SCON

First Step Guide Seventh Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to

this First Step Guide to ensure correct use.

This Instruction Manual is original.

•Using or copying all or part of this Instruction Manual without permission is prohibited.

•The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

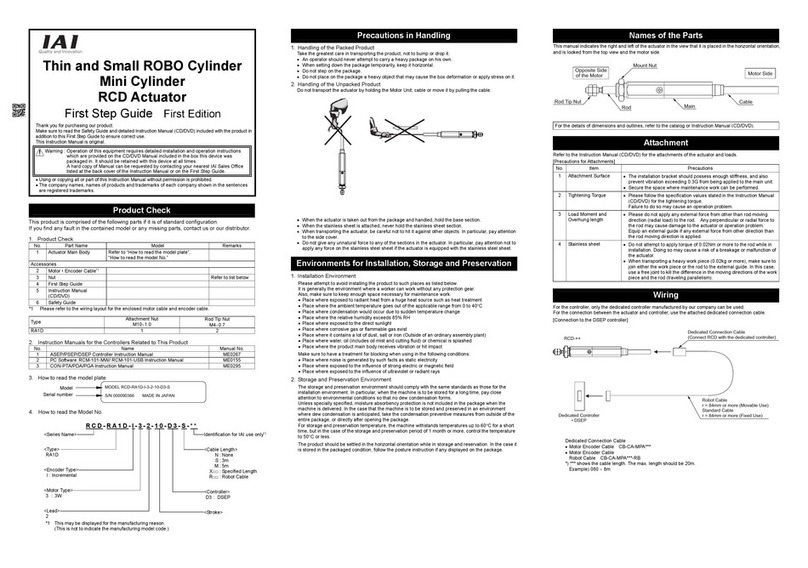

Product Check

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts

No. Part Name Model Reference

1 Controller Main Body

Refer to “How to read the model plate”, “How to read the model”

Accessories

2 I/O Flat Cable CB-PAC-PIO*** *** shows the cable

length

3 Service Connector for Pulse

Train Control Plug : 10114-3000PE, Shell : 10314-52F0 (Supplier : 3M) Enclosed in SCON-C/CA

4 System I/O Plug FMC1.5/4-ST-3.5 (Supplier : Phoenix Contact)

5 Power Supply Plug for Brake MC1.5/2-ST-3.5 (Supplier : Phoenix Contact)

Applicable Cable Size

0.5mm2(AWG20)

6 AC Power Supply plug MSTB2.5/6-STF-5.08 (Supplier : Phoenix Contact) Applicable Cable Size

2.0mm2(AWG14)

7 Absolute Battery AB-5 Enclosed in Absolute Type

8 Dummy plug DP-5 Enclosed in SCON-CGAL

9 First Step Guide

10 Instruction Manual (DVD)

11 Safety Guide

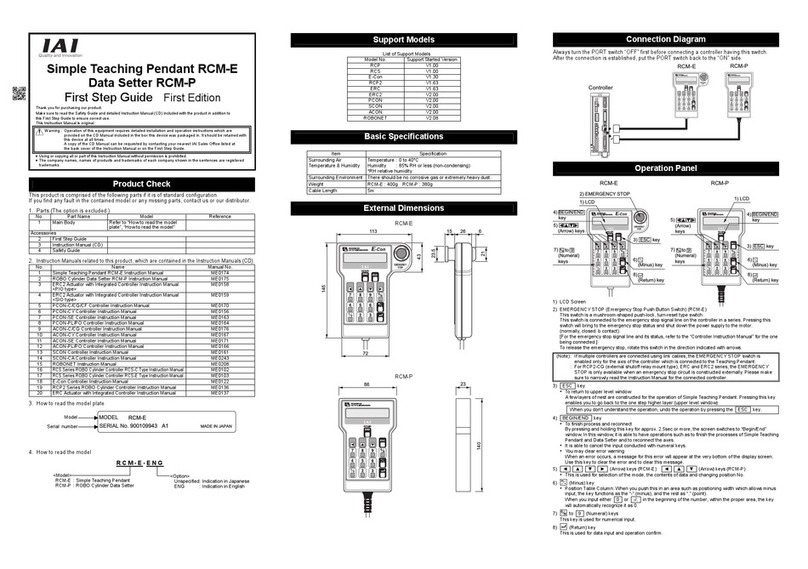

2. Teaching Tool (to be purchased separately)

A teaching tool such as PC software is necessary when performing the setup for position setting, parameter

setting, etc. that can only be done on the teaching tool.

