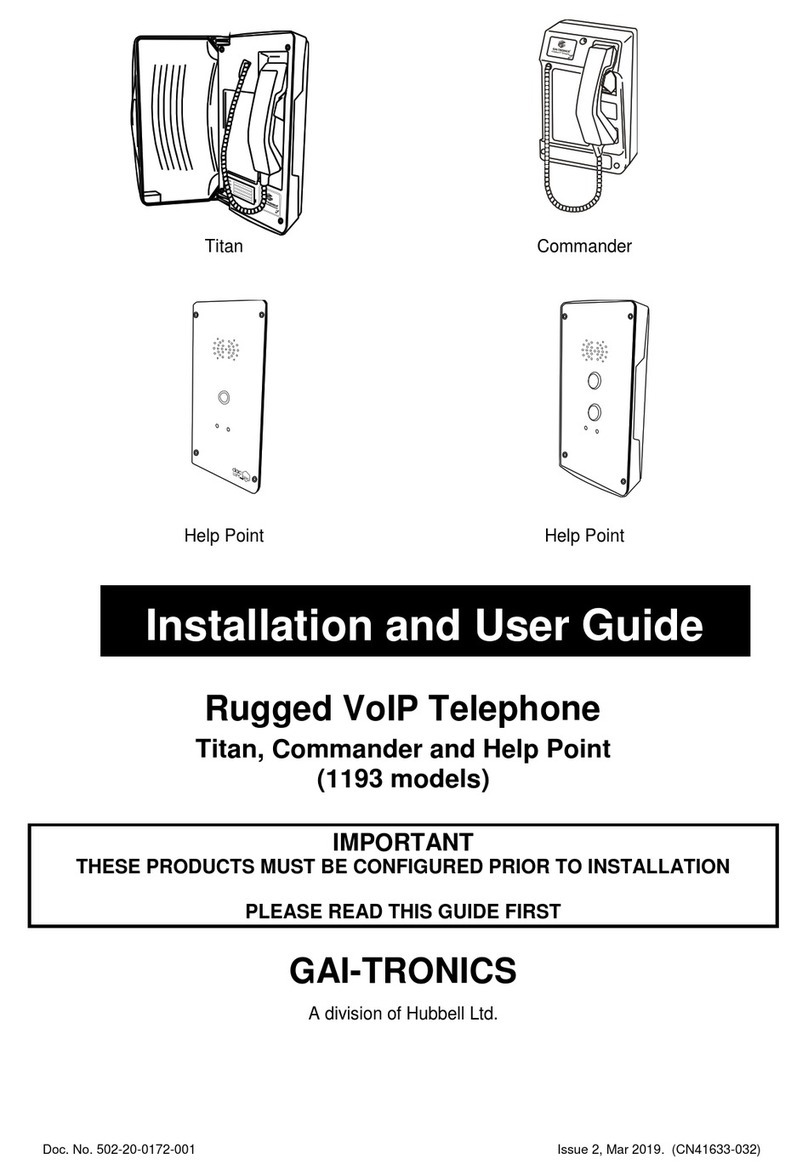

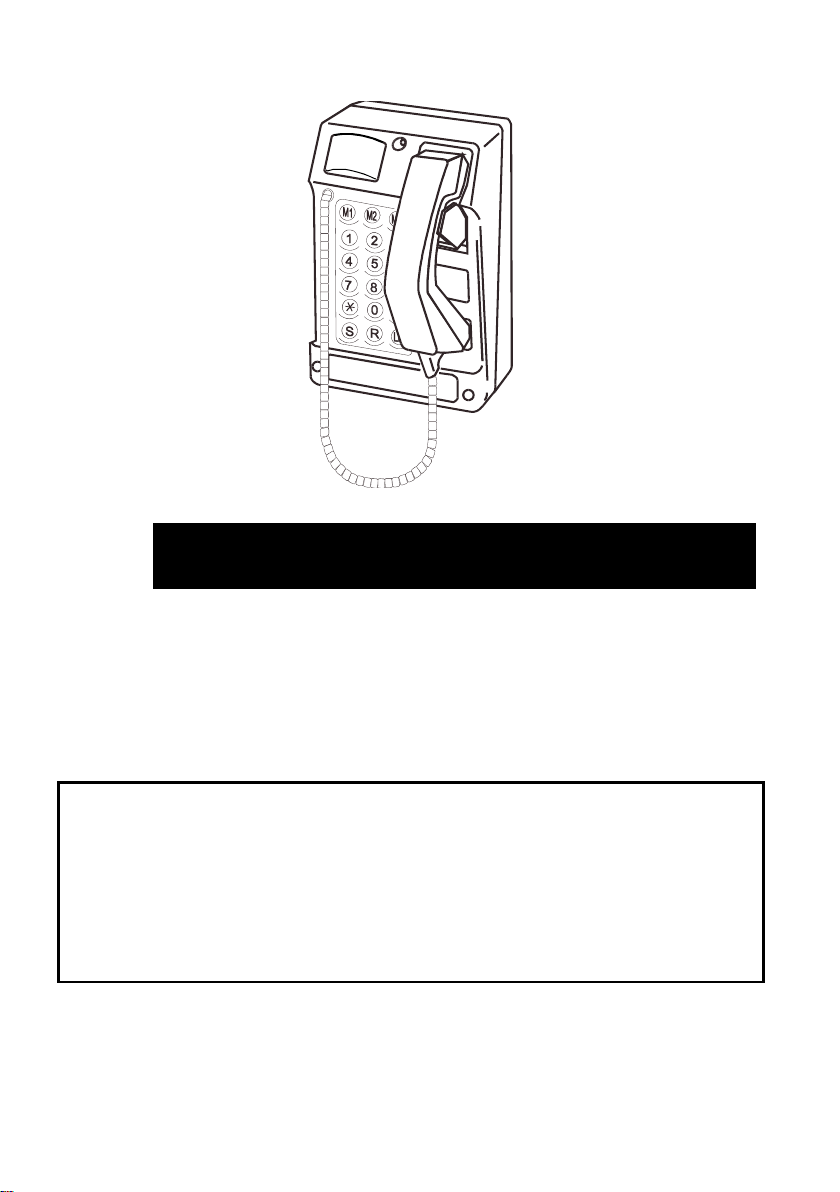

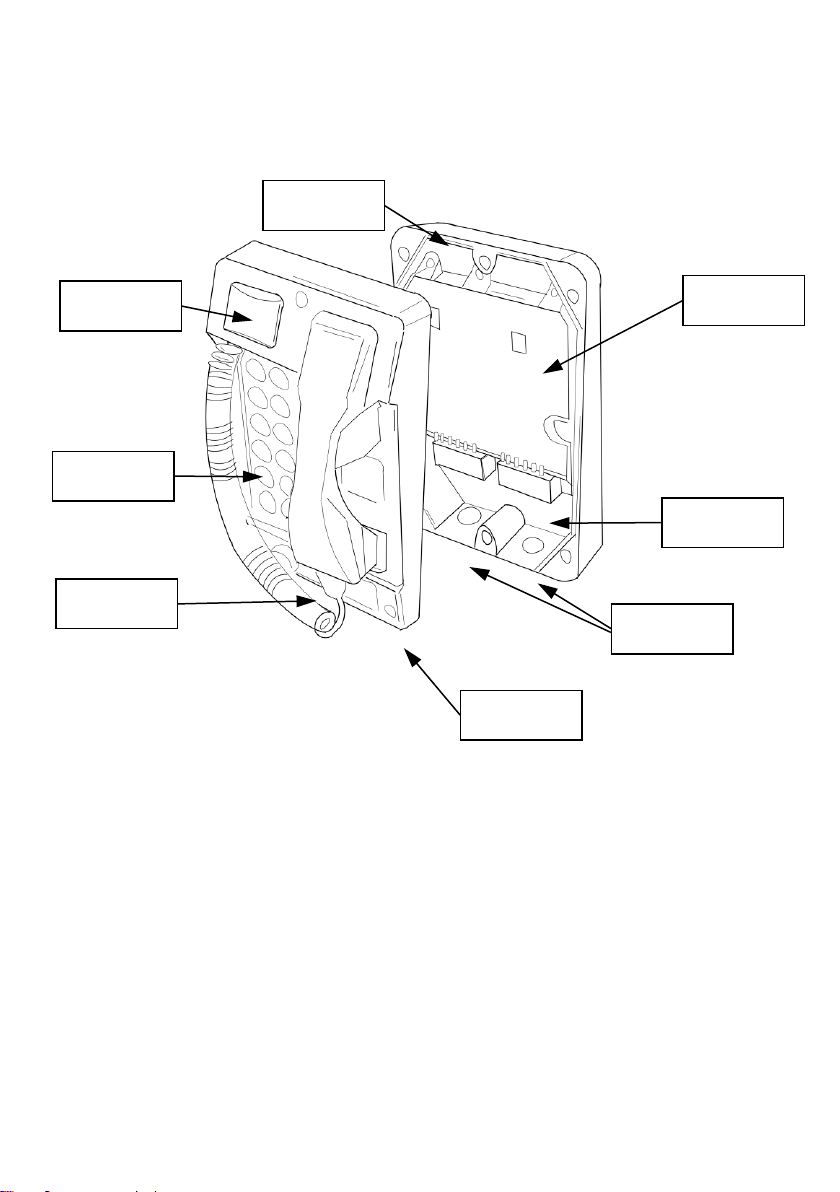

5.2 Pre- installation

The Auteldac 6 telephone is connected by hard-wiring - (unlike a plug

and socket on internal telephones). Because of this, installation must

be carried out by trained, competant personnel. Contact GAI-Tronics if

installation service is required.

The telephone is supplied suitable for vertical mounting only. Before

installing the unit, please take note of the following:

•Glands. Glands are not supplied. All glands and cables must meet

‘Increased Safety’ (‘e’ type) requirements. Only ‘e’ type glands and

suitable cables should be used and must be fitted correctly.

Glands must meet IP66 minimum and be certified Ex eb tb.

