ii

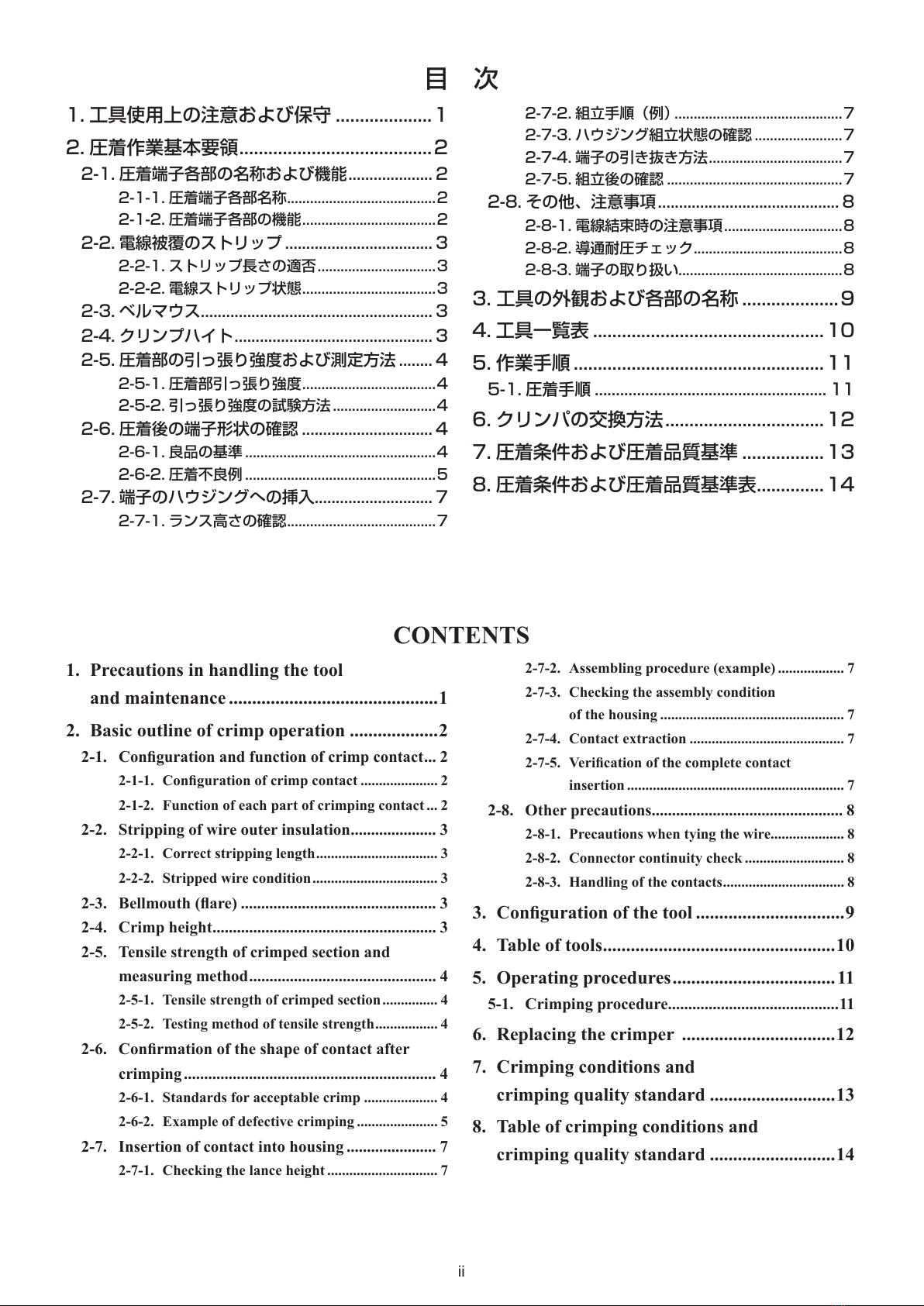

目 次

CONTENTS

1. 工具使用上の注意および保守 ....................1

2. 圧着作業基本要領 ........................................2

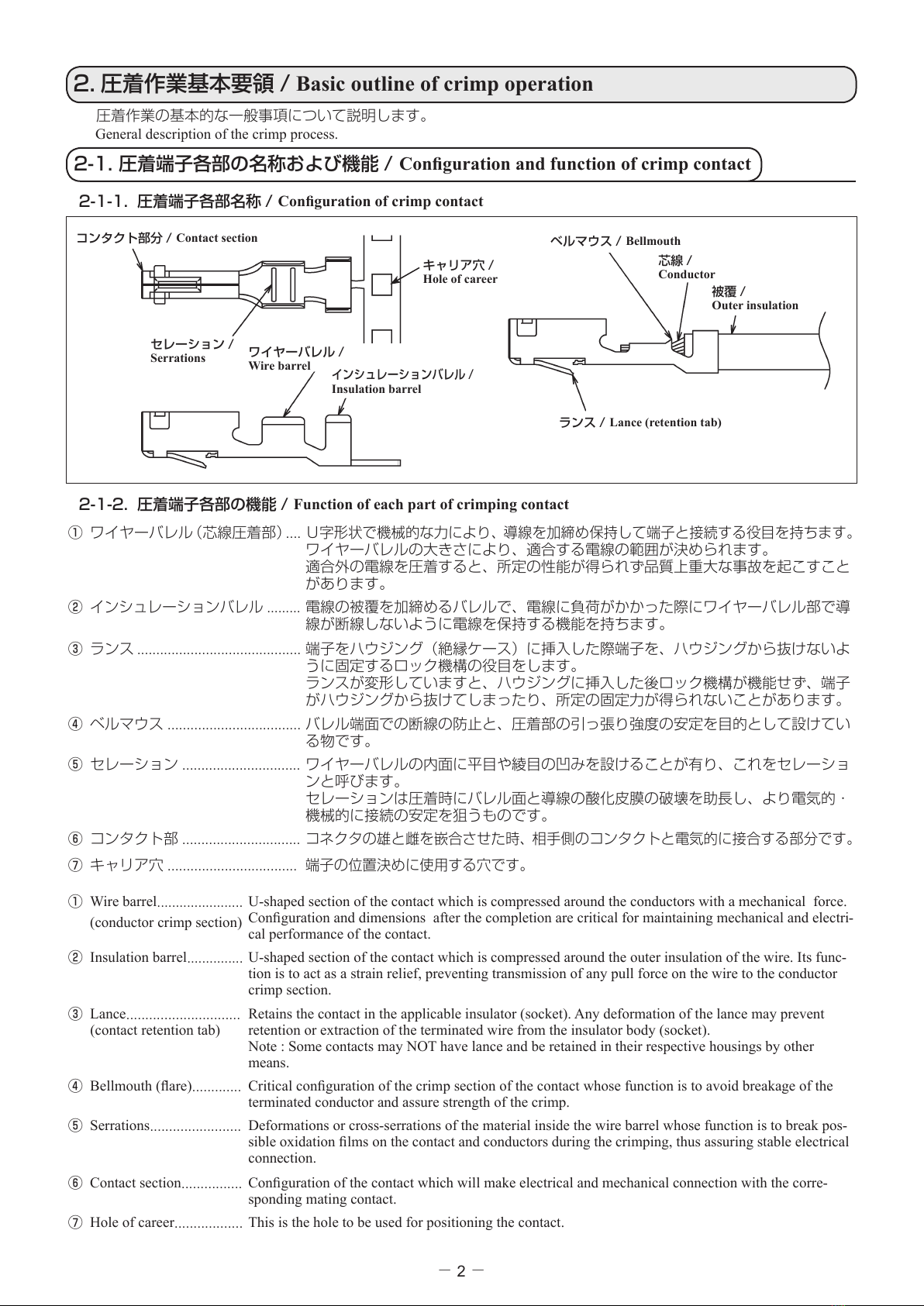

2-1. 圧着端子各部の名称および機能 .................... 2

2-1-1. 圧着端子各部名称 .......................................2

2-1-2. 圧着端子各部の機能 ...................................2

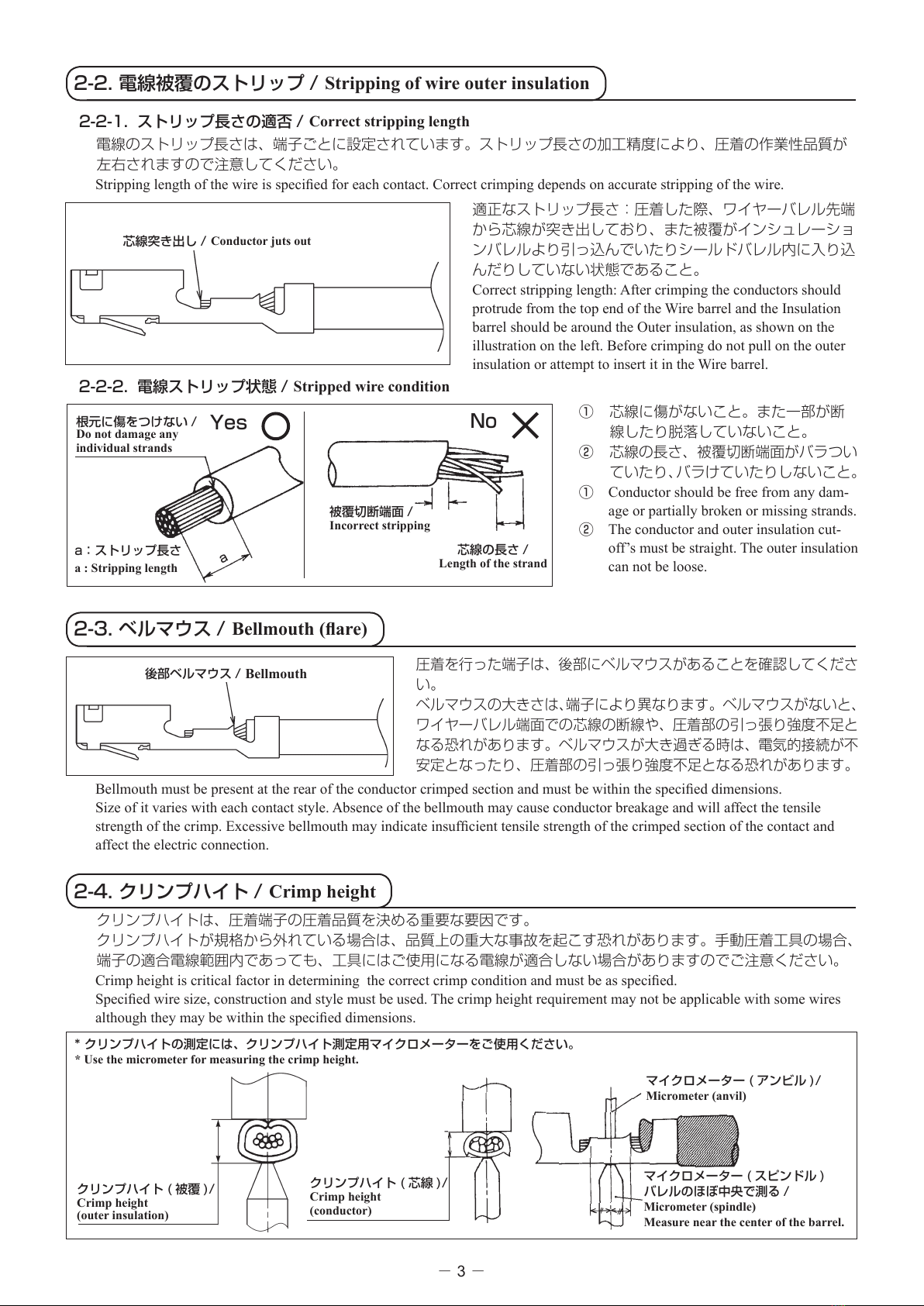

2-2. 電線被覆のストリップ ................................... 3

2-2-1. ストリップ長さの適否 ...............................3

2-2-2. 電線ストリップ状態 ...................................3

2-3. ベルマウス ....................................................... 3

2-4. クリンプハイト ............................................... 3

2-5. 圧着部の引っ張り強度および測定方法 ........ 4

2-5-1. 圧着部引っ張り強度 ...................................4

