I/O Signals

Function description for I/O Signals

Category Signal

Abbreviation Signal Name Function Description

CSTR PTP strobe signal

(start signal)

The actuator will start to move to the position set by

the command position number.

PC1 to PC256 Command position

number signal Input of the position number to move (binary input)

BKRL Forced brake

release signal The brake will forcibly be released.

RMOD Operating mode

selector signal

The operating mode is selectable when the MODE

switch of the controller is set to AUTO. (The operating

mode of the controller will become AUTO when this

signal is turned OFF, or MANU when this signal is

turned ON.)

*STP Pause signal

When this signal turns OFF while the actuator is

moving, the actuator will decelerate to stop. The

remaining movement is retained and will resume when

the signal is turned ON again.

RES Reset signal

An alarm will be reset when this signal is turned ON.

The remaining movement can be canceled when the

pause signal is OFF (STP is OFF).

SON Servo ON signal The servo remains ON while this signal is ON, or OFF

while this signal is OFF.

HOME Home return signal The controller will perform home return operation when

this signal is turned ON.

MODE Teaching mode

signal

The operating mode will change to the teaching mode

when this signal is turned ON. (At this time, the mode

will not be selected unless all signals of CSTR, JOG+

and JOG- are OFF and the actuator operation has

stopped.)

JISL Jog/inching selector

signal

The actuator will jog with JOG+ or JOG- when this

signal is OFF. It will inch with JOG+ or JOG- when this

signal is ON.

JOG +, JOG - Jog signal

When the JISL signal is OFF, the actuator will jog

toward the +/- direction upon detection of an OFF→ON

rise edge of this signal.

If an ON→OFF fall edge of this signal is detected while

the actuator is jogging, the actuator will decelerate to a

stop.

PWRT Teaching signal

When the write position is specified in the teaching

mode and this signal has remained ON for 20msec or

longer, the controller will write the current position in

the specified position field.

Input

ST0 to ST6 Start position

command

In the electromagnetic valve mode, the actuator will

move to the specified position when this signal is ON.

(The start signal is not required.)

PEND/INP Positioning

completion signal

This signal will turn ON when the target position has

been reached after movement and the actuator has

entered the in-position range. The PEND signal will not

turn OFF but the INP signal will turn OFF if the position

deviation exceeds the in-position range. PEND or INP

can be selected by the parameter.

PM1 to PM256 Completed position

number signal

The relevant position number will be output when

positioning has been completed (binary output).

HEND Home return

completion signal

This signal will turn ON when home return has been

completed.

ZONE1 Zone signal This signal will turn ON when the current actuator

position enters the range set by the parameters.

PZONE Position zone signal

This signal will turn ON when the current actuator

position enters the range specified in the position data

after position movement. The combined use with

ZONE 1 is possible, but PZONE becomes effective

only for movement to the set position.

RMDS Operating mode

status signal The operating mode status will be output.

*ALM Controller alarm

status signal

This signal remains ON in normal conditions of use

and turns OFF when an alarm is generated.

MOVE Moving signal This signal will remain ON while the actuator is moving

(including home return and push & hold times).

SV Servo ON status

signal This signal will remain ON while the servo is ON.

*EMGS Emergency stop

status signal

This signal remains ON while the controller is under

the emergency stop reset condition and turns OFF

when the emergency stop condition is enabled.

MODES Mode status signal

This signal will turn ON when the teaching mode is

enabled by the input of the mode signal and will turn

OFF when the mode changes to the normal mode.

WEND Write completion

signal

This signal will turn OFF after the controller has

switched to the teaching mode. It will turn ON when

writing in response to the PWRT signal has been

completed. When the PWRT signal turns OFF, this

signal will also turn OFF.

PE0 to PE6 Current position

number signal

In the electromagnetic valve mode, this signal will turn

ON when the actuator completes moving to the target

position.

LS0 to LS2 Limit switch output

signal

This signal will turn ON when the current actuator

position enters the positioning band of the target

position. It will be output even before the movement

command if home return has been completed.

LOAD Load output

judgment status

This signal will be output when the load exceeds the

current value set as the “threshold” within the range of

zone+ and zone- in the position data during push &

hold operation. It is used to judge whether pressing

has been performed normally.