Glands must be suitable for -40°C to +70°C

•Earth connection. The unit must be connected to an

equipotential bonding system for the whole area in which the

intrinsically safe equipment is being used. See section 5.4.3 for

details.

•Cable entries - Auteldac 6 has two M20 cable entry gland

positions. Before installing, give consideration to the options

available to ensure that the required connections can be made

using the available glands.

If a high voltage is connected to the relay contacts (for example to

activate a mains-powered beacon) then that cable must be

segregated from all other cables and routed through its own gland.

Upon installation care should be taken to ensure that incoming

cables are cleanly routed with a view to maintaining segregation

between hazardous voltage cabling and the telephone's internal

wiring (i.e. handset, hookswitch, ringer and headset if fitted).

ALL POSSIBLE MEASURES MUST BE TAKEN TO ENSURE

WATER, FLUID OR DUST DOES NOT CONTAMINATE THE

INTERNAL COMPONENTS OF THE TELEPHONE WHILST

UNPACKING, PREPARING AND INSTALLING IT IN INCLEMENT

WEATHER CONDITIONS OR BY NEGLIGENCE.

FAILURE TO TAKE THIS PRECAUTION WILL INVALIDATE YOUR

WARRANTY AND CERTIFICATION

The telephone body must NOT be opened, nor glands removed or

cables disconnected unless all supplies to the telephone, including

network cables, power cables and external devices have been isolated

outside the hazardous area. Terminals for incoming cables are ‘e’ type

and must be carefully connected so as to make an ‘e’ type termination.