Please prepare either of the following teaching tools such as PC software.

No. Part Name Model

1 PC Software

(RCS232C converter adapter and external equipment communication cable are included) RCM-101-MW

2 PC Software

(USB converter adapter, USB cable and external equipment communication cable are included)

RCM-101-USB

3 Touch Panel Teaching CON-PTA CON-PTA

4 Touch Panel Teaching CON-PDA (Dead-man switch is included) CON-PDA

5 Touch Panel Teaching CON-PGAS (Dead-man switch and TP adapter are included) CON-PGAS

6 Touch Panel Teaching TB-01 TB-01

7 Touch Panel Teaching TB-01 (with dead-man switch attached on the left) TB-01D

8 Touch Panel Teaching TB-01 (with dead-man switch attached on the right) TB-01DR

3. Instruction manuals related to this product, which are contained in the Instruction manual (DVD).

No. Name Manual No.

1 SCON Controller Instruction Manual ME0161

2 SCON-CA/CAL/CGAL Controller Instruction Manual ME0243

3 PC Software RCM-101-MW/ RCM-101-USB Instruction Manual ME0155

4 Touch Panel Teaching CON-PTA/PDA/PGAS Instruction Manual ME0295

5 Touch Panel Teaching TB-01 Position Controller Instruction Manual ME0324

4. How to read the model plate

5. How to read controller model

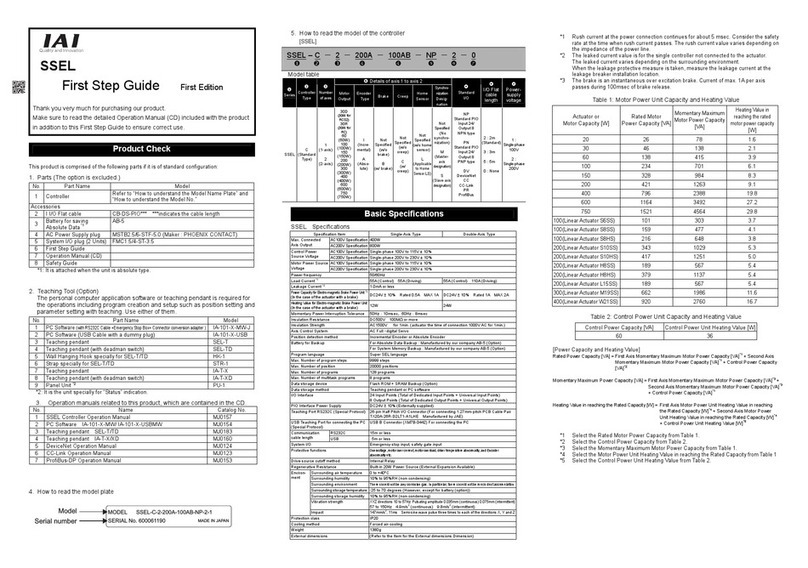

Basic Specifications

List of Specifications

SCON-C/CA

Item

Less than 400W 400W or more

SCON-CAL/CGAL

Corresponding Motor Capacity 12W to 399W 400W to 750W 12W to 200W

Power-supply Voltage

Single-Phase 100 to 115V AC

(Power fluctuation within

±

10%)

Single-Phase 200 to 230V AC

(Power fluctuation within

±

10%)

Single-Phase 200 to 230V AC

(Power fluctuation within

±

10%)

Single-Phase 100 to 115V AC

(Power fluctuation within

±

10%)

Single-Phase 200 to 230V AC

(Power fluctuation within

±

10%)

Power-supply Voltage 100V AC

Rush

Current*1

Power-supply Voltage 200V AC

20A (Controller side), 70A

(Drive side) 20A (Controller side),

80A (Drive side)

30A (Controller side),

80A (Drive side)

Load Capacity Refer to Power Capacity and Heat Generation

Leak Current*2 3.0mA Primary side when noise filter is connected to power supply line

Heat Generation Refer to Power Capacity and Heat Generation

Power Supply Frequency 50/60Hz

PIO Power Supply*3 24V DC±10%

Power Supply for Electromagnetic Brake

(for actuator equipped with brake)

24V DC±10% 1A (MAX.)