2-5-2. 引っ張り強度の試験方法 ...........................4

2-6. 圧着後の端子形状の確認 ............................... 4

2-6-1. 良品の基準 ..................................................4

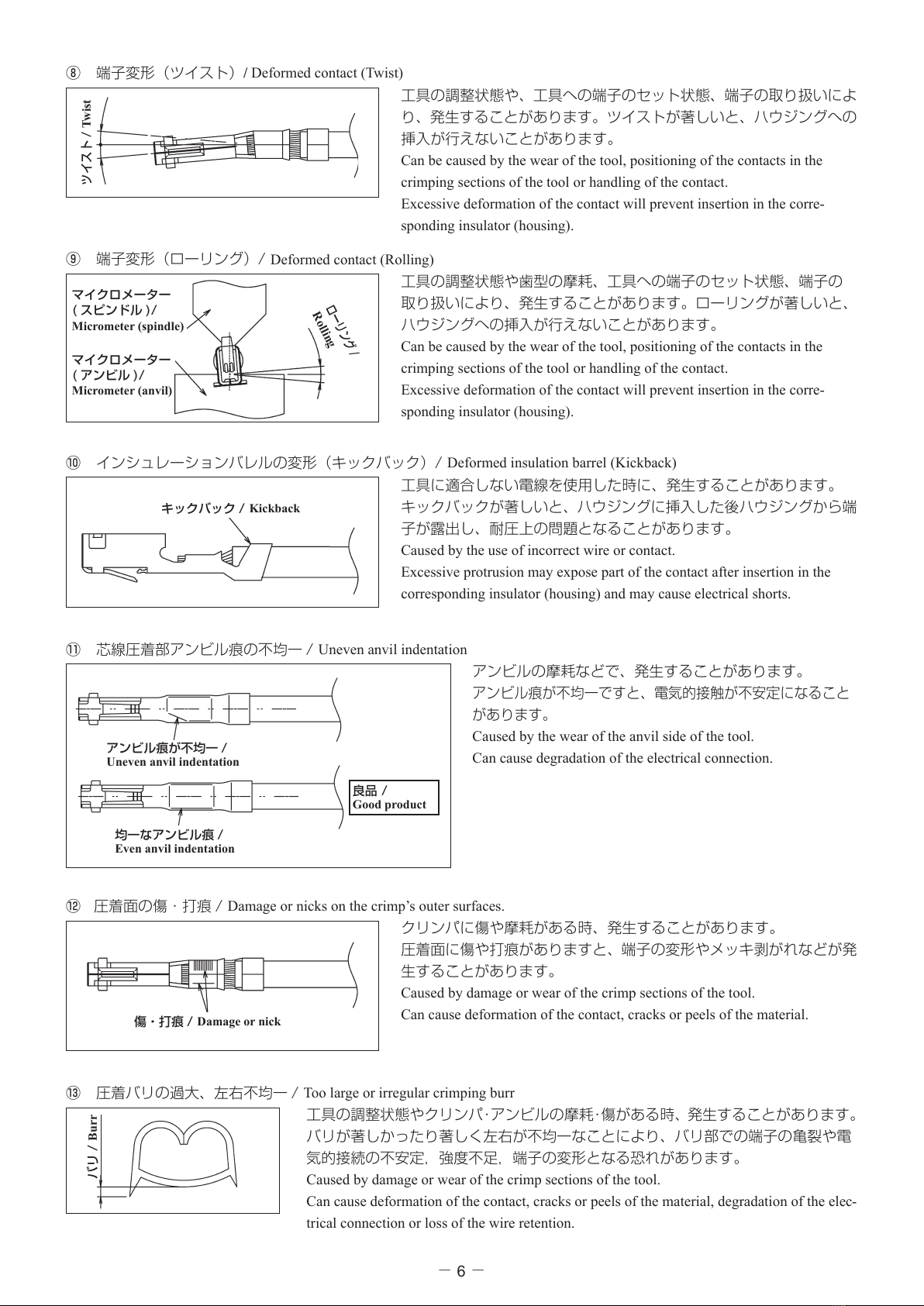

2-6-2. 圧着不良例 ..................................................5

2-7. 端子のハウジングへの挿入............................ 7

2-7-1. ランス高さの確認 .......................................7

2-7-2. 組立手順(例) ............................................7

2-7-3. ハウジング組立状態の確認 .......................7

2-7-4. 端子の引き抜き方法 ...................................7

2-7-5. 組立後の確認 ..............................................7

2-8. その他、注意事項 ........................................... 8

2-8-1. 電線結束時の注意事項 ...............................8

