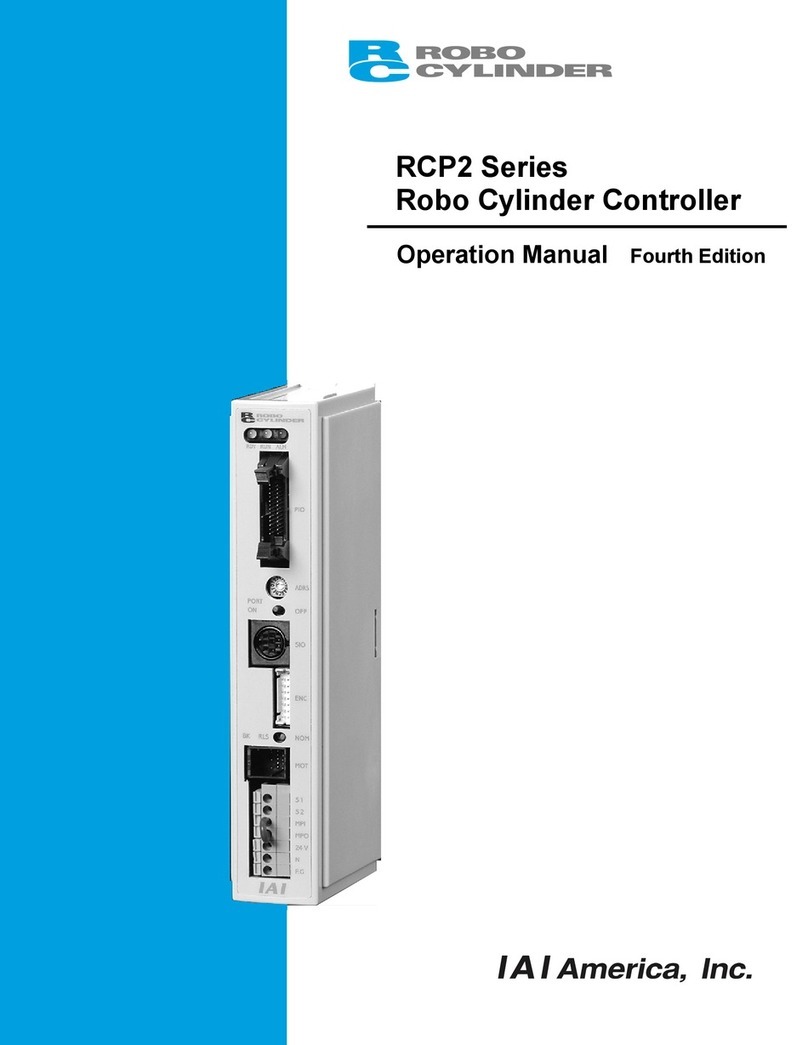

ROBO Cylinder RCP4W Actuator Slider

Dust-proof/Splash-proof Type

First Step Guide First Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to

this First Step Guide to ensure correct use.

This Instruction Manual is original.

•Using or copying all or part of this Instruction Manual without permission is prohibited.

•The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

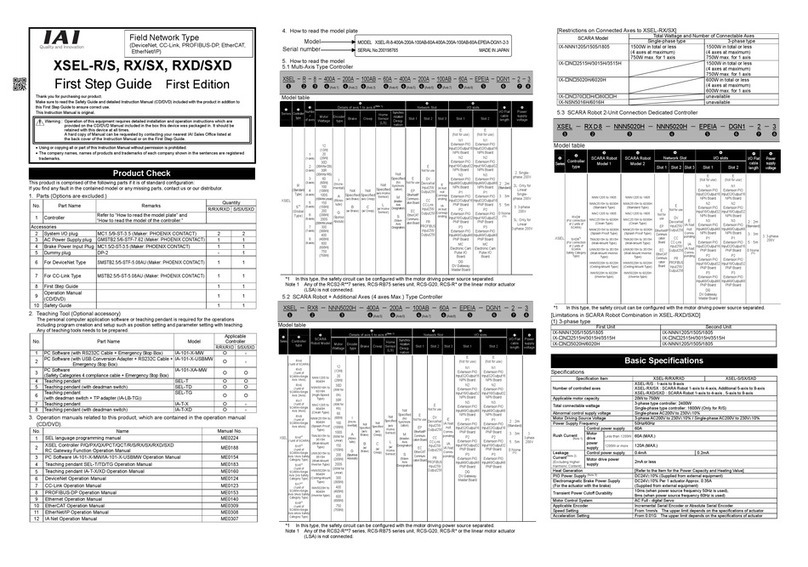

Product Check

The standard configuration of this product is comprised of the following parts.If you find any fault or missing

parts, contact your local IAI distributor.

