNER ZX Series User manual

Other HORNER Controllers manuals

HORNER

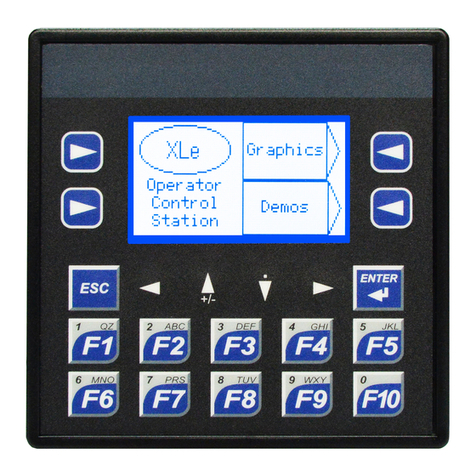

HORNER XLE-Model 2 User manual

HORNER

HORNER HE-X10 User manual

HORNER

HORNER XL4 6 User manual

HORNER

HORNER XLE Series User manual

HORNER

HORNER RCC Series User manual

HORNER

HORNER XL6 Prime Instruction Manual

HORNER

HORNER XL6 Series User manual

HORNER

HORNER XL4 User manual

HORNER

HORNER HE-EXL1E0 User manual

HORNER

HORNER XLE Use and care manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions