Pub. 42004-308C

GAI-Tronics Corporation P.O. Box 1060, Reading, PA 19607-1060 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model 234WM

Wall-Mount Stanchion Assembly

Confidentiality Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAI-

Tronics retains all intellectual property and other rights in or to the information contained herein, and

such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

General Information

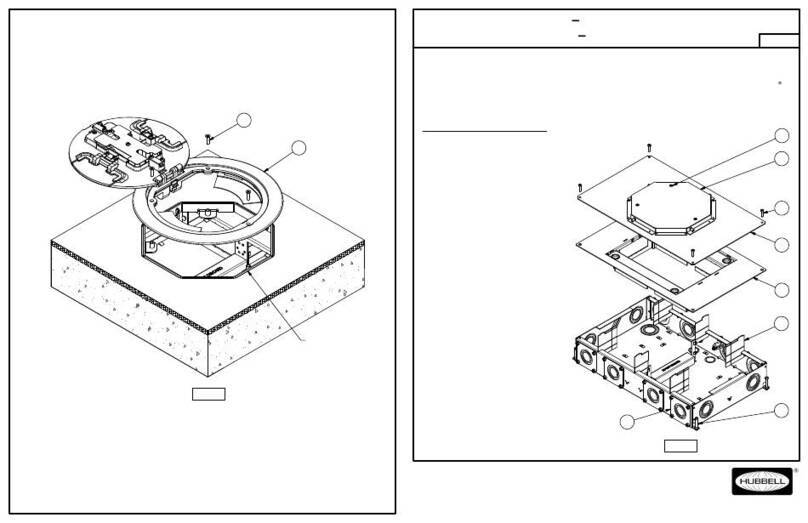

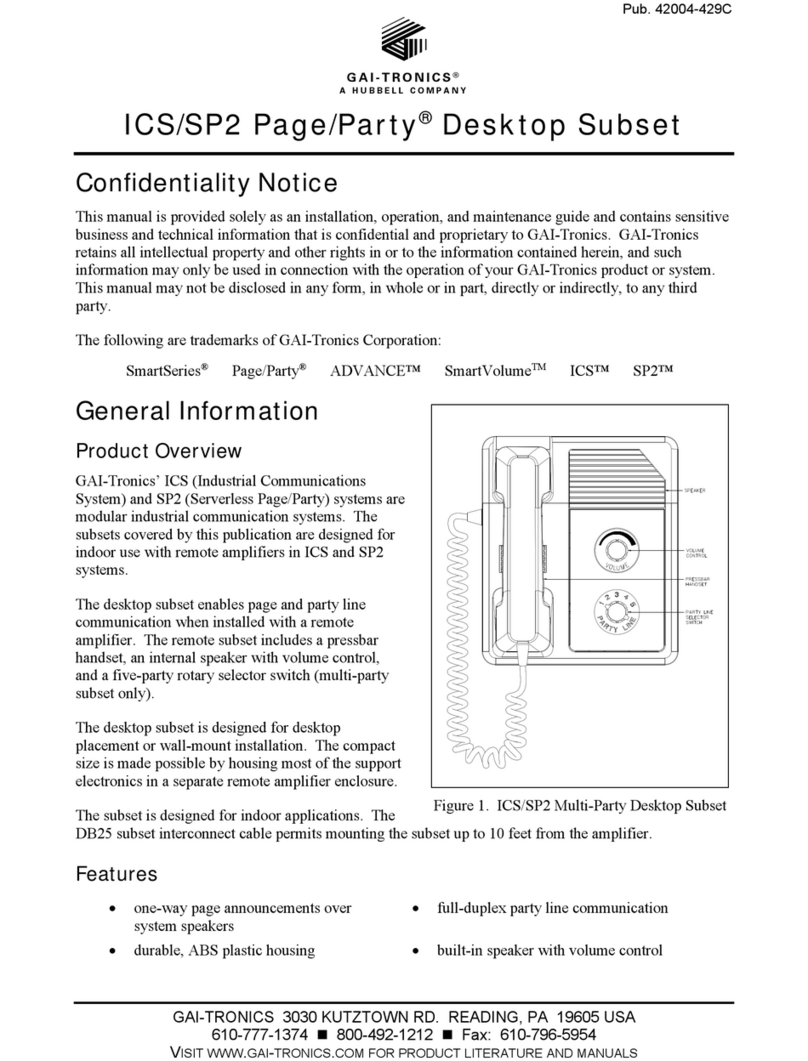

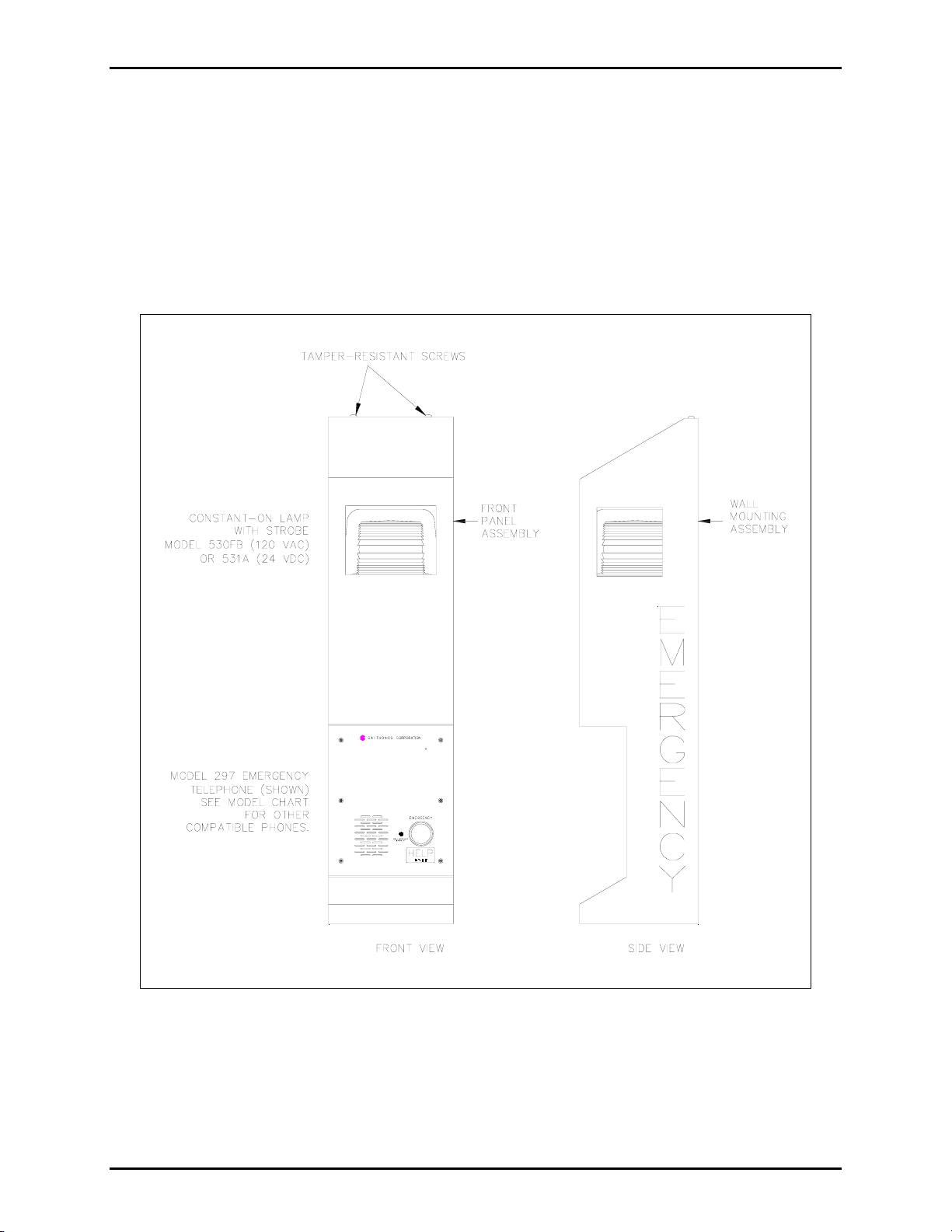

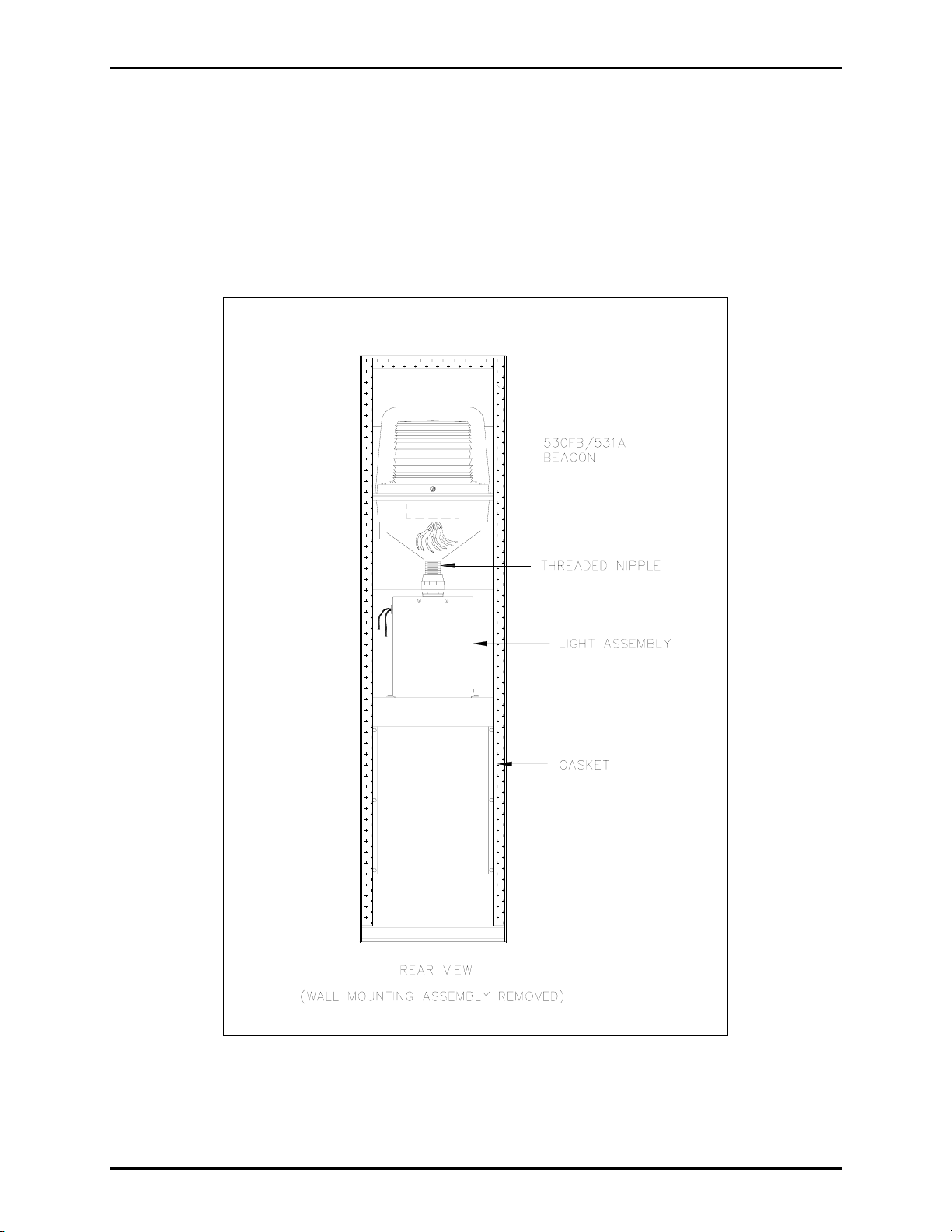

The Model 234WM Wall-Mount Stanchion Assembly is designed to house a Model 298 Series or 297

Series Emergency Telephone or Model 276 Series or 277 Series Flush Panel Handset Telephone, and a

Model 530FB or 531A Beacon (each sold separately). The stanchion is a simple, attractive, yet highly