Output

TRQS Torque level status

signal

This signal will be output when the slider (rod) collides

against an obstacle during push & hold operation and

the motor current value reaches the value set as the

“threshold” in the position data.

I/O Signals

Parameter (PIO) Pattern Selection

0 1 2 3 4 5

Positioning

mode

Teaching

mode

256-point

mode

512-point

mode

Electromagnetic

valve mode 1

Electromagnetic

valve mode 2

Number of

positioning points 64 points 64 points 256 points 512 points 7 points 3 points

Zone signal ○ * * * ○ ○

Pin

No. Category

Position zone

signal ○ ○ ○ * ○ ○

1A 24V P24

2A 24V P24

3A MC

4A MC

5A IN0 PC1 PC1 PC1 PC1 ST0 ST0

6A IN1 PC2 PC2 PC2 PC2 ST1 ST1 (JOG+)

7A IN2 PC4 PC4 PC4 PC4 ST2 ST2

8A IN3 PC8 PC8 PC8 PC8 ST3

9A IN4 PC16 PC16 PC16 PC16 ST4

10A IN5 PC32 PC32 PC32 PC32 ST5

11A IN6 MODE PC64 PC64 ST6

12A IN7 JISL PC128 PC128

13A IN8 JOG+ PC256

14A IN9 BKRL JOG- BKRL BKRL BKRL BKRL

15A IN10 RMOD RMOD RMOD RMOD RMOD RMOD

16A IN11 HOME HOME HOME HOME HOME

17A IN12 *STP *STP *STP *STP *STP

18A IN13 CSTR CSTR/PWRT CSTR CSTR

19A IN14 RES RES RES RES RES RES

20A

Input

IN15 SON SON SON SON SON SON

1B OUT0 PM1 PM1 PM1 PM1 PE0 LS0

2B OUT1 PM2 PM2 PM2 PM2 PE1 LS1 (TRQS)

3B OUT2 PM4 PM4 PM4 PM4 PE2 LS2 (-)

4B OUT3 PM8 PM8 PM8 PM8 PE3

5B OUT4 PM16 PM16 PM16 PM16 PE4

6B OUT5 PM32 PM32 PM32 PM32 PE5

7B OUT6 MOVE MOVE PM64 PM64 PE6

8B OUT7 ZONE1 MODES PM128 PM128 ZONE1 ZONE1

9B OUT8 PZONE PZONE PZONE PM256 PZONE PZONE

10B OUT9 RMDS RMDS RMDS RMDS RMDS RMDS

11B OUT10 HEND HEND HEND HEND HEND HEND

12B OUT11 PEND PEND/WEND PEND PEND PEND

13B OUT12 SV SV SV SV SV SV

14B OUT13 *EMGS *EMGS *EMGS *EMGS *EMGS *EMGS

15B OUT14 *ALM *ALM *ALM *ALM *ALM *ALM

16B

Output

OUT15 LOAD/TRQS *1 LOAD/TRQS *1 LOAD/TRQS *1 LOAD/TRQS *1

17B NC

18B NC

19B 0V N

20B 0V N

(NOTE) The terms inside parentheses indicate functions before home return.

*1: Signal for PCON-CF only

I/O Flat Cable

Model: CB-PAC-PIO * Enter the cable l

ength (L) in (up to 10m)

Example) 080 = 8m

HIF6-40D-1.27R

No. Signal

Name

Cable

Color Wiring No. Signal

Name

Cable

Color Wiring

1A 24W BR-1 1B OUT0 BR-3

2A 24W RD-1 2B OUT1 RD-3

3A OR-1 3B OUT2 OR-3

4A YW-1 4B OUT3 YW-3

5A IN0 GN-1 5B OUT4 GN-3

6A IN1 BL-1 6B OUT5 BL-3

7A IN2 PL-1 7B OUT6 PL-3

8A IN3 GY-1 8B OUT7 GY-3

9A IN4 WT-1 9B OUT8 WT-3

10A IN5 BK-1 10B OUT9 BK-3

11A IN6 BR-2 11B OUT10 BR-4

12A IN7 RD-2 12B OUT11 RD-4

13A IN8 OR-2 13B OUT12 OR-4

14A IN9 YW-2 14B OUT13 YW-4

15A IN10 GN-2 15B OUT14 GN-4

16A IN11 BL-2 16B OUT15 BL-4

17A IN12 PL-2 17B PL-4

18A IN13 GY-2 18B GY-4

19A IN14 WT-2 19B 0V WT-4

20A IN15 BK-2

Flat cable (A) (Press welding)

