Content

Trademarks...........................................................................................................................2

Content .................................................................................................................................3

Preface ..................................................................................................................................5

Technical Support...............................................................................................................6

Product modification ...........................................................................................................6

Warranty.............................................................................................................................6

Using the documentation ....................................................................................................7

General safety guidelines ....................................................................................................8

Obligations and liability .......................................................................................................8

Explanation of symbols and warnings .................................................................................8

Basic symbols .................................................................................................................9

Intended use.......................................................................................................................9

Improper use ......................................................................................................................9

Informal safety precautions...............................................................................................10

Training and instruction of personnel ................................................................................11

Storing ContaminationSensor...........................................................................................12

Storage conditions ............................................................................................................12

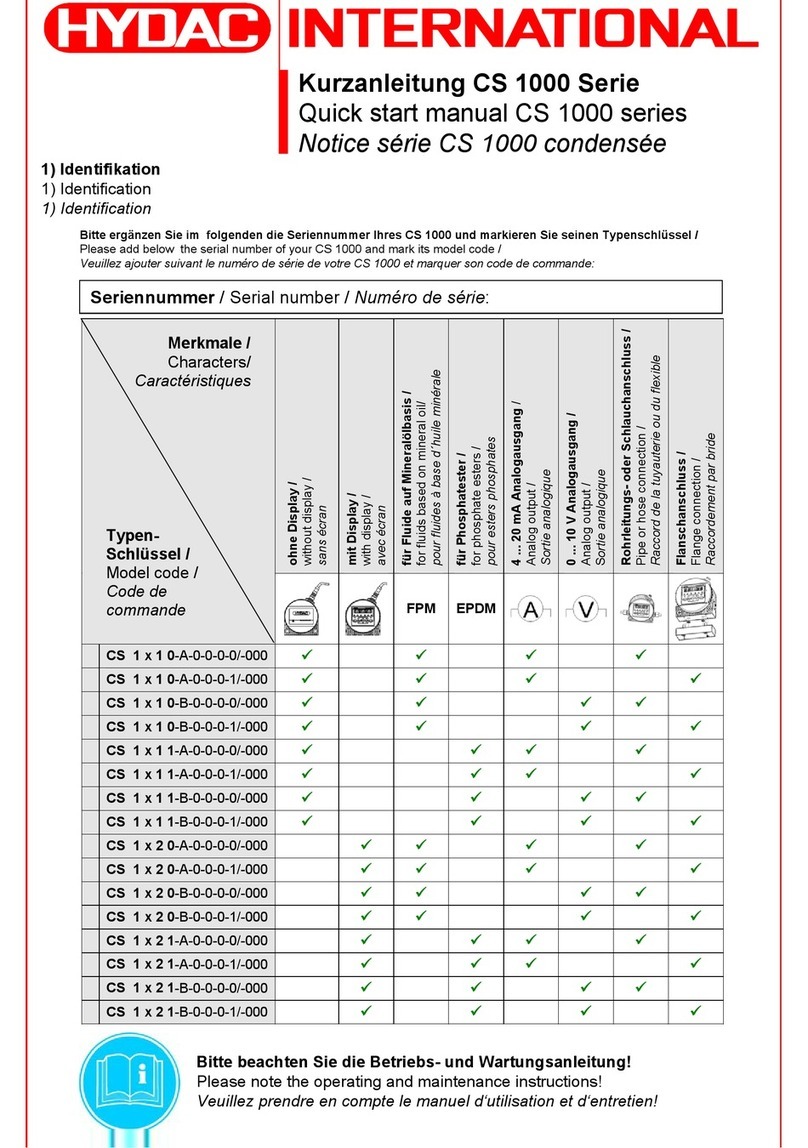

Interpreting the type label..................................................................................................13

Checking the scope of delivery.........................................................................................14

CS1220 VIMS Features.......................................................................................................15

CS1000 Restrictions on use..............................................................................................15

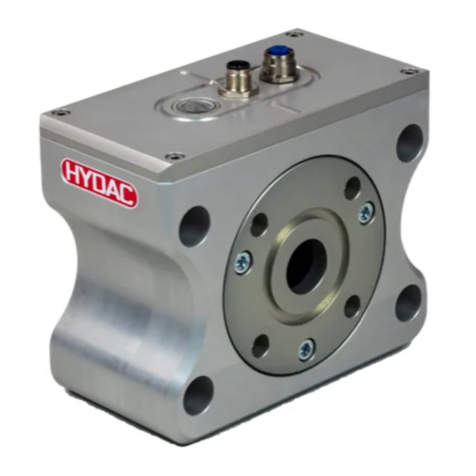

CS1x1x dimensions (without display)................................................................................16

Hydraulic connection types ...............................................................................................17

Flange connection type (Type CS1xxx-x-x-x-x-1/-xxx)...................................................17

Fastening / mounting the CS1000.....................................................................................17

CS1000 hydraulic installation............................................................................................18

Selecting the measurement point ..................................................................................19

Flow rate, differential pressure

p

characteristics ...............................20

Hydraulic connection of the CS1000 .............................................................................21

Electrical connection of the CS1000 .................................................................................22

Pin assignment..............................................................................................................22

Connection cable - Assignment / Color coding ..............................................................23

CS measurement modes....................................................................................................24

Mode M1: Continuous measurement ................................................................................24

mTIME: measuring period.................................................................................................24

Analog Output ....................................................................................................................25

Status messages................................................................................................................27

Status LED / display..........................................................................................................27

Taking the CS1000 out of operation..................................................................................28

Disposing of CS1000 ........................................................................................................28