1. Parts

No. Part Name Model Quantity Remarks

1 Main Body Refer to “How to read the model

plate”, “How to read the model No.” 1

Accessories

2 Motor • Encoder Cable (Note 1) 1

3 First Step Guide 1

4 Instruction Manual (DVD) 1

5 Safety Guide 1

Note 1 Please refer to [Wiring] for the applicable cables.

2. How to read the model plate

3. How to read the model No.

Note 1 Identification for IAI use only : It may be displayed for IAI use. It is not a code to show the model

type.

Caution in Handling

1. Handling of Robot

Pay attention to the followings when carrying an actuator by itself.

(1) Handling of the Packed Product

•Do not damage or drop. The package is not applied with any special treatment that enables it to resist an

impact caused by a drop or crash.

•An operator should never attempt to carry a heavy package on their own. Also, use an appropriate way for

transportation.

•If the shipping box is to be left standing, it should be in a horizontal position. Follow the instruction if there is

any for the packaging condition.

•Do not step or sit on the package.

•Do not put any load that may cause a deformation or breakage of the package.

(2) Handling after Unpackaged

•Do not carry the actuator by holding the cable, or do not move it by pulling the cable.

•Hold the body base when transporting the actuator.

•Do not hit or drop the product while carrying.

•Do not give any excessive force to any of the sections in the actuator.

2. Handling of Multi-Axes Type

This is the case that this product is delivered with other actuators being combined. Multi-axes type will be

delivered in a package with an outer case fixed to a wooden base. Tables are fixed so they would not accidently

move while in transportation. The end of the actuator is also fixed to avoid it swinging by external vibration.

(1) Handling of the Packed Product

•Do not damage or drop. The package is not applied with any special treatment that enables it to resist an

impact caused by a drop or crash.

•An operator should never attempt to carry a heavy package on their own. Also, use an appropriate way for

transportation.

•When suspending the package using ropes, pass the ropes from underneath the reinforcement frames at

the bottom of the base. When lifting with a forklift, also place the forks underneath the base.

•Do not apply an impact on the package or let it bounce when putting it down.

•Do not step or sit on the package.

•Do not put any load that may cause a deformation or breakage of the package.

(2) Handling after Unpackaged

•Secure the tables to prevent sudden movement during transport.

•Appropriately fix the tip of the actuators if it is overhanging so it would not widely shake with external

vibration. If the actuator assembly is transported without the ends being secured, do not apply an impact of

0.3G or more.

•In the case that the actuator needs to be carried up with ropes or another method, be sure to use an

appropriate cushioning to avoid the robot being deformed or put on an excessive pressure. And also, be

sure to keep the robot in a stable and horizontal posture. Make a tool to utilize the attachment holes and

tapped holes on the actuator and attach it if necessary.

•Do not attempt to apply load to the actuator or connector box. Also, avoid the cables being pinched or

caused an excessive deformation.

3. Handling of Robot Mounted on Mechanical Equipment (System)

Followings are the cautions for when transporting the actuators installed in the machinery equipment (system) in

the whole system.

•Affix the table so they would not move while transporting.

•If any end of the actuator is overhanging, secure it properly to avoid significant movement due to external

vibration. If the actuator assembly is transported without the ends being secured, do not apply an impact of

0.3G or more.

•Do not attempt to apply load to actuators or connector box when hanging the machinery equipment

(system) with tools such as a rope. Also, avoid the cables being pinched or caused an excessive

deformation.

Installation and Storage • Preservation Environment

1. Installation Environment

Do not use this product in the following environment.

Also make sure to keep enough work space necessary for maintenance.

•Location exposed to radiant heat from a huge heat source such as the heat treatment

•Location where the surrounding air temperature exceeds the range of 0 to 40 °C

•Location where condensation occurs due to abrupt temperature changes

•Location where relative humidity exceeds 85%RH

•The product gains the water-proof performance of IP65 protection structure if an air purge is conducted.

