Contents

MCS en(us) Page 4 / 80

BeWa MCS1000 3435427g V13x en 2014-07-16.doc 2014-07-16

Dimensions for MCS 15xx with flange adapter set (optional

accessory) .................................................................................................28

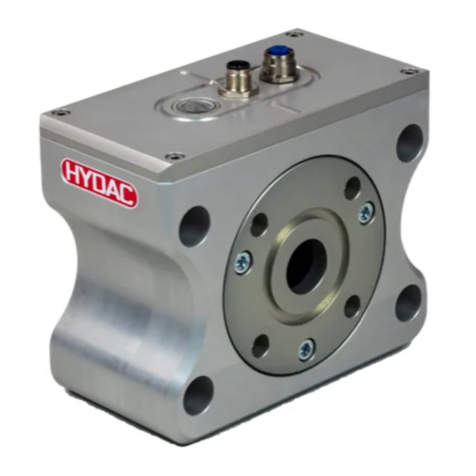

Mechanical installation/assembly .............................................................29

Connecting MCS14xx via flange adapter set.............................................30

Fastening sensor to underside..................................................................31

Fastening MCS 13xx/MCS 14xx................................................................32

Fastening the MCS 15xx ...........................................................................32

Fastening MCS 15xx with angle fastening set ...........................................33

Connecting MCS 15xx with pipe adapter set .............................................33

Connecting MCS 15xx with flange adapter plate (accessory)....................34

Connecting MCS 15xx with 4" SAE as per ISO 6162-1 (4x M16)..............35

Hydraulic installation of sensor.................................................................36

Diagram - flow rate, differential pressure p

and viscosity

....................36

Electrical connection of sensor.................................................................38

Plug pin assignment ..................................................................................38

Connection cable - Assignment / Color coding ..........................................39

Connecting cable wires..............................................................................40

Examples of connection.............................................................................41

Connection: operation voltage = measurement voltage .........................42

Using switching output 1 .....................................................................42

Using switching output 2 .....................................................................42

Using switching output 1 and 2 ...........................................................43

Connection: operation voltage measurement voltage .........................43

Using switching output 1 .....................................................................43

Using switching output 2 .....................................................................44

Using switching output 1 and 2 ...........................................................44

Using switching outputs ............................................................................45

Switching output - FE.NFE (factory setting)...............................................45

Switching output - ALL.RDY ......................................................................45

Switching logic "active low"........................................................................46

Example: Operation - 1 particle detected ...............................................46

Example: Operation - no particle detected .............................................46

Example: Operation - several particles detected ....................................47

Switching logic "active high" ......................................................................48

Example: Operation - 1 particle detected ...............................................48

Example: Operation - no particle detected .............................................48

Example: Operation - several particles detected ....................................49

Switching output "Device Ready" ..............................................................49

Parameterizing sensor/reading measured values....................................50

Connecting MCS 1000 with SMU 1200 .....................................................50

Connecting MCS with CSI-D-5 (Condition Sensor Interface).....................51