(supplied from external equipment)

SCON-C : 10ms (50Hz), 8ms (60Hz)Transient Power Cutoff Durability

SCON-CA : 20ms (50Hz), 16ms (60Hz)

20ms (50Hz), 16ms (60Hz)

Motor Control System Sine Wave PWM Vector Current Control

Corresponding Encoder Incremental Serial Encoder, Absolute Serial Encoder,

ABZ (UVW) Parallel Encoder

Incremental Serial Encoder,

Absolute Serial Encoder,

Actuator Cable Length MAX. 20m

Serial Communication Interface RS485 : 1CH … based on Modbus Protocol RTU/ASCII

Speed : 9.6 to 230.4Kbps

Control available with serial communication in the modes other than the pulse train

PIO

Specifications

Signal I/O dedicated for 24V DC (selected from NPN/PNP) … Input 16 ports max.,

output 16 ports max.

External Interface

(Each dedicated

controller) Fieldbus

Specification

DeviceNet/CC-Link/PROFIBUS/CompoNet*/MECHATR

OLINK*/EtherCAT*/EtherNET/IP*/PROFINET IO*

(*Specified only for SCON-CA)

DeviceNet/CC-Link/PROFIB

US/CompoNet/MECHATRO

LINK/EtherCAT/EtherNET/I

P/PROFINET IO

PIO MAX. 10m

RS485 Total cable length 100m or less.

Cable Length

Fieldbus Refer to each Fieldbus specification

Data Setting and Input PC Software, Touch Panel Teaching, Teaching Pendant

SCON-C : Saves position data and parameters to

non-volatile memory

(Limitation in number of writing 100,000 times)

Data Retention Memory

SCON-CA : Saves position data and parameters to

non-volatile memory

(There is no limitation in number of writing)

Saves position data and

parameters to non-volatile

memory

(There is no limitation in

number of writing)

Operation Mode Positioner Mode/Pulse Train Control Mode

(selected by Pulse Train Mode Changeover Switch on

Front Panel)

Positioner Mode

Number of Positions in Positioner

Mode

Standard 64 points, maximum 512 points (PIO Type), 768 points (only for SCON-CA Fieldbus Type)

(Note) Number of positions differs depending on the selection in PIO pattern and fieldbus operation mode.

SCON-C : Differential System (Line Driver System) :

MAX. 500Kpps

SCON-CA : Differential System (Line Driver System) :

MAX. 2.5Mpps

Input Pulse Frequency

Common to C/CA

: Open Collector Type :

200Kpps max. (under condition AK-04 is used)

Pulse Train

Control

Mode

(Dedicated

for PIO

Specifications)

Command Pulse

Multiplying Factor

(Electrical Gear : A/B)

1/50 < A/B <50/1

Setting Range of A and B (set to parameter) : 1 to 4096

SCON-C :

Differential System (Line Driver

System

):

MAX. 500Kpps (Linear output available up to

109Kpps)

SCON-

CA

:

Differential System (Line Driver System):

MAX. 2.5Mpps

Feedback Pulse

(Dedicated for PIO Specifications)

Common to C/CA

:

Open

Collector Type

:

MAX. 500Kpps (under condition JM-08 is used)

LED Display

(mounted on Front Panel)

PWR (green) : Controller in normal condition,

SV (green) : Servo on,

ALM (orange) : Alarm generated,

EMG (red) : Emergency Stop

PWR (green) : Controller in

normal condition / SV

(green) : Servo on / ALM

(orange) : Alarm generated /

EMG (red) : Emergency

Stop / WRG (orange) :

Warning generated

Electromagnetic Brake Compulsory Release

Switch (mounted on Front Panel)

Switching NOM (standard)/BK RLS (compulsory release)

Insulation Resistance 500V DC 10MΩor more

Insulation Strength 1,500V AC for 1 min. (Note) Withstand voltage of force control loadcell is 50V DC

Surrounding air temperature

0 to 40°C

Surrounding humidity

85%RH or less (non-condensing)

Surrounding environment

[Refer to Installation Environment]