2-8-2. 導通耐圧チェック .......................................8

2-8-3. 端子の取り扱い...........................................8

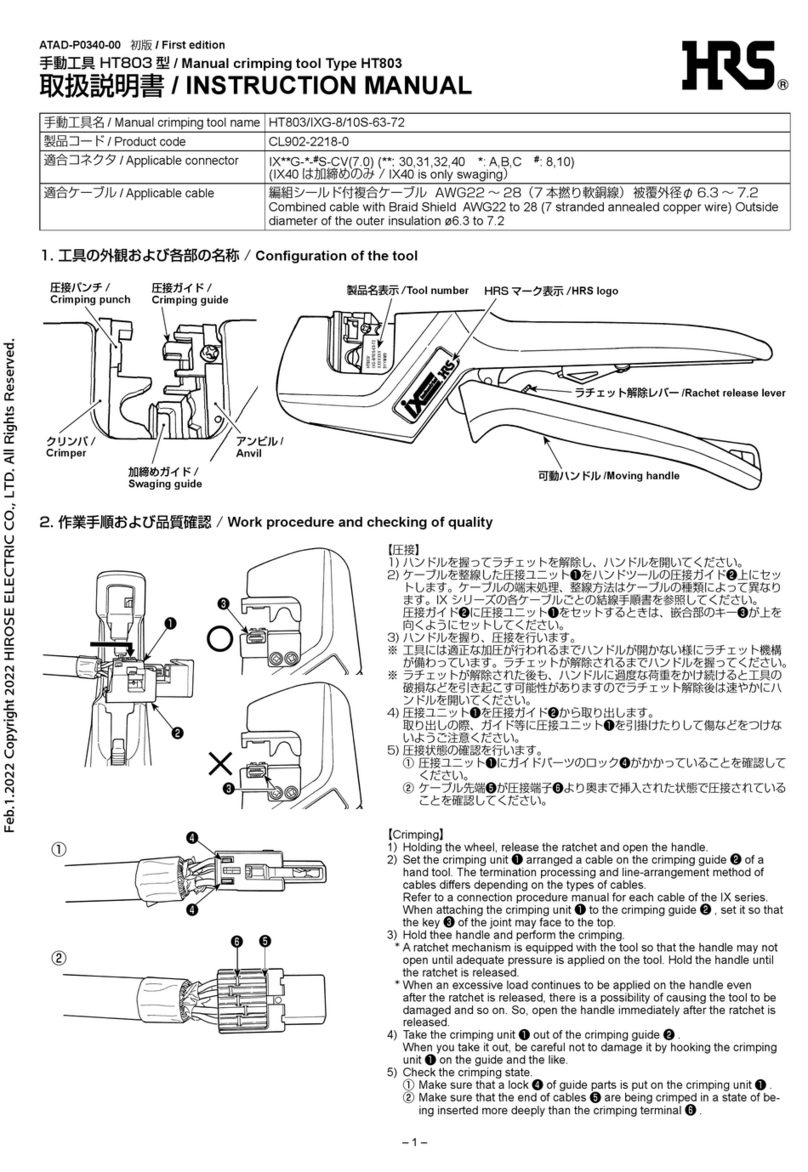

3. 工具の外観および各部の名称 ....................9

4. 工具一覧表 ................................................ 10

5. 作業手順 ....................................................11

5-1. 圧着手順 ....................................................... 11

6. クリンパの交換方法 .................................12

7. 圧着条件および圧着品質基準 .................13

8. 圧着条件および圧着品質基準表 .............. 14

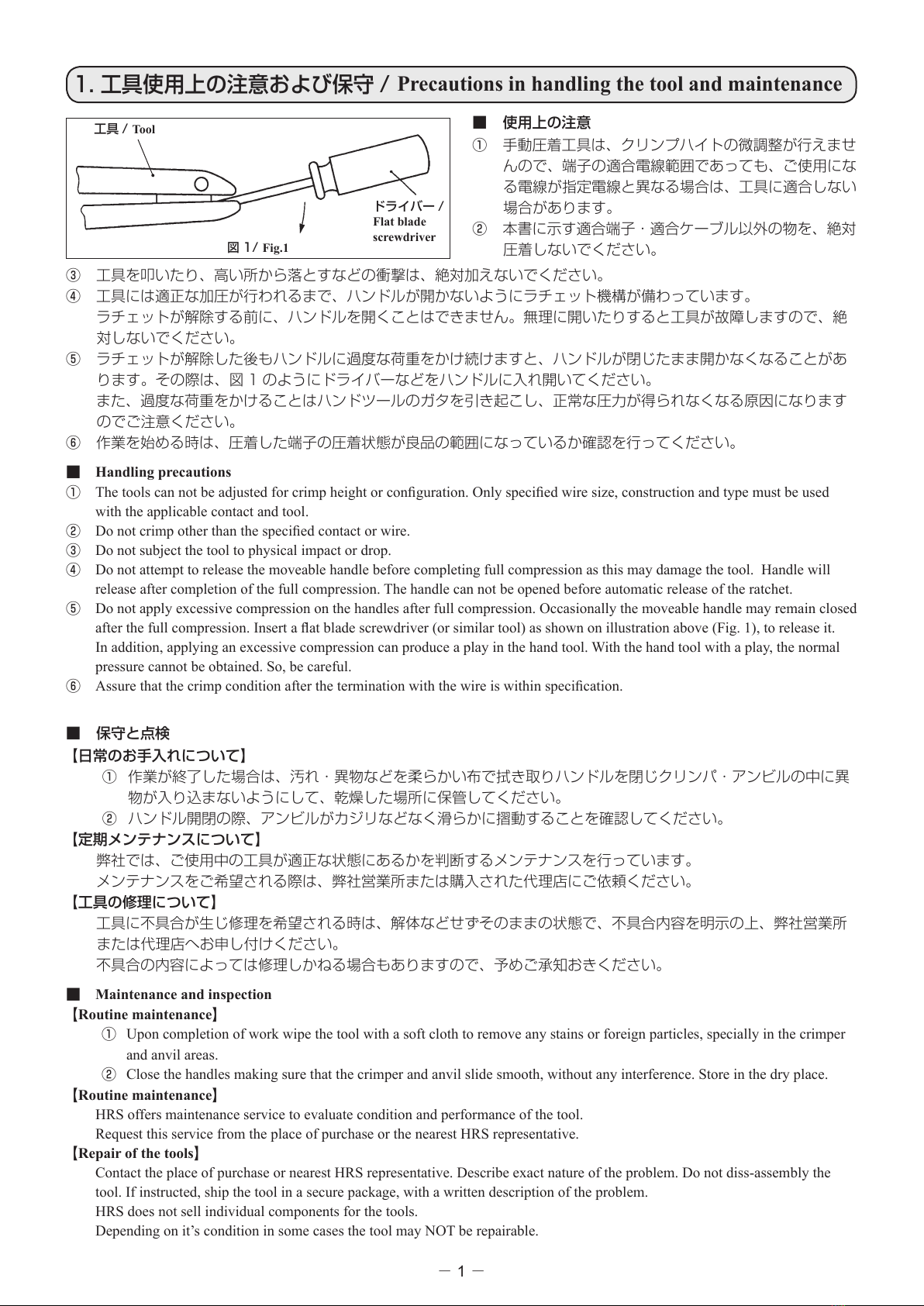

1. Precautions in handling the tool

and maintenance .............................................1

2. Basic outline of crimp operation ...................2

2-1.

Conguration and function of crimp contact

... 2

