MCS 1000 Series Content

HYDAC FILTER SYSTEMS GMBH en(us) Page 4 / 76

BeWa MCS1000 3435427f V130 en-us 2012-06-15.doc 2012-06-15

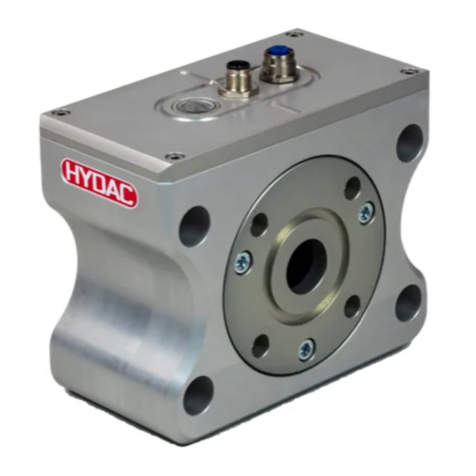

Connecting MCS15xx via flange adapter plate (accessories) .............................. 34

Connecting MCS15xx via SAE 4" per ISO 6162-1 (4xM16) ................................. 35

MCS hydraulic installation ....................................................................................35

Flow rate, differential pressure p

and viscosity

characteristics .....................36

Electrical connection of the MCS..........................................................................38

Plug pin assignment .............................................................................................38

Connection cable - Assignment / Color coding..................................................... 39

Connecting cable wires.........................................................................................40

Using switching outputs........................................................................................41

Switching output - FE.NFE (factory setting)..........................................................41

Switching output - ALL.RDY .................................................................................41

Switching logic "active low" .................................................................................42

Switching on sensors............................................................................................42

Example: Operation - 1 particle detected..........................................................42

Example: Operation - no particle detected........................................................43

Example: Operation - several particles detected ..............................................43

Switching logic "active high"................................................................................44

Switching on the sensor........................................................................................44

Example: Operation - 1 particle detected..........................................................44

Example: Operation - no particle detected........................................................45

Example: Operation - several particles detected ..............................................45

Switching output "Device Ready" ........................................................................46

Parameterizing MCS / reading off measured values ...........................................47

Connecting MCS 1000 with SMU 1200 ................................................................47

Connecting MCS with CSI-D-5 (Condition Sensor Interface) ............................... 48

Connecting MCS to HMG 3000 ............................................................................49

Evaluating measurement results ..........................................................................50

Menu structure .......................................................................................................51

PowerUp Menu .......................................................................................................52

MODE - select operating mode ............................................................................52

S.TIME - Set storing interval.................................................................................52

SEL.COM - Set protocol .......................................................................................52

ADRESS – Set bus address .................................................................................52

DFAULT - Reset to factory setting........................................................................52

CANCEL - cancel without saving..........................................................................53

SAVE - save changes...........................................................................................53

Measuring menu.....................................................................................................53

DSPLAY - Show measured variable.....................................................................53

SWT.OUT - Set switching output..........................................................................54

SWT.LOG - Set logic at the switching output .......................................................55

SWT.PLS - Set pulse length at the switching output ............................................55

CANCEL - cancel without saving..........................................................................55

SAVE - Save changes ..........................................................................................55

Error analysis / remedy..........................................................................................56