TABLE OF CONTENTS

Section

I

Page

........

GENERAL INFORMATION 1.1

1-1 Introduction ..............1.1

..........

1-3 Manual Description 1.1

.........

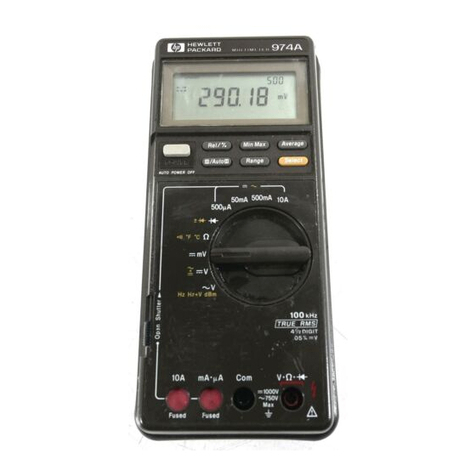

1-5 Instrument Description 1-2

.........

1-7 Safety Considerations 1.2

1-9 Instruments Covered by this Manual.

.

1.2

1-13 Specifications

.............

1-2

.......

1-15 Options and Accessories 1-24

1-17 Test Equipment

...........

1-25

Section

I1

Page

INSTALLATION

..............

2.1

2-1 Introduction

..............

2.1

2-3 Initial Inspection

............

2.1

..........

2-5 Preparation for Use 2.2

........

2-8 Line Voltage Selection 2.2

.............

2-10 Power Cords 2.2

.......

2-12 Grounding Requirements 2.3

2-14 Bench Use

..............

2.3

2-16 Rack Moiinting

............

2.3

.........

2-18 Interface Connections 2.4

2-19 Control Interface

...........

2.4

........

2-21 HP-1B Address Selection 2.4

2-23 Changing the Address from the

.............

Front Panel 2.5

2-24 Changing the Address from the

..............

Controller 2.5

2-25 InstaHation of Options

.........

2.6

2-28 Rear Terminal Assembly Removal

.

.

2.7

....

2-30 Plug-In Assenlbly Installation 2.8

...

2-32 Plug-In Assen~blyConfig~~ration 2.9

2-38 Wiring Block Preparation

.....

2-1

1

Section I11 Page

OPERATION

................

3.1

3-1 Introduction

..............

3.1

3-3 General Information

..........

3.1

3-4 AC Power

..............

3.1

3-6 Power On

...............

3.1

................

3-9 Operation 3.1

3-1

1

Voltage Measurements

........

3.

1

3-18 Resistance Measurements

.......

3.3

3-25 Current Measurements

........

3.4

3-32

Frequent

y

/Period Measurements .

.

3.6

3-39 HP 44491A General Purpose

Multiplexer

.............

3.6

3-45 HP44492A Reed Relay .......3.8

M~~ltiplexer

.............

3.8

Section 1V Page

..........

PERFORMANCE TESTS 4.1

4-

1

Introduction

..............

4.1

.........

4-3 Equipment Required 4.1

..............

4-5 Test Record 4.1

...........

4-7 Calibration Cycle 4.1

..........

4-9 Test Considerations 4.1

...............

4-10 General 4.1

4-12 Performance Tests

..........

4.2

DC Voltage Performance Tests

.......

4.2

...........

4-13 Preliminary Steps 4.2

4-14 DC Voltage Function

.

Offset Test

.

.4.2

.

...

4-16 DC voltage Function Gain Test 4.3

4-18 DC Voltage Function

.

Linearity

Test

.................

4.4

.......

AC Voltage Performance Tests 4.4

.

...

4-20 AC Voltage Function Gain Test 4.4

4-22 AC Voltage Function

.

Frequency

Response Test

............

4.5

DC Current Performance Tests

.......

4.7

4-24 DC Current Function

.

Offset Test

.

.4.8

4-26 DC Current Filnction

.

Gain Test

.

.4.8

AC Current Performance Tests

.......

4.9

.

...

4-28 AC Current Function Gain Test 4.9

2-Wire Ohms Performance Tests

.....

4-10

4-30 2-Wire Ohms Function

.

Offset

................

Test 4-10

4-32 2-Wire Ohms Function

.

Gain Test . 4-1

1

.....

4-Wire Ohms Performance Tests 4-11

4-34 4-Wire Ohms Function

.

Offset

................

Test 4-12

4-36 4-Wire Ohms Function

.

Gain Test . 4-13

Frequency Counter Performance Tests

.

.

4- 13

4-38 Frequency Counter

.

Acwracy

................Test 4-14

Rear lnput Performance Tests (Standard

............

Instrument) 4-14

4-40 Preliminary Steps ..........4-14

4-41 DC Voltage Function

.

Rear Terminal

Offset Test ............4-14

4-43 DC Ciu-rent Function

.

Rear Terminal

............

Offset Test

4-15

4-45 2-Wire Ohms F~tnction

.

Offset

................

Test 4-15

4-47 4-Wire Ohms F~unction

.

Offsct

Test

................

4-16

Rear Input Performance Tests (4449

l

A

General Purpose Relay Assy)

...

4-17

4-49 Preliminary Steps

..........

4-17