2

PREFACE

This manual is an integral part of the machine.

It must always accompany the machine and be kept within reach of the operator.

The enclosures mentioned are on integral part of this manual.

The purpose of this manual.

This manual gives information for the correct and safe use of the machine.

The owner must read this manual carefully before work with the machine.

Responsibility of the owner

The owner is responsible for accidents or damages caused to people or things due to negligence in following

the instructions in this manual.

Assistance in using this manual

Explanations: contact the dealer.

Request for additional copies of the manual: in case of loss or wear and tear, or in case one wants the

manual in a different language, the customer should ask the dealer or manufacturer.

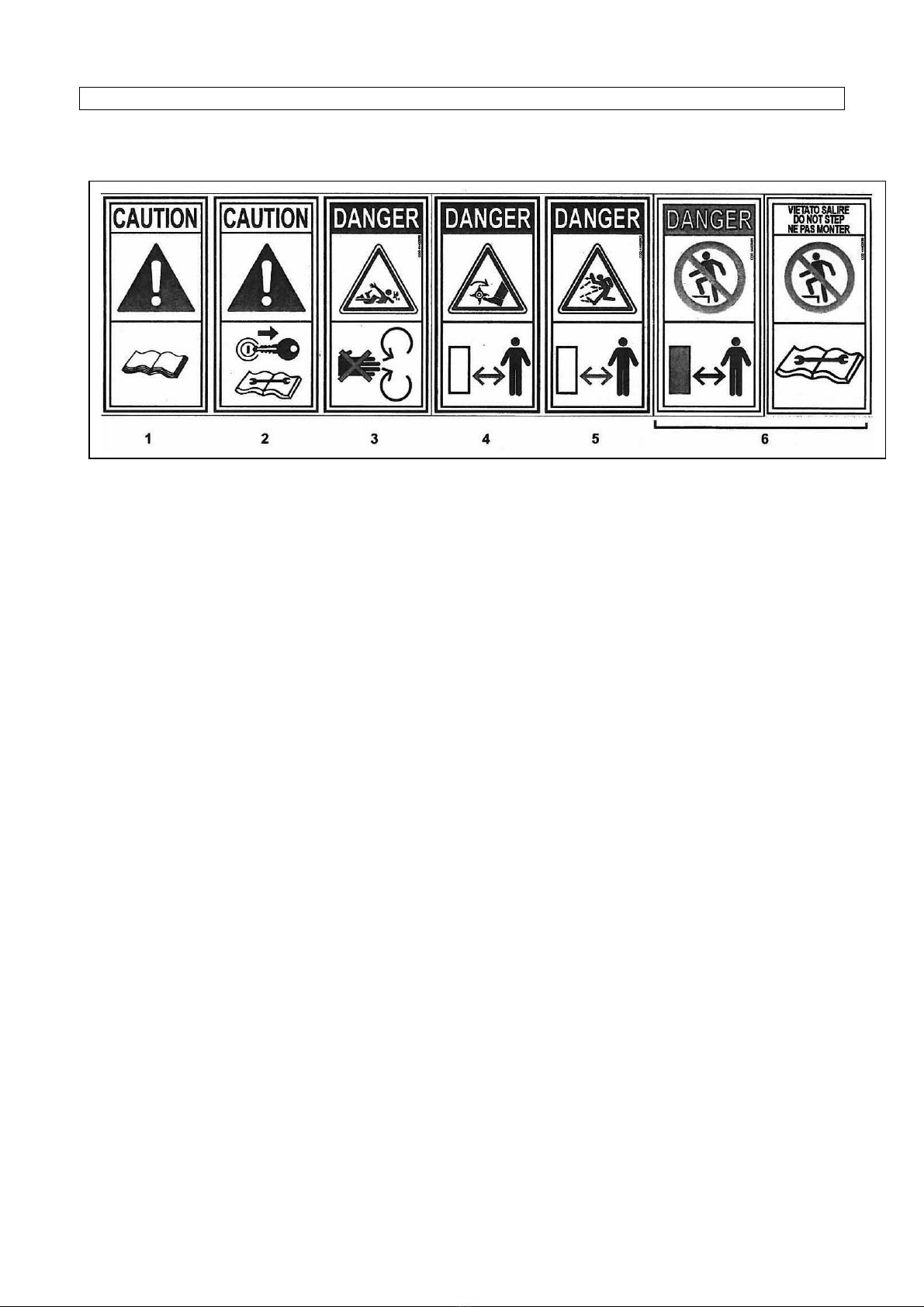

Pay attention to the warning signals

<Danger>: indicates a situation that is potentially dangerous which, if not avoided, will cause death or

serious damage.

<Warning>: indicates a situation that is potentially dangerous which, if not avoided, will cause death or

serious damage.

<Caution>: indicates a situation that is potentially dangerous which, if not avoided, can cause minor to

moderate damage or it indicates to be careful about an unsafe procedure.

<Important>: indicates instructions that must be followed precisely in order to avoid damage to the product,

process or environment.

<Note>: indicates supplementary information.