20B 0V BK-4

Flat cable (B) (Press welding) AWG28

BR: Brown, RD: Red, OR: Orange, YW: Yellow, GN: Green, BL: Blue, PL: Purple, GY: Gray, WT: White, BK: Black

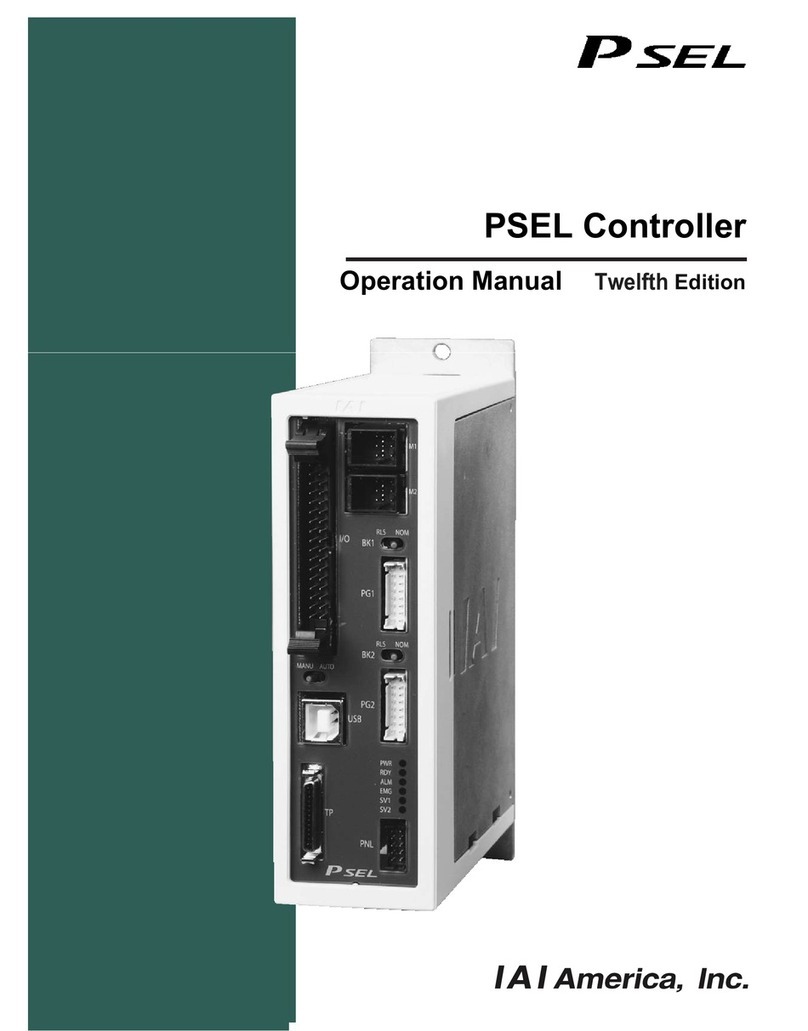

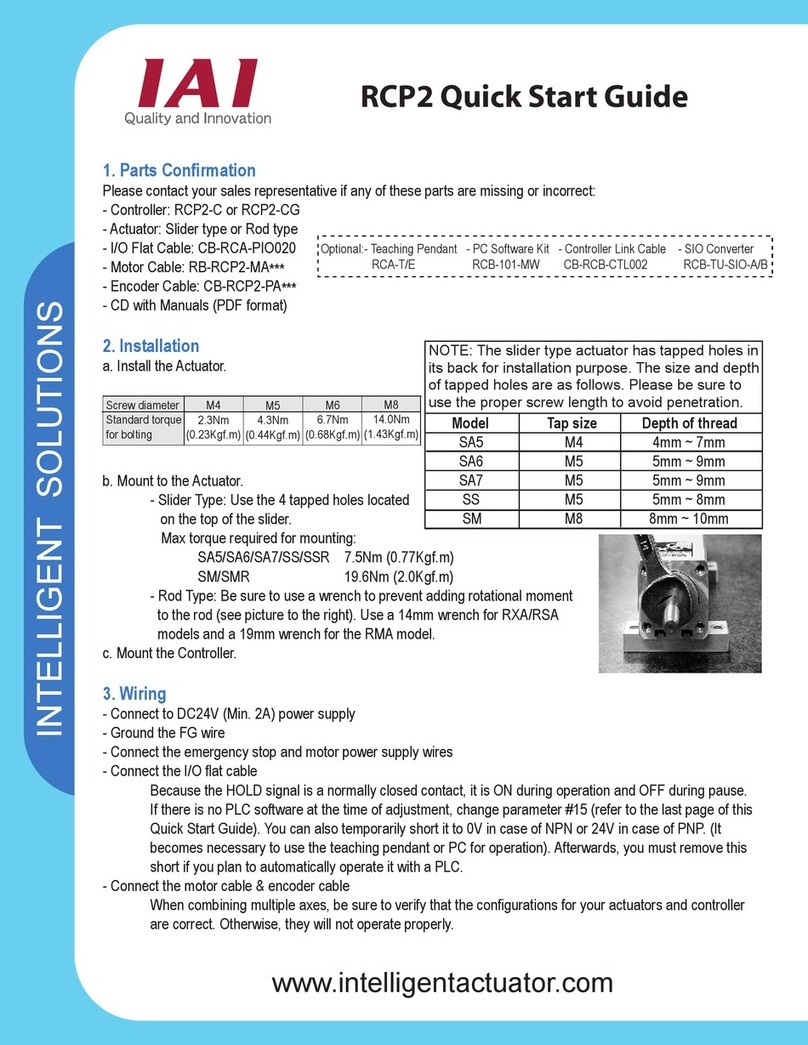

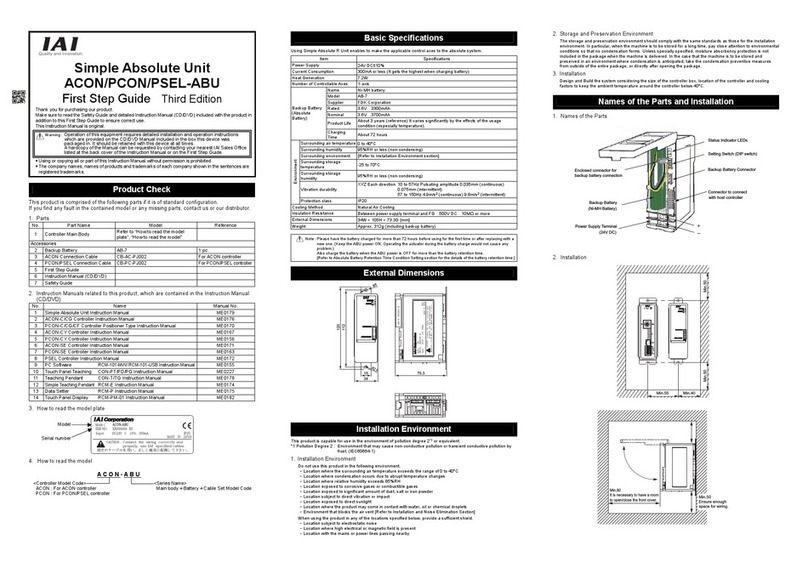

Starting Procedures

When using this product for the first time, pursue work while making sure to avoid omission

and incorrect wiring by referring to the procedure below.

1. Check of Packed Items

Check packed items with the packing list. Should there be any incorrect model or

insufficient item, contact your dealer.

2. Installation

Install the controller and actuator.

3. Wiring

Connect the 24V DC power supply, earth cable, emergency stop circuit, motor drive

power supply, motor cable, encoder cable and I/O flat cable.

4. Power Supply and Alarm Check

(1) Connect the PC or teaching pendant and set the mode selector switch to the

MANU side.

(2) After confirming that the emergency stop circuit is not activated, supply the input

power.

- When the controller functions properly:

The monitor LED [SV/ALM] illuminates for 2 seconds and then goes out.

- When an alarm generates:

The monitor LED [SV/ALM] illuminates in red.

After checking the contents of the alarm using the PC or teaching pendant,

remove the cause.

Flat calve (20 conductors) x 2

Half pitch MlL

socket

HIF6-40D-1.27R

(HIROSE)

Open-ended Open-ended