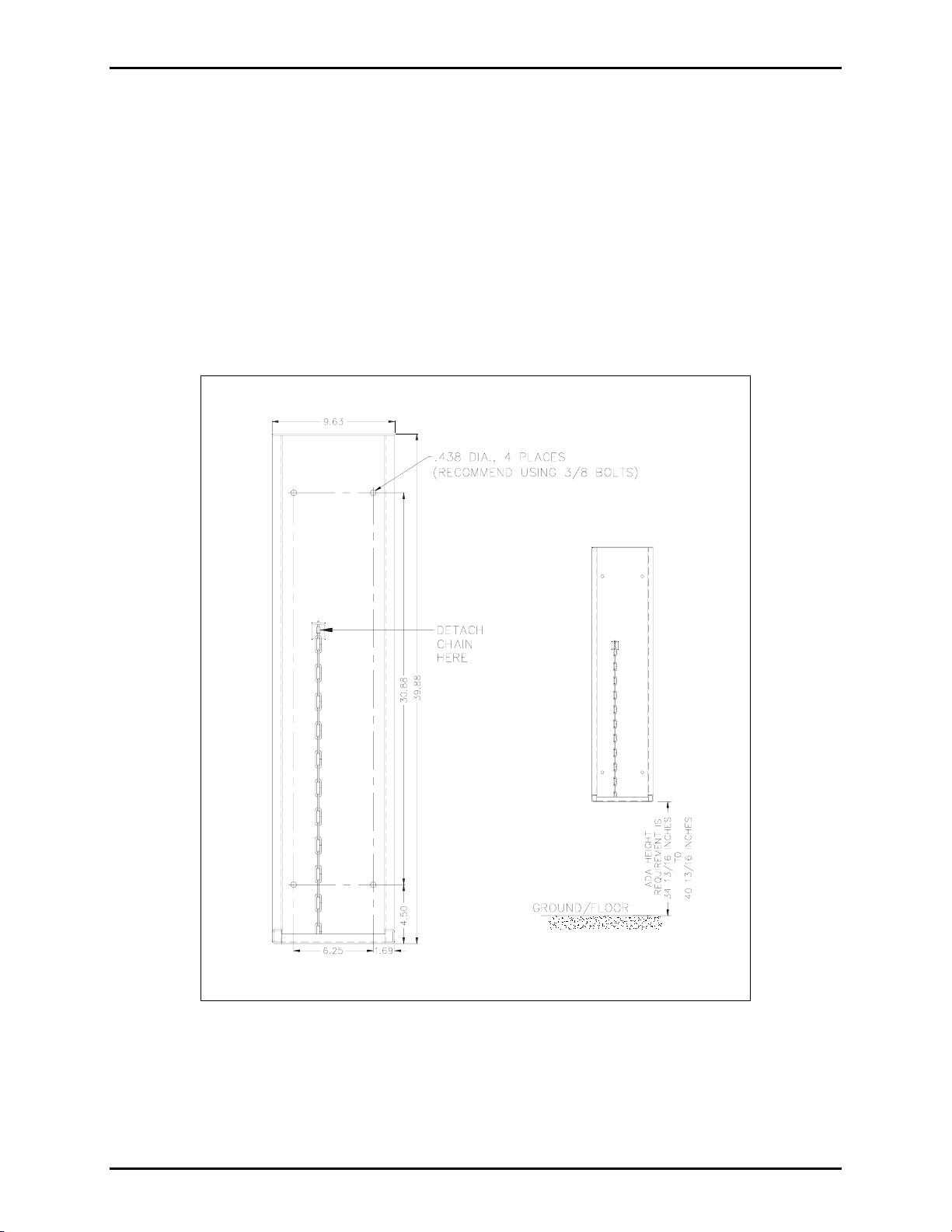

visible unit measuring 40.5 inches (1.03 meters) tall.

GAI-Tronics emergency telephones are designed for isolated high-risk areas requiring emergency

communications equipment. Emergency telephone users simply press the clearly labeled emergency push

button for immediate connection to a user-programmed central security telephone number. The following

is a list of GAI-Tronics telephone models that are compatible for use in the Model 234 Wall-Mount

Stanchion and the associated instruction publication number:

Pub. No. Emergency Phone Model

Pub. 42004-352 Model 297-001 Flush-Mount Emergency Phone

Pub. 42004-351 Model 297-003 S.M.A.R.T. Flush-Mount Emergency Phone

Pub. 42004-352 Model 298-001 Flush-Mount Emergency Phone with Keypad

Pub. 42004-351 Model 298-003 S.M.A.R.T. Flush-Mount Emergency Phone with Keypad

The beacon increases the visibility of the emergency telephone locations by providing a constant-on lamp

and a flashing strobe light that is automatically energized when the emergency button is pressed. A light

shines on the faceplate of the telephone mounted in the stanchion, illuminating it for nighttime use. Refer

to Pub. 42004-284 for installation information for the Model 530FB Strobe with Dual Constant-On

Lamps.