Surrounding storage temperature

-20 to 70°C (non-condensing)

Surrounding storage humidity

85% or less (non-condensing)

Environment

Vibration Durability

XYZ Each direction 10 to 57Hz Pulsating amplitude 0.035mm (continuous) 0.075mm (intermittent)

57 to 150Hz 4.9m/s

2

(continuous) 9.8m/s

2

(intermittent)

Protection Class IP20 or equivalent

Weight SCON-C : Approx. 800g

SCON-CA : Approx. 900g

SCON-C : Approx. 1100g

SCON-CA : Approx. 1200g

Approx. 560g

Cooling Method Natural air-cooling Forced Air Cooling Forced Air Cooling

External Dimensions 58W ×194H ×121D [mm] 72W ×194H ×121D [mm] 49W ×158H ×116D [mm]

*1 In-rush current will flow for approximately 20msec after the power is turned on (at 40°C).

Note that the value of in-rush current differs depending on the impedance of the power supply line.

*2

Leak current varies depending on the capacity of connected motor, cable length and the surrounding environment. Measure the

leak current at the point where a ground fault circuit interrupter is to be installed when leakage protection is conducted.

A ground fault circuit interrupter needs to be selected carefully considering the purposes of prevention of fire and

protection of human.

Use the harmonic type (for inverter) for the ground fault circuit interrupter.

*3 It is not necessary to supply power to PIO when operating with using ROBONET, Gateway Unit or SIO Converter

without using PIO. In this case, set the parameter No. 74 (PIO Power Supply Monitor) to “1” (Invalid). It will generate

the error code No. 0CF (I/O 24V Power Supply Error) if the setting is not done.

Power Capacity and Heat Generation

Rated Power Capacity =Motor Power Capacity +Control Power Capacity

Peek Max. Power Capacity =Peek Max. Motor Power Capacity +Control Power Capacity

Actuator Motor Type

Motor Power

Capacity

[VA]

Peek Max. Motor

Power Capacity

[VA]

Control Power

Capacity

[VA]

Rated Power

Capacity

[VA]

Peek Max. Power

Capacity [VA]

Heat Generation

[W]

12 41 123 89 171 30

30D (Excluding RS) 46 138 94 186 31

30R (for RS) 138 414 186 462 33

60 138 414 186 462 33

60 (RCS3-CTZ5) 197 591 245 639 32

100 234 702 282 750 35

100S (LSA) 283 851 331 899 36

150 328 984 376 1032 37

200 421 1263 469 1311 38

200S

(LSA excluding LS A-N15H)

486 1458 534 1506 38

200S (LSA-N15H) 773 2319 821 2367 56

300S (LSA) 662 1986 710 2034 40

400 920 2760 968 2808 45

400 (RCS3-CT8) 1230 3690 1278 3738 47

600 1164 2328 1212 2376 56

750 3042 3090

750S 1521 4563

48

1569 4611 58

RS : Rotary Shaft LSA : Linear Actuator

Selection of Circuit Interrupter

• 3 times of the rated current flows to the controller during the acceleration/deceleration. Select an interrupter that does not trip

with this value of current. If a trip occurs, select an interrupter that possesses the rated current of one grade higher. (Refer to

the operation characteristics curves in the product catalog.)

• Select an interrupter that does not trip with the in-rush current. (Refer to the operation characteristics curves in the product

catalog.)

• Consider the current that enables to cutoff the current even when a short circuit current is flown for the rated cutoff current.

Rated Interrupting Current >Short Circuit Current =Primary Power Capacity / Power Voltage

Consider margin for the rated current on the circuit breaker.

Rated Current for Circuit Interrupter >(Rated Motor Power Capacity [VA] +Control Power Capacity [VA]) /

AC Input Voltage ×Safety Margin (reference 1.2 to 1.4 times)

External Dimensions

SCON-C/CA

Less than 400W 400W or more

SCON-CAL/CGAL

DIN Rail

(8.5)

35.4 (Width of 35mm DIN Rail )

* There is no DIN rail part on the type with screw attachment. For DIN Rail

Mounting Type

82.5 from DIN rail center

130.7

116

4

49

158

(17)

For Screw-fixed Type

(6)

4.5

φ4.5

22.5

(6)

146.5

Serial numbe