sweeping. Click the label to switch between the two modes.

Start frequency label: to display start frequency of current sweeping. Click the label to

switch among different start frequencies.

Stop frequency label: to display stop frequency of current sweeping.

Sweeping point number label: to display total point number of current sweeping. Click the

label to switch among different point numbers.

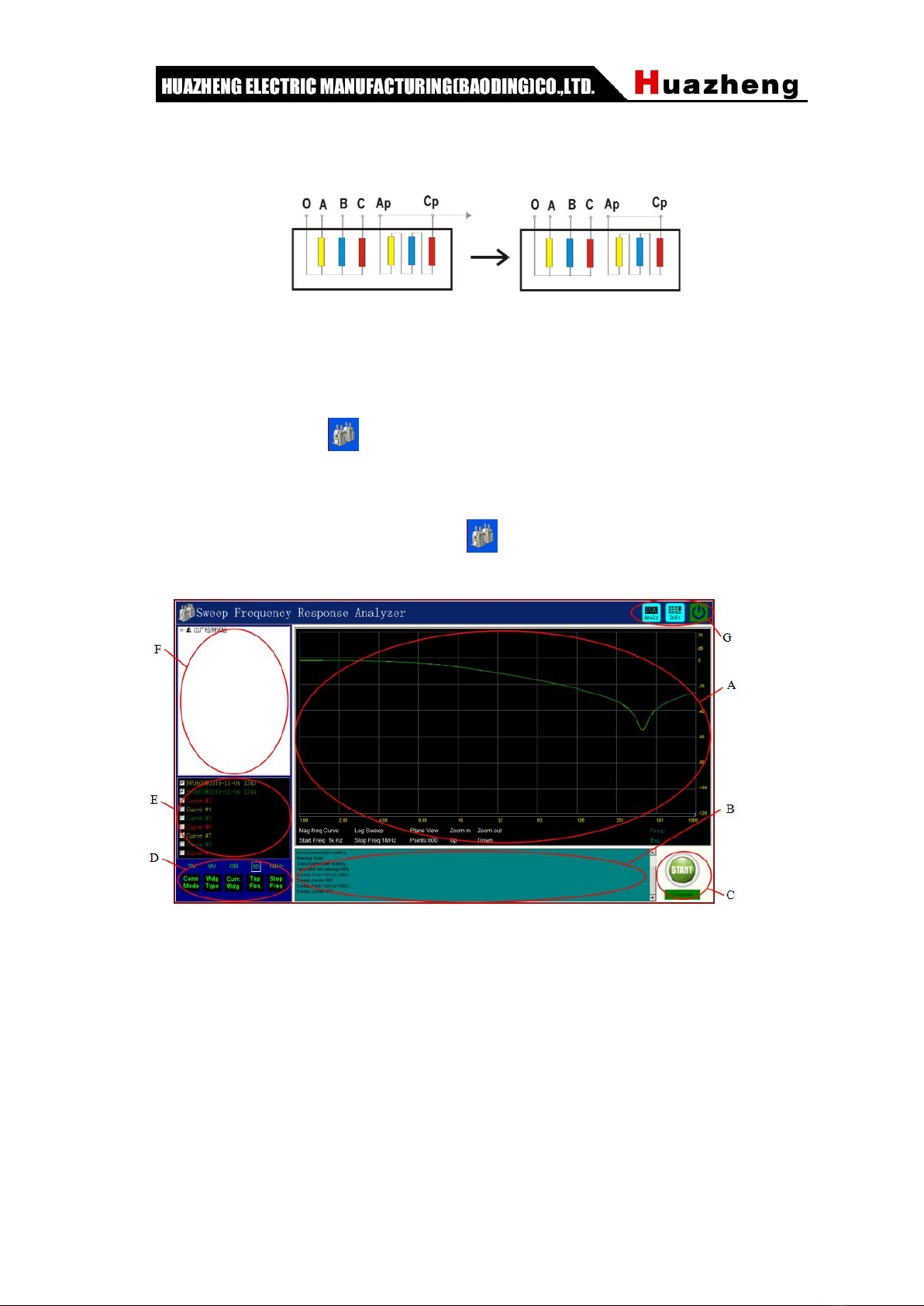

(B)Status Display Area

The status display area displays working status of the current equipment.

(C)Operating Zone

There are two keys in the operating area, start and stop that display in turn

according to service status, i.e. “start” displays under stop status and “stop” under start

status.

There is a current status display label under the key to display current status of the tester:

“Offline status”: computer is working under off-line status, when only data reading and

printing functions are available.

“Equipment connected”: computer is connected with equipment and testing is possible.

“Equipment disconnected”: computer is disconnected with equipment and testing is

impossible, generally requiring reconnection and restart of software.

(D)Test Parameter Setting Area

Area D displays parameter setting window that is used for setting of test parameters,

including winding wiring method, category , Tap position and number of the winding to be

tested, sweep stop frequency, etc.

(E)Curve Description Area

Area E displays description information of the current curve. The label in a color contains

description information of its corresponding curve in the same color.

(F)Data Selection Area

What locates at the top right corner (F) is data selection area. Test data applies

hierarchical management, where the first grade is name of substation, the second grade

name of transformer, the third grade category and number of transformer winding and the

last grade existing data. Data name is displayed in the manner of “data type @ test time”.

Data displayed in the part matches with content of the label in area (A). When

“amplitude-frequency curve” is displayed, the data selection area displays test result of

the amplitude-frequency curve and when “phase-frequency curve” is displayed, the data

selection area displays test result of the phase-frequency curve.

When “amplitude-frequency curve” or “phase-frequency curve” is displayed, the test result

is displayed in area A when relevant data is clicked.

(G)Function Key Area