Table of Contents

Safety Guide ......................................................................................................................1

Modes in SSEL Controller .................................................................................................8

Caution in Handling ...........................................................................................................9

International Standards Compliances ..............................................................................11

Name for Each Parts and Their Functions.......................................................................12

Actuator Axes...................................................................................................................21

Starting Procedures .........................................................................................................23

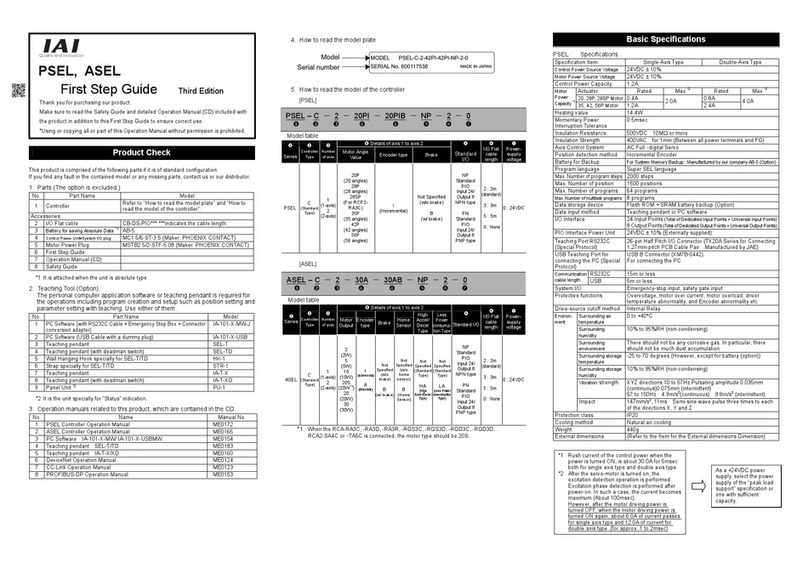

Chapter 1 Specifications Check .....................................................................................25

