List the type and size of the tools that would typically be used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

Tool Size (if

applicable)

3.0 Product Disassembly Process

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

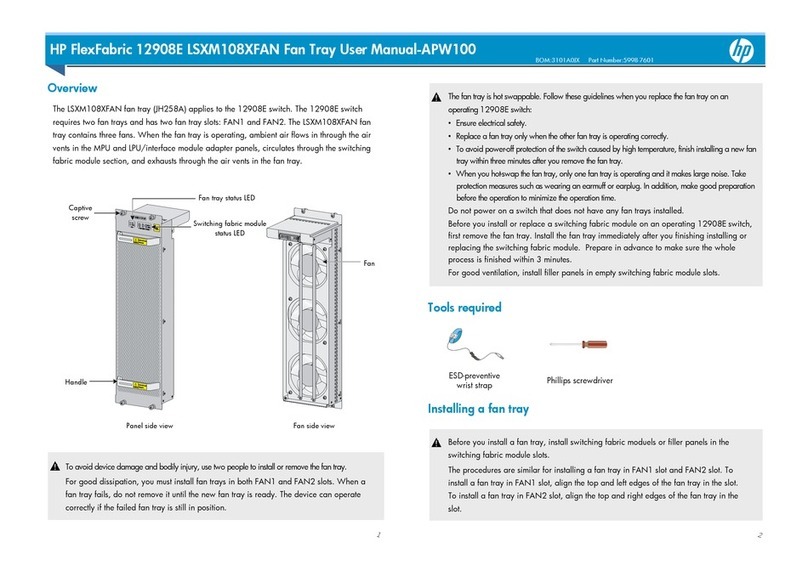

1. Unscrew the screws on mounting angle 2, and then remove the left and right mounting angles 2 from the chassis.

2. Unscrew the screws on front panel 3 and then remove front panel 3 from the chassis.

3. Unscrew the screws on blank panel 4, and then remove blank panel 4 from the chasssis.

4. Unscrew the screws on front panel 5, and then remove front panel 5 from the chassis.

5. Unscrew the screws on power cable channel sets 6, and then remove the power cable channel sets 6 from the chassis.

6. Unscrew the screws on blank power module panel 7, and then remove blank power module panel 7 from the chassis.

7. Unscrew the screws on power module 8, and then remove power module 8 from the chassis.

8. Remove the film 9 from the chassis.

9. Unscrew the screws on dust filter 13,14, and then remove the dust filter 13,14 from the chassis.

10. Unscrew the screws on fan frame 11,12, and then remove fan frame 11,12 from the chassis.

11. Unscrew the screws on net board panel 10, and then remove net board panel 10 from the chassis.

12. Unscrew the screws on panel 15, and then remove panel 15 from the chassis.

13. Unscrew the screws on net blank panel 16, and then remove net blank panel 16 from the chassis.

14. Unscrew the screws on flue panel A 17, and then remove the flue panel A 17 from the chassis.

15. Unscrew the screws on flue panel B 18, and then remove the flue panel B 18 from the chassis.

16. Unscrew the screws on flue panel C 19, and then remove the flue panel C 19 from the chassis.

17. Unscrew the screws on back cover 20, and then remove the back cover 20 from the chassis.

18. Remove shielding finger 21 from the chassis.

19. Unscrew the screws on back up rail 22, and then remove the back up rail 22 from the chassis.

20. Unscrew the screws on back down rail 23, and then remove the back down rail 23 from the chassis.

21. Remove all of the inner cables.

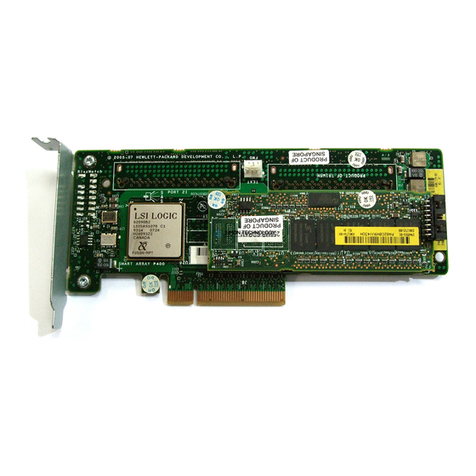

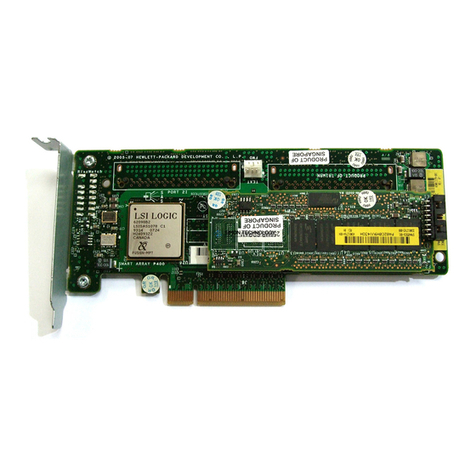

22. Unscrew the screws on PCB 24, and then remove PCB 24.

23. Unscrew the screws on strengthen plate 25, and then remove the strengthen plate 25.

24. Unscrew the screws on PCB 26, and then remove PCB 26.

25. Remove all of the labels and films.

26. Unscrew the screws on wire channel 2-2, and then remove wire channel 2-2 from mounting angle 2-1.

27. Unscrew the screws on pcb 3-2, and then remove pcb 3-3 from front panel 3-1.

28. Remove shielding finger 3-3 from front panel 3-1.

29. Remove film 3-4 from front panel 3-1.

30. Unscrew the screws on part 4-2, and then remove part 4-2 from front blank panel 4-1.

31. Remove shielding finger 4-3 from front blank panel 4-1.

32. Remove film 4-4 from front blank panel 4-1.

33. Unscrew the screws on part 5-2, and then remove part 5-2 from front panel 5-1.

34. Unscrew the screws on pcb 5-3, and then remove pcb 5-3 from front panel 5-1.

35. Remove shielding finger 5-4 from front panel 5-1.

36. Remove film 5-5 from front panel 5-1.

37. Unscrew the screws on power cable channel sets 6, and then remove the blocks 6-2 from wire road board 6-1

38. Unscrew the screws on part 11-1, and then remove the part 11-7 from fan frame 11-1.

39. Unscrew the screws on pcb 11-6, and then remove the pcb 11-6 from the part 11-1.

40. Remove the EMIS 11-5,11-4 from the fan frame 11-1.

41. Unscrew the screws on part 11-1,and then remove the handle 11-3 from the part11-1.

42. Remove the film 11-2 from the part 11-1.

43. Unscrew the screws on part 12-1, and then remove the part 12-7 from fan frame 12-1.

44. Unscrew the screws on pcb 12-6, and then remove the pcb 12-6 from the part 12-1.

45. Remove the EMIS 12-5,12-4 from the fan frame 12-1.

46. Unscrew the screws on part 12-1,and then remove the handle 12-3 from the part12-1.

EL-MF877-00 Page 2

Template Revision B