2-1-1. Conguration of crimp contact ..................... 2

2-1-2. Function of each part of crimping contact ... 2

2-2. Stripping of wire outer insulation..................... 3

2-2-1. Correct stripping length................................. 3

2-2-2. Stripped wire condition.................................. 3

2-3. Bellmouth (are) ................................................ 3

2-4. Crimp height....................................................... 3

2-5. Tensile strength of crimped section and

measuring method.............................................. 4

2-5-1. Tensile strength of crimped section............... 4

2-5-2. Testing method of tensile strength................. 4

2-6. Conrmation of the shape of contact after

crimping .............................................................. 4

2-6-1. Standards for acceptable crimp .................... 4

2-6-2. Example of defective crimping ...................... 5

2-7. Insertion of contact into housing ...................... 7

2-7-1. Checking the lance height .............................. 7

2-7-2. Assembling procedure (example) .................. 7

2-7-3. Checking the assembly condition

of the housing .................................................. 7

2-7-4. Contact extraction .......................................... 7

2-7-5. Verication of the complete contact

insertion ........................................................... 7

2-8. Other precautions............................................... 8

2-8-1. Precautions when tying the wire.................... 8

2-8-2. Connector continuity check ........................... 8

2-8-3. Handling of the contacts................................. 8

3. Conguration of the tool ................................9

4. Table of tools..................................................10

5. Operating procedures...................................11

5-1. Crimping procedure..........................................11

6. Replacing the crimper .................................12

7. Crimping conditions and

crimping quality standard ...........................13

8. Table of crimping conditions and

crimping quality standard ...........................14

Aug.1.2017 Copyright 2017 HIROSE ELECTRIC CO., LTD. All Rights Reserved.