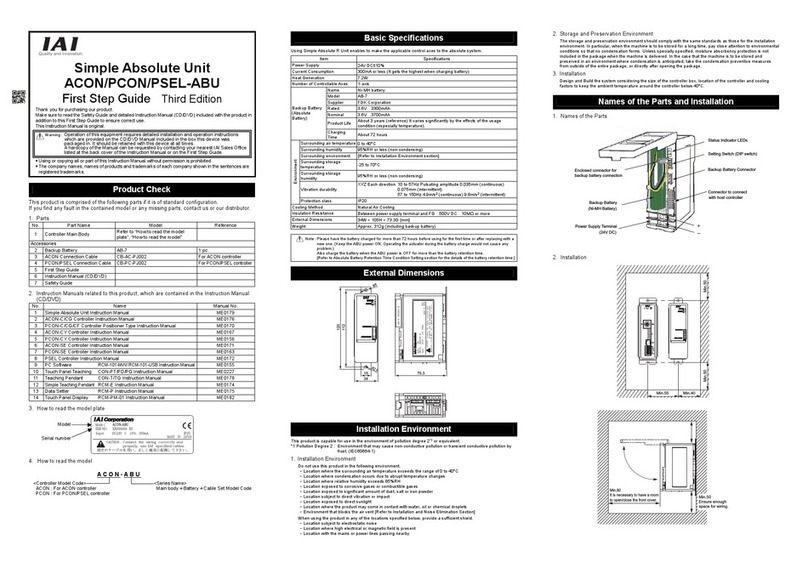

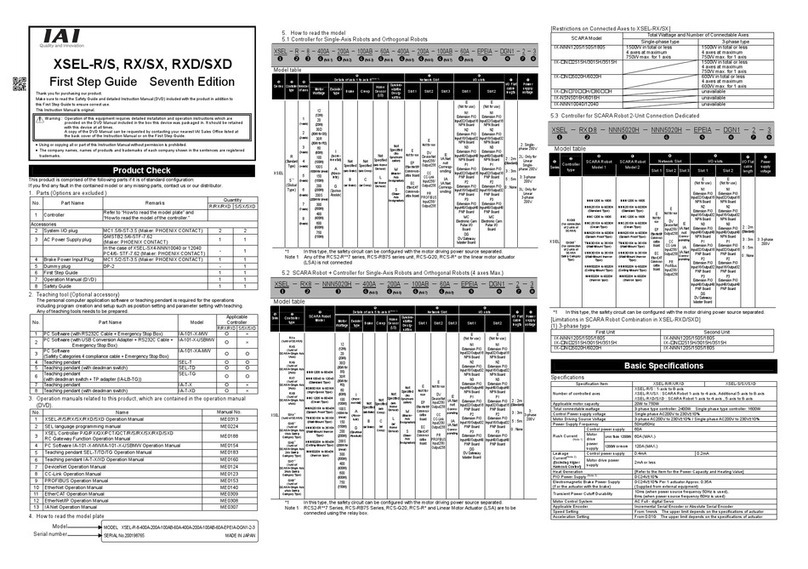

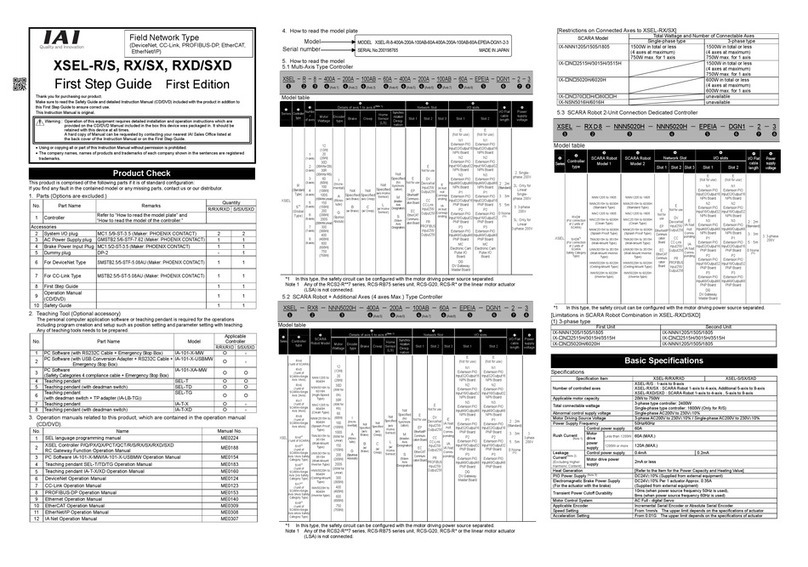

1.1 Product Check .............................................................................................................. 25

1.1.1 Components (Excluding Options) ...................................................................... 25

1.1.2 Teaching Tool (Optional) .................................................................................... 26

1.1.3 Operation Manuals Related to this Product, which are Contained in the

Operation Manual (DVD)....................................................................................26

1.1.4 How to Read the Model Plate ............................................................................ 27

1.1.5 How to Read the Model......................................................................................27

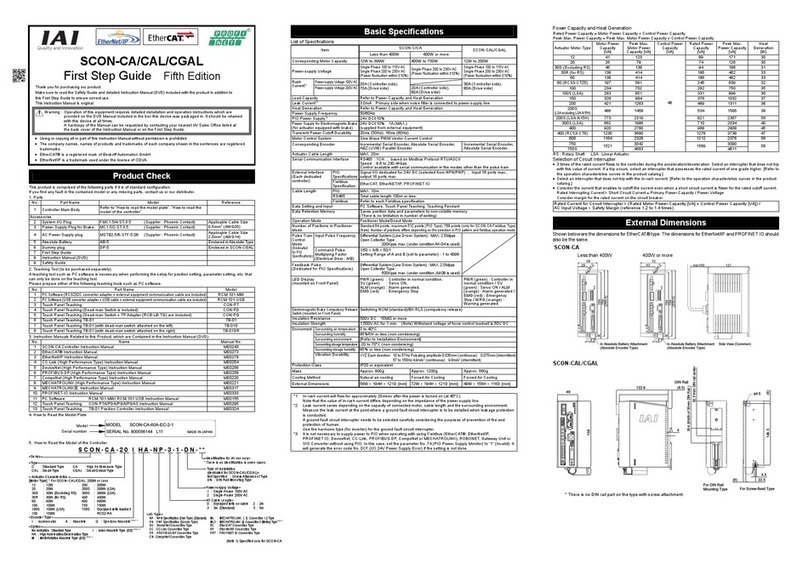

1.2 Basic Specifications...................................................................................................... 30

1.2.1 Specification List ................................................................................................ 30

1.2.2 Power Capacity and Heat output ....................................................................... 32

1.2.3 Selection of the Circuit Breaker.......................................................................... 34

1.2.4 Selection of the Leakage Breaker...................................................................... 34

1.3 External Dimensions ....................................................................................................35

1.3.1 2-axis Specification ............................................................................................35

1.3.2 2-axis Absolute Specification ............................................................................. 36

1.3.3 Specification with System Memory Backup Battery (Option)............................. 37

1.4 Option ........................................................................................................................... 38

1.4.1 PIO Board...........................................................................................................38

1.4.2 Field Network Board........................................................................................... 40

1.4.3 Panel Unit: PU-1 ................................................................................................41

1.4.4 Brake Box: RCB-110-RA13-0............................................................................. 42

1.4.5 Regenerative Resister Unit: RESU-1 and RESU-2............................................ 43

1.5 Installation and Storage Environment........................................................................... 45

1.6 Noise Prevention and the Installation........................................................................... 46

Chapter 2 Wiring ............................................................................................................51

2.1 Wiring (Connection of devices) Diagram...................................................................... 51

2.2 Circuit Diagram (Example) ........................................................................................... 52

2.2.1 Power Supply Circuit.......................................................................................... 52

2.2.2 Brake Release Power Supply ............................................................................ 52

2.2.3 Emergency Stop Circuit...................................................................................... 53

2.2.4 Motor Encoder Circuit ........................................................................................ 55

2.2.5 PIO Circuit..........................................................................................................56

2.2.6 Connection of Regenerative Resister Unit (Option)........................................... 61

2.2.7 Brake Box (RCB-110-RA13-0) (Option) ............................................................. 62

2.2.8 Teaching Port .....................................................................................................63

2.3 Wiring Method ..............................................................................................................64

2.3.1 Wiring for Power Supply Circuit .........................................................................64

2.3.2 Wiring the Emergency Stop Circuit (System I/O) ............................................... 66

2.3.3 Wiring for Actuator.............................................................................................. 67

2.3.4 Wiring for PIO..................................................................................................... 69

2.3.5 Wiring for Panel Unit .......................................................................................... 70

2.3.6 Wiring for Regenerative Resister Unit (RESU-1, RESU-2) (Option).................. 71

2.3.7 Wiring for the Brake Box (RCB-110-RA13-0)..................................................... 72

2.3.8 Wiring for the Teaching Tool...............................................................................74