•Location exposed to direct sunlight

•Location exposed to corrosive gases or combustible gases

•Location exposed to significant amount of dust, salt or iron powder (Outside of ordinary assembly plant)

•Location where oil (includes oil mist and cutting fluid) or chemical is splashed

•Location where the product main body receives vibration or hit impact

When using the product in any of the locations specified below, provide a sufficient shield.

•Place subject to electrostatic noise

•Location where exposed to the influence of strong electric or magnetic field

•Location where exposed to the influence of ultraviolet or radiant rays

2. Storage • Preservation Environment

The storage and preservation environment should comply with the same standards as those for the installation

environment. In particular, when the machine is to be stored for a long time, pay close attention to environmental

conditions so that no dew condensation forms.

Unless specially specified, moisture absorbency protection is not included in the package when the machine is

delivered. In the case that the machine is to be stored and preserved in an environment where dew condensation

is anticipated, take the condensation preventive measures from outside of the entire package, or directly after

opening the package.

For storage and preservation temperature, the machine withstands temperatures up to 60 °C for a short time, but

in the case of the storage and preservation period of 1 month or more, control the temperature to 50 °C or less.

Storage and preservation should be performed in the horizontal condition. In the case it is stored in the packaged

condition, follow the posture instruction if any displayed on the package.

Names of the Parts

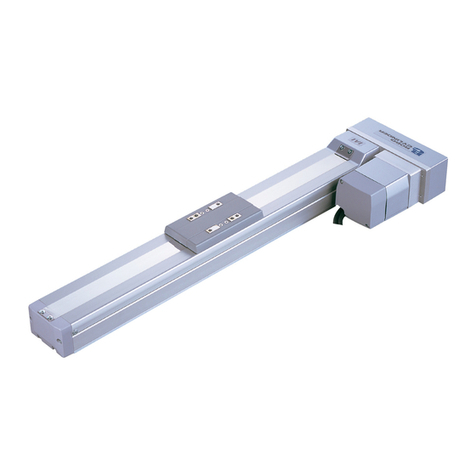

1. Standard Type

Bracket (Front) Base Table Bracket (Rear) Motor Cover

Cable

Air Inlet

φ6 for Air Purge

Bolt Cover (Front)

Side Cover

Front Cover

Grommet

Right

Left

Opening (with seal)

Bolt Cover (Rear)

Please refer to the Catalog or the Instruction Manual (DVD) for the dimensions and profile.

2. Wall-hang Type

Bolt Cover (Front) Bolt Cover (Rear)

Right

Left

Bracket (Front) Bracket (Rear)

Opening (with seal)

Please refer to the Catalog or the Instruction Manual (DVD) for the dimensions and profile.

3. Ceiling Type

Bolt Cover (Front) Bolt Cover (Rear)

Right

Left

Bracket (Front)

Bracket (Rear)

Opening (with seal)

Please refer to the Catalog or the Instruction Manual (DVD) for the dimensions and profile.

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the DVD Manual included in the box this device was packaged in. It should be retained

with this device at all times.

A hardcopy of the Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cove

of the Instruction Manual or on the First Ste

Guide.

Model

Serial number

MODEL RCP4W-SA5C-I-35P-10-500-P3-M-A1

SERIAL No.000061911 MADE IN JAPAN

RCP4W-SA5C- I-35P-10-500-P3-M-A1-**

Series

<Type>

SA5C, SA6C

SA7C

<Encoder Type>

I : Incremental

<Motor Type>

35P : 35 □

42P : 42 □

56P : 56 □

<Lead>

5 : 5mm

6 : 6mm

8 : 8mm

10 : 10mm

12 : 12mm

16 : 16mm

Identification for IAI use only

o

e

<Option>

A1 : Cable exit to the left side

A3 : Cable exit to the right side

GE : Food grease indicated

NM : Reversed home specification

TFL : Wall mount to the left type

TFR : Wall mount to the right type

HFL : Ceiling mount to the left type

HFR : Ceiling mount to the right type

<Cable Length>

N : No cable

P : 1m

S : 3m

M : 5m

X□□ : Specified length

R□□ : Robot Cable

<Applicable Controller>

P3 : PCON-CA

<Stroke>